MAGLINK LX

Installation Manual

| ummary

Rev. 09,

– April 2016

Page 2 of 24

S

UMMARY

1

PREFACE ............................................................................................................................................................. 3

2

GENERAL WARNINGS ......................................................................................................................................... 3

3

INTRODUCTION .................................................................................................................................................. 4

4

GENERAL INDICATIONS ...................................................................................................................................... 5

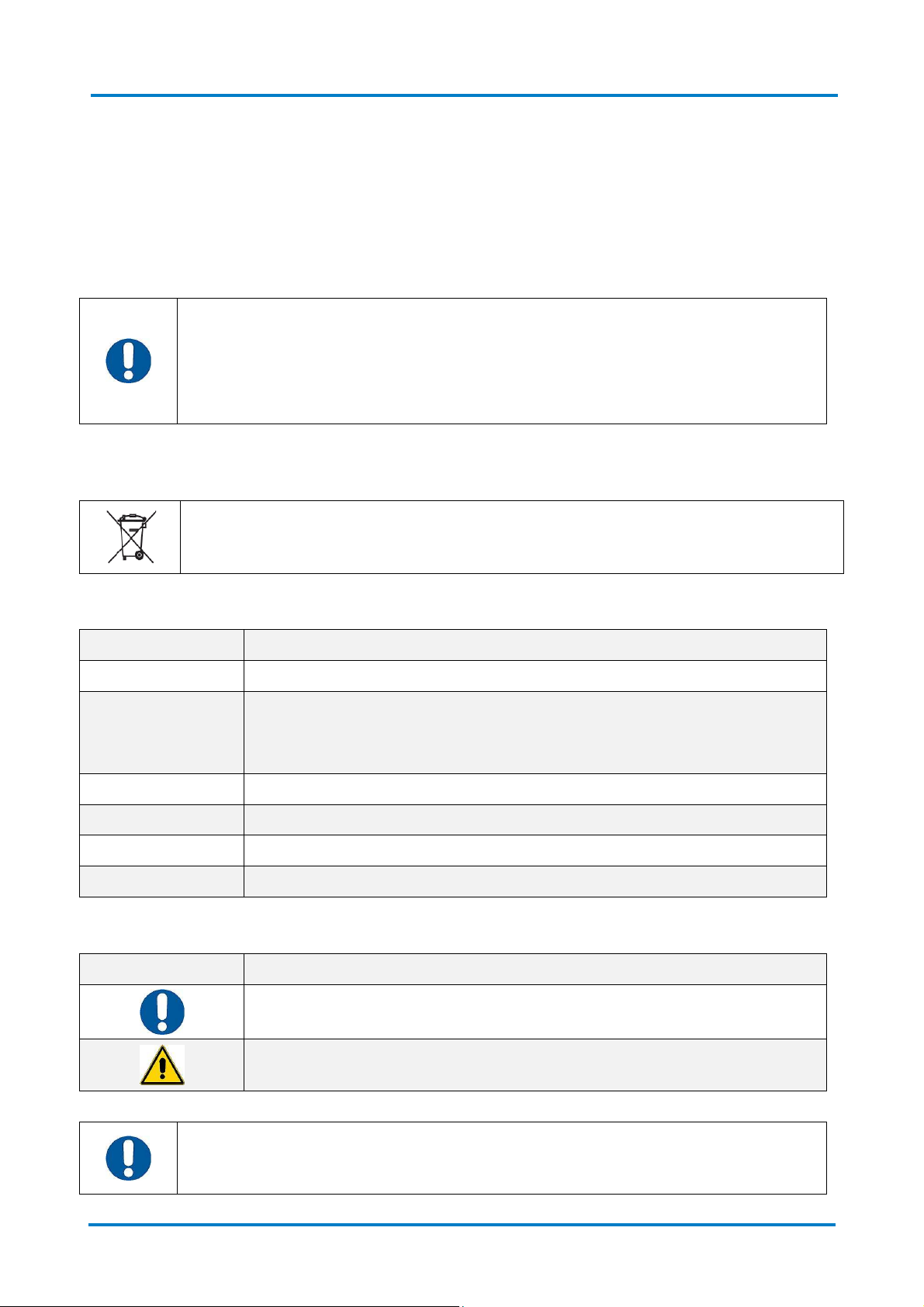

4.1

L

ABELLING AND TYPE DE IGNATION

............................................................................................................................ 7

5

INSTALLATION .................................................................................................................................................... 8

5.1

P

RELIMINARY WARNING

. ........................................................................................................................................ 8

5.2

P

LACE OF IN TALLATION

.......................................................................................................................................... 8

5.3

E

LECTRICAL CONNECTION

......................................................................................................................................... 8

5.4

I

N TALLATION PROCEDURE

....................................................................................................................................... 9

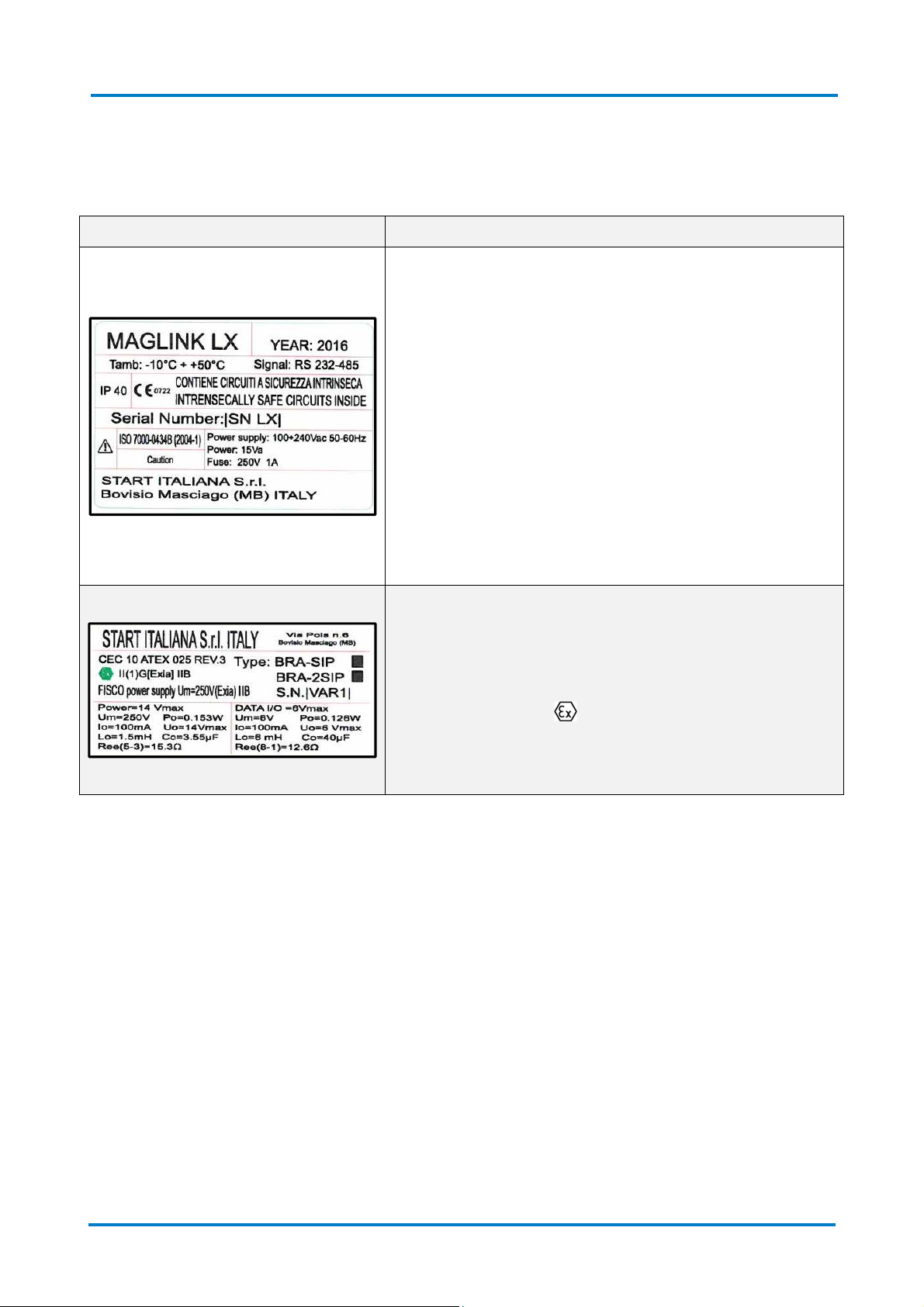

6

MODES OF COMMUNICATION ..........................................................................................................................11

6.1

C

ONNECTION TO INTRIN ICALLY AFE

XMT- I-485

PROBE

........................................................................................... 12

6.2

C

ONNECTING THE

XMT

EXPLO ION EXECUTION

.......................................................................................................... 13

6.3

C

ONNECTING THE

RF

R

ECEIVER

(

FOR

XMT- I-RF) ..................................................................................................... 14

6.4

I

NTERFACE TO RELAY DIAGRAM OF CONNECTOR

......................................................................................................... 15

6.5

M

ODEM

C

ONNECTION

.......................................................................................................................................... 16

6.6

DVD

CONNECTION

............................................................................................................................................... 16

6.7

D

IP WITCH

C

ONFIGURATION

.................................................................................................................................. 17

6.8

M

ICRO

D

C

ARD

.................................................................................................................................................. 17

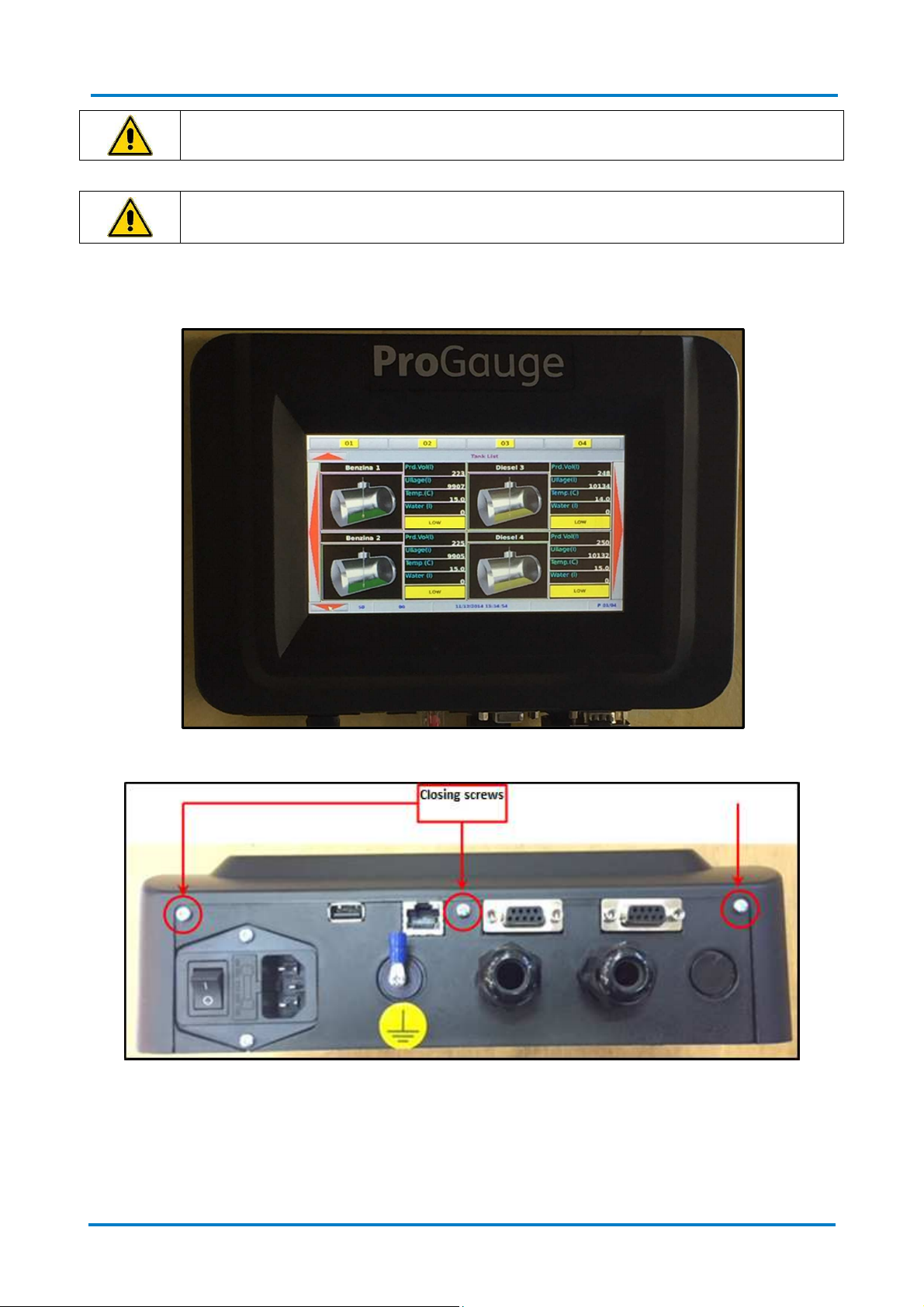

6.9

C

LO ING AND TART UP

......................................................................................................................................... 18

6.10

C

ONNECT THE CON OLE TO THE MANAGEMENT Y TEM

............................................................................................. 19

7

MAINTENANCE ..................................................................................................................................................21

8

SUPPORT ...........................................................................................................................................................22

9

SAFETY INSTRUCTIONS ......................................................................................................................................22

10

REVISIONS .........................................................................................................................................................23