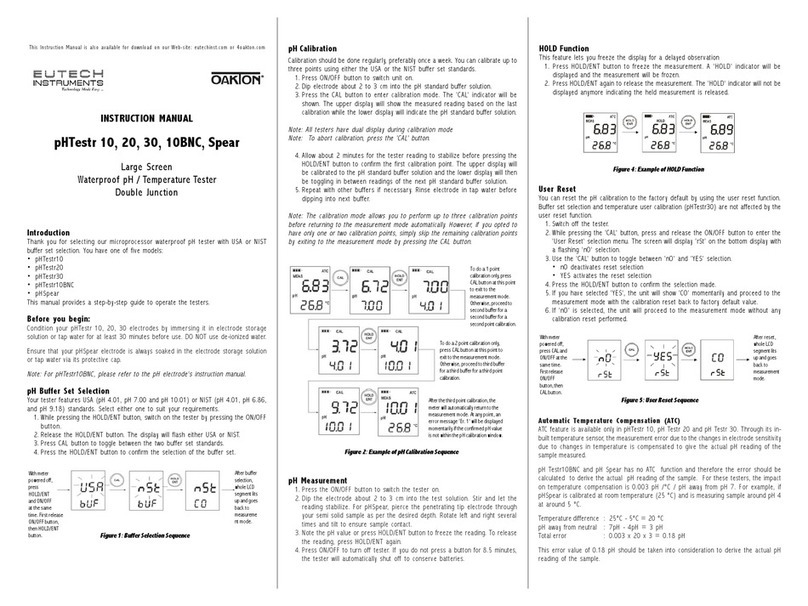

Tokyo Boeki Labmax 240 User manual

Automated Clinical Analyzer

Service Manual

Version 1.44

TOKYO BOEKI LTD.

IMPORTANT

Only the trained and authorized

serviceman is permitted to install

the system, following this Service

Manual.

Preface

T

0‑1

Preface

This Automated Clinical Analyzer is an IVD medical equipment for indoor

use and is based on the colorimetric and turbidimetric measurement.

Its main application is expected to be colorimetric measurement, clinical

chemistry testing, immuno-serological testing, hematological testing and

urine testing in hospitals, clinical laboratories and other research

laboratories.

1. Expression of Warning and Notice

: This mark means, “Refer to accompanying documents”.

: This mark means, “Hot surface”.

: This mark means, “Biohazard.”

In this manual, the items you have to be careful for safety are

indicated by the following levels.

Warning : If ignored, the accident may lead to death or heavy

injury.

Caution : If ignored, the accident may cause personal injury

or heavy damage on the instrument.

Notice : Notice outside of the above (To prevent instrument

damage)

Note

: Pay attention, additional explanation.

: Biohazard. There is the risk of your being infected.

In case of treating samples that may be hazardous or

infectious, wear rubber gloves not to touch directly.

Any spills on the skin should be washed off with a

great volume of water and sterilized.

And consult a physician if necessary.

Also any spills on the system should be wiped off

and sterilized at once.

The above expressions are internationally used to arouse attention.

!

!

0‑2

2. Warranty

(1) Warranty period

One year after the installation.

(2) Warranty content

If an instrument trouble occurs within the warranty period and

caused by the defect of the production, we will fix the instrument

at our expense.

(3) Exemption of warranty

Even though within the warranty period, the following cases are

outside of warranty.

1.

A trouble which is caused by the movement or transportation

after once installed.

2. A trouble which is caused by misusage or unauthorized repairing.

3. A trouble which is caused by the operation under the improper

installation condition.

4.

If a customer dismantled or modified an inside module and

cannot recover.

5.

If a customer performed the different things from the

instructions written in this book.

6. A trouble caused by a calamity, such as fire, earthquake or

thunderbolt.

7. Articles of consumption and parts with limited warranty period.

8. A trouble caused by the corrosion of electronic circuits or rapid

deterioration of optical parts, which is induced by the

circumstance containing corrosive gas in atmosphere.

9.

In case that any other program than OS (Windows) and the

program of this system is installed in PC used for this system,

excluding the case that we instruct to do so.

3. Safety Caution

(1) Electric shock prevention

Warning

When electrically charged, never open rear cover nor

covers of both sides. It may cause electrical shock.

!

Preface

T

0‑3

(2) Moving parts while operation

Caution

Do not touch sample pipette, reagent pipette nor

washing mechanism in operating.

You might be injured.

(3) Light from light source

Caution

Do not look at light source by naked eyes.

It might hurt your eyes.

Wearing safety goggles for ultra violet is

recommended.

(4) Inflammable substance

Caution

Do not use inflammable substance around the

system. It might cause fire or explosion.

(5) Sample handling

Caution

1. Do not touch infectious or dangerous samples

directly.

If the system is contaminated, please wipe out

at once.

2. Please make sure that no insoluble matter, such

as fibrin, is in sample. It may give improper

results.

(6) Waste liquid treatment

Caution

1. Waste liquid should be treated properly under

the related regulation.

It may cause pollution problem.

2.

About the concentration of poisonous chemicals

in a reagent, please ask the reagent maker.

!

!

!

!

!

0‑4

(7) Power plug

Caution

1. Do not plug or unplug with the wet hands.

It might cause electric shock.

2. Do not pull the cord when unplugging.

It might cause electric shock.

(8) Accuracy of measured data

Caution

During the operation, please check the system

condition by measuring control samples.

Inaccurate test results may lead wrong diagnosis

and improper patient treatment.

(9) Protective grounding

Caution

Use a 3-pin-plug whose ground terminal will be

connected first and be sure that the earth

resistance of terminal is less than 10 ohm.

It avoids electric shock.

(10) Warning mark

Caution

When warning or caution mark peeled off,

contact our serviceman to replace by a new one.

(11) Moving or Rejection

Caution

When not using the system for a long period, or

when moving or rejecting the system, remove

biohazards.

Wipe out the sample if the spilt sample is on the

system, with cloth dipped in 70% diluted ethyl

alcohol, in case the sample has or might have

biohazards.

!

!

!

!

!

Preface

T

0‑5

(12) Specified manner

Caution

If the system is used in a manner not specified

by the manufacturer, the protection provided by

the system may be impaired.

(13) Piping

Caution

In installation of the system and in feeding liquid

or drainage, take care not to bend or break piping.

4. Caution in Operation

(1) Usage

Notice

Mainly used for clinical chemistry electrolyte tests

and immuno-serological test of water soluble

samples.

The system may not be proper to use for the

purpose other than the above.

(2) Limited operator

Notice

1. The operation of system should be controlled by

a person who had training of an organization

authorized by the distributor.

2.

If used for clinical testing, the operation should

be controlled by a medical doctor or a medical

technologist.

(3) Circumstance limitation

Notice

Please follow and keep the standard installation

condition.

If you want to move the system, please consult

our serviceman.

!

!

!

!

!

0‑6

(4) Operation and maintenance

Notice

1. During the operation and maintenance, please

follow the instruction and never touch the points

besides designated.

2.

When electrically charged, never open rear panel

nor panels of both sides.

If you touch PCB, IC and other parts may be

broken down.

3.

During operation, do not touch sample pipette,

reagent pipettes washing mechanism, mixing

units, reaction tray, reagent tray nor sample

tray.

It may cause breakdown or emergency stop.

(5) Treatment on reagents and others

Notice

1. Reaction cuvette, sample cup and waste liquid

line are not sufficiently tolerant to organic

solvents. Do not use solvents.

2.

Do not use sticky substance on sample probe,

reagent probe nor reaction cuvette.

3.

Handling the reagents, which is supplied by

reagent makers, please keep the caution from

the reagent maker.

(6) Top cover

Caution

1. Take care not to have your fingers pinched,

when opening or closing the top cover.

You might be hurt.

2. Do not put anything on the top cover.

Liquid spilt into the air hole might cause a

malfunction.

!

!

!

Preface

T

0‑7

(7) Washing solution

Caution

Do not use other washing solution than the

certified one for the system.

It might cause a malfunction.

(8) Static electricity

Caution

Do not put a thing charged with static electricity

on the system, nor touch with hands charged with

static electricity. It could cause a malfunction of

the system.

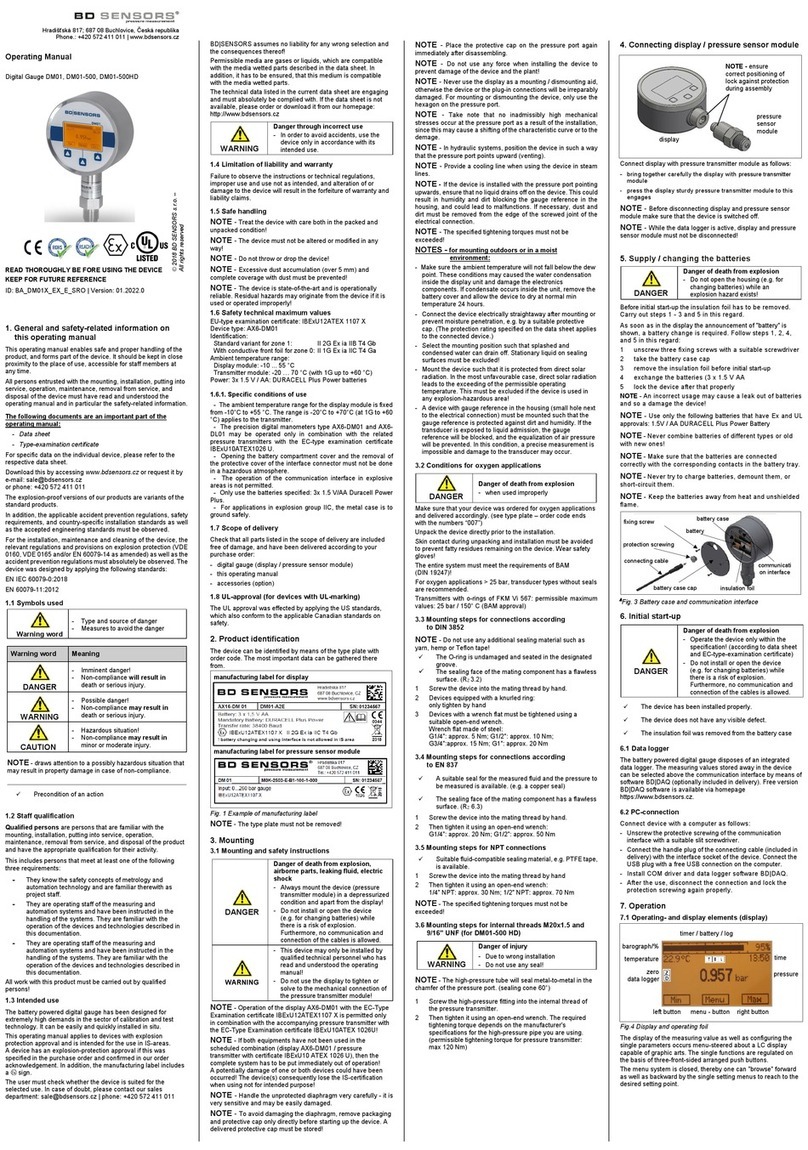

5. Installation and Servicing

(1)

Installation

Installation and checking of deliveries or transport condition will be

performed by our serviceman.

Prepare a receptacle with earth terminal (3 terminals) and

be sure the earth resistance of terminal is less than 10 ohm.

When moving the system, consult our serviceman.

(2)

Servicing

Come in contact with us about servicing.

!

!

0‑8

6. Installation Requirements

Only the trained and authorized serviceman is permitted to install or move

the system, following the requirements below.

3.1 Power supply requirements

(1) Power supply capacity should be over 600VA.

(2) Voltage : AC230V plus-minus 10%

Frequency : 50/60Hz plus-minus 1Hz.

(3) Earth resistance of ground terminal should be less than 10 ohm.

(4) Power must be supplied for 24 hours a day.

(5)

Install away from high frequency electromagnetic wave emitting equipment

(such as centrifuge, electric discharge), preferably not in the same room.

3.2 Required conditions

(1)

The system should be installed at altitude less than 2000 meters.

(2)

The system can be put in operation between 5 and 40 Celsius degrees.

But its performance is guaranteed only when room temperature is 15 ~ 30

Celsius degrees and the temperature variation during the operation should be

less than plus-minus 2 Celsius degrees/H.

(3) Room humidity should be 40 ~ 80 %, and no condensation.

(4) The table should be able to support over 100kgf/m

2.

(5) The gradient of the table should be less than 5mm/m.

(6)

Keep the space around the system for taking out the power cord

in an emergency, for good ventilation and for maintenance, as the following.

(7)

The following points should be taken into consideration to select the

installation position.

- No dust, good ventilation

- No direct sun light

- Small vibration

3.3 Water supply/drain requirements

Water reservoir and waste liquid reservoir should be set below the system

bottom level.

32 cm

100 cm

50 cm

ANALYZER

FRONT

AC INPUT

50 cm

A

lso keep the space of at

least 100 cm over the

system.

(At the minimum)

Preface

T

0‑9

7. Storage and Transportation Requirements

(1)

Indoor.

(2)

No direct sunlight.

(3)

No dust.

(4)

No upper load.

(5)

No dropping.

(6)

No throwing down.

(7)

Ambient temperature should be 1 ~ 45 Celsius degrees.

(8)

Ambient humidity should be 10 ~ 85% (no condensation).

1

Chapter 1

System configuration

1.1 Over view -------------------------------------------------------------------------------------1-2

1.2

Name of Each Unit ------------------------------------------------------------------------1-3

1.3 Panels ------------------------------------------------------------------------------------------1-6

1.4 Unit Layout ----------------------------------------------------------------------------------1-7

1.4.1 Unit Layout in the front view ------------------------------------------------1-7

1.4.2 Unit Layout in the right side view -----------------------------------------1-8

1.4.3 Unit Layout in the left side view ------------------------------------------- 1-9

1.4.4 Unit Layout in the rear view -------------------------------------------------1-10

1.4.5 Unit Layout of the first floor---------------------------------------------------1-11

1.4.6 Unit Layout of the second floor ----------------------------------------------1-12

1.4.7 Unit Location of the upper deck ---------------------------------------------1-13

Chapter 2

Functions and Movement of the System

2.1 Functions and Movement ----------------------------------------------------------------2-2

2.2 Analysis Process and Optical Measurement Point ------------------------------2-4

2.3 Automatic Analysis Process ------------------------------------------------------------2-5

2.4 Reagent Dispensation Process-----------------------------------------------------------2-8

2.5 Sample Dispensation Process ----------------------------------------------------------2-11

Chapter 3

Explanations about Units

3.1 Sampler (STF) --------------------------------------------------------------------------------3-2

3.2 Sample Pipette (STM) -------------------------------------------------------------------3-6

3.3 Sample Pump (SP) -----------------------------------------------------------------------3-11

3.4 Reagent Tray (RGT) ---------------------------------------------------------------------3-14

3.5 Reagent Pipette (RTM) -------------------------------------------------------------------3-22

3.6 Reagent Pump (RP) ----------------------------------------------------------------------3-26

3.7 Reaction Tray (RCT) --------------------------------------------------------------------3-30

3.8 Mixing unit -1, -2 (MU-1, MU-2) ------------------------------------------------------ 3-35

3.9 Mixing Pump (MP) ------------------------------------------------------------------------ 3-38

2

3.10 Spectrophotometer (SPM) ------------------------------------------------------------3-40

3.11 Reaction Cuvette Washing Mechanics (CWS) ----------------------------------3-44

3.12 Reaction Cuvette Washing Pump (CWP) ----------------------------------------3-48

3.13 Washing Solution Pre-heater (WSH) ---------------------------------------------3-52

3.14 Probe Washing Pump (PWP) --------------------------------------------------------3-56

3.15 Waste Liquid Pump-1, 2 (DP-1) ----------------------------------------------------3-60

Chapter 4

Control PCB

4.1 MCPU PCB ---------------------------------------------------------------------------------4-2

4.2 SCPU PCB --------------------------------------------------------------------------------4-5

4.3 UCNT-1 PCB -----------------------------------------------------------------------------4-8

4.4 UCNT-2 PCB-------------------------------------------------------------------------------4-12

4.5 LAMP DC PCB ---------------------------------------------------------------------------4-16

4.6 PM DRV PCB -----------------------------------------------------------------------------4-19

4.7 TCD PCB -----------------------------------------------------------------------------------4-22

4.8 SSRAC PCB -------------------------------------------------------------------------------4-24

4.9 MOTHER BOARD ----------------------------------------------------------------------4-27

4.10 Shift of AC Input Voltage -------------------------------------------------------------4-29

Chapter 5

Hidden Screens of Maintenance

5.1 How to Open the Hidden Screens and Explanation of Various Screens

5.1.1 How to Open the Hidden Screens ------------------------------------------5-2

5.1.2 Explanation of Various Screens ------------------------------------------ 5-4

5.2 Password Setting

5.2.1 Password Setting Procedure -------------------------------------------------5-5

5.2.2 Password Setting of Patient Information-------------------------------- 5-7

5.3 Result Print Setting -----------------------------------------------------------------------5-8

5.4 Temperature Monitor Screen ----------------------------------------------------------5-9

3

5.5

Machine offset screen

------------------------------------------------------------------ 5-11

5.6

Outline of manual operation screens

-------------------------------------------- 5-12

5.6.1 STF (Sampler) --------------------------------------------------------------------5-13

5.6.2 STM-R (Sample probe - rotation)------------------------------------------5-14

5.6.3 STM-UD (Sample probe - up/down) --------------------------------------5-15

5.6.4 SP (Sample pump) -------------------------------------------------------------5-16

5.6.5 RGT (Reagent tray)------------------------------------------------------------5-17

5.6.6 RTM-R (Reagent probe - rotation) ----------------------------------------5-18

5.6.7 RTM-UD (Reagent probe- up/down)--------------------------------------5-19

5.6.8 RP (Reagent pump) ----------------------------------------------------------5-20

5.6.9 RCT (Reaction tray) ----------------------------------------------------------- 5-21

5.6.10 MU-1 (Mixing unit-1) --------------------------------------------------------5-22

5.6.11 MU-2 (Mixing unit-2) --------------------------------------------------------5-23

5.6.12 MP (Mixing pump)-------------------------------------------------------------5-24

5.6.13 CWS (Reaction cuvette washing station) ------------------------------5-25

5.6.14 CWP (Reaction cuvette washing pump) -------------------------------5-26

5.6.15 PWP (Probe washing pump) ---------------------------------------------- 5-27

5.6.16 DP-1/2 (Drainage pump – 1, 2)---------------------------------------------5-28

5.6.17 DETECTOR (Colorimetry detector) -------------------------------------5-29

5.6.18 COVER (Sample & Top Covers Lock & Unlock) --------------------5-30

5.7 Manual Function Sub-screens --------------------------------------------------

5-31

5.7.1 Encoder Screen ----------------------------------------------------------------5-31

5.7.2 Sensor Screen -------------------------------------------------------------------5-32

5.7.3 Manual Auto Screen ---------------------------------------------------------5-33

5.7.4 Gain Screen ---------------------------------------------------------------------5-35

5.7.5 PF BTN Screen ----------------------------------------------------------------5-37

Appendix 1

Mechanical Assembly Drawing

1System Piping Diagram -------------------------------------------------------------- ASSY-1

2ISE Piping Diagram ------------------------------------------------------------------- ASSY-2

3Sampler (STF) --------------------------------------------------------------------------- ASSY-3

4Sample Pipette (STM) ------------------------------------------------------------------ ASSY-4

5Sample Pump (SP) --------------------------------------------------------------------- ASSY-5

4

6Reagent Tray (RGT) -------------------------------------------------------------------ASSY-6

7Reagent Pipette (RTM) ----------------------------------------------------------------ASSY-7

8Reagent Pump (RP) --------------------------------------------------------------------ASSY-8

9Reaction Tray (RCT) -------------------------------------------------------------------ASSY-9-1/2

ASSY-9-2/2

10 Mixing Unit-1, 2 (MU-1, MU-2) ----------------------------------------------------ASSY-10

11 Mixing Pump (MP) ---------------------------------------------------------------------ASSY-11

12 Spectrophotometer (SPM) ------------------------------------------------------------ASSY-12

13 Reaction Cuvette Washing Station (CWS) --------------------------------------ASSY-13

14 Reaction Cuvette Washing Pump (CWP) ----------------------------------------ASSY-14

15 Washing Solution Pre-heater (WSH) ---------------------------------------------ASSY-15

16 Probe Washing Pump (PWP) --------------------------------------------------------ASSY-16

17 Waste Liquid Pump -1,2 (DP-1, DP-2) -------------------------------------------ASSY-17

18 Water Supply Reservoir --------------------------------------------------------------ASSY-18

19 Washing Solution Reservoir ---------------------------------------------------------ASSY-19

20 Waste Liquid Reservoir ---------------------------------------------------------------ASSY-20

21 Reaction Waste Reservoir ------------------------------------------------------------ASSY-21

Appendix 2

Electrical Wiring Drawing

1Electrical Block Diagram -1/2 --------------------------------------------------------WIRING-1

Electrical Block Diagram -2/2 -------------------------------------------------------WIRING -2

2AC/DC Power Supply 1/3 -------------------------------------------------------------WIRING -3

AC/DC Power Supply 2/3 -------------------------------------------------------------WIRING -4

AC/DC Power Supply 3/3 -------------------------------------------------------------WIRING -5

3Sampler (STF) ---------------------------------------------------------------------------WIRING -6

4 STM Unit ----------------------------------------------------------------------------------WIRING -7

5Sample Pump (SP) ---------------------------------------------------------------------WIRING -8

6Reagent Tray (RGT) -------------------------------------------------------------------WIRING -9

7Reagent Pipette (RTM) ----------------------------------------------------------------WIRING -10

8Reagent Pump (RP) --------------------------------------------------------------------WIRING -11

9Reaction Tray (RCT) -------------------------------------------------------------------WIRING -12

10 Mixing Mecha.-1 (MU-1) --------------------------------------------------------------WIRING -13

11 Mixing Mecha.-2 (MU-2) --------------------------------------------------------------WIRING -13

12 Mixing Pump (MP) ---------------------------------------------------------------------WIRING -13

13 Spectrophotometer (SPM) ------------------------------------------------------------WIRING -14

14 Cuvette Wash Station (CWS) -------------------------------------------------------WIRING -15

5

15 Cuvette Washing Pump (CWP) ---------------------------------------------------- WIRING -15

16 Washing Solution Pre-heater (WSH) --------------------------------------------- WIRING -16

17 Probe Washing Pump (PWP) -------------------------------------------------------- WIRING -16

18 Drain Pump-1 (DP-1) ------------------------------------------------------------------ WIRING -17

19 Drain Pump-2 (DP-2) ------------------------------------------------------------------ WIRING -17

20 Water Supply Reservoir -------------------------------------------------------------- WIRING -17

21 Washing Solution Reservoir (Alkaline) ------------------------------------------- WIRING -17

22 Washing Solution Reservoir (Acidic)----------------------------------------------- WIRING -18

23 Waste Liquid Reservoir --------------------------------------------------------------- WIRING -18

24 Reaction Waste Reservoir ------------------------------------------------------------ WIRING -18

25 Solenoid Valve --------------------------------------------------------------------------- WIRING -18

26 Printer ------------------------------------------------------------------------------------ WIRING -19

27 Barcode Reader -------------------------------------------------------------------------- WIRING -19

28 MCPU PCB ------------------------------------------------------------------------------- WIRING -20

29 SCPU PCB -------------------------------------------------------------------------------- WIRING -21

30 UCNT-1 PCB ----------------------------------------------------------------------------- WIRING -22

31 UCNT-2 PCB ----------------------------------------------------------------------------- WIRING -23

32 LAMPDC PCB --------------------------------------------------------------------------- WIRING -24

33 PMDRV PCB ----------------------------------------------------------------------------- WIRING -25

34 SP PCB ------------------------------------------------------------------------------------ WIRING -26

35 SSRAC PCB ------------------------------------------------------------------------------ WIRING -27

36 TCD PCB ---------------------------------------------------------------------------------- WIRING –27

Periodic Check List

Service Manual

Chapter1

1‑1

Chapter 1 System Configuration

This chapter explains parts, layout and so on.

Contents

1. 1. Over View ------------------------------------------------------------- 1-2

1. 2. Name of Each Unit ------------------------------------------------- 1-3

1. 3. Panels ----------------------------------------------------------------- 1-6

1.4. Unit Layout ---------------------------------------------------------- 1-7

1.4.1. Unit layout in the front view ------------------------------- 1-7

1.4.2. Unit layout in the right side view--------------------------- 1-8

1.4.3. Unit layout in the left side view ----------------------------- 1-10

1.4.4. Unit layout in the rear view----------------------------------- 1-11

1.4.5. Unit layout of the first floor----------------------------------- 1-12

1.4.6. Unit layout of the second floor-------------------------------- 1-13

1.4.7. Unit layout on the upper deck -------------------------------- 1-14

1‑2

1.

SYSTEM CONFIGURATION

1.1.

Over View

Fig. 1-1 Over view of the analyzer

Water reservoir

Reaction waste reservoir

Reaction sol. separating

collection reservoir

(option)

<

System front view

>

<

Top view

>

ISE (Waste liquid reservoir)

A

cidic washing solution

reservoir

A

nalyzer

Top cover

Printer

Personal computer

Reaction waste liquid

reservoir (o

p

tion)

Water reservoir

Waste liquid reservoir

A

lkaline washing

solution reservoir

Table of contents