Toledo ZT-1 User manual

ZT-1

Load Module

User’s Manual

For Pre-calibrated Load Cells

or other Load Cell use.

Revision: A

ZT-1 User’s Manual – Installation

DOC #18172Page 2

ZT-1 User’s Manual – Installation

DOC #18172Page 3

THIS PAGE

INTENTIONALLY

LEFT BLANK

ZT-1 User’s Manual – Installation

DOC #18172Page 4

Table of Contents

Limited Warranty ................................................................................................................5

Features Overview .............................................................................................................6

Specifications .....................................................................................................................8

Installation ........................................................................................................................10

Mounting the ZT-1.........................................................................................................10

DC Power Connection...................................................................................................11

Shunt Resistor Selection...............................................................................................12

Strain Gage Load Cell / Sensor Connection .................................................................13

20mA-out Sensor Connection.......................................................................................17

10V-out Sensor Connection..........................................................................................18

Analog Voltage Output..................................................................................................19

Analog Current Output..................................................................................................20

Triggering – Internal Threshold.....................................................................................21

Triggering – External Probe..........................................................................................23

Calibration ........................................................................................................................25

Operation..........................................................................................................................30

Appendix...........................................................................................................................35

A) Sensor Installation (Doc# 11080) .......................................................................35

B) Calibration Sheets (2) (Form# 1224)..................................................................35

Table of Figures

Figure 1: Mounting Dimensions ...................................................................................10

Figure 2: DC Power Wiring ..........................................................................................11

Figure 3: Built-In 1M Ohm Shunt Resistor Wiring ......... Error! Bookmark not defined.

Figure 4: External Shunt Resistor Installation.............................................................12

Figure 5: Strain Gage Sensor Input .............................................................................14

Figure 6: Strain Gage Sensor Cable Stripping.............................................................15

Figure 7: Strain Gage Sensor Wiring ...........................................................................16

Figure 8: 20mA-out Sensor Input.................................................................................18

Figure 9: 10V-out Sensor Input...................................... Error! Bookmark not defined.

Figure 10: Analog Voltage Output Wiring.......................................................................19

Figure 11: Analog Current Output Wiring.......................................................................20

Figure 12: Internal Threshold Wiring..............................................................................22

Figure 13: Probe Input Wiring........................................................................................23

Figure 14: Probe Timing Diagram..................................................................................24

Figure 15: Calibration Gain Voltage Measurement........................................................28

Figure 16: Calibration Card Sample...............................................................................29

ZT-1 User’s Manual – Installation

DOC #18172Page 5

Limited Warranty

This unit is warranted by the manufacturer, Edrive Actuators, Inc., to be free

of defects in workmanship and materials for one year from date of

manufacturer’s shipment. This warranty is limited to repairing or replacing

products which manufacturer’s investigation shows were defective at the

time of shipment by the manufacturer.

All products subject to this warranty must be returned for examination, repair

or replacement

F.O.B. to: EDRIVE Actuators, Inc.

385 Stamm Road

Newington, CT 06111

Office: 860-953-0588

The express warranty set forth herein is in lieu of all other warranties,

expressed or implied, including without limitation any warranties of

merchant-ability or fitness for a particular purpose. All such warranties

are hereby disclaimed and excluded by the manufacturer.

Repair or replacement of defective products as provided above is the sole

and exclusive remedy provided thereunder. The manufacturer shall not be

liable for any further loss, damages, or expenses, including incidental or

consequential damages, directly or indirectly arising from the sale or use of

this product.

Any unauthorized repair voids this warranty.

There are no warranties that extend beyond those expressly set forth herein.

ZT-1 User’s Manual – Installation

DOC #18172Page 6

Features Overview

The ZT-1 tonnage load module is designed for critical force measurement applications

where accuracy, extreme stability, and dependable noise rejection is essential. It is

equipped with an LED bar-graph voltmeter for easy setup and diagnostic. The ZT-1 is

DIN rail mountable and is designed to interface with a PLC analog card and to display

output through a human machine interface (HMI).

•Designed to work with strain gage sensors and load cells. The ZT-1 can also

accept input from 4-20mA current output sensors or voltage output sensors.

•Simultaneously provides normal peak, reverse peak, and track voltage outputs.

Also simultaneously provides the associated 0-20mA current outputs.

•Built-in threshold trigger simplifies installation. External probe trigger can also be

used when situation required.

•LED bar-graph voltmeter for easy setup and diagnostic.

•Built-in 1 Mega Ohm calibration shunt resistor. User selected external shunt

resistor can be used for load cell applications.

•x1 and x10 amplifier gain ranges to work with either strong or weak signal from

the load sensor.

•Auto-Zero can be selected using dip switches to compensate for zeroing errors

caused by environmental changes such as temperature, humidity, and etc.

•Electrical noise rejection filter can be enabled when situation required.

•Plug-in connectors for easy wiring and installation.

•Standard DIN Rail mount simplifies systems integration.

•Modular with common bus design allows future upgrade and expansion.

ZT-1 User’s Manual – Installation

DOC #18172Page 7

THIS PAGE

INTENTIONALLY

LEFT BLANK

ZT-1 User’s Manual – Installation

DOC #18172Page 8

Specifications

Transducers

Full bridge, 120 to 1000 ohms.

Sensor Excitation

Built in +10VDC at 250mA max.

Balance Range

+/- 1mV/V of sensor imbalance

Gain Ranges

Low range = x50 to x550 adjustable

High range = x500 to x5,500 adjustable

Calibration Shunt

Built-in 1 mega ohm (.1%), or external custom shunt.

Output Range - Voltage

Normal Peak and Reverse Peak = 0 to 10VDC

Track output = -10 to +10VDC

Output Range - Current

Normal Peak and Reverse Peak = 0 to 20mA

Track output = -20 to +20mA

Circuit Inaccuracy

+/- .1% of full scale max.

Circuit Non-linearity

+/- .02% of full scale max.

Auto Zero

Time constant = 10 seconds. DIP switch selectable.

Frequency Response

DC to 5,000 Hz

Speed Limit

2000 SPM max. when triggered by External Probe

500 SPM max. when triggered by Internal Threshold

Operating Temperature

-4 to 158 degree F, or -20 to 70 degree C

Display

LED bar-graph voltmeter for setup and diagnostic

Trigger

Internal Threshold (.35V / .70V), or External Probe.

Probe Input

NPN/PNP proximity probes, solid state or dry contact

relays. Built-

in 24VDC at 80mA max. supplies power to the

probe.

Input Power

24VDC at 300mA max. Automatic resettable fuse.

Dimensions

0.9” W x 4.1” H x 4.7” D

Mounting

Standard DIN Rail mount

ZT-1 User’s Manual – Installation

DOC #18172Page 9

THIS PAGE

INTENTIONALLY

LEFT BLANK

ZT-1 User’s Manual – Installation

DOC #18172Page 10

Installation

Mounting the ZT-1

The ZT-1 is designed to clip onto standard top hat DIN rail (TH 35-7.5 or TH 35-15).

Figure 1: Mounting Dimensions

ZT-1 User’s Manual – Installation

DOC #18172Page 11

DC Power Connection

24VDC power is connected to the ZT-1 as shown in Figure 2.

Figure 2: DC Power Wiring

Notes:

1) The 24VDC source can be in range from 18VDC to 32VDC.

2) It is important to connect an Earth Ground to the GND terminal.

3) Do not apply power until all the wirings in this Installation Section are done.

ZT-1 User’s Manual – Installation

DOC #18172Page 12

Shunt Resistor – Strain Gage Load Cells

Shunt resistor only works directly with the Strain Gage Wheatstone bridge type load cells

and sensors.

User-specified external shunt resistor value is indicated on calibration data report..

Figure 3:

External Shunt

Resistor Installation

INSTALL

USER

SPECIFIED

SHUNT

RESISTOR

ZT-1 User’s Manual – Installation

DOC #18172Page 13

Strain Gage Sensor Connection

Refer to Figure 4 for the procedures below:

Connection:

1) Prepare the sensor cable for termination as described in Illustration A on page 15.

2) Remove the Phoenix plug from its socket on the top of the unit and wire the sensor

cable as described in Illustration B on page 16.

For specific load cell wire color code, refer to Load Cell

Specifications. Color Code wire designation may be different

than shown in Figure 4 & 6.

3) The Phoenix plug can then be inserted back into its socket.

Configuration:

1) Set the V / C dip switch to “V” position for voltage sensor. Strain Gage sensor outputs

voltage signal.

2) Set the Lg / Sm dip switch to “Sm” position for small signal. Strain Gage sensor

outputs un-amplified signal (small signal).

3) Set FIL dip switch to “No filter” position. Apply this filter only when electrical noise

becomes a problem at the ZT-1 analog outputs.

ZT-1 User’s Manual – Installation

DOC #18172Page 14

.

Figure 4: Strain Gage Sensor Input

ZT-1 User’s Manual – Installation

DOC #18172Page 15

Illustration A - Sensor Cable Termination

1) Strip the sensor cable as shown in Figure 5 below. Be sure not to nick any of the

signal conductors or cut the braid shield.

Figure 5: Strain Gage Sensor Cable Stripping

2) Strip approximately ¼" of insulation from each of the four signal conductors.

Note: If your sensor cable is not double shielded with both foil and a braid, electrical

noise may affect your output readings.

ZT-1 User’s Manual – Installation

DOC #18172Page 16

Illustration B - Sensors Connection

The ZT-1 accepts the signals from all strain gage load cells and sensors. Figure 6

illustrates the sensor connections.

Figure 6: Typical Load Cell Wiring

To be more specific, refer

to load cell specifications

for other color

configurations.

ZT-1 User’s Manual – Installation

DOC #18172Page 17

20mA-out Sensor Connection

The 20mA-out Sensor applies to sensors with output up to +/-20mA including the 4-20mA

output sensor. Refer to Figure 7 for the procedures below:

Connection:

1) Remove the Phoenix plug from its socket on the top of the unit and wire the sensor

cable as shown.

2) The Phoenix plug can then be inserted back into its socket.

Configuration:

1) Set the V / C dip switch to “C” position for current output sensor. 20mA-out sensor

outputs current signal.

2) Set the Lg / Sm dip switch to “Lg” position for large signal. 20mA-out sensor outputs

amplified signal (large signal).

3) Set FIL dip switch to “No filter” position. Apply this filter only when electrical noise

becomes a problem at the ZT-1 analog outputs.

ZT-1 User’s Manual – Installation

DOC #18172Page 18

Figure 7: 20mA-out Sensor Input

ZT-1 User’s Manual – Installation

DOC #18172Page 19

Analog Voltage Output

The analog voltage output is provided on a Phoenix connector for easy access and for

interfacing with other peripherals.

Figure 8: Analog Voltage Output Wiring

Output details:

•OUT terminal outputs either Peak tonnage or Track tonnage, depending on the

TRK/PEAK switch setting on the front panel.

•REV terminal outputs the reverse peak (snap-through) tonnage when the front panel

TRK/PEAK switch is set to PEAK.

Analog Voltage Output:

Swing between ± 10VDC

OUT = Normal Output

REV = Reverse Output

TRK = Track Output

COM = Analog Common

ZT-1 User’s Manual – Installation

DOC #18172Page 20

•TRK terminal always outputs the track tonnage, regardless of the front panel

TRK/PEAK switch.

Analog Current Output

The analog current output is provided on a Phoenix connector for easy access and for

interfacing with other peripherals.

Figure 9: Analog Current Output Wiring

Output details:

•OUT_C terminal outputs either Peak tonnage or Track tonnage, depending on the

Analog Current Output:

Swing between ± 20mA

OUT_C = Normal Output

REV_C = Reverse Output

TRK_C = Track Output

COM = Analog Common

Table of contents

Popular Control Unit manuals by other brands

Endress+Hauser

Endress+Hauser analytikjena TOC module operating manual

ICI Caldaie

ICI Caldaie NEREIX Master INSTRUCTIONS FOR INSTALLATION AND ASSISTANCE

Honeywell

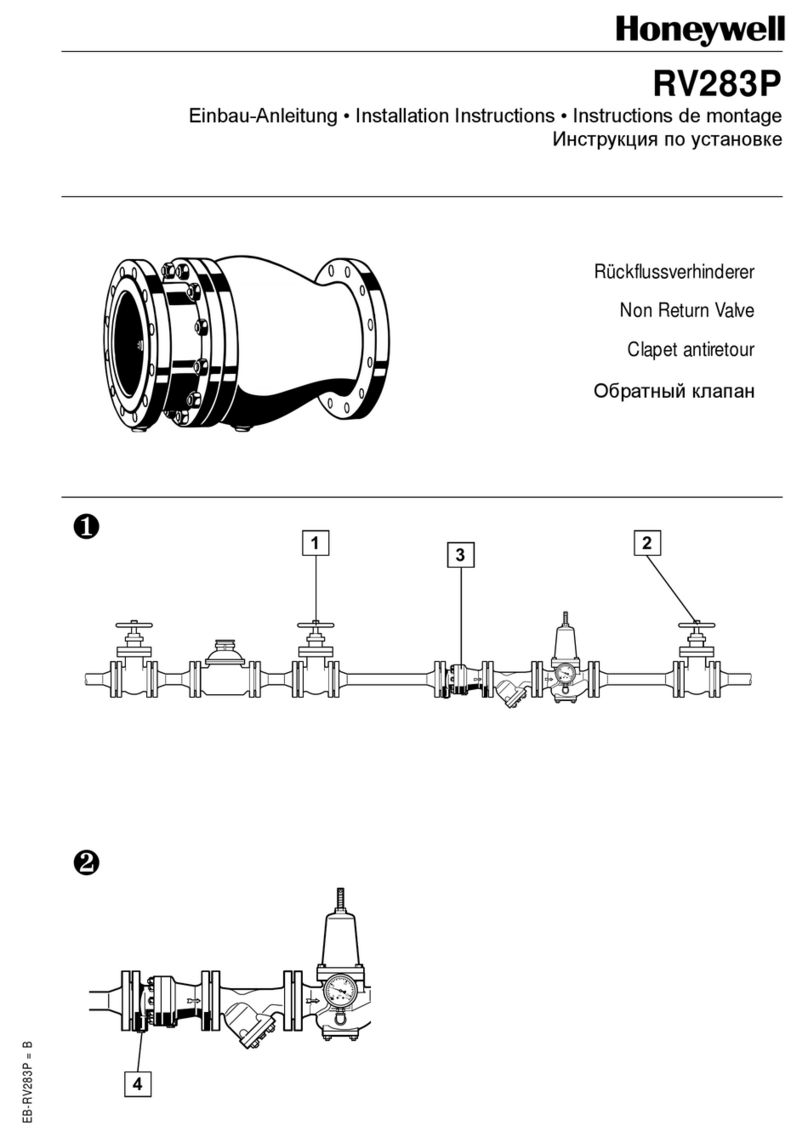

Honeywell RV283P installation instructions

Transient Modules

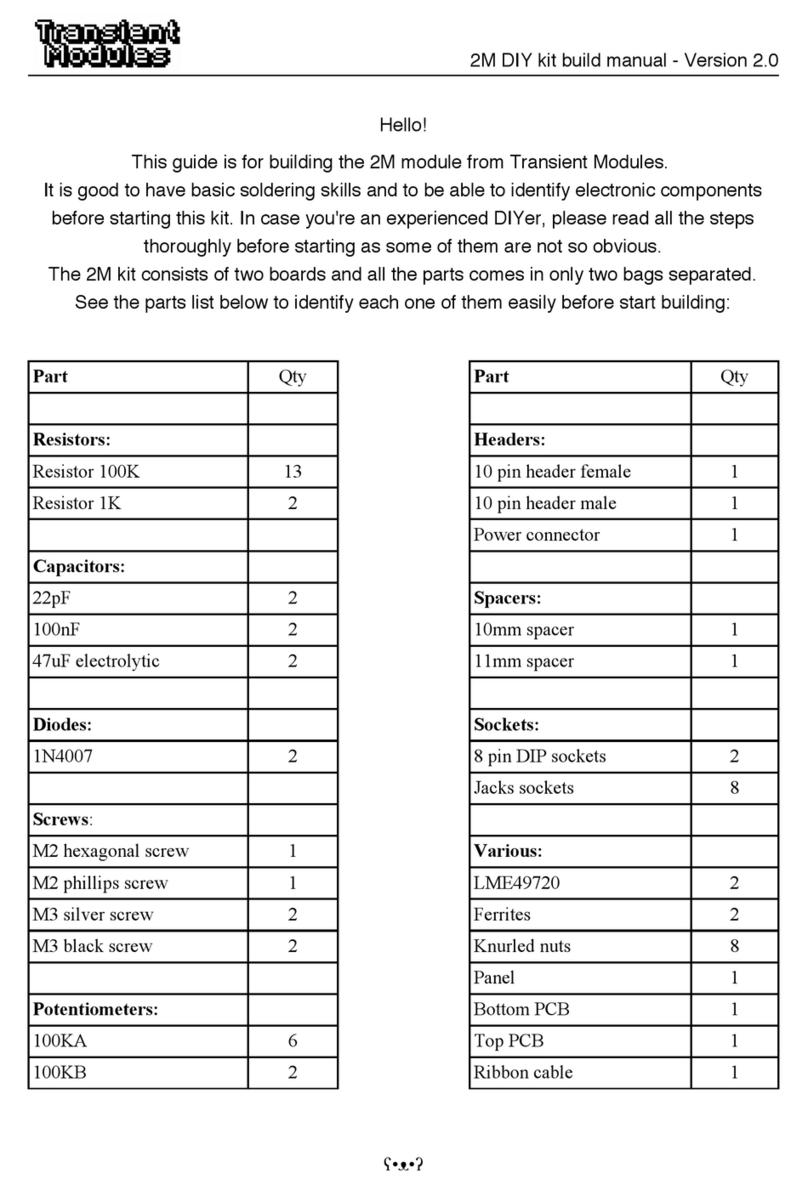

Transient Modules 2M Build manual

Advantech

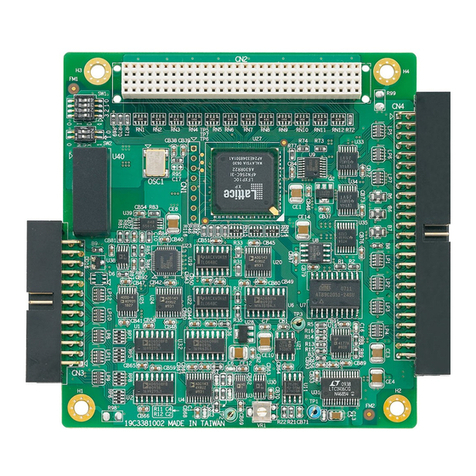

Advantech PCM-3810I Startup manual

Schmalz

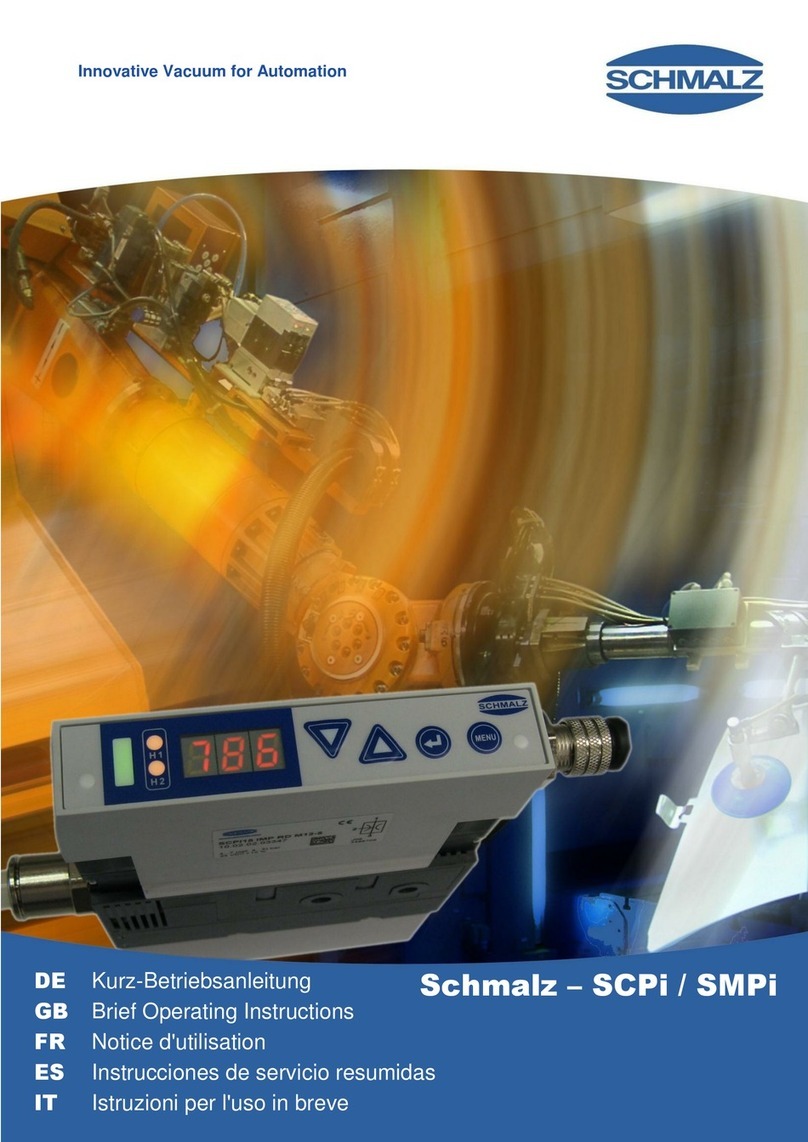

Schmalz SCPi Brief operating instructions

DOLD

DOLD SAFEMASTER BH 5928 Datasheet / Operating Instructions

Diamond Systems

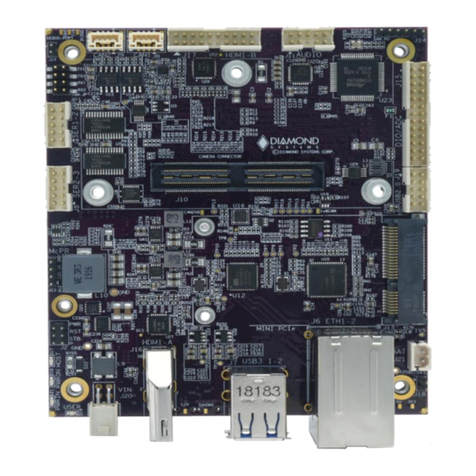

Diamond Systems STEVIE user manual

Infineon

Infineon GTM ATOM Interrupt 1 manual

Force

Force CNC BTN Series Installation, operation and maintenance manual

Panasonic

Panasonic AG-EC4G operating instructions

Honeywell

Honeywell Satronic TFI 812 Series quick start guide