4/ 12

The user of the sweeper is responsible for injuries and damage that are caused due to

non-compliance with these instructions.

2.1 Intended use

This sweeper is designed in accordance with the state of the art and recognized safety

regulations.

Nevertheless, use of the sweeper can lead to dangers for the user or third parties or

damage to the sweeper and other material assets.

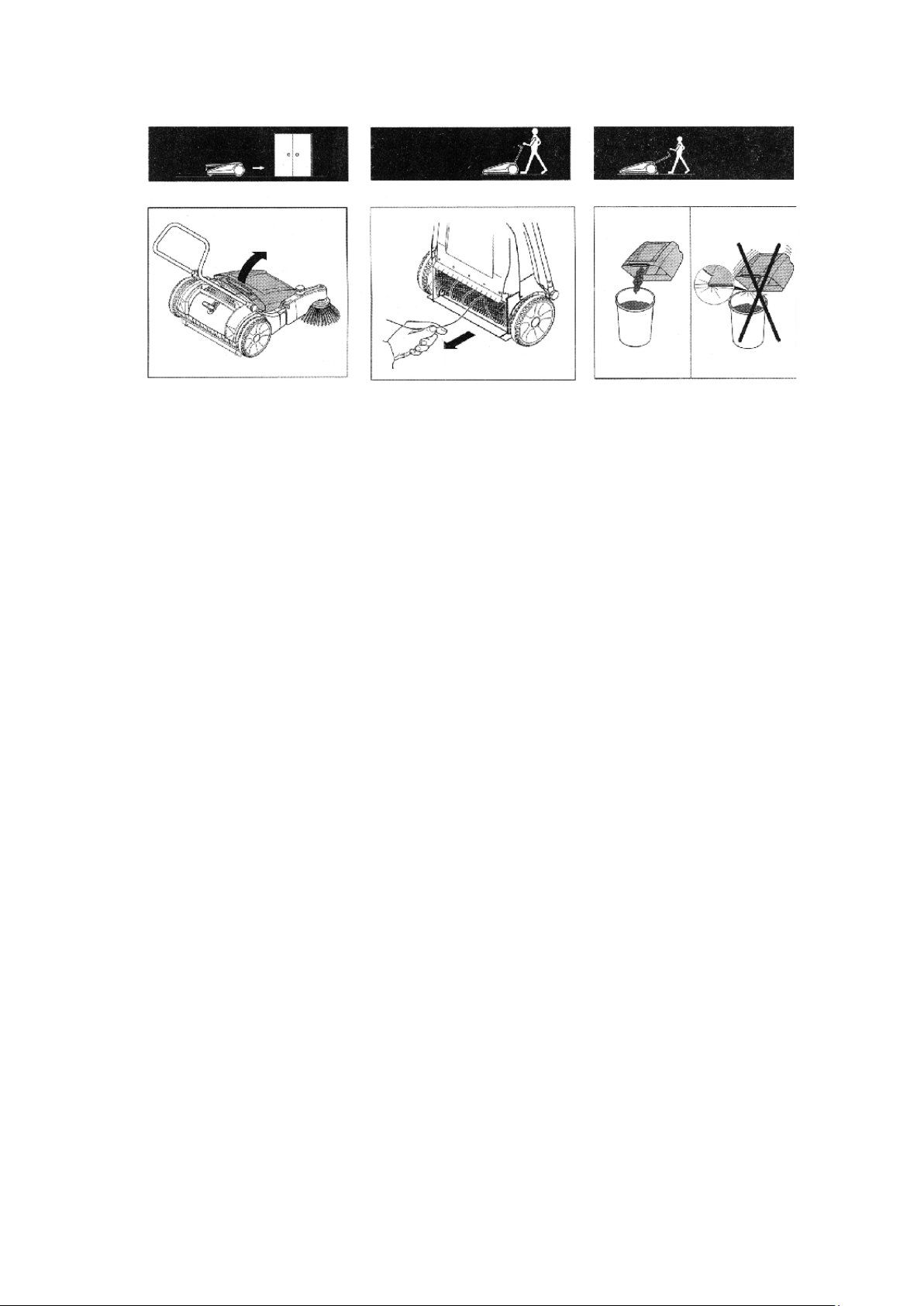

The sweeper is intended for commercial use, e.g. in hotels, schools, hospitals, factories,

shops, offices, and the equipment hire trade. The sweeper is intended exclusively for

removal of road dirt, leaves, grass, paper, and similar debris.

Sweeping snow with the sweeper is not permitted.

Any other use will be deemed as improper use. The manufacturer will not be liable for

damage caused as a result of this. The user is solely liable for the associated risks.

Claims of any kind due to damage caused by improper use are excluded.

The following information must also be observed when operating the sweeper:

• the safety instructions in these operating instructions.

• compliance with the operating, maintenance, and storage conditions prescribed by

the manufacturer.

• compliance with accident prevention regulations as well as country-specific safety

regulations, e.g. as issued by employers' professional liability associations, social

security authorities, occupational health and safety bodies and others.

• national and local regulations on time restrictions for operation of noise-emitting

equipment.

The sweeper must not be used, for example, for sweeping substances that are

hazardous to health, flammable or glowing (e.g. cigarettes, matches), liquids,

explosive or hazardous dusts (Ex), acids or solvents. The sweeper must not be used

in explosion-hazard areas or as a means of transport.

2.2 Safety instructions for operation/Maintaining operating safety

The user must not wear open long hair, tie, loose clothing, or jewelry, including rings.

There is a risk of injury, e.g. getting caught up or pulled into the machine. Use personal

protective equipment if necessary or required by regulations!

• Wear sturdy shoes with a high-grip, anti-slip sole.

• Always wear a dust protection mask in dusty conditions.

• Wear sturdy gloves.

Use the machine only in technically perfect condition for its intended purpose and

paying attention to safety and the environment.

Have any faults that affect safety rectified immediately by a specialist dealer.