Tomoe T-DYNAMO 7E User manual

R

INSTRUCTION MANUAL

Compact, Lightweight, High-output Pneumatic Actuator

Before placing an order

* "Before placing an order" has been described since 25 May, 2005.

FOR YOUR SAFE USAGE

1.PRODUCT FEATURES

1-1 Product features

1-2 Operating principle

1-3 Type description

1-4 Standard specifications

2.PRECAUTIONS FOR USE

2-1 Safety measures

2-2 Transportation and storage

2-3 Installation and working environment

2-4 Use and adjustment

2-5 Maintenance

3.STRUCTURE

3-1

Expanded view (Double-acting type cylinder)

3-2

Expanded view (Single-acting type cylinder)

3-3 Output torque curves

3-4 Air consumption

4.CYLINDER SYSTEM CONFIGURATION

4-1 System configuration

4-2 Speed controller

4-3 Adjustment of valve position

4-4 Manual operation procedure

4-5 Solenoid valve

4-6 Limit switch

5.CYLINDER MAINTENANCE

5-1 Disassembly procedure

5-2

Single-acting type cylinder side cover disassembly procedure

5-3 Assembly procedure

5-4

Single-acting type cylinder side cover assembly procedure

5-5 Troubleshooting

1

2

2

2

3

3

4

4

4

5

7

8

10

10

11

12

12

13

13

14

15

17

19

21

22

22

24

25

29

30

Page

CONTENTS

Warranty Period

The warranty period of the delivered product should be eighteen (18) months after shipment

from our factory or one (1) year after the date of starting trial runs, whichever comes first.

Scope of Warranty and Indemnity

If any damage or problem should occur during the foregoing warranty period due to our fault,

Tomoe Valve will replace or repair any defective part of the product free of charge at the

place where the product was purchased or where it was delivered (limited to Japan).

However, warranty is not applicable if the causes of defect should result from the following:

(1) The failure was caused by inappropriate conditions, environment, handling or use

methods, etc. which are not specified in the catalog, specifications or other relevant

documents that had been made and entered into between the customer and Tomoe

Valve.

(2) The failure was caused by the product other than the delivered Tomoe's product.

(3)

The failure was caused by modifications or repairs by a party other than Tomoe Valve.

(4) The failure was caused by use under the condition that had not been given as required

specifications of valves, etc., or by a problem that was not foreseen from the specified

conditions.

(5) The failure was caused by significant wear and tear of the seat ring, the gland packing,

etc.

(6) The failure was caused by poor application of consumables, such as lubricant.

(7) The failure was caused by inappropriate maintenance or inspection under highly

frequent valve operation.

(8) The failure was caused by power source or air supply.

(9) The failure was caused by foreign substances, such as dust, that entered and clogged in

the product.

(

10

) The failure was caused by inappropriate storage of the product, such as open air

storage.

(

11

)

The failure was caused by fire, flood, earthquakes, fall of rocks, and other acts of God.

(

12

) The failure was caused by other reasons which are not our responsibility.

In addition, the forgoing warranty is only applicable to the product itself and excludes com-

pensation of any other indirect or consequential damage.

Charged Repair Service and Supply of Discontinued Parts

Products are subject to discontinuation or modification without notice. For products

that are no longer manufactured or sold, repair or overhaul of the products may not be

available after 5 years since discontinuation. In addition, supply of the parts or spare

parts of the products may not be available.

■CONTACT

New (7E/7F/7G)

2018.10.31-PhCat.No.EM1045-③

●Head Office

3-11-11 Shinmachi, Nishi-ku, Osaka 550-0013, Japan

Global Sales Operations

www.tomoevalve.com

No. 317, Kamol Sukosol Building, Unit B, 12th Floor, Silom Road, Silom Sub-district, Bangrak District, Bangkok 10500, Thailand

TOMOE VALVE (THAILAND) CO., LTD.

15700 International Plaza Drive Suite150, Houston TX, 77032 USA

Telephone: +1-281-358-7571 Telefax: +1-281-358-7861

TOMOE USA Inc.

Room 1102, Building A, St.NOAH Plaza, No.1759 Jinshajiang Road, Putuo district, Shanghai. 200333, China

TOMOE VALVE INDUSTRY (NANTONG) CO., LTD.

http://www.tomoe.sh.cn

BlockF2 Latrade Industrial Park, JI. Sei Binti Tanjung Uncang, Batam 29422 Indonesia

PT. TOMOE VALVE BATAM

http://www.tomoe-batam.com

No 2, Toh Guan Road East, #02-02, Singapore 608837

TOMOE VALVE ASIA PACIFIC PTE. LTD.

www.tomoe.com.sg

Clearwater Road, Queensway Meadows Industrial Estate,

Newport, South Wales NP19 4ST, United Kingdom

www.tomoeeurope.co.uk

TOMOE VALVE LIMITED

1

2

The instructions hereunder are for long-lasting service of T-DYNAMO (hereinafter "this

product") without loss or hazard.

Please read this manual thoroughly before use in order to ensure correct use of the product.

Separate information for the safety precautions for handling valves should also be observed.

a

a

b

b

Port A

Port B

Cover⑥Case①

Parallel pin㉜

Piston packing㉔ Cover⑦

Piston⑤

Piston⑤

Shaft②

Yoke③

Parallel pin㉜

Spring㊷

Piston⑤

Shaft②Cover⑥

Piston⑤

Spring㊷

Port C

PortBb

b

a

a

Cover⑦Yoke③

FOR YOUR SAFE USAGE

The following instructions should always be followed.

WARNING

This mark indicates "possibility of death or serious injury".

This mark indicates items that "you must not do".

This mark indicates items "you must do".

CAUTION

■We will indicate the following marks for your attention. (The following are examples of marks.)

Introduction

●Be sure to read this instruction manual before transportation, storage, piping installation, operation, and mainte-

nance and inspection.

●This instruction manual does not describe all the assumed conditions on transportation, storage, piping installa-

tion, operation, maintenance and inspection of this product. If there are any questions, please contact our sales

department.

●Reference values and limit values for operation, maintenance, and inspection specified in this instruction manual

have been determined in consideration of maintenance management of this product. This product should be used

within the range of the reference values and the limit values.

●This product should be used by connecting only to a valve with an opening/closing angle of 90 degrees or less.

●Be sure to store this instruction manual in a readily accessible place for future reference after installation and

operation start. If a staff in charge is changed, information on the storage place of the instruction manual and

operation should be communicated to the next staff.

●If dents or scratches are made on impact, stop using the product for safety and replace the product.

*Details of this instruction manual are subject to change without notice.

1-1 Product features

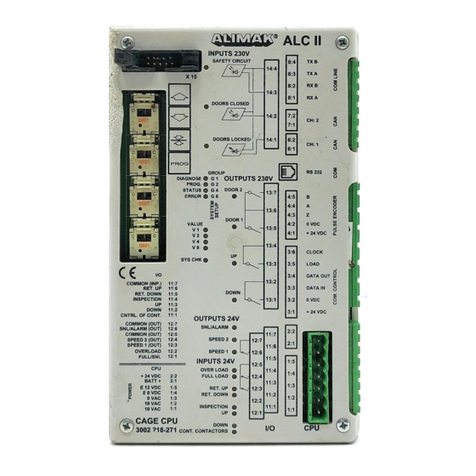

■Double-acting type cylinder

(1) The cylinder space which is enclosed by the case ①and the

covers ⑥and ⑦is divided into airtight chambers ⓐand ⓑ

by the pistons ⑤and the piston packing ㉔.

(2) The shaft

②

penetrates the chamber

ⓑ

of the case. The yoke

③

is

fitted in the hole across the shaft in such a way that it allows it to slide

in the hole. The top of the yoke is connected with the parallel pins

㉜

so it rotates in accordance with the movement of the pistons.

(3) The compressed air enters chamber ⓐthrough port A and

pushes the pistons. The air in chamber ⓑis exhausted through

port B as the pistons move due to a pressure difference

between the two chambers. Integrated with these pistons, the

parallel pins ㉜also move and torque in the shaft is generated.

■Single-acting type cylinder

(1) The cylinder space which is enclosed by the case ①and the

covers ⑥and ⑦is divided into airtight chambers ⓐand ⓑ

by the pistons ⑤and the piston packing ㉔.

(2) The shaft ②penetrates the chamber ⓑof the case. The yoke

③is fitted in the hole across the shaft in such a way that it

allows it to slide in the hole. The top of the yoke is connected

with the parallel pins ㉜so it rotates in accordance with the

movement of the pistons.

(3) The compressed air enters chamber ⓑthrough port B and

pushes the pistons. The air in chamber ⓐis exhausted

through port C as the pistons ⑤move and the spring ㊷is

squeezed due to a pressure difference between the two

chambers. Integrated with these pistons ⑤, the parallel pins

㉜also move and torque in the shaft is generated.

(4) When air supply to Port B is stopped, the pistons are pushed

back due to the force of the spring ㊷and torque in the shaft

is generated.

1-2 Operating principle

This product is a pneumatic rotary actuator driven by pneumatic pressure of 0.4 to 0.7 MPa for the purpose of

actuating a 90˚ butterfly valve. The case is of aluminum alloy which is fabricated by means of extrusion. This manu-

facturing method enables the cylinder to be light weight, compact in design and highly accurate. The attachment

installation member complies with the NAMUR standard. NAMUR standard attachment parts can be installed directly.

1. PRODUCT FEATURES

Piston movement

Air flow

Double-acting type cylinder Single-acting type cylinder

■We will indicate level of danger or damage caused by neglecting these cautions as the

following:

This mark indicates "possibility of injury to personnel or physical

damage only".

1

2

The instructions hereunder are for long-lasting service of T-DYNAMO (hereinafter "this

product") without loss or hazard.

Please read this manual thoroughly before use in order to ensure correct use of the product.

Separate information for the safety precautions for handling valves should also be observed.

a

a

b

b

Port A

Port B

Cover⑥Case①

Parallel pin㉜

Piston packing㉔ Cover⑦

Piston⑤

Piston⑤

Shaft②

Yoke③

Parallel pin㉜

Spring㊷

Piston⑤

Shaft②Cover⑥

Piston⑤

Spring㊷

Port C

PortBb

b

a

a

Cover⑦Yoke③

FOR YOUR SAFE USAGE

The following instructions should always be followed.

WARNING

This mark indicates "possibility of death or serious injury".

This mark indicates items that "you must not do".

This mark indicates items "you must do".

CAUTION

■We will indicate the following marks for your attention. (The following are examples of marks.)

Introduction

●Be sure to read this instruction manual before transportation, storage, piping installation, operation, and mainte-

nance and inspection.

●This instruction manual does not describe all the assumed conditions on transportation, storage, piping installa-

tion, operation, maintenance and inspection of this product. If there are any questions, please contact our sales

department.

●Reference values and limit values for operation, maintenance, and inspection specified in this instruction manual

have been determined in consideration of maintenance management of this product. This product should be used

within the range of the reference values and the limit values.

●This product should be used by connecting only to a valve with an opening/closing angle of 90 degrees or less.

●Be sure to store this instruction manual in a readily accessible place for future reference after installation and

operation start. If a staff in charge is changed, information on the storage place of the instruction manual and

operation should be communicated to the next staff.

●If dents or scratches are made on impact, stop using the product for safety and replace the product.

*Details of this instruction manual are subject to change without notice.

1-1 Product features

■Double-acting type cylinder

(1) The cylinder space which is enclosed by the case ①and the

covers ⑥and ⑦is divided into airtight chambers ⓐand ⓑ

by the pistons ⑤and the piston packing ㉔.

(2) The shaft

②

penetrates the chamber

ⓑ

of the case. The yoke

③

is

fitted in the hole across the shaft in such a way that it allows it to slide

in the hole. The top of the yoke is connected with the parallel pins

㉜

so it rotates in accordance with the movement of the pistons.

(3) The compressed air enters chamber ⓐthrough port A and

pushes the pistons. The air in chamber ⓑis exhausted through

port B as the pistons move due to a pressure difference

between the two chambers. Integrated with these pistons, the

parallel pins ㉜also move and torque in the shaft is generated.

■Single-acting type cylinder

(1) The cylinder space which is enclosed by the case ①and the

covers ⑥and ⑦is divided into airtight chambers ⓐand ⓑ

by the pistons ⑤and the piston packing ㉔.

(2) The shaft ②penetrates the chamber ⓑof the case. The yoke

③is fitted in the hole across the shaft in such a way that it

allows it to slide in the hole. The top of the yoke is connected

with the parallel pins ㉜so it rotates in accordance with the

movement of the pistons.

(3) The compressed air enters chamber ⓑthrough port B and

pushes the pistons. The air in chamber ⓐis exhausted

through port C as the pistons ⑤move and the spring ㊷is

squeezed due to a pressure difference between the two

chambers. Integrated with these pistons ⑤, the parallel pins

㉜also move and torque in the shaft is generated.

(4) When air supply to Port B is stopped, the pistons are pushed

back due to the force of the spring ㊷and torque in the shaft

is generated.

1-2 Operating principle

This product is a pneumatic rotary actuator driven by pneumatic pressure of 0.4 to 0.7 MPa for the purpose of

actuating a 90˚ butterfly valve. The case is of aluminum alloy which is fabricated by means of extrusion. This manu-

facturing method enables the cylinder to be light weight, compact in design and highly accurate. The attachment

installation member complies with the NAMUR standard. NAMUR standard attachment parts can be installed directly.

1. PRODUCT FEATURES

Piston movement

Air flow

Double-acting type cylinder Single-acting type cylinder

■We will indicate level of danger or damage caused by neglecting these cautions as the

following:

This mark indicates "possibility of injury to personnel or physical

damage only".

WARNING

CAUTION

CAUTION

��

2-1 Safety measures

2.1.1 Handling of this product

This product should be handled by knowledgeable and experienced technicians only.

Compressed air, etc. is hazardous if wrongly handled. Assembly, operation, maintenance of a machine

or a unit utilizing compressed air should be handled by technicians who have read the instruction

manual (hereinafter "this manual") thoroughly and understand the contents completely.

2.1.2 Safety check

Handling or dismantling of the machine or the unit must not be carried out until safety

precautions are ensured.

The machine should only be dismantled after checking the following items to ensure safety.

①Safety precautions for this product, such as preventions against falling of parts, material or other

accidental happenings, have been taken.

②The surface temperature of this product is a temperature where the surface can be touched.

③Supply air, etc. that are power sources and compressed air in the air piping system have been

removed.

④No fluid flows in the pipelines.

⑤The power of the system has been shut off.

Before restarting of the unit, check the following items.

①This product is fixed to a valve securely.

②There is no failure or damage on the appearance of this product, or loss of parts.

③Tools have not been left on this product.

④Nothing hinders operation of this product (operation of the cylinder, opening/closing of the valve).

⑤There is no leakage of electrical and pneumatic signals.

⑥There is no leakage of compressed air, etc.

2.1.3 Fail-safe design

When the unit is used for the point where fail-safe design is required, adopt a method where the

system responds in a way that will cause no harm using a single-acting type cylinder (spring back

cylinder), a lock-up valve, etc. in case of loss of all or a part of power that controls the machine.

2.1.4 Water hammer

Design should be performed in consideration of water hammer. Water hammer may occur even

within the opening and closing times in the range of the product specifications, depending on the

pipeline conditions or valve operating conditions.

2-2 Transportation and storage

2.2.1 Mass

Products with large mass (approx. 20 kg) should be transported using equipment or a machine, not

by man power alone. See the catalog issued by our company, product drawings, etc. for the mass

of this product. Qualified personnel should perform work with a forklift or a crane, or slinging work in

accordance with laws and regulations, and safety provisions of business establishments.

2.2.2 Falling

When this product is unloaded or transversely held, it should be held appropriately to prevent it from

falling and being damaged.

2.2.3 Dust-proofing, water-proofing

The plug (tentative seal plug) connected to the piping connection should not be removed until

pneumatic piping work is performed. If dust-proofing and water-proofing measures are not taken,

dirt, dust, rainwater, etc. will infiltrate this product, causing defective operation. If the plug is lost,

take protective measures using a cover or protection tape instead. For single-acting type cylinders,

orient the elbow of the exhaust port downwards to prevent infiltration of dirt, dust, rainwater, etc.

2. PRECAUTIONS FOR USE

3

4

Type

Torque (N·m)

(When supply pressure

is 0.4MPa and

rotation angle is 0°)

Supply air pressure

condition/temperature

Air supply

pressure (MPa)

Body shell max (MPa)

Air connection (Rc)

Rotating angle

Ambient temperature

Travel time (sec)

With speed controller *

Dehumidified air / -10°C ~ +60°C

0.4 ~ 0.7MPa

1.05MPa

Rc (PT)1/4

90°

-10°C ~ +60°C

T35

35

T85

85

T200

200

T380

380

T750

750

T85S

30

T200S

65

T380S

116

T750S

240

1~15 2~15 3~15 7~20 12~25 2~15 6~15 8~20 15~25

Double-acting type cylinder (7E) Single-acting type cylinder(7F/7G)

1-3 Type description

1-4 Standard specifications

Double-acting type cylinder (7E) Single-acting type cylinder (7F/7G)

T85

① ② T85S

① ② ③

* The output torque of single-acting type differs from that of double-acting type. Please refer to 1-4 Standard

specifications.

*

The opening and closing times are the times in the case of a single unit of a cylinder with a standard speed

controller (SP-K017-Z03-006) and a solenoid valve (PCS2408-NB-100MC) when the air supply pressure is 0.4

MPa.

The opening and closing times depend on pneumatic piping system, etc.

①Identification of this product

②Identification of type

③Operation type: Spring return

①Identification of this product

②Output torque (*)

WARNING

CAUTION

CAUTION

��

2-1 Safety measures

2.1.1 Handling of this product

This product should be handled by knowledgeable and experienced technicians only.

Compressed air, etc. is hazardous if wrongly handled. Assembly, operation, maintenance of a machine

or a unit utilizing compressed air should be handled by technicians who have read the instruction

manual (hereinafter "this manual") thoroughly and understand the contents completely.

2.1.2 Safety check

Handling or dismantling of the machine or the unit must not be carried out until safety

precautions are ensured.

The machine should only be dismantled after checking the following items to ensure safety.

①Safety precautions for this product, such as preventions against falling of parts, material or other

accidental happenings, have been taken.

②The surface temperature of this product is a temperature where the surface can be touched.

③Supply air, etc. that are power sources and compressed air in the air piping system have been

removed.

④No fluid flows in the pipelines.

⑤The power of the system has been shut off.

Before restarting of the unit, check the following items.

①This product is fixed to a valve securely.

②There is no failure or damage on the appearance of this product, or loss of parts.

③Tools have not been left on this product.

④Nothing hinders operation of this product (operation of the cylinder, opening/closing of the valve).

⑤There is no leakage of electrical and pneumatic signals.

⑥There is no leakage of compressed air, etc.

2.1.3 Fail-safe design

When the unit is used for the point where fail-safe design is required, adopt a method where the

system responds in a way that will cause no harm using a single-acting type cylinder (spring back

cylinder), a lock-up valve, etc. in case of loss of all or a part of power that controls the machine.

2.1.4 Water hammer

Design should be performed in consideration of water hammer. Water hammer may occur even

within the opening and closing times in the range of the product specifications, depending on the

pipeline conditions or valve operating conditions.

2-2 Transportation and storage

2.2.1 Mass

Products with large mass (approx. 20 kg) should be transported using equipment or a machine, not

by man power alone. See the catalog issued by our company, product drawings, etc. for the mass

of this product. Qualified personnel should perform work with a forklift or a crane, or slinging work in

accordance with laws and regulations, and safety provisions of business establishments.

2.2.2 Falling

When this product is unloaded or transversely held, it should be held appropriately to prevent it from

falling and being damaged.

2.2.3 Dust-proofing, water-proofing

The plug (tentative seal plug) connected to the piping connection should not be removed until

pneumatic piping work is performed. If dust-proofing and water-proofing measures are not taken,

dirt, dust, rainwater, etc. will infiltrate this product, causing defective operation. If the plug is lost,

take protective measures using a cover or protection tape instead. For single-acting type cylinders,

orient the elbow of the exhaust port downwards to prevent infiltration of dirt, dust, rainwater, etc.

2. PRECAUTIONS FOR USE

3

4

Type

Torque (N·m)

(When supply pressure

is 0.4MPa and

rotation angle is 0°)

Supply air pressure

condition/temperature

Air supply

pressure (MPa)

Body shell max (MPa)

Air connection (Rc)

Rotating angle

Ambient temperature

Travel time (sec)

With speed controller *

Dehumidified air / -10°C ~ +60°C

0.4 ~ 0.7MPa

1.05MPa

Rc (PT)1/4

90°

-10°C ~ +60°C

T35

35

T85

85

T200

200

T380

380

T750

750

T85S

30

T200S

65

T380S

116

T750S

240

1~15 2~15 3~15 7~20 12~25 2~15 6~15 8~20 15~25

Double-acting type cylinder (7E) Single-acting type cylinder(7F/7G)

1-3 Type description

1-4 Standard specifications

Double-acting type cylinder (7E) Single-acting type cylinder (7F/7G)

T85

① ② T85S

① ② ③

* The output torque of single-acting type differs from that of double-acting type. Please refer to 1-4 Standard

specifications.

*

The opening and closing times are the times in the case of a single unit of a cylinder with a standard speed

controller (SP-K017-Z03-006) and a solenoid valve (PCS2408-NB-100MC) when the air supply pressure is 0.4

MPa.

The opening and closing times depend on pneumatic piping system, etc.

①Identification of this product

②Identification of type

③Operation type: Spring return

①Identification of this product

②Output torque (*)

WARNING

CAUTION

2.3.5 Vibration and impact at installation location

The following measures should be taken if there is vibration or impact at the location where this

product is installed.

①When this product is used with the following conditions, after checking vibration or impact

conditions (particularly acceleration value, etc.), consult with our sales department.

1) Location where excessive vibration or impact is exerted

2) Location where vibration or impact is exerted continuously

②Installation sections and connecting sections, etc. of this product should be locked to fix and fasten

securely. Particularly, when the product is used under highly frequent opening/closing conditions,

fastening should be performed with a significant margin in consideration of fatigue resistance.

③Vibration isolation measures should be taken to reduce vibration or impact on the machine.

Pipelines should be fixed with supports, or vibration isolation material should be installed.

④Joints should be checked periodically against looseness and deformation. In case of abnormal

conditions, bolts should be retightened or parts should be replaced. Coming off of fastening

bolts may cause falling off or rotation in an unexpected direction of this product.

2.3.6 Design of a connection part between a valve and this product

The following items should be checked when a connection part between a valve and this product is

designed.

①Thrust load and lateral load should not be applied to the output shaft of this product.

②At independent retainer should be installed to the valve stem of the valve to prevent travel in

the shaft direction. If the output shaft of this product is used as a retainer for the valve stem of

the valve, the valve stem may protrude due to fluid pressure when this product is removed.

③The dimension to fit the output shaft of this product and the valve stem of the valve should be

secured sufficiently. Please refer to separate dimensional outline drawings for appropriate fit

dimension. If the fit dimension is insufficient, strength at fitting section may become insufficient,

resulting in damage.

2.3.7 Precautions at pneumatic piping

Pneumatic pipelines should be connected to this product while paying attention to the following

items. If dents or scratches are made on impact, to ensure safety stop using the product and

replace the product.

①

This product, attachments, and pneumatic pipelines should be kept free from external force or shock.

Rough handling may cause deformation of the output shaft, or air leakage due to damage of O-rings.

②Standing on this product should be avoided at connecting pipelines. This product should not

be inserted by hitting the product.

③Before connecting pipelines, pipeline members and fittings, particularly the air filter

secondary-side should be thoroughly cleaned by air blowing (flushing) or other suitable

cleaning method to remove cutting dust, oils and other debris.

④When the pipelines and fittings are screwed into the unit, care must be taken to avoid infiltra-

tion of any cutting dust or sealant into this product.

⑤When the fittings are screwed into the unit, excessive force may cause damage. After the

joints are screwed in lightly, the joints should be retightened in a 1/4 turn as a guide. The

reference value of the tightening torque is approx. 10 – 14 Nm.

⑥In order to prevent infiltration of foreign substances into the piping air ports and vents, plugs

(tentative seal plugs) have been installed before shipping. Remove all of them before using.

2.3.8 Precautions for attachments

The following items should be checked on the attachments of this product.

①The speed controller that is standard equipment of this product is fully opened when shipped.

Before using, please turn it in the closing direction (clockwise) and adjust the opening and closing

times. Please refer to 4-2 Speed controller for operation procedure of the speed controller.

②The rotation speed should be adjusted with the speed controller. No speed adjustment should

be attempted by means of a pressure reducing valve. High speed opening/closing may cause

water hammer of the valve. Therefore, care should be taken in speed adjustment.

③If the opening and closing times of this product influence system operation timing, leave a

sufficient margin for the opening and closing times. The opening and closing times may

change due to conditions, such as fluid pressure and temperature.

④In order to prevent damage during transportation, parts, such as resin silencers, may be packed

without being installed. Please install them before operation after completing valve installation.

2.2.4 Storage

This product should be stored as follows to prevent contamination, discoloration, and material

deterioration.

①This product should be stored in a place with no dust or water droplet while avoiding direct

sunlight, high temperatures and humidity.

②This product should be stored in a packed state or with equivalent protective measures.

③When this product which has been stored for more than 1 year is used, the operational status

of the product should be checked. If any abnormal condition is found, overhaul, and replace-

ment of deformed or degraded parts should be performed.

2-3 Installation and working environment

2.3.1 Obtaining space for installation location

For installation location, work space should be obtained around this product. If work space cannot

be obtained, parts may not be removed at maintenance.

2.3.2 Installation location and working environment

In the following installation locations or working environments, special actions, such as compliance with

laws and regulations, may be required in some cases as well as functional conformance to specifications. If

there are any questions, please contact our sales department at planning stage.

①Special working environments which are not described in the specifications.

②In the case where substantial damage to human beings, assets, environments, etc. is

predicted if the product fails.

e.g.: Facilities related to High Pressure Gas Safety Act, facilities related to Industrial Safety

and Health Act, Nuclear power related facilities, vehicles, medical facilities, etc.

2.3.3 Atmosphere of installation location

The following measures should be taken depending on the atmosphere of the location where this

product is installed.

①Locations which are exposed to gas containing salt, corrosive gas, chemical solution, organic

solvent, steam, etc. should be avoided. For some kinds of atmosphere, anti-corrosive mea-

sures can be taken. Please consult with our sales department.

②If there is a possibility that this product is exposed to direct radiant heat or chemicals, the

product and attachments should be protected with a cover, etc.

③When a single-acting type cylinder is used outdoors or in a location where the unit is exposed

to water, the elbow of the exhaust port should be oriented downwards to prevent infiltration of

dirt, dust, rainwater, etc.

④This product should not be submerged.

2.3.4 Temperature of installation location

The following measures should be taken depending on the temperature of the location where this

product is installed.

Using the product out of the specified temperature range causes thermal degradation or hardening of

O-rings, thermal expansion of parts, defective operation due to difference of thermal shrinkage, etc.

①The ambient temperature of the installation location should be based on the specifications.

②The supplied compressed air, etc. should be based on the specifications.

③If the product is exposed to direct sunlight, the working temperatures of this product and

attachments should not exceed the upper limit.

④This product should be kept away from heat sources, and installed in a location where the

temperature is within the specified temperature range. Particularly, ambient temperature may

exceed the specified temperature range near a motor, an air compressor, etc.

⑤The attachments should be used within the appropriate temperature range of the attachments.

5

6

WARNING

CAUTION

2.3.5 Vibration and impact at installation location

The following measures should be taken if there is vibration or impact at the location where this

product is installed.

①When this product is used with the following conditions, after checking vibration or impact

conditions (particularly acceleration value, etc.), consult with our sales department.

1) Location where excessive vibration or impact is exerted

2) Location where vibration or impact is exerted continuously

②Installation sections and connecting sections, etc. of this product should be locked to fix and fasten

securely. Particularly, when the product is used under highly frequent opening/closing conditions,

fastening should be performed with a significant margin in consideration of fatigue resistance.

③Vibration isolation measures should be taken to reduce vibration or impact on the machine.

Pipelines should be fixed with supports, or vibration isolation material should be installed.

④Joints should be checked periodically against looseness and deformation. In case of abnormal

conditions, bolts should be retightened or parts should be replaced. Coming off of fastening

bolts may cause falling off or rotation in an unexpected direction of this product.

2.3.6 Design of a connection part between a valve and this product

The following items should be checked when a connection part between a valve and this product is

designed.

①Thrust load and lateral load should not be applied to the output shaft of this product.

②At independent retainer should be installed to the valve stem of the valve to prevent travel in

the shaft direction. If the output shaft of this product is used as a retainer for the valve stem of

the valve, the valve stem may protrude due to fluid pressure when this product is removed.

③The dimension to fit the output shaft of this product and the valve stem of the valve should be

secured sufficiently. Please refer to separate dimensional outline drawings for appropriate fit

dimension. If the fit dimension is insufficient, strength at fitting section may become insufficient,

resulting in damage.

2.3.7 Precautions at pneumatic piping

Pneumatic pipelines should be connected to this product while paying attention to the following

items. If dents or scratches are made on impact, to ensure safety stop using the product and

replace the product.

①

This product, attachments, and pneumatic pipelines should be kept free from external force or shock.

Rough handling may cause deformation of the output shaft, or air leakage due to damage of O-rings.

②Standing on this product should be avoided at connecting pipelines. This product should not

be inserted by hitting the product.

③Before connecting pipelines, pipeline members and fittings, particularly the air filter

secondary-side should be thoroughly cleaned by air blowing (flushing) or other suitable

cleaning method to remove cutting dust, oils and other debris.

④When the pipelines and fittings are screwed into the unit, care must be taken to avoid infiltra-

tion of any cutting dust or sealant into this product.

⑤When the fittings are screwed into the unit, excessive force may cause damage. After the

joints are screwed in lightly, the joints should be retightened in a 1/4 turn as a guide. The

reference value of the tightening torque is approx. 10 – 14 Nm.

⑥In order to prevent infiltration of foreign substances into the piping air ports and vents, plugs

(tentative seal plugs) have been installed before shipping. Remove all of them before using.

2.3.8 Precautions for attachments

The following items should be checked on the attachments of this product.

①The speed controller that is standard equipment of this product is fully opened when shipped.

Before using, please turn it in the closing direction (clockwise) and adjust the opening and closing

times. Please refer to 4-2 Speed controller for operation procedure of the speed controller.

②The rotation speed should be adjusted with the speed controller. No speed adjustment should

be attempted by means of a pressure reducing valve. High speed opening/closing may cause

water hammer of the valve. Therefore, care should be taken in speed adjustment.

③If the opening and closing times of this product influence system operation timing, leave a

sufficient margin for the opening and closing times. The opening and closing times may

change due to conditions, such as fluid pressure and temperature.

④In order to prevent damage during transportation, parts, such as resin silencers, may be packed

without being installed. Please install them before operation after completing valve installation.

2.2.4 Storage

This product should be stored as follows to prevent contamination, discoloration, and material

deterioration.

①This product should be stored in a place with no dust or water droplet while avoiding direct

sunlight, high temperatures and humidity.

②This product should be stored in a packed state or with equivalent protective measures.

③When this product which has been stored for more than 1 year is used, the operational status

of the product should be checked. If any abnormal condition is found, overhaul, and replace-

ment of deformed or degraded parts should be performed.

2-3 Installation and working environment

2.3.1 Obtaining space for installation location

For installation location, work space should be obtained around this product. If work space cannot

be obtained, parts may not be removed at maintenance.

2.3.2 Installation location and working environment

In the following installation locations or working environments, special actions, such as compliance with

laws and regulations, may be required in some cases as well as functional conformance to specifications. If

there are any questions, please contact our sales department at planning stage.

①Special working environments which are not described in the specifications.

②In the case where substantial damage to human beings, assets, environments, etc. is

predicted if the product fails.

e.g.: Facilities related to High Pressure Gas Safety Act, facilities related to Industrial Safety

and Health Act, Nuclear power related facilities, vehicles, medical facilities, etc.

2.3.3 Atmosphere of installation location

The following measures should be taken depending on the atmosphere of the location where this

product is installed.

①Locations which are exposed to gas containing salt, corrosive gas, chemical solution, organic

solvent, steam, etc. should be avoided. For some kinds of atmosphere, anti-corrosive mea-

sures can be taken. Please consult with our sales department.

②If there is a possibility that this product is exposed to direct radiant heat or chemicals, the

product and attachments should be protected with a cover, etc.

③When a single-acting type cylinder is used outdoors or in a location where the unit is exposed

to water, the elbow of the exhaust port should be oriented downwards to prevent infiltration of

dirt, dust, rainwater, etc.

④This product should not be submerged.

2.3.4 Temperature of installation location

The following measures should be taken depending on the temperature of the location where this

product is installed.

Using the product out of the specified temperature range causes thermal degradation or hardening of

O-rings, thermal expansion of parts, defective operation due to difference of thermal shrinkage, etc.

①The ambient temperature of the installation location should be based on the specifications.

②The supplied compressed air, etc. should be based on the specifications.

③If the product is exposed to direct sunlight, the working temperatures of this product and

attachments should not exceed the upper limit.

④This product should be kept away from heat sources, and installed in a location where the

temperature is within the specified temperature range. Particularly, ambient temperature may

exceed the specified temperature range near a motor, an air compressor, etc.

⑤The attachments should be used within the appropriate temperature range of the attachments.

5

6

WARNING

CAUTION

2.4.6 Modification

This product should not be modified. Deterioration of durability or breakage of this product may pose a

danger to the environment.

2.4.7 External manual operation

Care must be taken for the following items at external manual operation.

①For only double-acting type cylinders, a valve can be opened or closed manually by turning the

output shaft of the actuator with a spanner after the supply and exhaust pressures become the

same with the bypass valve (except Type T750).

Please note that, when the bypass valve is opened, the valve opening changes due to fluid

pressure.(Please refer to 4-4 Manual operation procedure for how to use the bypass valve.)

②The manual operation torque may change abruptly depending on the valve opening, and you

may lose balance, resulting in falling. Manual operation should be performed while securing

safety with scaffolding, space, etc.

③In the case of Type T750, large operating force is required and operation with small tools is

dangerous. Thus external manual operation should not be performed with a spanner or a

monkey wrench. Please use a manual gear for the operation.

④

For single-acting type cylinders, manual opening/closing operation should not be performed with a

spanner, a monkey wrench, or a manual lever for double-acting type cylinders (hereinafter "dedicated

lever"). If the output shaft is turned with a spanner, a monkey wrench, or the dedicated lever, the shaft is

rotated backwards by the spring force, which is dangerous. Please use the manual screw handle.

⑤

The spanner, monkey wrench, or special lever used at manual operation must be removed at comple-

tion of the operation. In case of automatic operation with them mounted, the spanner, monkey wrench,

or special lever may come off and fall out, which may cause personal injuries or machine damage.

⑥In the case of a unit with a manual gear, before switching operation to automatic operation

after manual operation, check that the manual gear is at the position of automatic operation

and the bypass valve is closed. (They are not returned automatically.)

2.4.8 Others

①If air supply is stopped for a long period of time after compressed air, etc. is supplied to this

product, the valve opening position may not be kept.

②When operation is restarted after a long downtime (5 days or more), operation time may be

longer than usual due to increase in grease viscosity or valve resistance, etc.

2.5.1 Residual pressure

Even after supply of compressed air, etc. to this product is stopped, compressed air may gush out

or unexpected operation may occur due to residual pressure in the cylinder. Installation work and

maintenance should be performed after removing residual pressure from the cylinder.

2.5.2 Maintenance and inspection of this product

Maintenance and inspection should be performed according to 5-1 Disassembly procedure in this

manual. At maintenance and inspection of this product, inspection should be made while paying

attention to the following items.

①For single-acting type cylinders, the cover may fall out due to the force of the internal spring

even if compressed air, etc. is not supplied, which may cause injury or damage.

②Bolts should not be loosened, while compressed air, etc. are supplied, or this product or the

valve can be operated. Compressed air may gush out or unexpected operation may occur.

2.5.3 Daily check

Daily check including the following items on this product should be performed.

①Water accumulated in the filter regulator etc. should be drained from the drain exhaust port.

②During operation of this product, visual check and noise check should be performed from a

safe location. Inspection should be made on defective appearance, such as looseness of the

bolts, abnormal noise during operation, rattling, air leakage to the outside, air leakage from

exhaust vents and piping joints, etc.

③If compressed air, etc. is supplied even if operation of this product is stopped, inspection

should be made on looseness of the bolts, air leakage to the outside, and air leakage from

exhaust vents and piping joints.

2-5 Maintenance

2.4.1 Operating air

The following items should be checked on operating air of this product.

1) Use clean operating air to operate this product.

2) It should be checked that compressed air, etc. supplied to this product should be within the range

between 0.4 MPa and 0.7 MPa.

3) Supplied air should be filtered with an air filter etc. to remove foreign substances. The filter should

be of 40 µm or finer mesh.

4) Supplied air should be dehumidified with an air dryer, etc. (dew-point temperature at atmospheric

barometric pressure is -15°C or lower) to remove moisture from the air.

5) Compressed air, etc. should be kept free from the following to prevent defective or abnormal

operation of the unit.

• Chemicals, synthetic oils with organic solvent base, corrosive gas, deteriorated compressor oil

6) Attachments (solenoid valve, regulator, filter, pneumatic line size, joint, etc.) should be selected with

consideration of pressure loss so that the air pressure is within the range of the specified pressure

at the air inlet port of this product. Otherwise the opening and closing times may slow down.

7) In case of lack of supply of compressed air, etc. to this product, intermittent operation of the pistons

occur, or the valve is stuck. Care should be taken to avoid lack of air supply amount and air supply

pressure. When the pneumatic pipeline is 5 m or more, take measures, such as use of a large-

diameter pipeline, etc.

8) Cylinder capacity of a pneumatic actuator varies largely subject to type of actuator. Please select

the suitable air compressor capacity. Please refer to 3-4 Air consumption.

2.4.2 Supply pressure adjustment

Piping should be designed so that suitable compressed air amount and pressure are supplied to this product.

Insufficient air supply amount or air supply pressure may affect opening/closing operation of the valve.

In cases of pneumatic devices in which the pneumatic pipeline inlet of this product or the end of the plant

pipeline is connected with a long pipeline, air supply amount and air supply pressure may be insufficient

for this product due to loss at pipelines. An auxiliary air tank should be installed, etc. as needed.

2.4.3 Operation check

When this product is purchased separately, operation check should be performed with the following

procedure.

①It should be checked that there is no flaw in the appearance, damage or loss of parts.

②This product should be checked separately for proper operation.

③After connecting to the valve, adjust the valve opening. (Please refer to 4-3 Adjustment of valve

position for details.)

④Valve opening/closing operation should be checked.

When this product integrated with a valve (hereinafter "finished product") is purchased, operation check

should be performed with the following procedure.

①It should be checked that there is no flaw in the appearance, damage or loss of parts.

②It should be checked that pipelines for compressed air and electric signals are connected.

③It should be checked that there is no air leakage from pipeline connecting sections and this product.

④Valve opening/closing operation should be checked.

2.4.4 Valve opening adjustment

Valve opening should be adjusted while paying attention to the following points.

①When finished products are purchased, the stopper bolts at the closing side should not be

loosened. If the stopper bolts at the closing side are loosened, the valve full closing position

changes, and valve seat leakage may occur.

②Before adjustment, compressed air, etc. should be discharged from this product. If there is any

residual pressure due to compressed air, the stopper bolts may fall out.

③After adjustment, it should be checked that there is no air leakage from the stopper bolts.

2.4.5 Opening and closing time

If the opening and closing time is shorter than the minimum time of the product specifications, durability

of this product may be deteriorated.

2-4 Use and adjustment

CAUTION

CAUTION

CAUTION

7

8

WARNING

CAUTION

2.4.6 Modification

This product should not be modified. Deterioration of durability or breakage of this product may pose a

danger to the environment.

2.4.7 External manual operation

Care must be taken for the following items at external manual operation.

①For only double-acting type cylinders, a valve can be opened or closed manually by turning the

output shaft of the actuator with a spanner after the supply and exhaust pressures become the

same with the bypass valve (except Type T750).

Please note that, when the bypass valve is opened, the valve opening changes due to fluid

pressure.(Please refer to 4-4 Manual operation procedure for how to use the bypass valve.)

②The manual operation torque may change abruptly depending on the valve opening, and you

may lose balance, resulting in falling. Manual operation should be performed while securing

safety with scaffolding, space, etc.

③In the case of Type T750, large operating force is required and operation with small tools is

dangerous. Thus external manual operation should not be performed with a spanner or a

monkey wrench. Please use a manual gear for the operation.

④

For single-acting type cylinders, manual opening/closing operation should not be performed with a

spanner, a monkey wrench, or a manual lever for double-acting type cylinders (hereinafter "dedicated

lever"). If the output shaft is turned with a spanner, a monkey wrench, or the dedicated lever, the shaft is

rotated backwards by the spring force, which is dangerous. Please use the manual screw handle.

⑤

The spanner, monkey wrench, or special lever used at manual operation must be removed at comple-

tion of the operation. In case of automatic operation with them mounted, the spanner, monkey wrench,

or special lever may come off and fall out, which may cause personal injuries or machine damage.

⑥In the case of a unit with a manual gear, before switching operation to automatic operation

after manual operation, check that the manual gear is at the position of automatic operation

and the bypass valve is closed. (They are not returned automatically.)

2.4.8 Others

①If air supply is stopped for a long period of time after compressed air, etc. is supplied to this

product, the valve opening position may not be kept.

②When operation is restarted after a long downtime (5 days or more), operation time may be

longer than usual due to increase in grease viscosity or valve resistance, etc.

2.5.1 Residual pressure

Even after supply of compressed air, etc. to this product is stopped, compressed air may gush out

or unexpected operation may occur due to residual pressure in the cylinder. Installation work and

maintenance should be performed after removing residual pressure from the cylinder.

2.5.2 Maintenance and inspection of this product

Maintenance and inspection should be performed according to 5-1 Disassembly procedure in this

manual. At maintenance and inspection of this product, inspection should be made while paying

attention to the following items.

①For single-acting type cylinders, the cover may fall out due to the force of the internal spring

even if compressed air, etc. is not supplied, which may cause injury or damage.

②Bolts should not be loosened, while compressed air, etc. are supplied, or this product or the

valve can be operated. Compressed air may gush out or unexpected operation may occur.

2.5.3 Daily check

Daily check including the following items on this product should be performed.

①Water accumulated in the filter regulator etc. should be drained from the drain exhaust port.

②During operation of this product, visual check and noise check should be performed from a

safe location. Inspection should be made on defective appearance, such as looseness of the

bolts, abnormal noise during operation, rattling, air leakage to the outside, air leakage from

exhaust vents and piping joints, etc.

③If compressed air, etc. is supplied even if operation of this product is stopped, inspection

should be made on looseness of the bolts, air leakage to the outside, and air leakage from

exhaust vents and piping joints.

2-5 Maintenance

2.4.1 Operating air

The following items should be checked on operating air of this product.

1) Use clean operating air to operate this product.

2) It should be checked that compressed air, etc. supplied to this product should be within the range

between 0.4 MPa and 0.7 MPa.

3) Supplied air should be filtered with an air filter etc. to remove foreign substances. The filter should

be of 40 µm or finer mesh.

4) Supplied air should be dehumidified with an air dryer, etc. (dew-point temperature at atmospheric

barometric pressure is -15°C or lower) to remove moisture from the air.

5) Compressed air, etc. should be kept free from the following to prevent defective or abnormal

operation of the unit.

• Chemicals, synthetic oils with organic solvent base, corrosive gas, deteriorated compressor oil

6) Attachments (solenoid valve, regulator, filter, pneumatic line size, joint, etc.) should be selected with

consideration of pressure loss so that the air pressure is within the range of the specified pressure

at the air inlet port of this product. Otherwise the opening and closing times may slow down.

7) In case of lack of supply of compressed air, etc. to this product, intermittent operation of the pistons

occur, or the valve is stuck. Care should be taken to avoid lack of air supply amount and air supply

pressure. When the pneumatic pipeline is 5 m or more, take measures, such as use of a large-

diameter pipeline, etc.

8) Cylinder capacity of a pneumatic actuator varies largely subject to type of actuator. Please select

the suitable air compressor capacity. Please refer to 3-4 Air consumption.

2.4.2 Supply pressure adjustment

Piping should be designed so that suitable compressed air amount and pressure are supplied to this product.

Insufficient air supply amount or air supply pressure may affect opening/closing operation of the valve.

In cases of pneumatic devices in which the pneumatic pipeline inlet of this product or the end of the plant

pipeline is connected with a long pipeline, air supply amount and air supply pressure may be insufficient

for this product due to loss at pipelines. An auxiliary air tank should be installed, etc. as needed.

2.4.3 Operation check

When this product is purchased separately, operation check should be performed with the following

procedure.

①It should be checked that there is no flaw in the appearance, damage or loss of parts.

②This product should be checked separately for proper operation.

③After connecting to the valve, adjust the valve opening. (Please refer to 4-3 Adjustment of valve

position for details.)

④Valve opening/closing operation should be checked.

When this product integrated with a valve (hereinafter "finished product") is purchased, operation check

should be performed with the following procedure.

①It should be checked that there is no flaw in the appearance, damage or loss of parts.

②It should be checked that pipelines for compressed air and electric signals are connected.

③It should be checked that there is no air leakage from pipeline connecting sections and this product.

④Valve opening/closing operation should be checked.

2.4.4 Valve opening adjustment

Valve opening should be adjusted while paying attention to the following points.

①When finished products are purchased, the stopper bolts at the closing side should not be

loosened. If the stopper bolts at the closing side are loosened, the valve full closing position

changes, and valve seat leakage may occur.

②Before adjustment, compressed air, etc. should be discharged from this product. If there is any

residual pressure due to compressed air, the stopper bolts may fall out.

③After adjustment, it should be checked that there is no air leakage from the stopper bolts.

2.4.5 Opening and closing time

If the opening and closing time is shorter than the minimum time of the product specifications, durability

of this product may be deteriorated.

2-4 Use and adjustment

CAUTION

CAUTION

CAUTION

7

8

CAUTION

T35 only

T750 only

2.5.4 Periodical inspection

Periodical inspection including the following items on this product should be performed.

①After opening and closing 50,000 times or 1 year of use, whichever one is earlier, inspection

should be made on looseness of each bolt and air leakage. The bolts should be retightened

and consumables should be replaced as needed.

②From the second year, the above-mentioned inspection should be made every year.

2.5.5 Removal and installation

①Before this product is removed from the valve power and compressed air, etc. must be shut off

and residual pressure must be removed from the machine and pipelines completely. Otherwise

compressed air may gush out or unexpected operation may occur.

②When two or more valves and the products are removed, numbers or symbols shall be put on

the valves and the products to identify the corresponding valve and product. Mistaken installa-

tion may cause failure or defective operation of the unit.

③Match marks should be made on the top plates of this product and the valve to indicate the

installation orientation of this product. Mistaken installation orientation may cause defective

operation.

④Loosen the hexagon bolts which fix this product on the valve to remove this product. If joints

are included in the valve, please be careful not to lose them. Loss of joints may cause defec-

tive operation.

⑤When this product is removed, the valve full closing position may be changed. Valve seat

leakage should be checked. In case of leakage, the full closing position should be adjusted.

Please refer to 4-3 Adjustment of valve position for adjustment of the full closing position.

⑥At installation, it should be checked that opening of the valve and the opening of this product

are the same. If the openings are not the same, opening and closing operation is performed in

the reverse way.

2.5.6 Replacement of consumable parts

The product should be disassembled and assembled in a clean location which is free from dust and dirt.

Please refer to 5-1 Disassembly procedure for replacement procedure of consumables. Consum-

able parts of single-acting type cylinders should be replaced according to 5-2 Single-acting type

cylinder side cover disassembly procedure.

2.5.7 Lubricant

Grease has been applied to the sliding elements of this product. Lubrication by supply air is not

required. However, it is recommended to apply grease after opening and closing 50,000 times or 1

year of use, whichever one is earlier.

2.5.8 Safety check

During maintenance and inspection, all workers should be informed of the following conditions:

power and compressed air, etc. are shut off, residual pressure is discharged completely, or power

and compressed air, etc. are supplied again.

2.5.9 Disposal

This product should be disposed while paying attention to the following items.

①This product should not be disposed of by incineration. There is a risk of toxic gas generation

and bursting. Therefore please dispose of it as general industrial waste. The product does not

contain materials which cannot be disposed of as general industrial waste.

②When this product is disposed after sorting, materials should be classified according to the

materials specified on drawings.

③When a single-acting type cylinder is disassembled and disposed of, care should be taken to

springs flying out.

At disassembly of the single-acting type cylinder, please refer to 5-2 Single-acting type

cylinder side cover disassembly procedure.

④This product should be disposed in accordance with laws and regulations.

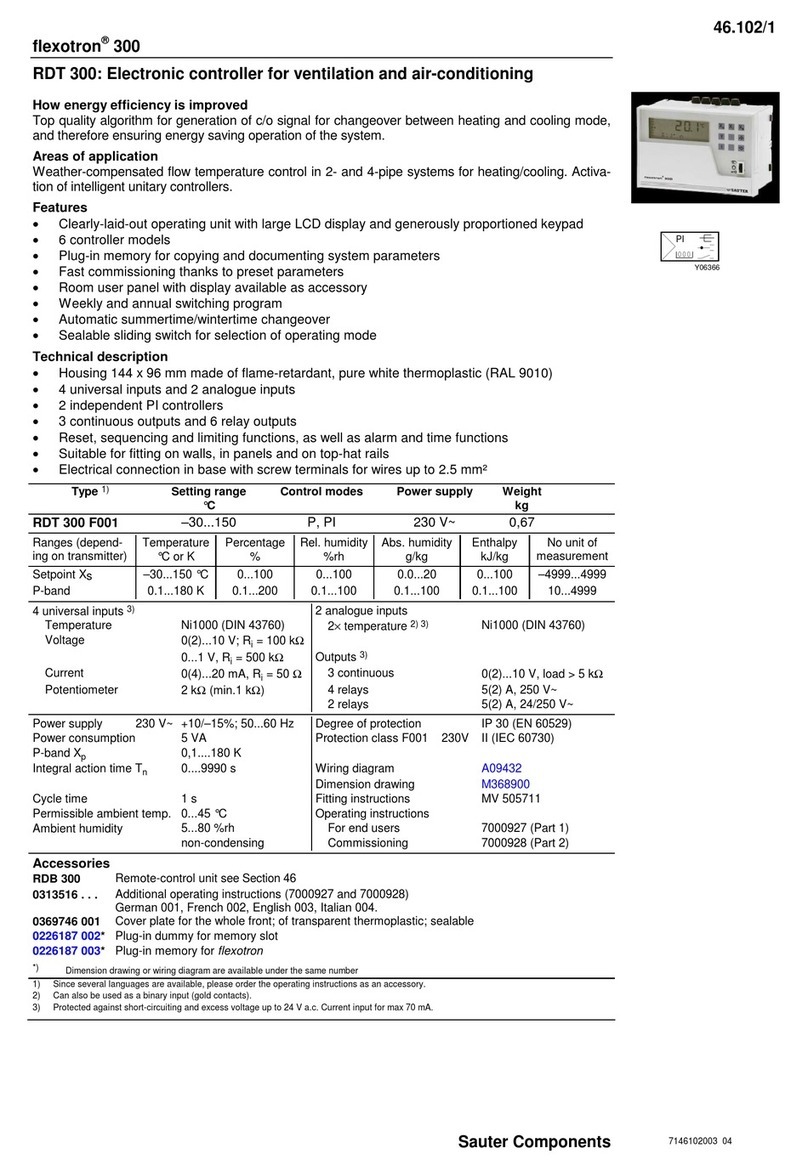

Note) Parts indicated by "★" in Remarks are included in "O-ring set". To order the parts, please specify "O-ring set". When replacing consum-

ables, please replace all the parts indicated by "★".

No. Description Q'ty Remarks No. Description Q'ty Remarks

1 Case 1 25 O-ring for rotating shaft (top) 1 ★

2 Shaft 1 26 O-ring for rotating shaft (bottom) 1 ★

3 Yoke 1 27 Cover packing 2 ★

4 Stopper 1 29 O-ring (base plate) 1 ★

5 Piston 2 30 Connecting pin (shaft-yoke) 1 ★

6 Cover 1 1 31 Sunk plug (shaft-yoke) 1 ★

7 Cover 2 1 32 Parallel pin (piston) 2

8 Base plate 1 34 C-retainer (lower shaft) 1 ★T85~T750

9 Bearing 2 35 C-retainer (piston) 2 T85~T750

11 Indicator plate 1 36 Bearing housing 1 T750 only

13 Bearing 1 (shaft-piston) 2 ★T35: 1 pc 46 Spring washer (cover 1

,

2) 8

14 Bearing 2 1 ★T35 only 47

Hexagon socket head cap screw (cover 1, 2)

8

15 Bearing 3 (lower shaft) 1 ★49

Hexagon socket head cap screw (base plate)

4 T35: 2pcs

16 Bearing 4 (upper shaft) 1 ★T35 only 50 Spring washer (base plate) 4 T35: 2pcs

17 Wear ring 2 ★51 Hexagon nut (opening side stopper) 1

18 Piston support 4 ★52 Hexagon nut (closing side stopper) 1

19 Thrust plate 1 ★53 Hexagon stop screw (opening side) 1

21 Position indicator 1 54 Hexagon stop screw (closing side) 1

23 Slit cover 1 55 Spring washer (closing side stopper) 1

24 Piston packing 2 ★60 Seal washer 1 ★

Note) Parts whose part number is enclosed by a box (□) in the expanded view are included in "O-ring set".

To order the parts, please specify "O-ring set".

When replacing consumables, please replace all the above-mentioned parts.

3-1 Expanded view (Double-acting type)

3. STRUCTURE

5

9

35

32

46, 47

1

36

23

21

11

5

32

4

2

9

46, 47

3

3

53

51

7

35

52

55

54

49,50

8

9

10

6

CAUTION

T35 only

T750 only

2.5.4 Periodical inspection

Periodical inspection including the following items on this product should be performed.

①After opening and closing 50,000 times or 1 year of use, whichever one is earlier, inspection

should be made on looseness of each bolt and air leakage. The bolts should be retightened

and consumables should be replaced as needed.

②From the second year, the above-mentioned inspection should be made every year.

2.5.5 Removal and installation

①Before this product is removed from the valve power and compressed air, etc. must be shut off

and residual pressure must be removed from the machine and pipelines completely. Otherwise

compressed air may gush out or unexpected operation may occur.

②When two or more valves and the products are removed, numbers or symbols shall be put on

the valves and the products to identify the corresponding valve and product. Mistaken installa-

tion may cause failure or defective operation of the unit.

③Match marks should be made on the top plates of this product and the valve to indicate the

installation orientation of this product. Mistaken installation orientation may cause defective

operation.

④Loosen the hexagon bolts which fix this product on the valve to remove this product. If joints

are included in the valve, please be careful not to lose them. Loss of joints may cause defec-

tive operation.

⑤When this product is removed, the valve full closing position may be changed. Valve seat

leakage should be checked. In case of leakage, the full closing position should be adjusted.

Please refer to 4-3 Adjustment of valve position for adjustment of the full closing position.

⑥At installation, it should be checked that opening of the valve and the opening of this product

are the same. If the openings are not the same, opening and closing operation is performed in

the reverse way.

2.5.6 Replacement of consumable parts

The product should be disassembled and assembled in a clean location which is free from dust and dirt.

Please refer to 5-1 Disassembly procedure for replacement procedure of consumables. Consum-

able parts of single-acting type cylinders should be replaced according to 5-2 Single-acting type

cylinder side cover disassembly procedure.

2.5.7 Lubricant

Grease has been applied to the sliding elements of this product. Lubrication by supply air is not

required. However, it is recommended to apply grease after opening and closing 50,000 times or 1

year of use, whichever one is earlier.

2.5.8 Safety check

During maintenance and inspection, all workers should be informed of the following conditions:

power and compressed air, etc. are shut off, residual pressure is discharged completely, or power

and compressed air, etc. are supplied again.

2.5.9 Disposal

This product should be disposed while paying attention to the following items.

①This product should not be disposed of by incineration. There is a risk of toxic gas generation

and bursting. Therefore please dispose of it as general industrial waste. The product does not

contain materials which cannot be disposed of as general industrial waste.

②When this product is disposed after sorting, materials should be classified according to the

materials specified on drawings.

③When a single-acting type cylinder is disassembled and disposed of, care should be taken to

springs flying out.

At disassembly of the single-acting type cylinder, please refer to 5-2 Single-acting type

cylinder side cover disassembly procedure.

④This product should be disposed in accordance with laws and regulations.

Note) Parts indicated by "★" in Remarks are included in "O-ring set". To order the parts, please specify "O-ring set". When replacing consum-

ables, please replace all the parts indicated by "★".

No. Description Q'ty Remarks No. Description Q'ty Remarks

1 Case 1 25 O-ring for rotating shaft (top) 1 ★

2 Shaft 1 26 O-ring for rotating shaft (bottom) 1 ★

3 Yoke 1 27 Cover packing 2 ★

4 Stopper 1 29 O-ring (base plate) 1 ★

5 Piston 2 30 Connecting pin (shaft-yoke) 1 ★

6 Cover 1 1 31 Sunk plug (shaft-yoke) 1 ★

7 Cover 2 1 32 Parallel pin (piston) 2

8 Base plate 1 34 C-retainer (lower shaft) 1 ★T85~T750

9 Bearing 2 35 C-retainer (piston) 2 T85~T750

11 Indicator plate 1 36 Bearing housing 1 T750 only

13 Bearing 1 (shaft-piston) 2 ★T35: 1 pc 46 Spring washer (cover 1

,

2) 8

14 Bearing 2 1 ★T35 only 47

Hexagon socket head cap screw (cover 1, 2)

8

15 Bearing 3 (lower shaft) 1 ★49

Hexagon socket head cap screw (base plate)

4 T35: 2pcs

16 Bearing 4 (upper shaft) 1 ★T35 only 50 Spring washer (base plate) 4 T35: 2pcs

17 Wear ring 2 ★51 Hexagon nut (opening side stopper) 1

18 Piston support 4 ★52 Hexagon nut (closing side stopper) 1

19 Thrust plate 1 ★53 Hexagon stop screw (opening side) 1

21 Position indicator 1 54 Hexagon stop screw (closing side) 1

23 Slit cover 1 55 Spring washer (closing side stopper) 1

24 Piston packing 2 ★60 Seal washer 1 ★

Note) Parts whose part number is enclosed by a box (□) in the expanded view are included in "O-ring set".

To order the parts, please specify "O-ring set".

When replacing consumables, please replace all the above-mentioned parts.

3-1 Expanded view (Double-acting type)

3. STRUCTURE

5

9

35

32

46, 47

1

36

23

21

11

5

32

4

2

9

46, 47

3

3

53

51

7

35

52

55

54

49,50

8

9

10

6

A A

B

B

T750S only

T750S only

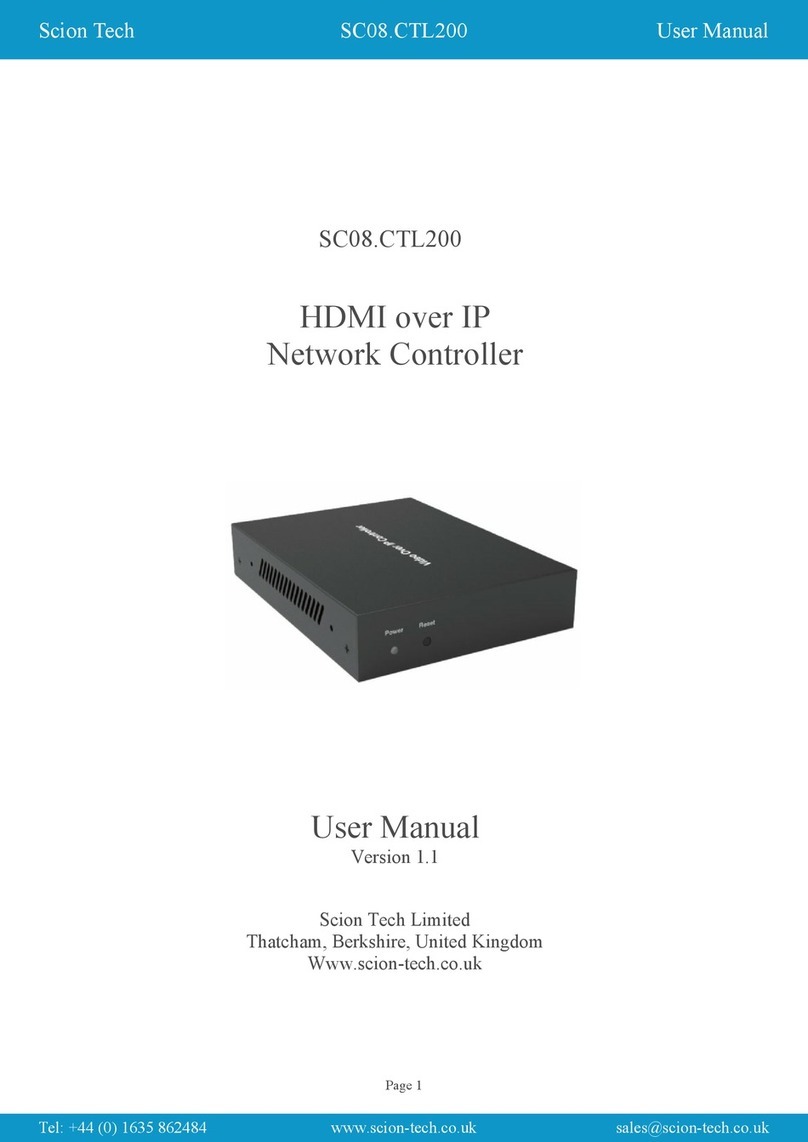

3-2 Expanded view (Single-acting type)

Note) Parts whose part number is enclosed by a box (□) in the expanded view are

included in "O-ring set". To order the parts, please specify "O-ring set".

When replacing consumables, please replace all the above-mentioned parts.

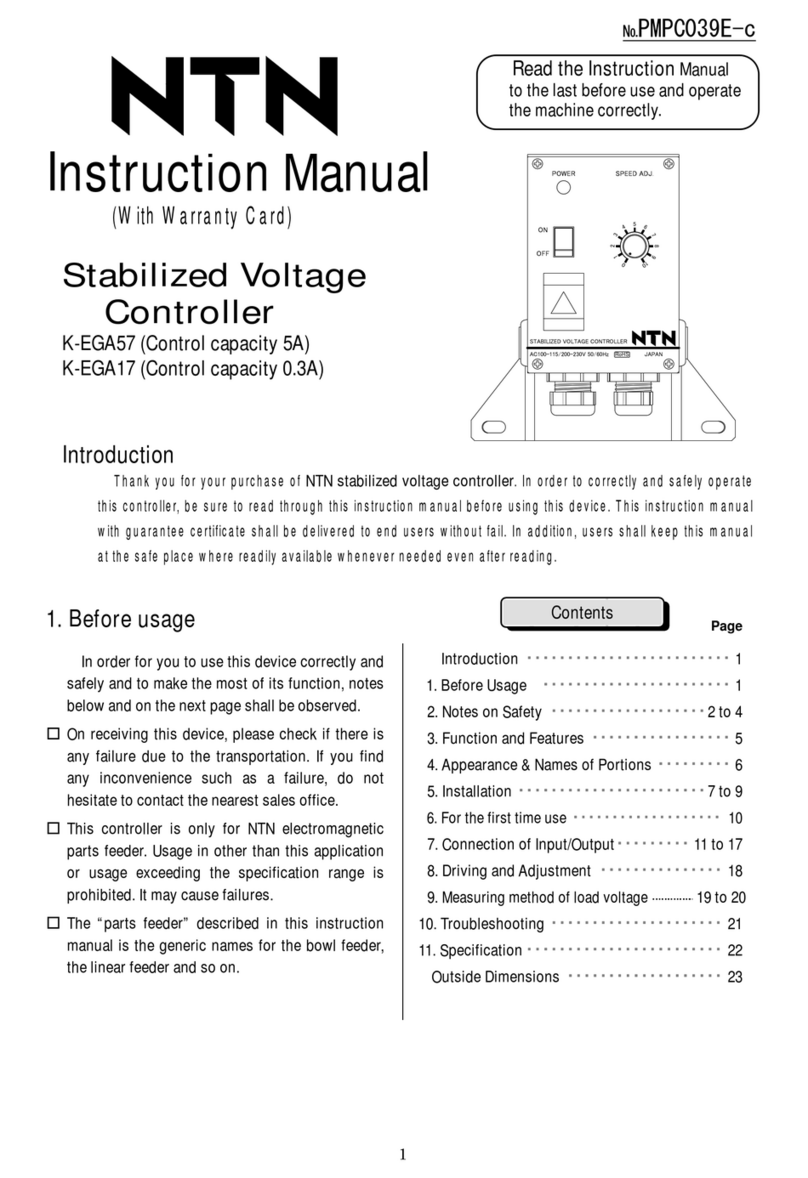

3-3 Output torque curves

3-4 Air consumption

①The table shows the torque at an operating air pressure of 0.4 MPa.

②Output torque for an operating air pressure of P MPa is given by : = P x (torque value obtained from the

table)/0.4. (Only double-acting type cylinder)

③In the case of single-acting type cylinders, the spring force does not change even if the operating air pressure is

changed. Thus the torque indicated by the dotted lines is constant regardless of the operating air pressure.

④In the case of single-acting type cylinders, the output torque value at openclose is different from that at close

open. The continuous lines and dotted lines indicate the torques respectively.

7G (Open with pressure) 7F (Close with pressure)

Continuous line Torque at closeopen with air pressure Torque at closeopen with spring

Dotted line Torque at openclose with spring Torque at openclose with air pressure

⑤A valve for the single-acting type cylinder should be selected referring to the torque indicated with a dotted line.

Note) Parts indicated by "★" in Remarks are included in "O-ring set". To order the parts, please specify "O-ring set". When replacing consum-

ables, please replace all the parts indicated by "★".

VD: Double-acting type cylinder air consumption (Nℓ)

VS: Single-acting type cylinder air consumption (Nℓ)

A,B: Cylinder capacity (ℓ)

P: Operating pressure (MPa)

N:

Operating frequencies in a given time (1 round trip = 1)

CD: Double-acting type cylinder air consumption (Nℓ/sec)

CS: Single-acting type cylinder air consumption (Nℓ/sec)

t: Unit time (sec)

(1) Required air consumption

(2) Air consumption within a unit time

Double-acting type

Double-acting type

VD=(A+B)

CD=

P+0.1013

0.1013 N

Single-acting type

Single-acting type

VS=(B) P+0.1013

0.1013 N

VD

t

CS= VS

t

(Note) The compressor should have a larger capacity

than air consumption calculated in above (1)

and (2).

Cylinder capacity(ℓ)

A B

Cylinder

Type

T35

T85

T200

T380

T750

0.2

0.4

0.8

1.8

3.2

0.2

0.5

1.1

2.1

4.6

Cylinder capacity(ℓ)

---

T85S

T200S

T380S

T750S

---

0.5

1.1

2.1

4.6

■Double-acting type(7E) ■Single-acting type(7F/7G)

Cylinder

Type

No. Description Q'ty Remarks No. Description Q'ty Remarks

1 Case 1 30 Connecting pin (shaft-yoke) 1 ★

2 Shaft 1 31 Sunk plug (shaft-yoke) 1 ★

3 Yoke 1 32 Parallel pin (piston) 2

4 Stopper 1 34 C-retainer (lower shaft) 1 ★

5 Piston 2 35 C-retainer (piston) 2

6 Cover 1 1 36 Bearing housing 1 T750S only

7 Cover 2 1 37 Stopper bolt 1 T750S only

8 Base plate 1 42 Spring 2

9 Bearing 2 43 Spring guide 2

11 Indicator plate 1 44 Hexagon bolt (spring guide) 2

13 Bearing 1(shaft-piston) 2 ★45 Spring washer (spring guide) 2

15 Bearing 3 (lower shaft) 1 ★46 Spring washer (cover 1,2) 8

17 Wear ring 2 ★48

Hexagon socket head cap screw (cover 1, 2)

8

18 Piston support 4 ★49

Hexagon socket head cap screw (base plate)

4

19 Thrust plate 1 ★50 Spring washer (base plate) 4

21 Position indicator 1 51 Hexagon nut (cover 2) 1

23 Slit cover 1 52 Hexagon nut (base plate) 1

24 Piston packing 2 ★53 Hexagon stop screw (cover 2) 1

25 O-ring for rotating shaft (top) 1 ★54 Hexagon stop screw (base plate) 1

26 O-ring for rotating shaft (bottom) 1 ★55 Spring washer (base plate) 1

27 Cover packing 2 ★60 Seal washer (cover 2) 1 ★

29 O-ring (base plate) 1 ★62

Hexagon socket head taper plug (cover 1)

1

5

9

46, 48

36

23

21

11

5

4

46, 48

3

53

51

7

8

52

55

54

49,50

2

1

6

42

35

44 45 43

37

45

43

35

32

43

44

45

42

32

9

62

11

12

10

100

1000

0 10 20 30 40 50 60 70 80 90

Torque [Nm]

Opening [degree] Opening [degree]

Double-acting type cylinder output torque

T750

T380

T200

T85

T35

Torque [Nm]

Single-acting type cylinder output torque

0

10

100

1000

10 20 30 40 50 60 70 80 90

T-750S - continuous line

T-750S - dotted line

T-380S - dotted line

T-200S - dotted line

T-85S - dotted line

T-380S - continuous line

T-200S - continuous line

T-85S - continuous line

A A

B

B

T750S only

T750S only

3-2 Expanded view (Single-acting type)

Note) Parts whose part number is enclosed by a box (□) in the expanded view are

included in "O-ring set". To order the parts, please specify "O-ring set".

When replacing consumables, please replace all the above-mentioned parts.

3-3 Output torque curves

3-4 Air consumption

①The table shows the torque at an operating air pressure of 0.4 MPa.

②Output torque for an operating air pressure of P MPa is given by : = P x (torque value obtained from the

table)/0.4. (Only double-acting type cylinder)

③In the case of single-acting type cylinders, the spring force does not change even if the operating air pressure is

changed. Thus the torque indicated by the dotted lines is constant regardless of the operating air pressure.

④In the case of single-acting type cylinders, the output torque value at openclose is different from that at close

open. The continuous lines and dotted lines indicate the torques respectively.

7G (Open with pressure) 7F (Close with pressure)

Continuous line Torque at closeopen with air pressure Torque at closeopen with spring

Dotted line Torque at openclose with spring Torque at openclose with air pressure