ir33+ Electronic controller for stand-alone refrigerating units

+05Z0028EN- rel. 1.0 - 13.03.2014

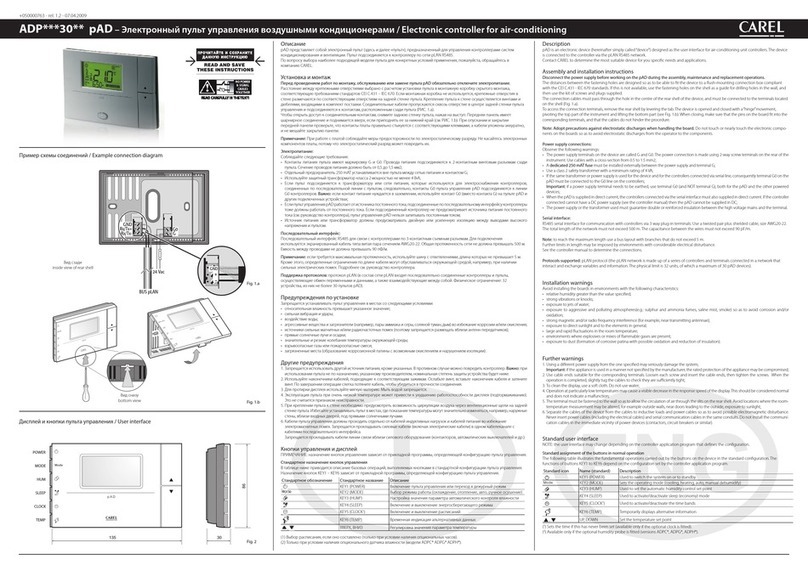

Dimensions (mm)

Panel mounting

Rear (with 2 quick-fit side brackets)

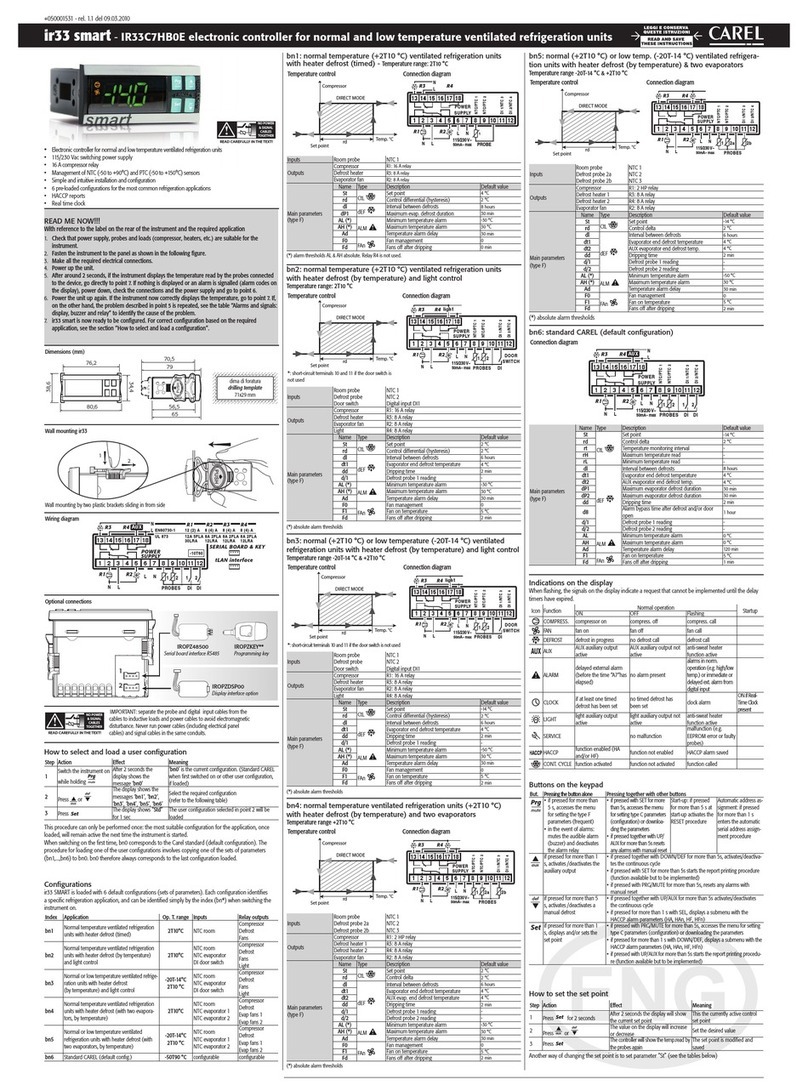

Technical characteristics

power supply:

Model Voltage Power

IREVxxExxxx 230 V~, 50/60 Hz 3 VA, 25 mA~ max.

IREVxxHxxxx 115...230 V~, 50/60 Hz 6 VA, 50 mA~ max.

IREVxxLxxxx 12...24 V~, 50/60 Hz, 12...30 Vdc 3 VA, 300 mA~ /mAdc max.

Insulation guaranteed by the power supply:

IREVxxExxxx

IREVxxHxxxx

insulation in reference to very low

voltage parts

reinforced, 6 mm clearance, 8 mm

creepage, 3750 V insulation

insulation from relay outputs basic, 3 mm clearance, 4 mm creepage,

1250 V insulation

IREVxxLxxxx insulation in reference to very low

voltage parts

externally guaranteed by safety transfor-

mer (SELV power supply)

insulation from relay outputs reinforced, 6 mm clearance, 8 mm

creepage, 3750 V insulation

Inputs

S1 (probe 1) NTC

S2 (probe 2) NTC

DI1

S3 (probe 3)

free contact, contact resistance < 10 Ω, closing current 6 mA

NTC

DI2

S4 (probe 4)

free contact, contact resistance < 10 Ω, closing current 6 mA

NTC

Maximum distance of probes and digital inputs less than 10 m. Note: During installation

keep the power and loads connection separate from probe cables, digital inputs, repeater

display and supervisory system

Probe type

NTC std.

CAREL

10 kΩ a 25 °C, range –50T90 °C

measurement error 1 °C range –50T50 °C

3 °C range 50T90 °C

Relay outputs (depending on the model)

EN60730-1 UL873

model relay 250 V~ operat.

cycles

250 V~ operat.cycles

IRxxxx(E,A)(P,Q,S,U,V,X,Y,Z)xxx R2 (*) 5(1) A 100000 5 A res. 1 FLA

6 LRA C300

30000

IRxxxx(E,A)(N,R,C,B,A,M,L,T)xxx R3 (*) 5(1) A 100000 5 A res. 1 FLA

6 LRA C300

30000

IRxxxx(E,A)(N,R,C,B,A,M,L,T)xxx

IRxxxx(0,L,H)(N,R,C,B,A,M,L,T)xxx

R1, R2

R2, R3,

R4 (*)

8(4)A N.O.

6(4)A N.C.

2(2)A N.O./N.C.

100000 8 A res. 2 FLA

12 LRA C300

30000

IRxxxx(E,A)(P,Q,S,U,V,X,Y,Z)xxx

IRxxxx(0,L,H)(N,R,C,B,A,M,L,T)xxx

R1 12(2)A

N.O./N.C.

100000 12 A res. 5 FLA

30 LRA C300

30000

insulation in reference to very low

voltage parts

reinforced, 6 mm clearance, 8 mm creepage, 3750 V

insulation

insulation between the relay outputs

indipendent

basic, 3 mm clearance, 4 mm creepage, 1250 V

insulation

Connections wire section 0.5 - 2.5 mq max current 12A

(*): Relay not suitable for fluorescent loads (neon lights, ...) that use starters (ballasts) with

phase-shift capacitors. Fluorescent lamps with electronic control devices or without phase-

shift capacitors can be used, within the operating limits specified for each type of relay.

The installer has to provide the correct dimensioning of the power supply and cable con-

nection between the instruments and the loads. Depending on the model, the maximum

current in the common terminals 1, 3 or 5 is 12 A. When using the controller at maximum

operating temperature and full load, use cables featuring a maximum operating tempera-

ture of 105 °C at least.

Clock error at 25 °C ±10 ppm (±5.3 min/year)

error in the temperature range -10T60 °C

-50 ppm (-27 min/year)

Operating temperature -10T60 °C for all versions

Operating humidity <90% r.H. non-condensing

Storage temperature -20T70 °C

Storage humidity <90% r.H. non-condensing

Front panel degree of protection smooth and stiff panel installation with

gasket IP65

Control pollution status 2 (normal situation)

PTI of the insulating material printed circuit board 250, insulation 175

Period of electric stress across insulating parts long

Heat and fire resistance category category D and category B (UL 94-V0)

Class of protection against voltage surges category II

Type of disconnection or interruption 1.B relay contacts (micro-disconnection)

Construction of control incorporated control, electronically

Classification according to protection against

electric shock

Class II, by appropriate incorporation

Max. distance between interface and display 10 m

Programming key available on all models

Safety standards: compliant with the European

reference standards.

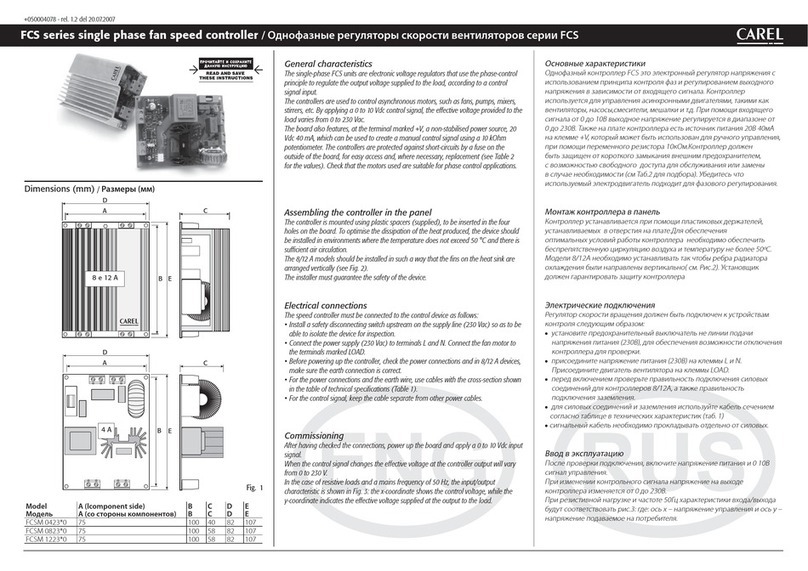

Signals on the display

Icon Function Normal operation Startup

ON OFF blink

COMPRESSOR compressor ON compressor OFF compressor

required

FAN fan ON fan OFF fan required

DEFROST defrost in progress defrost not

required

defrost required

AUX auxiliary output AUX

active

auxiliary output

AUX not active

anti-sweat heater

function active

ALARM delayed external alarm

(before the expiry of

the time‘A7’)

no alarm present alarms and

malfunctions

CLOCK at least one timed

defrost has been set

no timed defrost

is present

clock alarm ON if RTC

present

LIGHT auxiliary output

LIGHT active

auxiliary output

LIGHT not active

anti-sweat heater

function active

SERVICE no malfunctions malfunction (es.

EEPROM error or

probe fault)

HACCP function not enabled function enabled

(HA and/or HF)

HACCP alarm

enabled

CONTINUOUS

CYCLE

function enabled function not

enabled

function required

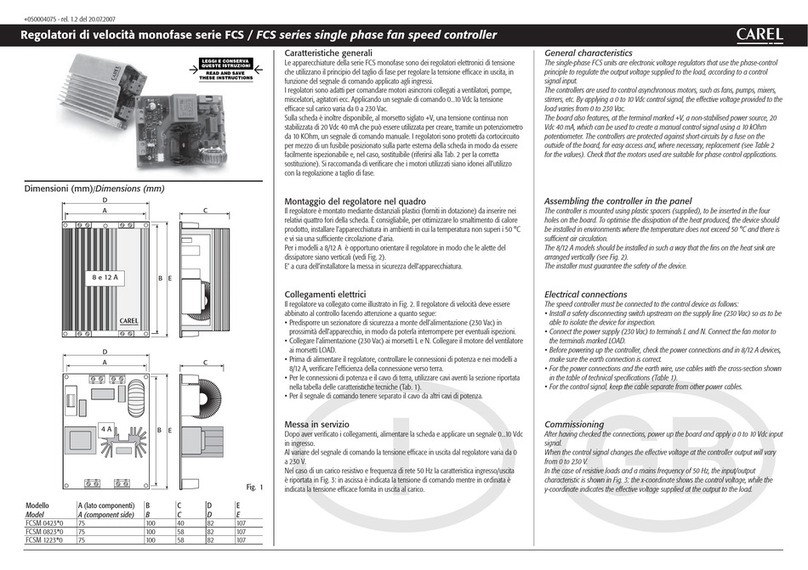

Optional connections

1

2IROPZDSP00

Display interface option

IROPZ48500

Serial board interface RS485

IROPZKEY**

Programming key

Option codes

Code Description

IROPZDSP00 remote display interface

IREVXGD000 remote repeater dispaly

IROPZ485S0 RS485 serial board interface with automatic recognition of the polarity +/-

PSOPZPRG00 programming key kit

PSOPZKEY00 parameter programmin key with 12 V batteries

PSOPZKEYA0 parameter programming key external 230 Vac power supply

IROPZKEY00 parameter programming key, extended memory with 12 V batteries

PSTCON0*B0 repeater display connection cables (*: 1= 1,5 m; 3= 3 m; 5= 5m)

NOPOWER

& SIGNAL

CABLES

TOGETHER

READCAREFULLY IN THE TEXT!

Description: ir33+* represent a range of electronic microprocessor controllers with LED

display developed for the management of stand-alone refrigerating units.

Part number list:

IREVM0LN0U, IREVM0EN0U

IREVS0LN0U, IREVS0EA0U,

IREVC0LN0U, IREVC0LC0U

IREVC0HN0U, IREVC0HC0U, IREVF0EN0U

drilling template

71x29 mm

34.7

79.5

82

76.2

80.6

38.6

60

64

E, AVersion

65

69

Buttons on the keypad

Button Normal function Start-up Autom.address

assignment

Pressing the button alone Pressing together with other buttons

PRG /

MUTE

- if pressed for more than

3 s accesses the menu

for setting the password

to access the type “F”

(frequent) parameters or

“C” (Configuration)

- in the event of alarm:

silences the audible alarm

(buzzer) and disables the

alarm relay

PRG+ON-OFF/UP:

if pressed together

for more than 3

s reset any alarm

with manual reset

if pressed for

more than 5

s at start-up,

starts the

default

parameter

setting

if pressed for 1

s enters the au-

tomatic serial ad-

dress assigning

procedure

ON-OFF/

UP

- if pressed for more than 3s

disables the regulation / if

pressed for more than 1s,

enables the regulation

- during the parameters

modification increase the

value displayed move to-

wards the next paramenter

ON-OFF/UP+AUX/DOWN: if pressed together for

more than 3 s enable/disable the continuous cycle

operation

ON- OFF/UP+ SET/DEF: if pressed together for

more than 3 s display the temperature read by the

defrost probe no 1

ON-OFF/UP+ PRG/MUTE: if pressed together for

more than 3 s reset any alarm with manual reset

AUX/

DOWN

- if pressed for more than

1 s, enables/disables the

auxiliary output

- during the parameters

modification decrease the

value displayed or move

towards the previous param.

AUX/DOWN + ON-OFF/UP: if pressed together for

more than 3 s enable/disable the continuous cycle

operation

AUX/DOWN + SET/DEF: if pressed together for more

than 1 s display a submenu with the HACCP alarm

parameters (HA, HAn, HF, HFn)

SET/DEF - if pressed for more than 1s,

enables/displays and/or

set the set point

- if pressed for more than 5 s,

enables a manual defrost

SET/DEF+ AUX/DOWN: if pressed together for more

than 1 s display a submenu with the HACCP alarm

parameters (HA, HAn, HF, HFn)

SET/DEF+ ON-OFF/UP: if pressed together for

more than 3 s display the temperature read by the

defrost probe no 1

Table of alarms and signals: display, buzzer and relay

Code Display icon Alarm

relay

Buzzer Reset Description

‘rE’ + flashing ON ON automatic virtual control probe fault

‘E0’ + flashing OFF OFF automatic room probe S1 fault

‘E1’ + flashing OFF OFF automatic defrost probe S2 fault

‘E2’-3-4 + flashing OFF OFF automatic probe S3-4-5 fault

‘___’ no OFF OFF automatic probe not enabled

‘LO’ flashing ON ON automatic low temperature alarm

‘HI’ flashing ON ON automatic high temperature alarm

‘AFr ’ flashing ON ON manual antifreeze alarm

‘IA’ flashing ON ON automatic immediate alarm from external

contact

‘dA’ flashing ON ON automatic delayed alarm from external contact

‘dEF’ ON OFF OFF automatic defrost running

‘Ed1’-2 no OFF OFF automatic/

manual

defrost on evaporator 1-2 ended by

timeout

‘Pd’ + flashing ON ON automatic/

manual

maximum time pump-down alarm

‘LP’ + flashing ON ON automatic/

manual

low pressure alarm

‘AtS’ + flashing ON ON automatic/

manual

autostart in pump-down

‘cht’ no OFF OFF automatic/

manual

high condenser temperature pre-

alarm

‘CHT’ + flashing ON ON manual high condenser temperature alarm

‘dor’ flashing ON ON automatic door open for too long alarm

‘Etc’ flashing OFF OFF real time claock fault

‘EE’ + flashing OFF OFF automatic EEPROM error, unit parameters

‘EF’ + flashing OFF OFF automatic EEPROM error, operating parameters

‘HA’ flashing OFF OFF manual HACCP alarm, type ‘HA’

‘HF’ flashing OFF OFF manual HACCP alarm, type ‘HF’

‘rCt’ signal Instrument enabled for program-

ming from the remote control (not

available on ir33+)

‘Add’ signal Automatic address assignment

procedure in progress

‘ccb’ signal Request to start continuous cycle

‘ccE’ signal Request to end continuous cycle

‘dFb’ signal Request to start defrost

‘dFE’ signal Request to end defrost

‘On’ signal Switch ON

‘OFF’ signal Switch OFF

‘rES’ signal Reset alarms with manual reset;

Reset HACCP alarms; Reset tempera-

ture monitoring

‘n1’...‘n6’ flashing ON ON automatic Indicates an alarm on unit 1 to 6

present in the network

‘dnL’ signal Download in progress

‘d1’...‘d6’ flashing OFF OFF Download with errors on unit 1 to 6

Note: the buzzer is disabled if parameter‘H4 =1

Fig. 1

Fig. 2

How to set the set point (desired temperature value)

Step Action Effect Meaning

1Press for 1 second

After 1 second the display will

show the current set point

This the currently active

control set point

2Press or

The value on the display will

increase or decrease Set the desired value

3Press

The controller will show the tem-

perat. read by the probes again

The set point is modi-

fied and saved

Another way of changing the set point is to set parameter“St” (see the tables below)

How to access and set parameters

type “F” (FREQUENT, not protected by password)

type “C” (CONFIGURATION, password protected)

Step Action Effect Meaning

1Press for 3 seconds

After 3s the display will

show the 1st parameter, “0”

(password)

Access to type “F” param. is

direct without password

2Press or

The value on the display will

increase or decrease.

Enter the password“22” to

access the type “C” param.

or whatever different value

for the type “F” parameters.

3Press

The display will show “St”

(Setpoint)

This is the current value of

the Setpoint

4Press or

If the password set is 22 the

display will scroll the list of type

“C” parameters (CONFIGURA-

TION) otherwise the list of type

“F” parameters (FREQUENT )

Set the desired value

5Press

The display will show the

parameter name

This is the current value of

the parameter

6Press or

The value on the display will

increase or decrease Set the desired value

7Press

The display will show the

parameter name again

Important: parameters not

yet saved

8

Repeat steps 2, 3, 4 &

5 for all parameters

required

9Press for 5

seconds

The controller will display

the temperature read by the

probes again

Important: only now have

all the parameters been

updated

For both types of access (type “F” and type “C”) there is a timeout (no button on the keypad

pressed for 1 min), the procedure is ended without saving the parameter.

Accessing the parameters divided by functional blocks (allows the user to scroll

the list of parameters in blocks)

Once having accessed the type “F” or “C” parameters (see tables above)

Step Action Effect Meaning

1Press

The display will show the name

of the functional block that the

parameter belongs to

Example ‘CMP’ for the com-

pressor parameters,‘dEF’ for

the defrost parameters

2Press or

The display will show the name

of the other functional blocks

Example ‘Fan’ for the fan

parameters

3Press

The display will show the name

of the first parameter in the

functional block selected

Example “F0” for ‘Fan’

Alarms with manual reset:

the alarms with manual reset can be reset by pressing the and for more than 3 s.

Manual defrost:

as well as the automatic defrost function, a manual defrost can be enabled, if the tempera-

ture conditions allow, by pressing the button for more than 5 s.

HACCP function:

ir33+ is compliant with the HACCP standards in force since it allows the monitoring of the

temperature of the stored food.

“HA” alarm = exceeded maximum threshold: up to three HA events are saved (HA, HA1,

HA2) respectively from the more recent (HA) to the oldest (HA2) and a HAn signal that di-

splays the number of occurred HA events.

“HF” alarm = power failure lasting over a minute and exceeded AH maximum threshold:

up to three HF events are saved (HF, HF1, HF2) respectively from the more recent (HF) to the

oldest (HF2) and a HFn signal that displays the number of occurred HF events.

HA/HF alarm setting: AH parameter (high temp. threshold); Ad and Htd (Ad+Htd = HACCP

alarm activation delay).

Display of the details:

access to HA or HF parameters pressing the button and use or buttons to

glance over.

HACCP alarm erasing:

press the and buttons for more than 5 seconds, the message‘res’indicates that the

alarm have been deleted. To cancel the saved alarms press the + + buttons for

more than 5 seconds.

Continuous cycle:

Pressing the buttons and simultaneously for more than 3 s enables the continuous

cycle function. During operation in continuous cycle, the compressor continues to operate

for the time ‘cc’ and it stops when reaches the ‘cc’ time out or the minimum temperature

envisaged (AL = minimum temperature alarm threshold).

Continuous cycle setting: “cc” parameter (continuous cycle duration): “cc” = 0 never acti-

ve; “c6” parameter (bypassing the alarm after the continuous cycle): “cc” = 0 never active; it

avoids or delays the low temperature alarm after the continuous cycle.

Procedure for setting the default parameter values

To set the default parameter values on the controller, proceed as follows:

1: switch the instrument off;

2: switch the instrument back on, holding the button until the message “Std” is shown

on the display.

Note: the default values are only set for the visible parameters (C and F). For further details

see table “Summary of operating parameters”.

Fig. 3