Novar NOVAR 300 Manual

2005

NOVAR 300

Capacitor Controller for

Power Factor Correction

Operation & Maintenance Manual

NOVAR_CM

Issue: March 2005

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 2 of 29

CONTENTS

1. INTRODUCTION..................................................................................................................................3

1.1 APPLICATION....................................................................................................................................3

1.2 DESCRIPTION AND OPERATION ...................................................................................................6

2. TECHNICAL SPECIFICATION ...........................................................................................................7

2.1 RATINGS, OPERATING RANGES & FEATURES...........................................................................7

2.2 ELECTROMAGNETIC COMPATIBILITY (EMC) ............................................................................11

2.3 EUROPEAN LOW VOLTAGE DIRECTIVE (LVD)..........................................................................11

3. COMMISSIONING .............................................................................................................................12

3.1 SYSTEM CONNECTIONS ..............................................................................................................12

3.2 USER ADJUSTMENTS ...................................................................................................................13

3.3 SETTING OF DUAL-IN-LINE SWITCH ...........................................................................................15

3.3.1 Sequence ..................................................................................................................................15

3.3.2 Safety Lockout Time .................................................................................................................16

3.3.3 Stage Limit.................................................................................................................................17

3.4 SETTING OF C/K VALUE................................................................................................................18

3.4.1 Examples of Calculation and C/K Settings...............................................................................18

3.5 SETTING OF TARGET COS PHI....................................................................................................19

3.6 CONNECTION ERRORS ................................................................................................................20

3.7 USE OF EXPANDED DISPLAY ......................................................................................................20

4. FAULT FINDING AND TEST PROCEDURES.................................................................................22

4.1 FAULT FINDING ..............................................................................................................................22

4.1.1 Connection error .......................................................................................................................22

4.1.2 Low system voltage...................................................................................................................22

4.1.3 System current errors................................................................................................................22

4.1.4 Incompatible settings ................................................................................................................22

4.1.5 Factory programmed settings ...................................................................................................22

4.1.6 Input magnitude errors and transients......................................................................................23

4.1.7 Internal NOVAR hardware fault ................................................................................................23

4.1.8 Perceived software fault............................................................................................................23

4.1.9 Capacitors permanently connected..........................................................................................23

4.1.10 Hunting ....................................................................................................................................23

4.2 TEST PROCEDURES .....................................................................................................................24

4.2.1 Test equipment..........................................................................................................................24

4.2.2 Test sequences.........................................................................................................................24

5. SERVICING........................................................................................................................................26

5.1 OUT OF SERVICE...........................................................................................................................26

5.2 IN SERVICE .....................................................................................................................................26

5.3 FITTING OF LOCKABLE FRONT COVER.....................................................................................27

6. CIRCUIT DESCRIPTION...................................................................................................................28

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 3 of 29

1. INTRODUCTION

There is a warning symbol on the equipment, an exclamation mark within a triangle. This

warns the user to refer to the operation and maintenance manual before commissioning,

installing or operating the equipment.

WARNINGS

1. Installation, commissioning and maintenance should only be carried out by suitably

qualified personnel.

2. Terminations exposed during installation, commissioning and maintenance may

present a hazard unless the equipment is electrically isolated.

3. The equipment should only be operated as intended e.g. with the covers in place,

and within the specified electrical and environmental limits.

1.1 APPLICATION

Many power utilities world wide apply financial penalties to industrial consumers of electrical

energy when inductive loads are connected. The established solution for compensating

inductive loads is to apply power factor correction (PFC) by switching capacitors on to the

system. To optimise the operation of PFC, and realise maximum benefits and cost savings,

a means of controlling the capacitor switching is necessary.

NOVAR 300 works by continuously measuring the system's kvar component and then

switching the optimum quantity of capacitor compensation in, or out, to achieve the desired

power factor.

NOVAR 300 uses true rms measuring techniques together with appropriate mathematical

calculations in preference to mean sensing and zero crossing detection which has proved

inaccurate on systems with distorted waveforms.

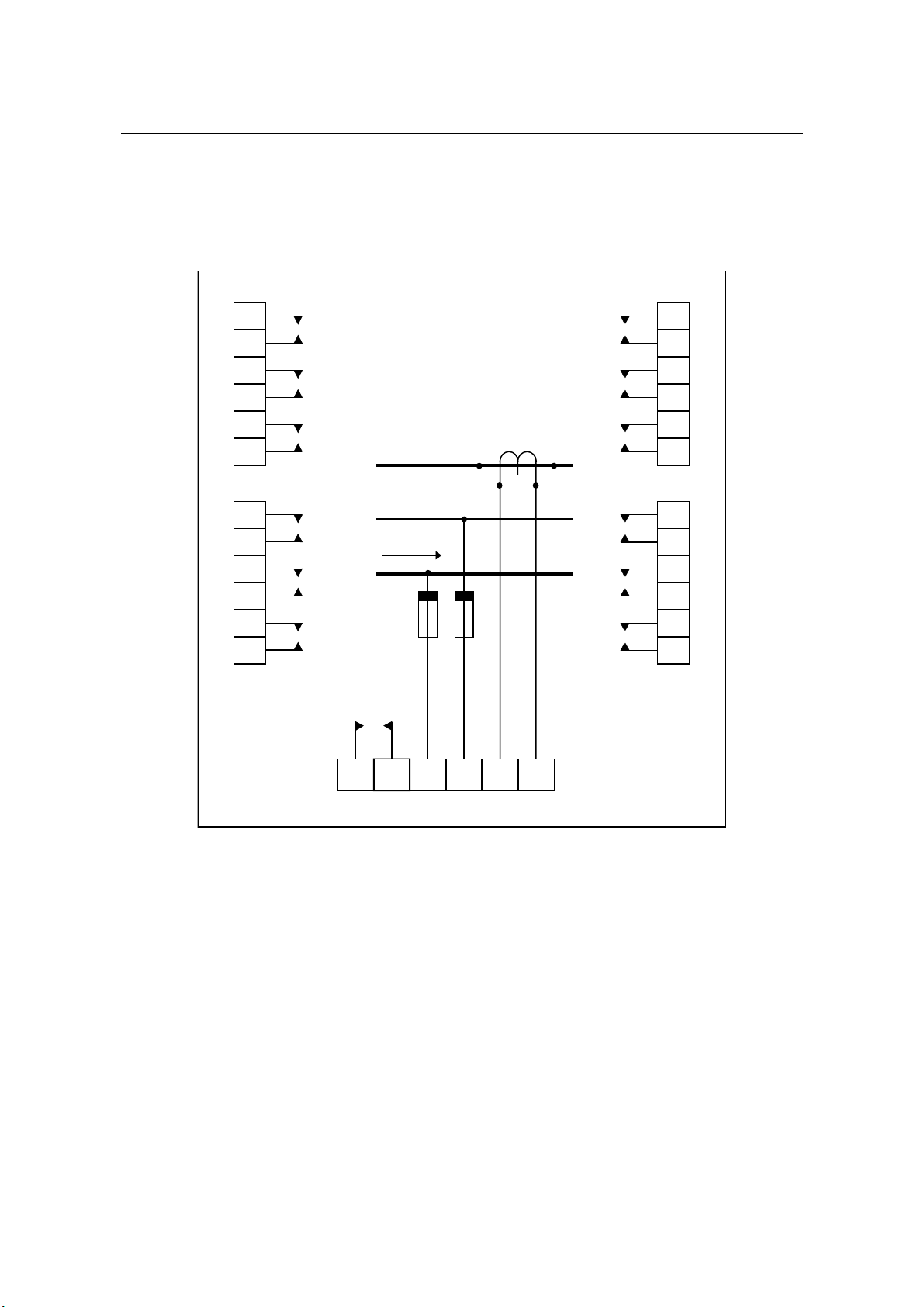

The NOVAR 300 should be connected to the system as shown in the appropriate diagrams

(Figures 1 and 2).

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 4 of 29

11

12

13

14

15

16

5

6

7

8

9

10

23

24

25

26

27

28

17

18

19

20

21

22

432129

7

8

9

10

11

12

A

B

C

30

1

2

3

4

5

6

P1

S1 S2

P2

To Load

Alarm

(if fitted)

For contact pairs fitted

see number of stages

FIGURE 1 - Wiring diagram for volt free contacts

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 5 of 29

432129

A

B

C

30

11

12

13

14

15

16

4

5

6

P1

S1 S2

P2

To Load

Alarm

(if fitted)

5

6

7

8

9

10

1

2

3

Common

28

27

26

25

24

23

12

11

10

22

21

20

19

18

17

9

8

7

For contact pairs fitted

see number of stages

FIGURE 2 - Wiring diagram for common contacts

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 6 of 29

1.2 DESCRIPTION AND OPERATION

Multi-stage controllers are available in standard units of 6 and 12 stages. These provide up

to 12 pairs of "volt-free" contacts.

The following switches are mounted on the controller front panel :

* An auto/manual control (upper button)

* A directional control marked +, 0, - (lower button)

* A ten-way programme selector switch

Depressing the auto/manual switch causes the Controller to enter MANUAL mode as

indicated by the LED adjacent to the switch. Capacitor stages can be switched 'in' by

pressing the directional control button once. Pressing this button once more places the

Controller in the MANUAL 'off' position and no further stages will be switched 'in' or 'out'.

Pressing this button once more will result in capacitor stages being removed until pressed

again. the three LED's associated with this button will, at all times, indicate the operational

mode.

When capacitors are being connected, a LED associated with the inductive (IND) control

lights. As they are being disconnected, a LED associated with the capacitive (CAP) control

lights.

The ten-way selector switch is used to select:

* The time interval between steps

* The sequence in which the stages are connected

* The limit which determines the number of steps taken in the sequence selected.

These are detailed in section 3.3.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 7 of 29

2. TECHNICAL SPECIFICATION

2.1 RATINGS, OPERATING RANGES & FEATURES

Voltage Rating (Vn) 110 V, 120 V, 415 V, 480 V.

Others available in range 63.5 V to 500 V max.

Current Rating (In) 1 A or 5 A. Others available in the range 0.5 A to 5 A max.

Input Connections IA, VBC, or IB, VCA or IC, VAB

IR, VYB, or IY, VBR or IB, VRY,

IR, VST, or IS, VTR or IT, VRS.

Line Current Transformers Class 1, 5 VA

Operating Ranges

Voltage 85 ... 110 % Vn

Current 0...120 % In

Frequency 50/60 Hz

Humidity 0...93 % +2 % -3 % Relative (non-condensing)

Temperature Range Storage: -40... 80°C

Operating: -10... 55°C

Settings c/k 0.03...1.00

cos phi 0.80...1.00...0.95 leading

Overload Ratings 1.5 x Vn for 10 seconds

2 x In continuously

20 x In for 3 seconds

Isolation The controllers will withstand:

2 kV rms, 50/60 Hz for 1 minute between:

- all terminals to case

- current terminals to all others

- voltage terminals to all others

- output contact pairs (Volt Free versions)

Impulse Voltage Test The controller will withstand:

5 kV 1.2/50 us, 0.5J, to BS923 and IEC 255-22-1 between:

- all terminals and case

- current input terminals

- voltage input terminals

- output contacts (open)

- any pair of independent circuits

Output and Alarm contact

rating

Make 1250 VA, 500 V a.c. resistive

Carry 5 A a.c.

Break 5 A a.c.

Type: one normally open

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 8 of 29

2.1 RATINGS, OPERATING RANGES & FEATURES (cont.)

No-volt release All output contacts are disabled within 15 ms. After the

supply voltage is restored, normal operation is resumed,

and the outputs are energised in sequence after the

appropriate safety lockout time has elapsed.

Burdens Current circuit: 0.2 VA at In

Voltage circuit: 9 VA (6 stages energised)

15 VA (12 stages energised)

Net weight All models: 1.5 kg

Terminals Barrier type: M3.5

Plug-in wire size: 1...2.5 mm2(18...14 AWG)

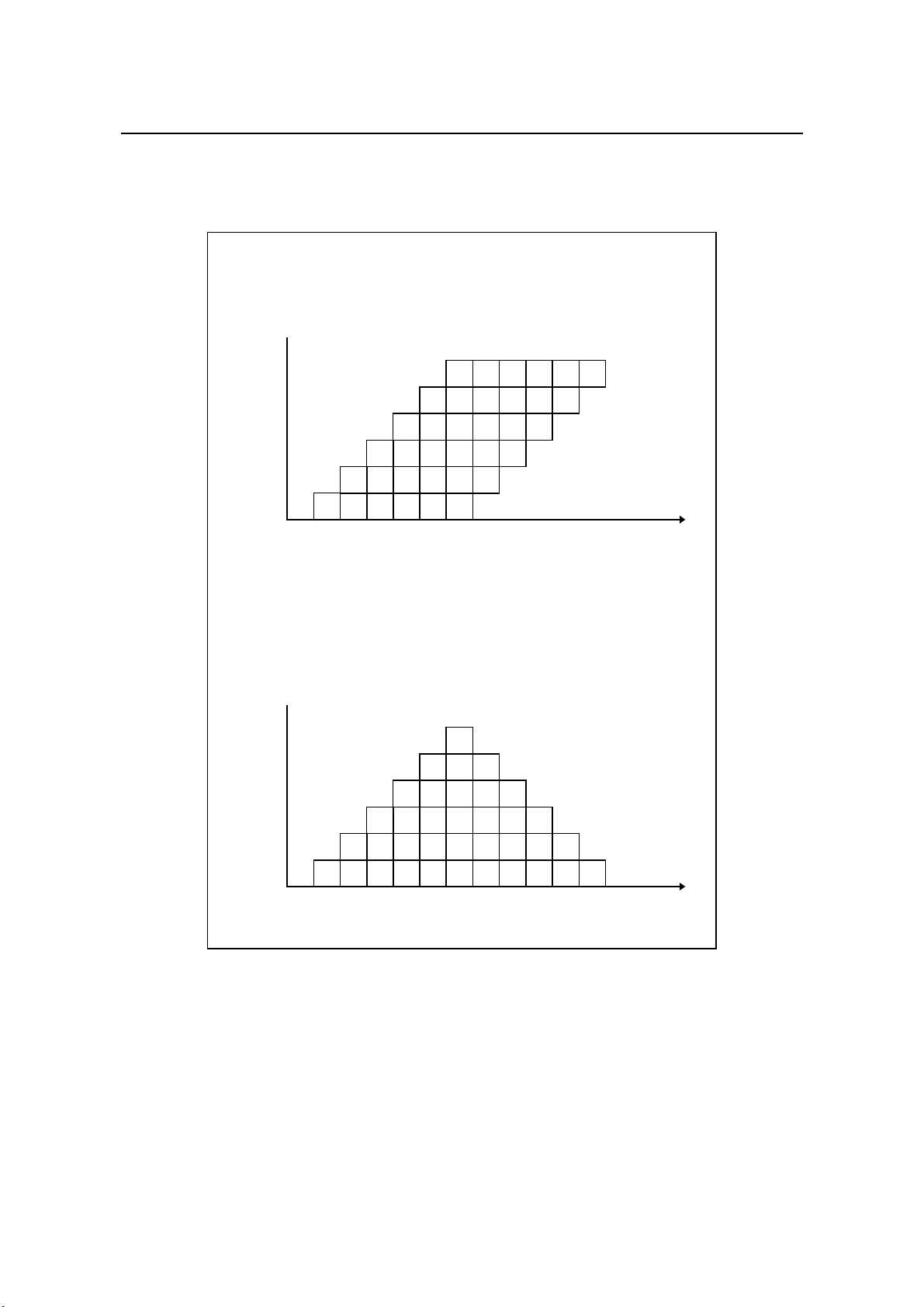

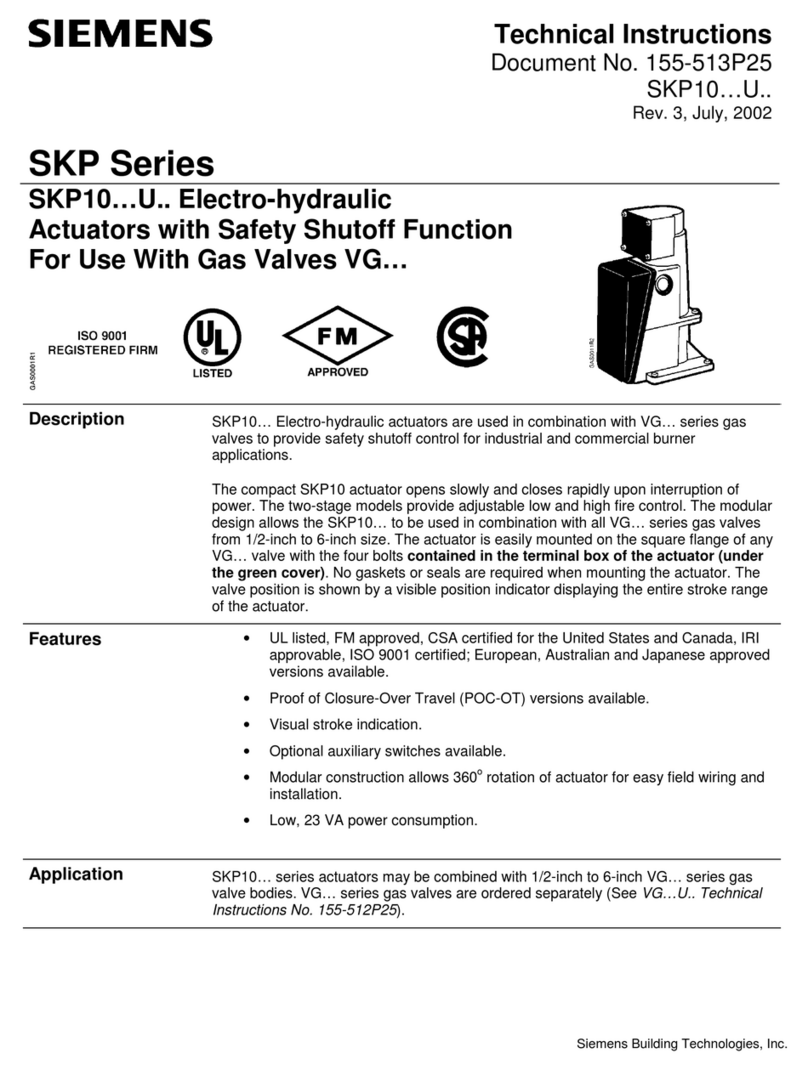

Switching style Rotational or linear (see Figure 3). Selected at time of

order. Rotational switching evens the contactor wear (for

the largest step size only) and generally reduces the

system response time. It is implemented for all sequences

on NOVAR 300, if requested.

Intelligent switching If twice the minimum capacitor size (or more) is required,

then the NOVAR will switch in a double step. This applies

for all sequences. For sequence 00 (1:1:1:1), the second

capacitor will be connected after an additional delay of two

seconds.

Limit selection Up to 12 plus alarm output. The maximum possible for any

configuration is determined by the number of relays fitted

and the selected sequence. If the selected value is too

high, the unit will automatically override it to the highest

allowable value.

Safety lockout The time required to safely discharge a capacitor can be

set to any of 8 different values. The NOVAR will not allow

any capacitor to be re-energised until this time has

elapsed.

Providing that the safety lockout time has passed, the

capacitor can be called after one fifth of the programmed

time. It is not possible to override this lockout time.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 9 of 29

2.1 RATINGS, OPERATING RANGES & FEATURES (cont.)

Exit from manual The AUTO/MAN button allows the user to switch between

automatic and manual operating mode as required.

To safeguard against leaving a system indefinitely in

manual mode, an automatic exit has been included. This

will return the operating mode from manual to automatic

five minutes plus the selected safety lockout time after the

last manual mode operation. Relevant manual mode

operations are pressing the lower button and operation of

an output relay.

Models without the automatic exit from manual are

available.

Alarm output Signals failure to meet target cos ϕ

See also Self Test

Self Test At reset and every ten minutes in operation, the NOVAR

executes an internal hardware check for correct

functioning. During this process, the model number will be

displayed.

If the unit fails this self test, the IND and CAP LEDs are

toggled and the alarm relay (if fitted) is also “flashed “ in

time with this.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 10 of 29

1 1 1 1 1 1

2 2 2 2 2 2

3 3 3 3 3 3

4 4 4 4 4 4

5 5 5 5 5 5

6 6 6 6 6 6

1

2

3

4

5

6

Capacitors

connected

Switching steps Time

ROTATIONAL SYSTEM RESPONSE

1 1 1 1 1 1

2 2 2 2 2 2

3 3 3 3 3 3

4 4 4 4 4

5 5 5

6

1

2

3

4

5

6

Capacitors

connected

Switching steps Time

LINEAR SYSTEM RESPONSE

1

2

1

3

2

1

2

1 1

FIGURE 3 - Rotational/linear capacitor switching

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 11 of 29

2.2 ELECTROMAGNETIC COMPATIBILITY (EMC)

Phenomenon Standard Limits Met and Claimed

Conducted EN50081-1 EN55022:1987CClass B (Table II)

Emissions 1992

Radiated EN50081-1 EN55022:1987R Class B (Table IV)

Emissions 1992

Electrostatic prEN50082-2 8 kV air discharge, prEN50082-2: 9.1.2

Discharge 1991 4 kV contact discharge,

(IEC 801-2) Informative Annex: 1.1.4

Fast prEN50082-2 2 kV Input AC power ports (direct)-prEN50082-2:9.5.1

Transients 1991 4 kV Output ports (cap. clamp)- prEN50082-2: 9.5.1

(IEC 801-4)

Radiated prEN50082-2 10 V/m (*modulated 80% A.M., 1 kHz)

Immunity 1991 26 MHz to 1000 MHz.

(IEC 801-3) prEN50082-2: 9.1.1 and * Informative Annex 1.1.2

Conducted prEN50082-2 10 V rms (modulated 80% A.M., 1kHz)

Immunity 1991 150 kHz to 29 MHz

(IEC 801-6)

Burst Test IEC255-22-1 1 MHz burst disturbance test Class III

1988 2.5 kV common mode, 1 kV differential mode

C- Conducted Emissions Limits: 0.15 MHz to 0.5 MHz ,66-56 dBµV Q-P,56-46 dBµV Ave.,

(to EN55022:1987 Class B) limits decrease linearly with log frequency.

0.5 MHz to 5 MHz, 56 dBµV Q-P, 46 dBµV Ave.

5 MHz to 30 MHz, 60 dBµV Q-P, 50 dBµV Ave.

R- Radiated Emissions Limits: 30 MHz to 230 MHz, 30 dBµV/m (at 10m).

(to EN55022:1987 Class B) 230 MHz to 1000 MHz, 37 dBµV/m (at 10m).

2.3 EUROPEAN LOW VOLTAGE DIRECTIVE (LVD)

Designed to IEC1010-1 requirements.

WARNING

The circuit boards are susceptible to electrostatic discharge (ESD) and appropriate ESD

protection should be taken to avoid damage, when handling or adjusting these. The

8 kV ESD susceptibility rating applies with the front label fitted.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 12 of 29

3. COMMISSIONING

WARNINGS

1 Installation, commissioning and maintenance should only be carried out by suitably

qualified personnel.

2 Terminations exposed during installation, commissioning and maintenance may

present a hazard unless the equipment is electrically isolated.

3 The equipment should only be operated as intended e.g. with the covers in place,

and within the specified electrical and environmental limits.

4 No capacitor controller is suitable for the isolation of system voltage from capacitor

banks for the purpose of maintenance etc. Some NOVAR units are specially

programmed to not return to 'auto' mode from 'manual'. These units will still reset to

'auto' on loss of volts and so are still unsuitable for capacitor bank isolation.

Before connection of the NOVAR into a customer's system, ensure that the safety lockout

time programmed into the NOVAR is equal to or greater than that required for safe

discharge of system capacitors. Unless this has been specified on ordering, the NOVAR will

be set to 60 seconds. If the system requires a greater time this must be set before powering

up the NOVAR.

3.1 SYSTEM CONNECTIONS

Refer to Figures 1 and 2.

The NOVAR power factor controllers employ solid state circuitry for the measurement of

vars. The vars determination is directionally sensitive. Voltage and current supplies to the

controllers must be mutually at 90 degrees when the system is at unity power factor.

On a three phase supply, the required phase shift is obtained by connecting the controller

current input to a current transformer in one phase, and connecting the voltage input across

the remaining two phases. Any phase can be used for the current input if the correct phase

relationship exists between current and voltage.

The following combinations are possible :

CT in Phase Voltage Connections

(across phases)

A(R) (R) BC (ST) (YB)

B(S) (Y) CA (TR) (BR)

C(T) (B) AB (RS) (RY)

Connections between the controller and the capacitor contactors are also shown in Figures

1 and 2.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 13 of 29

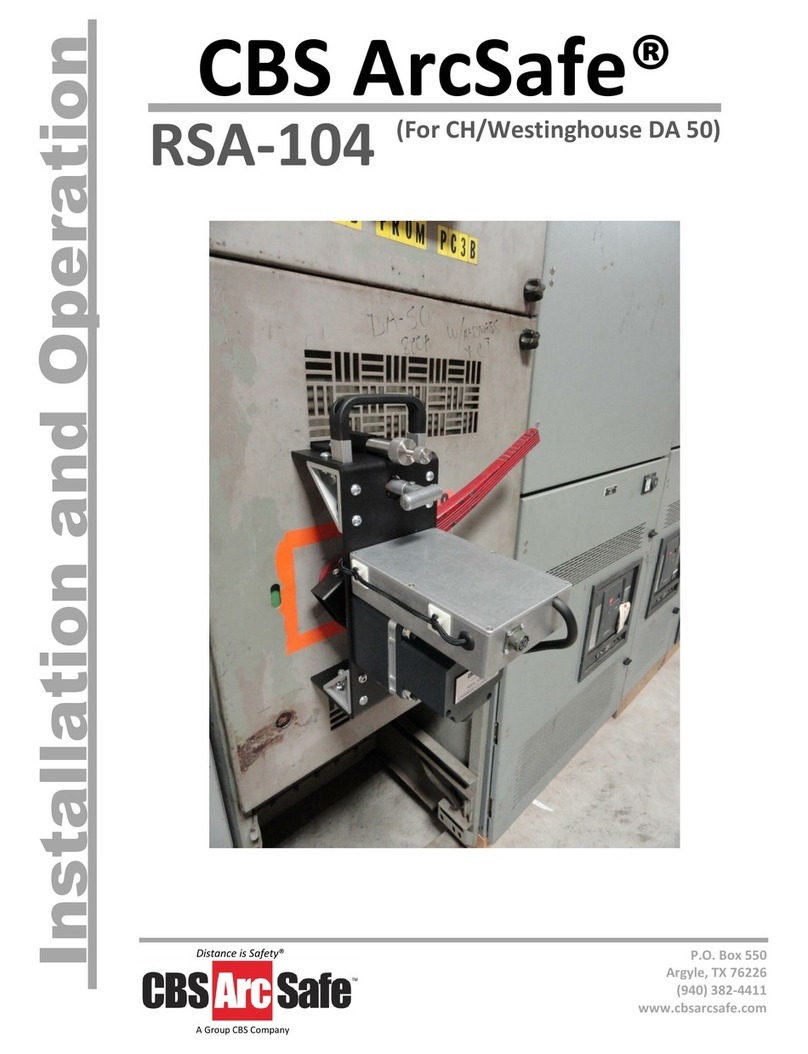

3.2 USER ADJUSTMENTS

The following user adjustments are available and should be set during commissioning.

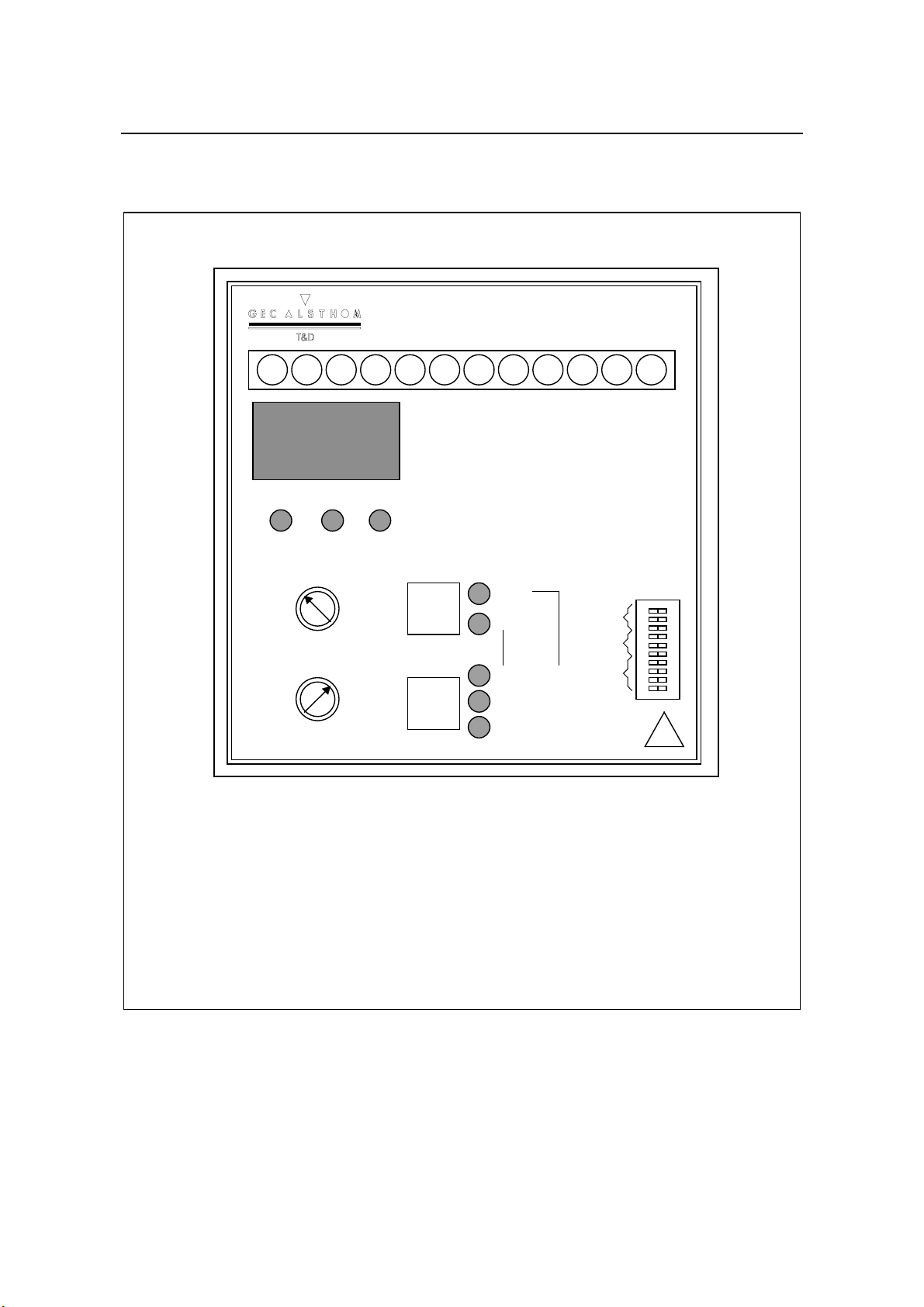

Refer to also to Figure 4.

Parameter Fascia Key Means of Selection

Sequence GDIL switch *

Time GDIL switch *

Limit GDIL switch *

C/k CPotentiometer

cos ϕDPotentiometer

Warning

Due to the presence of electrostatic sensitive devices on the printed circuit board, care must

be taken to effectively earth oneself before commencing commissioning. The

recommended method is to use a standard wrist strap that is connected to earth.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 14 of 29

1

Model 305

Novar

300

% Vn

% In

COS ϕ

POWER CAP IND

A

UTO

MANUAL

+

0

-!

COS ϕ

C/K

2345678910 11 12

% Vn

% In

COS ϕ

01

Sequence

Time

Limit

E

F

D

C

G

HJK

B

A

Fascia Key

A - Secret-until-lit display of energised stages

B - High definition liquid crystal display

C - C/K setting

D - COS ϕsetting

E - Dual mode button: auto/manual

F - Dual mode button: capacitor switching (man) and display selection (auto)

G - DIL switch (sequence, time and limit setting)

H - Power on indication LED

J - Switching in progress, circuit is capacitive

K - Switching in progress, circuit is inductive

1

2

3

4

5

6

7

8

9

10

FIGURE 4 - NOVAR indication and user adjustments

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 15 of 29

3.3 SETTING OF DUAL-IN-LINE SWITCH

Settings of sequence, lockout time and stage limit should be set prior to powering up the

NOVAR. When a controller leaves the factory, the DIL switch will be pre-set to the following

default values, regardless of model type, unless specified on the order. Refer to Figure 5.

SEQUENCE = 1:1:1:1:1 . . .

TIME = 60 seconds

LIMIT = the number of stages of the controller, i.e., for 6 stages limit equals 6.

If these settings are suitable for the user’s application, this section may be ignored.

1

2

3

4

5

6

7

8

9

10

01

LIMIT

TIME

SEQUENCE

FIGURE 5 - DIL switch factory default settings

3.3.1 Sequence

The settings of this switch determine the controller's sequence, safety lockout time and limit

of switching.

Note: The settings can only be altered on-site on the NOVAR 305 models.

Unless otherwise requested, the NOVAR will have a sequence setting of 1:1:1:1 (sequence

0), a safety lockout time of 60 seconds and a limit equal to the number of stages supplied

with the unit.

Eight sequence settings are available. The sequence controls the number of steps taken for

a desired number of capacitor stages. For instance, sequence 00 is used for capacitors

which are all the same size. Alternatively, sequence 07 is used where each of the first four

steps is progressively twice the size of the previous step (a ratio of 1:2:4:8).

The correct switch setting should be selected using table 1 as a guide. In the expanded

display mode the setting can be checked by pressing the lower push-button once more (a

digit 5, representing the letter S will appear in digit position 4 of the display).

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 16 of 29

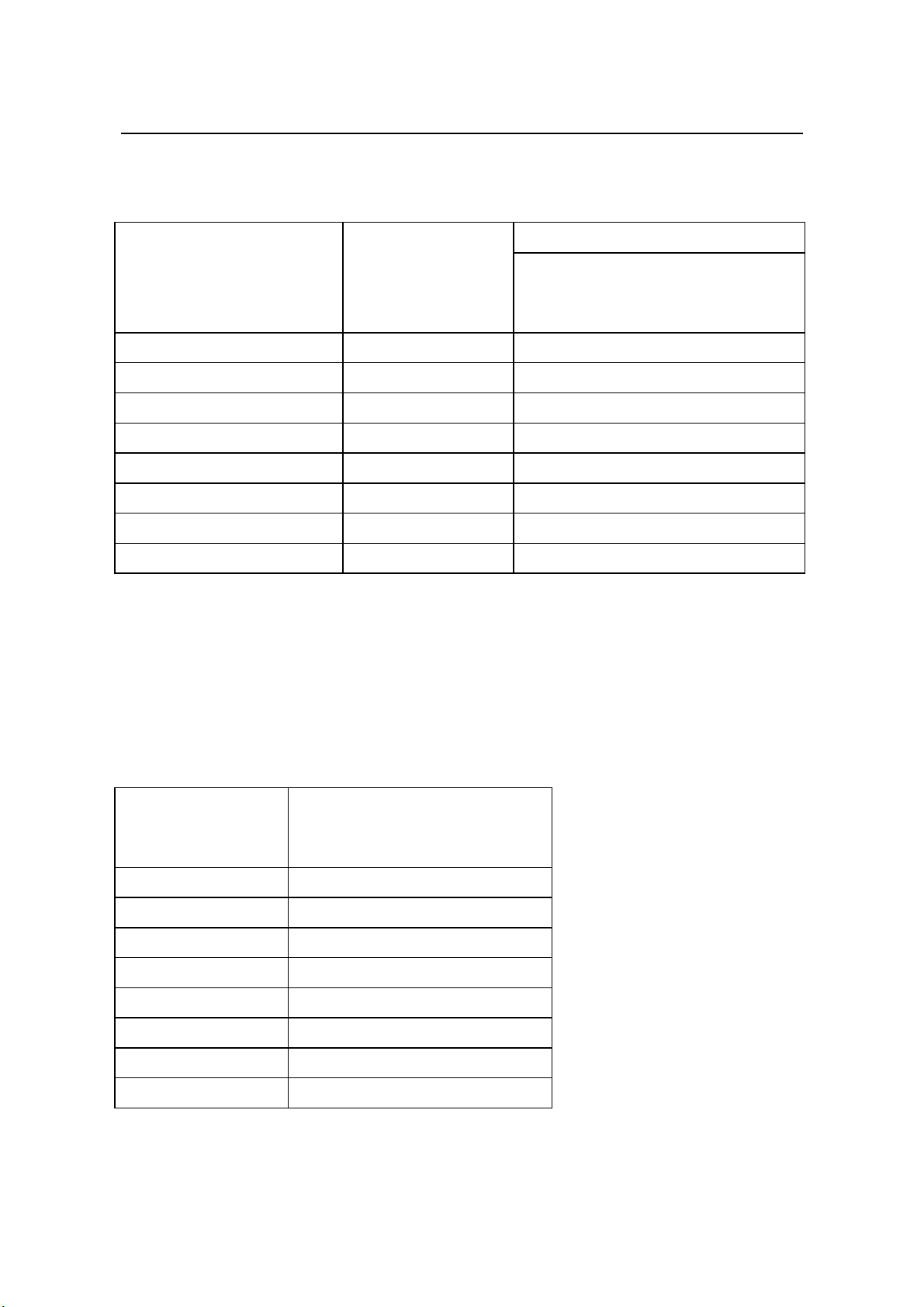

Table 1 - Sequence settings

Max no. of steps per controller

Switches Number of Stages

Sequence

Number

Sequence 1 2 3 1 3 6 9 12

00 1:1:1:1:1 etc 0 0 0 1 3 6 9 12

01 1:1:2:2:2 etc 1 0 0 1 4 10 16 22

02 1:2:2:2:2 etc 0 1 0 1 5 11 17 23

03 1:2:3:3:3 etc 1 1 0 1 6 15 24 33

04 1:2:3:4:4 etc 0 0 1 1 6 18 30 30

05 1:2:4:4:4 etc 1 0 1 1 7 19 31 31

06 1:2:3:6:6 etc 0 1 1 1 6 24 30 30

07 1:2:4:8:8 etc 1 1 1 1 7 31 31 31

3.3.2 Safety Lockout Time

Proper selection of switching time delay is a function of the electrical system and capacitor

voltage rating. Usually, as a guide, the time interval must be larger than the discharge time

of the capacitor being switched. This time required for discharge is known as the safety

lockout time. The dual-in-line switch should be set to the desired time by reference to Table

2. In expanded display mode, the setting selected can be checked by pressing the lower

push button once more (a ‘t’ symbol will appear in digit 4 of the display).

Table 2 - Lockout time settings

Safety Lockout

Time (Seconds)

Switches

456

10 000

20 100

30 010

60 110

180 001

300 101

480 011

600 111

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 17 of 29

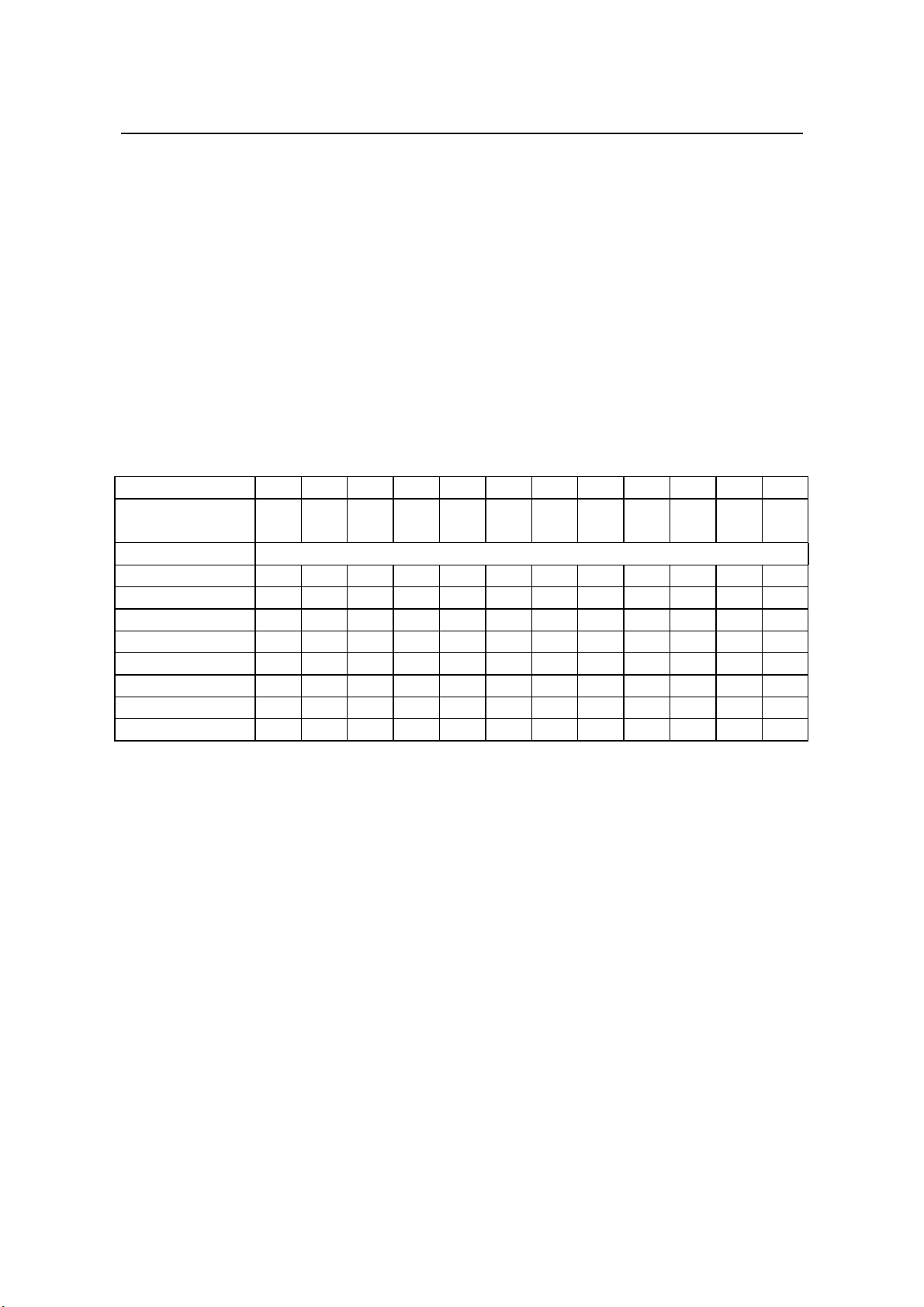

3.3.3 Stage Limit

The number of stages switched can be limited to anywhere between 1 and 12. A limit

function prevents unused stages being switched where no capacitors are present. Table 3

shows, for each sequence selected, the switch positions necessary to achieve the desired

stage limit. This selected stage limit will equate to a finite number of steps depending on the

sequence chosen. In expanded display mode, the limit selected can be checked by

pressing the lower push button once more (an ‘L’ will appear in the fourth display digit).

Note: The limit is the number of capacitors connected to the NOVAR and must be set

correctly. If the limit is set higher than the number of capacitors connected then the system

response will be slowed down.

Table 3 - Limit settings

Stage Limit 12345678910 11 12

Switch number 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10 7 8 9 10

Switch setting 1 0 0 0 0 1 0 0 1 1 0 0 0 0 1 0 1 0 1 0 0 1 1 0 1 1 1 0 0 0 0 1 1 0 0 1 0 1 0 1 1 1 0 1 0 0 1 1

Sequence number Maximum number of steps

00 12345678910 11 12

01 1246810 12 14 16 18 20 22

02 1357911 13 15 17 19 21 23

03 136912 15 18 21 24 27 30 33

04 13610 14 18 22 26 30 ---

05 13711 15 19 23 27 31 ---

06 13612 18 24 30 -----

07 13715 23 31 ------

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 18 of 29

3.4 SETTING OF C/K VALUE

The c/k potentiometer should be set according to the following equation;

C/k

Smallest Capacitor

Step Size in vars

3VI 5=××

×

where: V = nominal primary system voltage

I = primary rating of the current transformer

This is indicated on the display by the small c symbol in the upper part of digit 4 if the

expanded display mode is selected on models having displays.

3.4.1 Examples of Calculation and C/K Settings

Example 1

A 25 kvar capacitor operating on a 415 V, 3 phase supply, is controlled by a single stage

controller operating via a 200/5 CT but without a VT.

C = 25,000 vars, V = 415 V, I = 200 A

C/k 25,000 5

3 415 200 0.87=×

×× =

The NOVAR 300 is scaled to give a deadband of 150 % nominal capacitor size.

(i.e. NOVAR 300 will switch capacitors in circuit when the input lagging vars exceed three

quarters of a capacitor step size . NOVAR 300 will switch capacitors out of circuit when the

input leading vars exceed three quarters of a capacitor step size .)

The value of C/K can be directly entered into the unit.

Example 2

A multi-stage unit controls a 6 stage capacitor bank. Each stage is rated at 100 kvar. The

voltage is 415 V and the CT is 1000/5. There is no VT.

C = 100,000 vars, V = 415 V, I = 1,000 A

C/k 100,000 5

3 415 1,000 0.70=×

×× =

As above, this value can be directly entered into the unit.

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 19 of 29

Example 3

A multi-stage unit controls a six stage capacitor bank. Each stage is rated at 100 kvar. The

VT is 3.3 kV/110 V and the CT ratio is 500/5.

C = 100,000 vars, V = 3 300 V, I = 500 A

C/k 100,000 5

3 3,300 500 0.17=×

××

=

As above, this value can be directly entered into the unit.

NB: The NOVAR 300 calculation has been formulated in such a way that it will work for any

value of secondary amps and volts which can be used with the unit. However, if the nominal

secondary amps used is other than 5 amps, the value represented by the scalings on the

c/k potentiometer will no longer be the actual capacitor starting current in amps. This makes

no difference to the operation of the unit.The NOVAR 300 ratings must match the

secondary rating of any CT and VT used.

3.5 SETTING OF TARGET COS PHI

This is set using the potentiometer, labelled “cos ϕ“, located on the front panel.

To make use of the expanded display mode, the lower push-button should be pressed once

more .The display will now indicate the potentiometer setting and a large C in the fourth digit

of the display.

kW C/k

Minimum

(Deadband)

0.03

Lead

Lag

kvar

C/k

Maximum

(Deadband)

1.0

Range of C/k adjustment for cos ϕ= 1.0

kW

kvar

Range of cos ϕfor a given C/k

C/k

C/k

ϕ1

ϕ2

Lead

Lag

cos ϕ

adjustment

0.80 lag to

0.95 lead

FIGURE 6 - Ranges for C/k and cos ϕsettings

NOVAR 300 Operation & Maintenance Manual NOVAR_CM

Page 20 of 29

3.6 CONNECTION ERRORS

NOVAR 300 gives a certain amount of information to assist with connection. There are six

possible ways in which it is possible to connect a system. Of these six, only one is correct.

For three of the others, NOVAR 300 will give indication of a connection error as follows.

At system unity power factor, the NOVAR 300 error mode is looking for a phase angle of

90°between amps and volts. As a system can in theory be operating anywhere within a

band of 90°either side of this, the error mode looks for its inputs to be within this band.

Refer to Figure 4 for vector diagrams showing the correct and incorrect connections.

The correct connection (a)

Input is IAwith VBC.

For this case, the NOVAR will go straight into AUTO mode.

The most common connection error is that of a reversed CT (b). In this case the NOVAR

will display 270°for a system at unity power factor.

If VBA is selected instead of VBC (c) then the NOVAR will display 150°.

If VCA is selected instead of VBC (d) then the NOVAR will display 210°.

The above values will change if the system is not at unity power factor (e.g. if the system is

at 40°lagging then a CT reversal would appear as 230°).

Because VAB or VAC are within the above stated bands, then the NOVAR is not able to

distinguish between these and a system working at the relevant power factor.

If VAB is selected (e) then the NOVAR will display a cos ϕof 0.5 leading corresponding to an

angle of 60°leading.

If VAC is selected (f) then the NOVAR will display a cos ϕof 0.5 lagging corresponding to an

angle of 60°lagging.

3.7 USE OF EXPANDED DISPLAY

Once it is known that the NOVAR is connected into the system correctly, it is necessary to

set up the working parameters of the unit.

If a display model is being used, then it enables more accurate settings if expanded display

mode is now entered. This is achieved by pressing the lower push button for more than 5

seconds.

Table of contents

Other Novar Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson Fisher 630 Series installation guide

Matelec

Matelec Hydrowhiz FPC-63X21 quick start guide

Siemens

Siemens RVP550 installation instructions

LAE electronic

LAE electronic CDC122T1R2 Instructions for installation and use

Honeywell

Honeywell AQS51-KAM Product data

Johnson Controls

Johnson Controls tyco PowerSeries Neo Reference manual

Siemens

Siemens SKP Series Technical instructions

Garnet

Garnet SEELEVEL PosiGround 672-H manual

ASCON TECNOLOGIC S.r.l.

ASCON TECNOLOGIC S.r.l. TLK48 B quick guide

CBS ArcSafe

CBS ArcSafe RSA-104 Installation and operation

Rockwell Automation

Rockwell Automation Allen-Bradley Logix 5000 Series Programming manual

Honeywell

Honeywell Touchpoint Plus Safety manual