Toolots DZW-1200 User manual

1

Direct Cooling Type

Deli / Bakery Cases Installation and

Operation Manual

Please read this manual completely before attempting to install or operate this equipment

DZW-1200 DZW-1500 DZW-1800 DZW-2000

2

TABLE OF CONTENTS

Section Page

Warning ---------------------------------------------------------------- 3-4

Technical Specification--------------------------------------------------4

Installation----------------------------------------------------------------4-5

Operation-----------------------------------------------------------------5-8

Maintenance-------------------------------------------------------------8-9

Parts Breakdown--------------------------------------------------------8-12

Electrical Diagram-------------------------------------------------------12

3

Warning

DANGER –RISK OF FIRE OR EXPLOSION. FLAMMABLE REFRIGERANT USED. TO BE REPAIRED

ONLY BY TRAINED SERVICE PERSONNEL. DO NOT PUNCTURE REFRIGERANT TUBING.

PELIGRO - RIESGO DE INCENDIO O EXPLOSION. REFRIGERANTE INFLAMABLE UTILIZADO.

PARA SER REPARADO SOLAMENTE POR PERSONAL DE SERVICIO CALIFICADO. NO PINCHAR

LA TUBERÍA REFRIGERANTE.

DANGER –RISQUE DE FEU OU D’EXPLOSION. LE FRIGORIGÈNE EST INFLAMMABLE.

CONFIER LES RÉPARATIONS À UN TECHNICIEN SPÉCIALISÉ. NE PAS PERFORER LA TUBULURE

CONTENANT LE FRIGORIGENE.

CAUTION –RISK OF FIRE OR EXPLOSION. FLAMMABLE REFRIGERANT USED. CONSULT

REPAIR MANUAL/OWNER’S GUIDE BEFORE ATTEMPTING TO SERVICE THIS PRODUCT. ALL

SAFETY PRECAUTIONS MUST BE FOLLOWED.

ATENCION - RIESGO DE INCENDIO O EXPLOSIÓ N. REFRIGERANTE INFLAMABLE UTILIZADO.

CONSULTE EL MANUAL DE REPARACIÓ N / GUÍA DEL PROPIETARIO ANTES DE INTENTAR DAR

SERVICIO A ESTE PRODUCTO. DEBEN CUMPLIR CON TODAS LAS PRECAUCIONES DE

SEGURIDAD.

ATTENTION –RISQUE DE FEU OU D’EXPLOSION. LE FRIGORIGÈNE EST INFLAMMABLE.

CONSULTER LE MANUEL DU PROPRIÉTAIRE/GUIDE DE RÉPARATION AVANT DE TENTER UNE

RÉPARATION. TOUTES LE MESURES DE SÉCURITÉ DOIVENT ÊTRE RESPECTÉES.

CAUTION –RISK OF FIRE OR EXPLOSION DUE TO PUNCTURE OF REFRIGERANT TUBING;

FOLLOW HANDLING INSTRUCTIONS CAREFULLY. FLAMMABLE REFRIGERANT USED. A

TENCION - RIESGO DE INCENDIO O EXPLOSIÓ N DEBIDO A LA PERFORACION DE LA TUBERÍA

REFRIGERANTE; SIGA LAS INSTRUCCIONES DE MANIPULACIÓ N CON CUIDADO.

REFRIGERANTE INFLAMABLE UTILIZADO.

ATTENTION –RISQUE DE FEU OU D’EXPLOSION SI LA TUBULURE CONTENTANT LE

FRIGORIGÈNE EST PERFORÉE; SUIVRE LES INSTRUCTIONS DE MANUTENTION AVEC SOIN. LE

FRIGORIGÈNE EST INFLAMMABLE.

CAUTION –RISK OF FIRE OR EXPLOSION DUE TO FLAMMABLE REFRIGERANT USED.

FOLLOW HANDLING INSTRUCTIONS CAREFULLY IN COMPLIANCE WITH LOCAL

GOVERNMENT REGULATIONS.

4

ATENCIÓ N –RIESGO DE INCENDIO O EXPLOSIÓ N DEBIDO A REFRIGERANTE INFLAMABLE

UTILIZADO. SIGA LAS INSTRUCCIONES DE MANIPULACIÓ N CON CUIDADO CONFORME A

LAS REGLAS DE LA MUNICIPALIDAD.

ATTENTION –RISQUE DE FEU OU D’EXPLOSION SI LE FRIGORIGÈNE EST INFLAMMABLE.

SUIVRE LES INSTRUCTIONS DE MANUTENTION AVEC SOIN CONFORMÉMENT AUX

RÈGLEMENTATION GOUVERNEMENTALE LOCAUX.

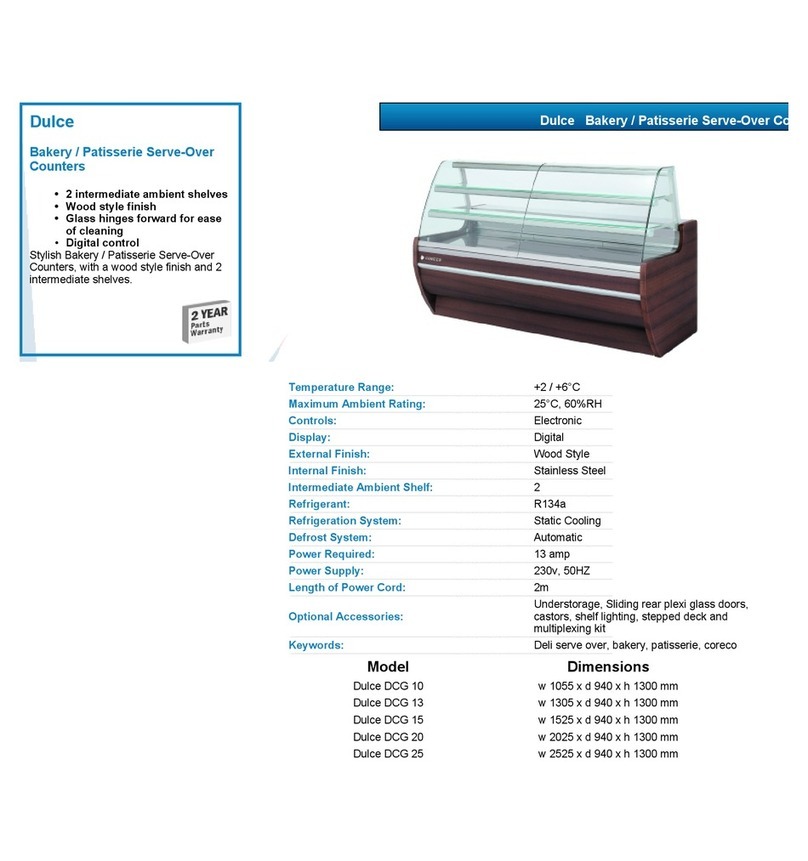

TECHNICAL SPECIFICATIONS

MODEL

DZW-1200

DZW-1500

DZW-1800

DZW-2000

Number of doors

2

Capacity (cu.ft)

15.3

18.2

21.4

30

Number of

Shelves

2

HP

1/3

1/3

1/2

1/2

Electrical

110V/60HZ/1P

Amps

5.0

5.8

6.2

6.8

Temperature

Range

33-41 °F

Refrigerant

R290a

Dimensions

47.2”x32.5”x45.2”

59”x32.5”x45.2”

70.8”x32.5”x45.2”

79”x32.5”x45.2”

Shipping Weight

551

639

720

785

INSTALLATION

TRANSPORTATION

1. To prevent the oil contained in the compressor from flowing into the cooling circuit,

it is necessary to always carry, store and handle the unit in a vertical position and

follow the instructions found on the packaging.

2. If the unit was placed in a non-vertical position during the transportation, keep the

unit in a vertical position for approximately 24 hours before using the unit and

turning it on, to allow the oil to flow back into the compressor.

5

UNPACKING

1. Remove the wooden baseboard and plastic covering.

2. Make sure that the unit has not been damaged.

3. Remove plastic film from all the stainless-steel panels, if applicable.

IMPORTANT: The packaging should be kept away from children as it is potentially

dangerous. Dispose of the packaging according to the regulation from the local authorities.

POSITION

1. Never clean the unit with pressurized water jets.

2. Place the unit on a flat and stable surface.

3. Install the unit in a location where it can be overseen by trained personnel.

4. For good ventilation, keep 20 cm (7 inches) between the unit and walls or other

objects. Increase the distance if the objects surrounding are heating sources. When

the unit is in place, press the brake on the wheels to keep it from moving.

5. Fix the shelves on the unit.

ELECTRICAL CONNECTION

Before inserting the plug into the electrical socket, carefully read the following

precautions:

1. Make sure that the unit is correctly connected to a properly grounded outlet, in

compliance with current safety standards.

2. Make sure that the voltage is in accordance with what is indicated on the rating

label.

3. The current voltage available should be enough for the maximum energy required by

the unit.

4. If necessary, use multiple outlets, which are all properly grounded, in compliance

with current safety standards.

5. If in doubt, please consult qualified technicians.

THE REFRIGERATED SHOWCASE MUST BE CONNECTED TO AN ELECTRICAL SOCKET WITH A

GROUND.

OPERATION

Before using, the unit should be completely cleaned as it comes into contact with food.

1. Make sure that the main switch is in the (I) position, then plug in the unit.

6

2. Before starting the unit, ensure the sliding doors are properly closed.

3. Turn the main switch to the (I) position, the condensing unit will automatically start.

4. For lighting, press the lighting button. The lighting button is located on the

thermostat.

5. If there is some condensation in front of the curved glass, please turn the switch to (I)

position for defogging.

6. Allow the unit to reach proper temperature before loading with product.

WORKING TEMPERATURE ADJUSTMENT

To reset the temperature inside the showcase, please follow as below:

CAUTION: You are suggested not to reset the temperature controller frequently.

Temperature Controller Operation

Front Panel Commands

7

Main Functions

1. How to see the setpoint

1. Push and immediately release the SET key: the

display will show the Set point value;

2. Push and immediately release the SET key or wait for 5 seconds to display

the probe value again.

2. How to change the setpoint

1. Push the SET key for more than 2 seconds to change the Set point value;

2. The value of the set point will be displayed and the “°C” or “°F” LED starts

blinking; 、3. To change the Set value push the or arrows within

10s.

4. To memorise the new set point value push the SET key again or wait 10s.

3. How to start a manual defrost

Push the DEF key for more than 2 seconds and a manual defrost will start.

4. How to change a parameter value

To change the parameter’s value operate as follows:

1. Enter the Programming mode by pressing the Set + n keys for 3s (the “°C” or “°F”

LED starts blinking).

2. Select the required parameter. Press the “SET” key to display its value

3. Use “UP” or “DOWN” to change its value.

8

4. Press “SET” to store the new value and move to the following parameter. To exit:

Press SET + UP or wait 15s without pressing a key. NOTE: the set value is stored even

when the procedure is exited by waiting the time-out to expire.

For more info, please refer to the controller manual

MAINTENANCE

CLEANING

For health standards and good quality of beverages or foods, clean interiors of the unit as

often as possible.

CAUTION: Do not clean the unit by means of a water jet or pressurized washer.

1. Before carrying out cleaning, turn the unit off and remove the power plug.

2. Do not use abrasive powders that might damage the interior parts of the showcase.

3. Use neutral soap and warm water to wash the interiors. Rinse carefully with water to

remove any soap residues.

4. To maintain a high standard of working performance, leave the unit turned on during

the night and day to avoid deposits.

CAUTION: Do not use any damaging solvents (petrol, alcohol, etc.) for cleaning the unit.

The unit may get damaged. Do not use and sharp objects for cleaning. The unit may be

cleaned with a damp towel but should never directly come in contact with water. After

cleaning the unit, make sure all parts are dried completely.

INSTRUCTIONS FOR DISPOSAL

When replacing your old unit with a new one, comply with the following information:

Old units are not to be disposed of as regular waste. Valuable raw materials can be

obtained by recycling old units.

Render your old unit unusable:

Cut off and remove the main power plug from the unit, then discard separately.

CAUTION: Substances and gases in the thermal insulation must be disposed of

professionally. Ensure that refrigeration tubing is not damaged prior to disposal. Please

discard the unit according to the regulations of local law.

9

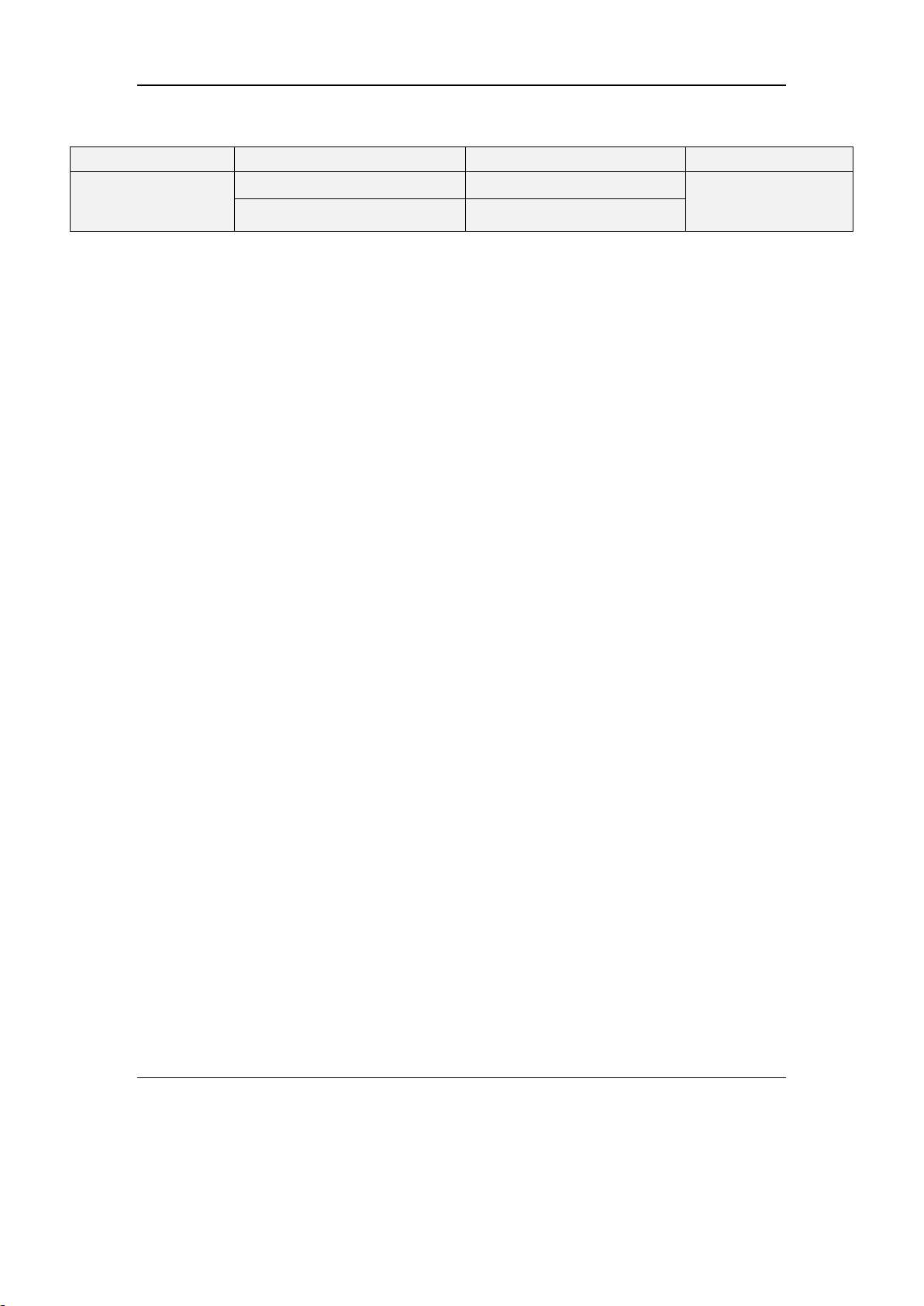

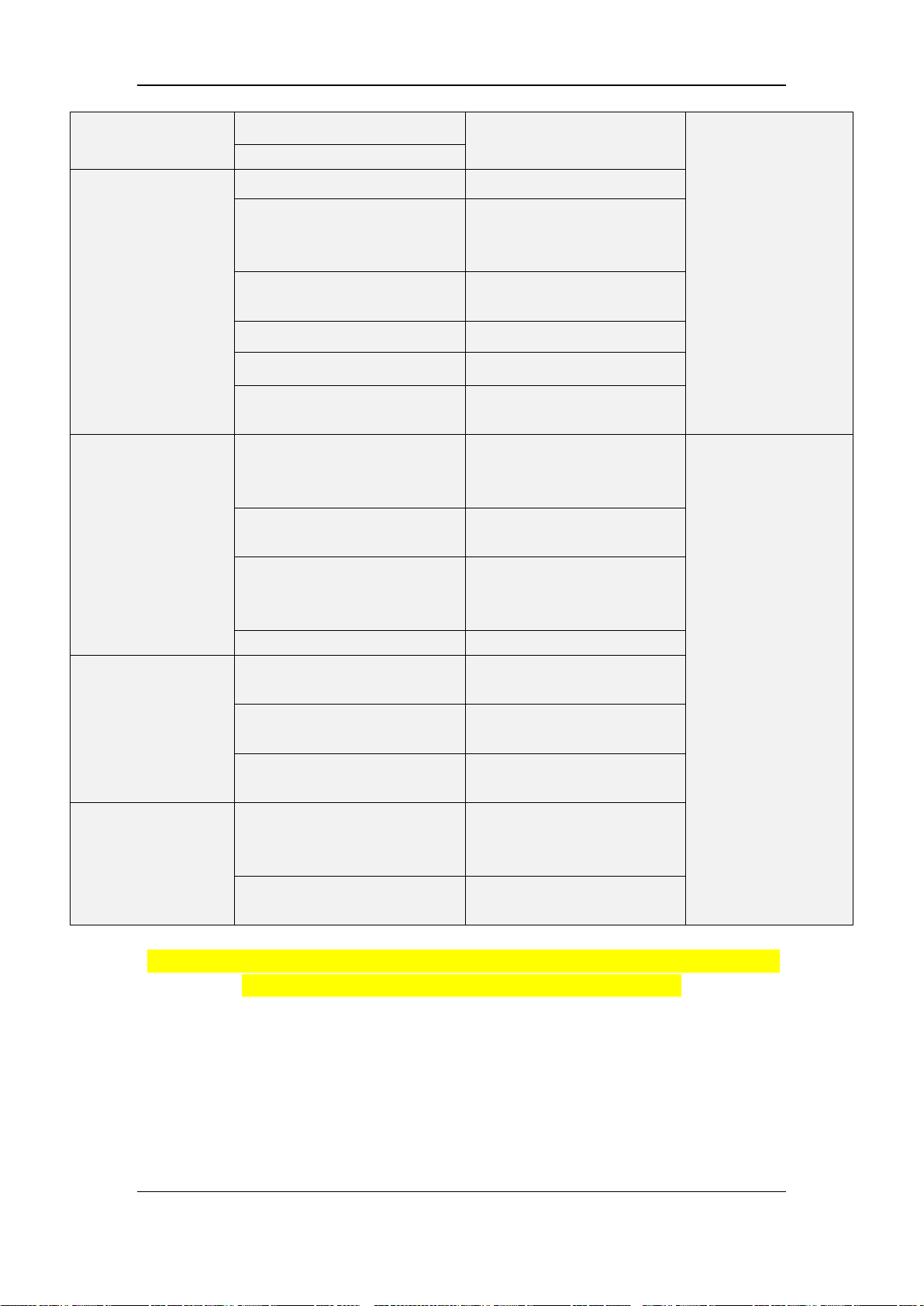

Troubleshooting

System

Possible Reasons

Solution

Remark

No power input

/power direction

Broken fuse

Replace

As for authorized

service department

Poor connection of plug and

Repair or replace the socket

10

WARNING: If the machine has any problems or has been damaged, do not try to repair or

replace it by yourself. Please contact local service department.

Parts breakdown

lamp does not light

socket

to check and repair

Failure in input control circuit

Compressor does not

work

Thermostat does not work

Replace

Thermostat is not on the

working position

Turning to the working

position

Poor contract of

thermostat

Insert the plug tightly

Loose plug pins in the starter

Insert the plug tightly

Broken compressor

Replace

Broken starter or

capacitor

Repair or replace

Compressor runs,

but the

temperature in the

showcase is

high

Circulating temperature is

too high

Adjust the thermostat

properly

Ask for authorized

service department

to check and too

much dust and dirt

on repair it

Too much dust and dirt on the

condenser

Clean it on time

Fr thick

Stop the machine

to defrost. Set the

temperature higher

Thermostat is out of work

Replace

Condenser fan does

not

run

The capacitor of the fan is out

of work

Replace

The ball-bearing of the fan

motor lacks oil

Fill oil

The winding of the fan motor

is damaged

Replace

Compressor

starts/stops

frequently

The winding of the

compressor is short

circuit

Check with a multi meter,

replace the compressor.

Poor contact of the

socket

Repair or replace

11

12

Part

Description

MFG Code

MFG Description

1

Bottom deck

138-0001

#DZX.0.1 BOTTOM DECK

2

Sliding door

138-0002

#DZX.0.2 SLIDING DOOR

3

Structure body

138-0003

#DZX.0.3 STRUCTURE BODY

4

Evaporator

138-0004

#DZX.0.4 EVAPORATOR

5

Top panel

138-0005

#DZX.0.5 TOP PANEL

6

Top water tray

138-0006

#DZX.0.6 TOP WATER TRAY

7

Evaporator cover

138-0007

#DZX.0.7 EVAPORATOR COVER

8

Ladder for shelves

138-0008

#DZX.0.8 LADDER FOR SHELVES

9

Shelves

138-0009

#DZX.0.9 SHELVES

10

Left panel

138-0010

#DZX.0.10 LEFT PANEL

11

Air guide board

138-0011

#DZX.0.11 AIR GUIDE BOARD

12

Front glass

138-0012

#DZX.0.12 FRONT GLASS

13

Front panel

138-0013

#DZX.0.13 FRONT PANEL

14

Condenser

138-0014

#DZX.0.14 CONDENSER

15

Compressor board

138-0015

#DZX.0.15 COMPRESSOR BOARD

16

Condenser fan

138-0016

#DZX.0.16 CONDENSER FAN

17

Water tray

138-0017

#DZX.0.17 WATER TRAY

18

Compressor

138-0018

#DZX.0.18 COMPRESSOR

19

Bottom frame

138-0019

#DZX.0.19 BOTTOM FRAME

20

Caster

138-0020

#DZX.0.20 CASTER

21

Back vent

138-0021

#DZX.0.21 BACK VENT

22

Control Panel

138-0022

#DZX.0.22 CONTROL PANEL

23

Switch

138-0023

#DZX.0.23 SWITCH

24

Thermostat

138-0024

#DZX.0.24 THERMOSTAT

25

Right Panel

138-0025

#DZX.0.25 RIGHT PANEL

26

Side glass

138-0026

#DZX.0.26 SIDE GLASS

27

Heating tube

138-0027

#DZX.0.27 HEATING TUBE

13

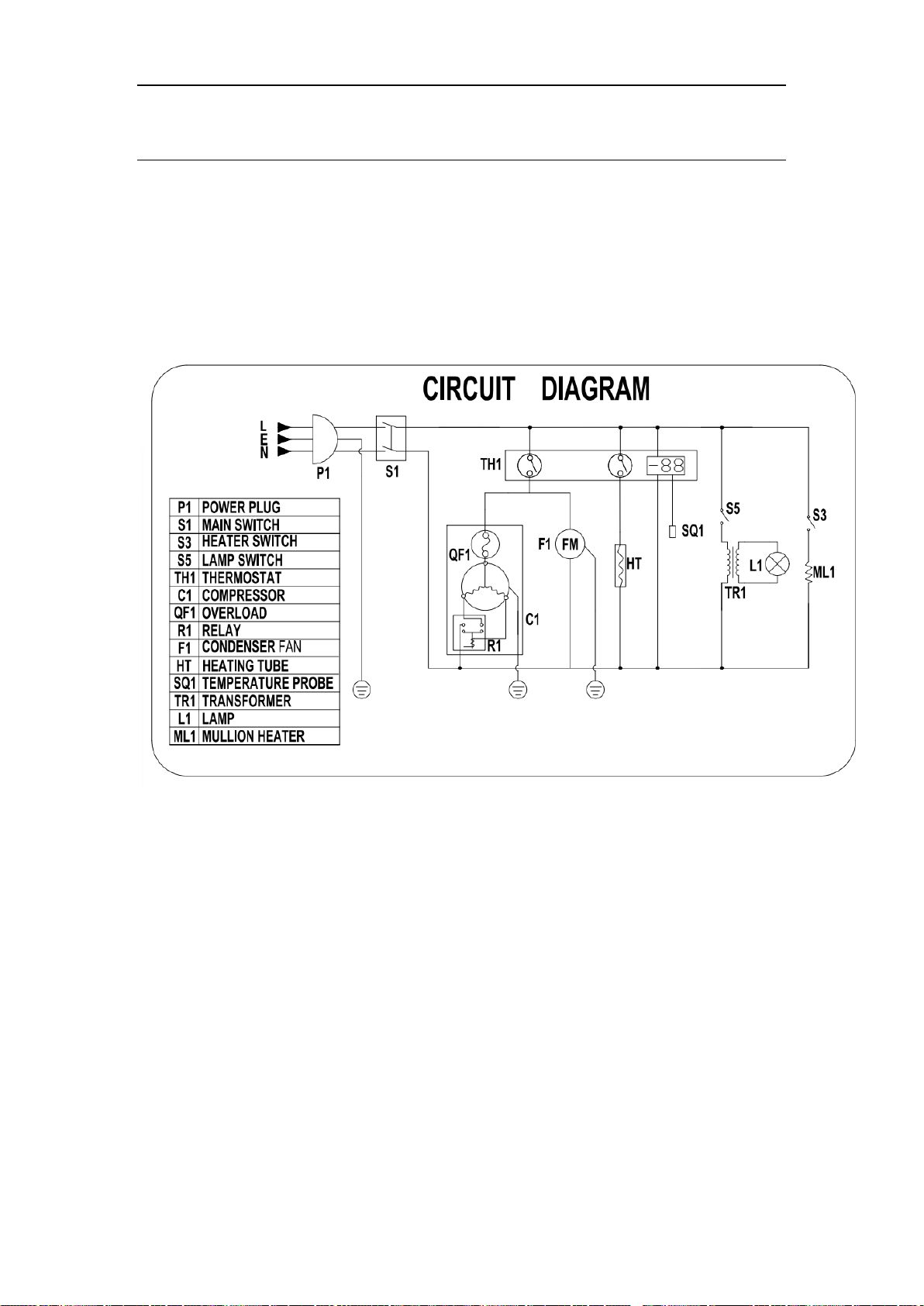

CIRCUIT DIAGRAM

This manual suits for next models

3

Table of contents

Popular Display Case manuals by other brands

Bartscher

Bartscher Panorama 550L Translation of the original instruction manual

Hatco

Hatco FLAV-R-SAVOR PFST-1X Installation & operating manual

Alto-Shaam

Alto-Shaam HALO-HEAT TY-48 Operation and care manual

Avantco

Avantco 177HDC13 user manual

Ubert

Ubert HT Series user manual

Federal

Federal SN48 Installation & operation instructions