Series ’90 Non-Refrigerated Bakery Page 2

Contents

INTRODUCTION………………………………………………………….……………3

WARNING LABELS & SAFETY INSTRUCTIONS…………………………………4

PRE-INSTALLATION PROCEDURES……………………………………………….5

INSPECTION FOR SHIPPING DAMAGE…………………………………………………………..…5

INSTALLATION INSTRUCTIONS…………………………………………………...5

REMOVING CASE FROM SHIPPING SKID………………………………………………………….5

REMOVING PACKAGING MATERIAL………………………………………………………………5

LEVELING THE CASE………………………………………………………………………………….5

GRILL REMOVAL……………………………………………………………………………………….6

LIGHTS……………………………………………………………………………………………………6

SHELVING………………………………………………………………………………………………..7

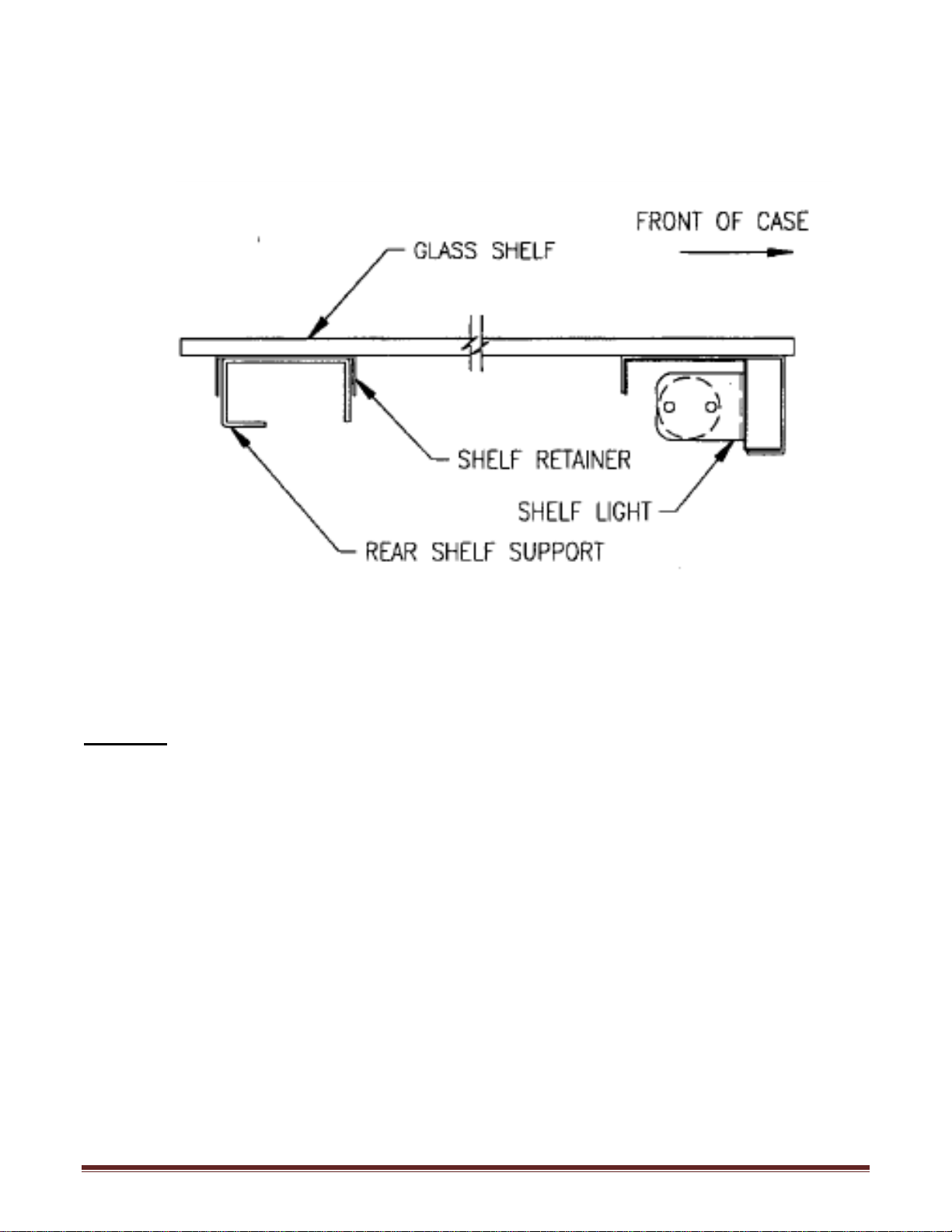

OPTIONAL GLASS SHELVES………………………………………………………………………….8

CLEANING……………………………………………………………………………………………..…8

ELECTRICAL INFORMATION & GROUNDING………………………….……….9

OPERATING INSTRUCTIONS………………………………………………………10

INITIAL START-UP……………………………………………………………………………….....…10

CONTROLS…………………………………………………………………………………………...…10

DOORS……………………………………………………………………………………………...……10

HINGED FRONT GLASS……………………………………………………………………………....11

LIGHT REPLACEMENT……………………………………………………………………………....12

SHELVES……………………………………………………………………………………………..….12

CLEANING INSTRUCTIONS………………………………………………………..13

DAILY CLEANING……………………………………………………………………………………..13

WEEKLY CLEANING……………………………………………………………………………….…13

INTERIOR CLEANING………………………………………………………………………………...14

EXTERIOR CLEANING………………………………………………………………………………..14

SERVICE INFORMATION…………………………………………………………...15

PRE-SERVICE CHECKLIST……………………………………………………………………….….16

SALE & DISPOSAL……………………………………………………………………16

OWNER RESPONSIBILITY………………………………………………………………………...…16

ELECTRICAL DATA………………………………………………………………….17

REPLACEMENT PARTS……………………………………………………….....18-19

REPLACEMENT PARTS SN48, SN59, SN77, SN96………………………………………………….18

REPLACEMENT PARTS SN48SS, SN59SS, SN77SS………………………………………………...19

WIRING DIAGRAM- MAIN WIRING………………………………………………20

WIRING DIAGRAM- SN48 & SN59 W/LIGHTS…………………………………...21

WIRING DIAGRAM- SN77 W/LIGHTS……………………………………………..22

WIRING DIAGRAM- SN48SS & SN59SS W/LIGHTS…………………………......23

WIRING DIAGRAM- SN77SS W/LIGHTS………………………………..………...24