Toolots LP Series User manual

1

Instructions

To The LP Series Luggage Wrapping Machines

ORIGINAL INSTRUCTION

2

Contents

§1 Information on the Luggage Wrapping Machines........ 3

§2 Main Technical Index of the LP Series.......................... 3

§3 Repair Guarantee to the Product................................... 4

§4 Before the Installation.................................................... 5

§5 Operating Instructions to the Controlling Panel........... 6

§6 Operating Instructions to the textscr................................ 8

§7 Equipment Maintenance.............................................. 11

§8 Put into Use................................................................... 12

§9 Performance of the Functions & Others.................... 13

9-1.Error in Counting................................................ 13

9-2.Sketch Picture of the Operation on the Film:. 13

9-3、Film-Stretching.................................................... 13

§10 Safety in the Use........................................................ 14

§11 Noise and Vibration.................................................... 15

Packing list .................................................................. 16

3

§1 Information on the Luggage Wrapping Machines

1.With the LLDPE stretching film as the packing materials, this device is professional in the

packing and wrapping of luggage in the airport

2. The packing cost will be reduced, a more convenient storage and transportation will be

achieved and an easier recycle of the packing materials will be conducted with the

application of the LP series luggage wrapping machines, thus ensuring a less polluted

environment. This is currently one of the popular environmental-friendly packing methods.

3. LP Luggage wrapper is designed to stretch wrap luggage and related items for security

purposes in an airport setting. Film provides extra support while the luggage is being

transport to protect them become damaged. And the plastic and closing label cannot be

removed and replaced by a thief . Additionally , wrapped luggage can easily be separated

and identified.

*The machine is a movable and manually operated rotary turntable device use

stretch film to wrap the luggage .The operator placed the luggage on the platform and

adjusts vertical rods to secure bag according the luggage's size .Then begin the wrap

process, the operator press start button on control panel pack the luggage by a 3 to 5

layers of stretch film. The operator cuts film tail and removed from the turntable. The

machine is ready to accommodate the next piece of luggage.

4. Besides the basic stock packager, it. has produced various stretch wrapping machines in

such types as cylinder paper/shade cloth, cable, plane and cylinder radial. We also

produce other packagers for brown paper, EPE, the ordinary PE film, etc. Please contact

the marketing department of our company for details.

§2 Main Technical Index of the LP Series

1.Packing Standard:

PK-600F-L SERIES:

Wrapping size: (200-500)mm W x (200-800)mm L x (300-500)mmH

PK-600F-LAND LP600F-N SERIES

Wrapping size: (200-1000)mm W x (300-1000)mm L x (300-1000)mmH

4

2.Turntable loading:≤100 kg(special type exclusive)

3.Materials:

Materials

Width

Thickness

Inner Core of the Film Scroll

Outer-Dia.

LLDPE Stretching Film

500 mm

17-35μm

76mm(3 inch)

≤187 mm

4.Power Supply:AC220V/50HZ,0.75kw 20A -1p((Conversion to AC 110V/60HZ))。

The power must be separated and fixed, any temporary wire or co-wire with other devices is

prohibited. Please check the live wire, neutral wire and ground wire when connects.

(Damages on the device or others caused by improper power supply are invalid in our repair

guarantee.)

5.Power:0.75KW

6.Weight:220Kg

7.Working Speed:20-40pcs/hour

8.Revolting Speed:0-36rpm

§3 Repair Guarantee to the Product

1. The manufacturer bears all the repairing costs of the product for one year since the very

leaving of the product from the manufacturer under the prerequisite that all the installation,

repairs and operation are in accordance with the set requirement. Users should bear other

costs.

2.The manufacturer reserves the right to determine whether the non-performing component is

to be repaired or changed.

3. The manufacturer reserves the right to search the causes of the failure.

4. Any damages, caused by improper usage (unqualified power, improper operation, etc.) or

artificial factors, are excluded in the repair guarantee.

5. The manufacturer is not responsible for any losses except the packager itself.

6. The manufacturer is not responsible for the damages caused by the repairing of unqualified

technicians.

5

7. The manufacturer bears no free requirements or improvements towards the packager that

are excluded in this guarantee or the purchasing contract, except that the manufacturer is

willing to do so to upgrade its products.

§4 Before the Installation

1. Check and find whether the packager, its components and accessories listed in the packing

list are all included and find whether there is any damage to the packager. (Please

immediately negotiate with relevant transporting departments or contact the delivering party

in case of any damage mentioned above.)

2. Check the qualification card to make sure that the product you purchased is qualified and

meets your ordered requirements.

3. Open the package in the marked position (note: avoid any damage to the device); check

the device and its accessories, following the random packing list.

4. Please read this instruction carefully before install, adjust and operate the device.

5. This device should be installed in a dry place where there is no dust, no leaking, no

flammable or explosive chemical preparations or other things eroding. The surrounding

temperature should range from –10 to 50oc.

6 Check other connecting parts to find whether the electric joint is less screwed or falls off.

Please fix the less-screwing or falling-off accessories and wires in time.

7. A correct, stable, credible and fixed power supply is a must.

(Any temporary wire is prohibited.)

8. Delivery by sea, the machine will be assembly. Delivery by air, the machine will be

disassembly. Connect the line according to the wire NO.

9. The chains and decelerator of the device have already been lubricated or oiled before leaving

6

the manufacture, please confirm before operation.

10. Switch on the power and turn on the air switch, power-controlling switch of the operating

panel in the electric cabinet consecutively. The device will be ready for operation test and

adjustment after it is powered and self-examined.

§5 Operating Instructions to the Controlling Panel

1. Key switch: key button, one of the manual buttons, control the source, Press this button to

off, the power is off, press the button to up, the power is on

2. Emergency Stop: a red push-pull mushroom-shape auto-lock button. When press the

button, all the actions and the PLC inner parameter will stop and replace, and the machine

will not remember its previous actions. When the button is revolved right-wards and pulled

7

out, the machine should be reset to its initiative.

3. Start : a green instantaneous button with a light (as for machines with top-plate , the same

button is a common one and there is no indicator light, other functions are normal.) This

button functions in three aspects: 1). When the turntable is in its origin and the film system

is at its lowest position, press this button, the machine will run automatically according to

the set parameter and program. 2) When the turntable is in its origin and at the same time

the film system is at the highest or lowest position (with goods loaded) while the machine is

ready, press the button and the machine will run automatically according to the set

parameter and program. When the program is completed, the machine returns to its origin.

The stopping location of the film system (up or below) depends on the set up –down times

of the system.3)when the turntable is in its origin and the film system is not in the lowest or

highest position, press the button, the film system will go to its lowest position, then the

machine will run automatic according to the set parameter and program

4. Speed : At the left, the button control the film carriage speed. At right, This switch is to

adjust the speed of the turntable . It is suggested that the speed be higher when the goods

are stable and vice versa.

5. Film Tension: one black button, in the middle of the switch “start”and switch “Stop”. This

switch is adjustable to set various film tension between the film system and the goods being

wrapped . Please adjust this switch to adapt to various goods being wrap . Note: an

over-tension will collapse the goods and the film, and even causes the so-called sandglass

phenomenon. Usually, the film wraps the goods being wrap tenderly and will wrap it tightly

later with its re-constriction. Turn clockwise and the tension will be enforced. The

pre-stretch adjusts the speed of the film output generator and the tension by adjusting the

speed-gap between the turntable and the generator. The Non-prestretch adjusts the damp

and the changeable tension of the stretching rubber roller. Therefore the pre-stretch on the

machine should be carried out by the coordination of adjusting the speed of the

rotating-plate while the block-stretch on the machine does not need this.

6. Manual/auto: one black button, two gears switch, Press this button to left ,it is manual

mode ,Press this button to right, it is auto mode.

7. Up/Down:one manual button, when the machine is in manual mode, press the button to

left ,the film carriage will be up, Press the button to right, the film carriage will be down

8. Stop: a saffron button with a light. This button is a self-block one with a light. Press the

button and the machine is in the state of pause. Repress the button and the machine

8

continues.

§6 Operating Instructions to the textscr

The introduction of the main menu

Press “work load”, the menu go to the below interface

Input the password: 8888,then you can check how many luggage wrapped.

Note:1) when you want to check the work load,you must input the password everytime.2) when

9

there is no luggage on the turntablw, the machine will not calculate the work load.

Input the password, the menu go to the below interface:

“work load”: how many luggage you wrapped

“clear”: Clear the work load to 0

Press “manual”,the menu go to the below interface:

“Turntable run”: press the button,the turntable will run

10

“Turntable stop”: press the esc,the turntable will stop running.

Before go to “setting”,first select the big and small. “big”means big luggage,”small ”means

small luggage(the height not more than 500mm).

Press 0 go to big luggage,press 1 go to small luggage,

Press”setting”,the menu go to the below interface:

“big parameter”setting the parameter of the big luggage

“time delay”setting the time delay when the film system arrive to the highest position

11

“Up cycle”(the layer you want to wrap at the top of the loads):press the set.on the textscr, the

cursor will glitter, then you can input the figure.

“Down cycle”(the layer you want to wrap at the bottom of the loads):Press the set .on the

textscr.the cursor will glitter, then you can input the figure

“Up-down”(the layer of Traverse, up-down)

“small parameter”setting the parameter of the small luggage:

You just need setting the cycle for the small luggage

Mark: all of the above menu, press back,you can go to the premenu.

§7 Equipment Maintenance

1. Load the goods stably and handle them slightly to avoid the distortion of the under-pan or the

shortening of the life of the components.

2.The height of the goods should not exceed the set one. Otherwise, the packing will be

undermined.

3.To ensure a normal operation, the electric cabinet should be closed tightly and the

components and the joints of wiring should be cleaned and checked periodically.

12

§8 Put into Use

1 . Manual Operation:

Load goods on the turntable and put the film scroll on the scroll seat. Thread the film properly in

accordance with the requirements (see film-threading methods §9-2) and then start the

turntable generator to activate the turntable and the film will wrap the goods.

2. Automatic Operation:

Restore the machine in its initiative state, load goods, thread the film properly and set the top

circle amount and the bottom circle amount, up-down times, ,then press the auto-start button,

the whole process will be completed automatically. To enforce enwinding, press the Start

button during the ascending or descending in the auto-process. Auto-running is strongly

recommended in this machine.

3. Brief Introduction to the Auto-Running

Press start when the machine is in its initiation (see the auto-run of §5) and the rotating-plate

begins to speed-up (performs constant running when reaches its max. speed). When the film

outputs with the running of the turntable , the turntable begins to count and the film system

begins to ascend when the number meet the set parameter on the bottom. Re-press the start

during the ascending process of the film system, the ascending will pause and the turntable will

run and count the circle amount The film system continues its ascending process after the

enforcement meet the set parameter. The film system ascends till the goods beyond the

irradiation of the photoelectric switch. The times should be counted as 1 and the rotating-plate

continues to run and count. The film system begins to descend when the machine meet the set

roof circle amount and stops at the bottom. The times should be counted as 1 again and the

machine begins to count the bottom circle amount. The ascending and descending process

repeats till reaches the set parameter and then the packing is complete. The rotating-plate

decelerates slowly and stops at the initial checking and measuring point.

13

§9 Performance of the Functions & Others

9-1.Error in Counting

The counting begins when the film system reaches its highest location in the auto-process, if at

this time the sensor and the testing point are not at the same place, usually the roof circle

amount does not appear as a integer. To ensure that the error is no more than half a circle, the

circle amount can be increased or decreased, depending on the specific situation. The counting

on the bottom circle amount after a circulation occurs as the mentioned-above.

9-2.Sketch Picture of the Operation on the Film:

Please thread the film as guided below.

Diagram 1 LP600F-L(Pre-Strechin

9-3、Film-Stretching

9

-3-1 Capability Features of the LLDPE Stretching Film

The film brings backpressure to the being packed, thus protecting the latter. The

backpressure of the film is produced by the stretching. The cohesion reduces

skidding and causes a repeating effect, forming a dynamic coat.

14

0-40% Min. memory

40-75% Memory begins to react

75-100% Medium backpressure

100-200% Backpressure that easily attains max. percentage

200-250% It is suggested to chose proper films and stretching equipments

to attain max. stretching

250%+ Affected by the stress, the film begins to intensely loose

300%+ Memory damaged, the film only equals to plastic film

9-3-2 Pre-Stretch:

According to the capabilities of the stretching film listed in §9-3, only the pre-stretching

proportion of the pre-stretcher is set at 1:2.5 can the pre-stretcher perform its best. The

pre-stretching proportion of this packager is based on the above-mentioned and is in conformity

with the requirements of film tension in §5 Operating Instructions to the Controlling Panel,

according to the test conclusion. The result will be the best when it is wrapped above the goods.

The spring amount in the width of the film is about 10%.

9-3-3 Block-Stretch:

Generally the result of the block-stretching method does not match that of the pre-stretching, for

the protraction of the film produced by the former method is counteracted by the width and

thickness of the film. The requirements vary in accordance with the specific packing method.

With a relatively strong single-layer restriction and a lower cohesion, the block-stretching

method can enhance the part enlacement

§10 Safety in the Use

1. Test on the voltage of the controlling panel of direct current generator and that of the

meg-powder arrester or between the PLC inputting point and the ground wire is prohibited.

2. Check and find whether there are less-crowdedness or fall-off in the joint between different

components periodically during the normal performance of the machine. If any, restore

them to their original.

3. The rotating-plate of the machine should run clockwise.

4. Standing or piling goods below the film system is strictly prohibited!

5. To avoid damaging the rubber roller or hurting the finger, do not put hand or other things into

15

the film system when the roller is running!

6. The operator should stay in a safe place and keep a certain distance from the rotating-plate

during the process of the machine. To avoid any hurt on the people in case of goods

falling-down, the operator should not approach the machine until a process is completed

and the machine stops. A safety isolating net (self-provided by the client or ordered

separately) should be installed if necessary.

7. To avoid any damage to the machine or any hurt on the people by the leakage, the ground

wire connecting or the neutral wire connecting should be firm and reliable (a mixed

connection of the neutral and ground wire is prohibited).

8. The re-installation of and the re-test on the machine should be carried out by professionals

after the removal of the machine from its original place. The machine should not be put into

operation before its safety capability is re-tested by professionals.

9. The checking on the electrical equipment and its joints and the cleaning of the electric

cabinet should be carried out periodically.

§11 Noise and Vibration

This noise level of the machine don’t exceed 70 dB (A) during normal working. The vibration

level is low and the machine will not harm the operator for vibration。The peak C-weighted

sound pressure at workstation is 69pa.

Picture 1:how to connect the wire when the machine disassembly

16

Packing list

Luggage wrapping machine

Name

Model

Unit

QTY

MARK

Luggage wrapping

machine

LP600F-L

SET

1

Attachment tools

SUIT

1

Fuse

PCS

4

3:10A 1:2A

Stretch film

ROLL

1

instruction

PCS

1

Instantaneous Button

PCS

1

Potentiometer

This manual suits for next models

1

Table of contents

Popular Stretch Wrapping System manuals by other brands

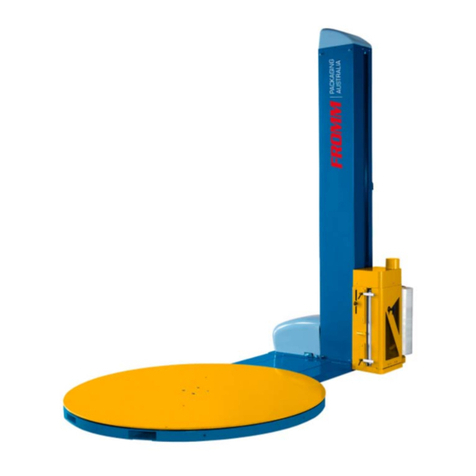

Tanco

Tanco 1510 Operator's handbook

GALLERY

GALLERY STRETCHER-240 instruction manual

Atlanta

Atlanta EVA manual

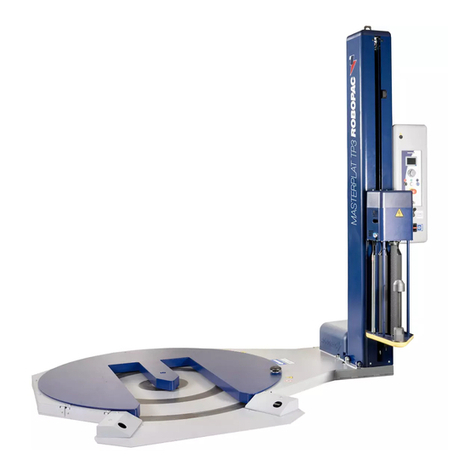

Robopac

Robopac Masterplat PLUS FRD Series Use and maintenance manual

Pro Mach

Pro Mach Orion CTS Flex Stretchwrapper manual

ItaldibiPack

ItaldibiPack DIBIPACK 3246 STCN Installation, use and maintenance