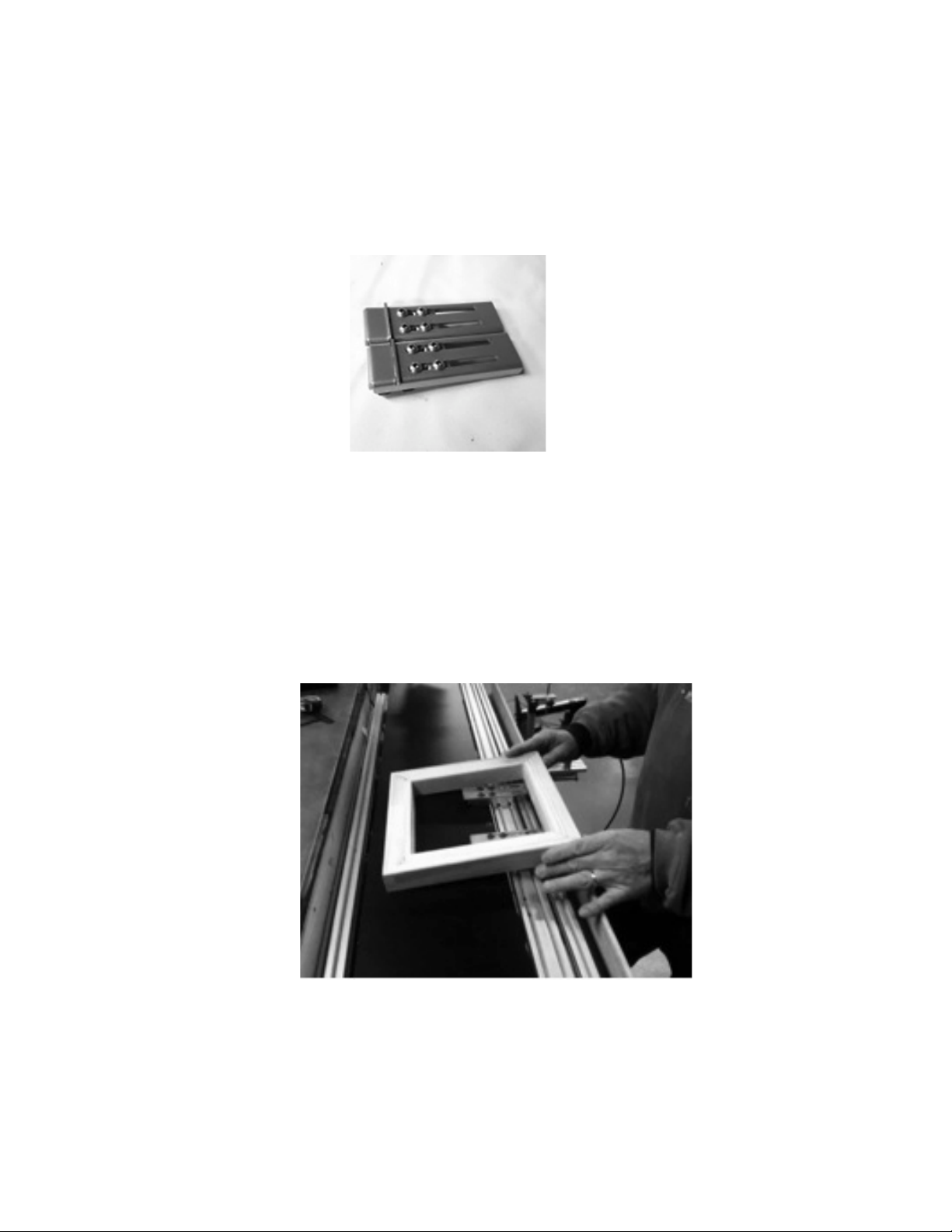

Foot Pedals & Mount

There are (2) foot pedals located on a steel plate. The pedal on the right controls the

“Clamping Bar”, the pedal on the left controls the “Stretching Bar”. Both foot pedals

are configured to allow air to flow when depressed. DO NOT have any part of your body

near the bars when in motion. Depressing the foot pedal once turns air on, depressing it

again turns off the air.

The clamping foot pedal engages the clamping bar to grip the canvas, the stretching pedal

controls the stretching bar. The stretching force is controlled on the right side of the

machine, the gauge on the deck indicates stretching force.

A color-coded tubing harness is attached to the foot pedal assembly. The loose ends must

be connected to the under-side of the machine (pictured below) to their corresponding

color-coded quick-connect fittings. The “Black” & “ White” are for the clamping pedal,

the “Orange” and “Yellow” are for the stretching pedal and the remaining “grey”

connector is for your staple gun. You should have a “white plug” inserted into that

connector to block off air until you are ready to connect a staple gun (optional

equipment). Simply depress the grey ring and pull out the plug.

A staple gun is not included with the GS-60.

There are (2) preinstalled T-nuts in the middle track that allow for a holster and a staple

gun. A holster is not included with the GS-60 but it is configured for one. Refer to

this section if you purchase one from us.