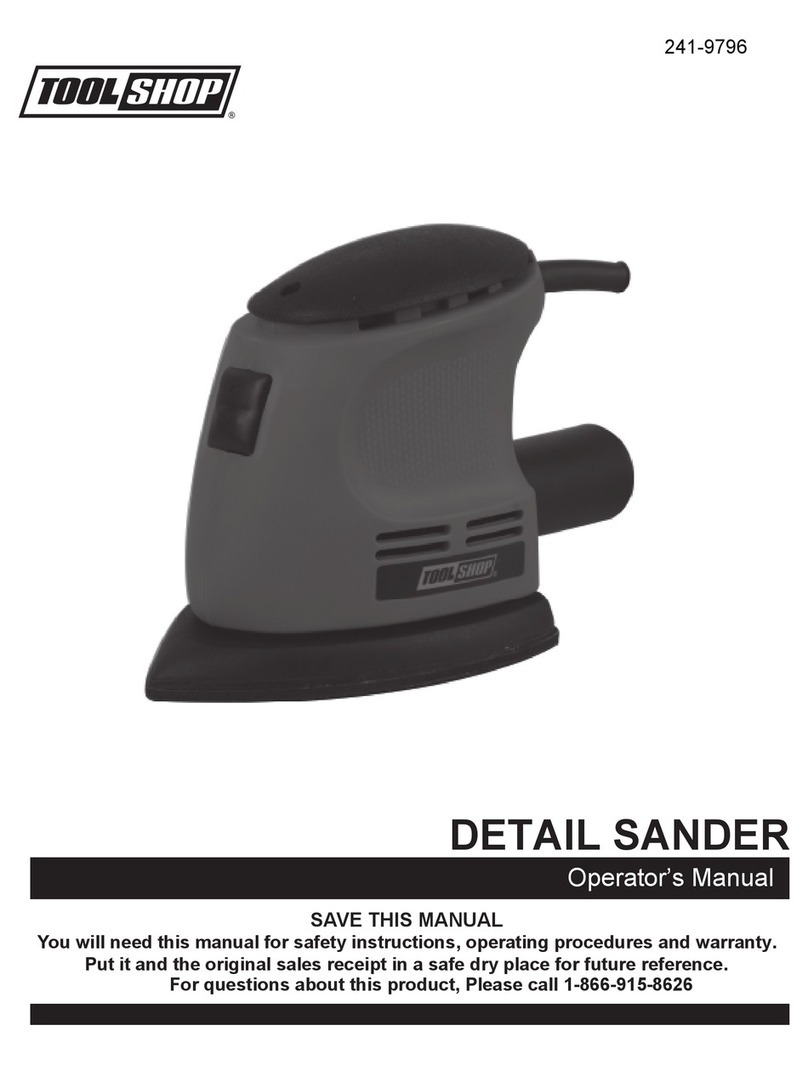

Toolshop 241-9796 User manual

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

Operator’s Manual

241-9796

DETAIL/FINISH SANDER

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING:When using electric tools, machines or equipment, basic safety pre-

cautions should always be followed to reduce the risk of re, electric shock,

and personal injury.

!

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas can cause injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose tools to the rain. Keep the work area

well lit. Don’t use tools in the presence of ammable gases or liquids.

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords.

Bystanders can be a distraction and can be injured.

4. GROUNDED TOOLS must be plugged into an outlet that is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity to the ground away from the operator, should the tool malfunction elec-

-

trically. Do not remove the grounding prong from the plug or alter the plug in

any way. If in doubt as to whether the outlet is properly grounded according

to code, check with a qualied electrician.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULA-

TION. This tool is double insulated. It is equipped with a polarized plug.

One blade is wider than the other, so it will t into a polarized outlet only one

way. If you have difculty inserting the plug, try reversing it. If it still doesn’t

t , do not alter the plug; have a qualied electrician install a polarized outlet.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working wher-

ever “live” electrical wires may be encountered, try to ascertain whether

there is a danger of shock. DO NOT TOUCH ANY METAL PARTS

OF THE TOOL while using it. Hold the tool only by the plastic grip to prevent

electric shock if you contact a live wire.

7. DO NOT MISUSE THE CORD.

Never carry your tools by the cord or pull on

the cord to unplug it. Protect the cord from potential sources of damage:

heat, oil & solvents, sharp edges, or moving parts. Replace damaged cords

immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD. An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWER TOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of

reach of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it was

not intended.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be

caught in moving parts. Protective, non-electrically conductive gloves, protective

eyewear and non-skid footwear are recommended. Wear protective hair

covering to contain long hair and keep yourself from harm.

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use

3

SAFETY PRECAUTIONS FOR DETAIL

SANDER

• Always follow instructions for fitting and changing sandpaper

• Do not put undue pressure on the sander such that it slows down.

• After switching off, always wait until the sander has stopped before putting it

down.

• Do not expose this tool to water or liquids. The abrasive pads, steel wool pad,

and polishing pad are not intended for wet use.

IMPORTANT SAFETY INSTRUCTIONS

!

15. USE EYE PROTECTION. Use a full-face mask if the work you’re doing

produces metal lings, dust or wood chips. Goggles are acceptable in other

situations. Wear a clean dust mask if the work involves creating a lot of ne

or coarse dust.

16. SECURE WORK. Use clamps or a vise to hold the work, this frees both

hands to operate the tool.

17. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across machines that are running.

18. MAINTAIN TOOLS. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories.

For safe performance. Keep handles dry, clean and free from oil and grease.

19. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF posi-

tion before plugging in.

20. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING KEYS

OR WRENCHES before turning the tool on. Left attached, these parts can y

off a moving part and result in injury.

21. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHED ON OR OFF.

Have your tool repaired before using it.

22. DISCONNNECT THE PLUG FROM THE POWER SOURCE BEFORE MAKING

ANY ADJUSTMENTS.

Changing attachments or accessories can be dangerous

if the tool could accidentally start.

23. STAY ALERT. Watch what you are doing & use common sense. Don’t operate

any tool when you are tired.

24. CHECK FOR DAMAGED PARTS. Before using this tool, any part that is

damaged should be carefully checked to determine that it will operate prop-

erly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mountings, and other conditions

that may affect its operation. Inspect screws and tighten any ones that are

loose. Any part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise indicated elsewhere in the in-

struction manual. Have defective switches replaced by an authorized service

center. Don’t use the tool if switch does not turn it on and off properly.

25. REPLACEMENT PARTS. When servicing, use only identical replacement

parts.

26. SERVICE AND REPAIRS should be made by qualied repair technicians at

an authorized repair center. Improperly repaired tools could cause serious

shock or injury.

4

= Voltage: 120 Volts AC, 60Hz

= No load speed: 12,000 OPM

= Dust-sealed front rocker switch

= Sanding sheet size: 5-1/2” X 5-1/2” X 3-1/8”

=Includes 3 pcs. sanding paper(80,120,180)

OPERATING PROCEDURES

INSTALLING SANDPAPER

WARNING: Unplug the sander before replacing sandpaper.

The Detail Sander comes complete with a 5 hole hook and loop style mounting

system. The palm sanders sanding sheets will be affixed to the sanders

base without the use of clamps.

Connect the sanding sheet to the sanding plate:

Turn the tool upside down. Next, align the sanding sheet with the sander’s base

and press the sanding sheet rmly into place. Conrm that the holes punched in

the sanding sheet match the dust holes in the sanding plate. Holes must match for

the dust system to work properly.

To remove the sanding sheet, carefully peel the sanding sheet away from the

sanding plate.

NOTE: Check the sandpaper regularly for tears, cracking, and other damage.

Damaged paper can allow the pad beneath to be damaged.

Because of the operator vigilance required, the pad is considered a

consumable part and is not covered under warranty.

RUNNING THE TOOL

1. Identify the item you wish to sand or polish and choose the proper grit sandpa-

per or abrasive pad best suited for the job. If preparing wood for painting or

removing paint, use a course grit sanding sheet. Use a fine grit for finishing

work.

2. Secure the item to be sanded. Make sure that the sanding sheet is firmly

fixed to the sander.

3. With the sander not in contact with the workpiece, press the Switch to the “ON”

position.

4. Carefully place the palm Sander onto the workpiece and begin sanding.

WARNING: Do not sand any area to heavily or for more than a few seconds at a

time. Apply even pressure in a random pattern over the entire surface.

5. To sand down proiles and grooves, use the point or edge of the sander base.

6. Every few minutes, check the condition and wear of the sanding sheet. Re-

place if necessary.

SPECIFICATIONS

!

!

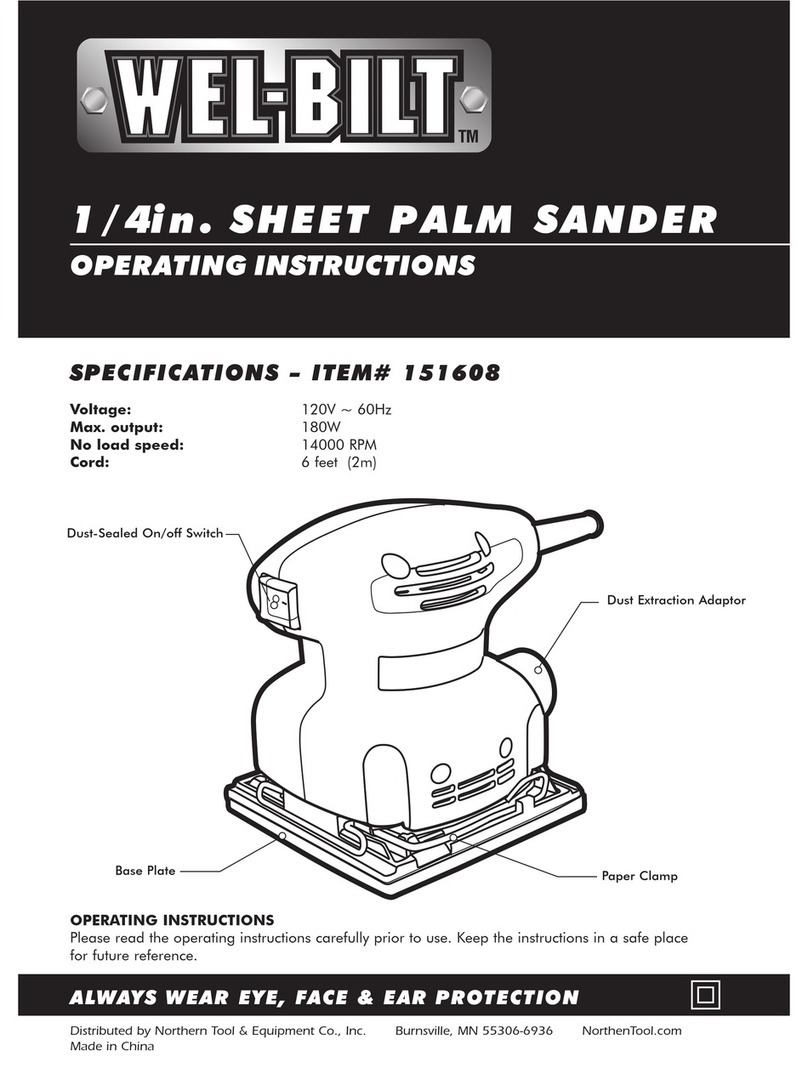

FUNCTIONAL DESCRIPTION

1

23

1. Dust-sealed on/off switch

2. Sanding base

3. Dust bag

=Current Rating: 0.8 amps

!

5

WARNING: Do not use torn or severely worn sandpaper. You may damage your

work surface or suffer physical injury.

7. When you are done sanding the desired area, remove the sander from the

work surface before turning the sander OFF.

CONTROL THE DUST IN THE WORKPLACE.

For dust collection to work, the five dust extraction holes must be aligned properly

between the sanding sheets and sanding pad. Using the dust extraction feature of

the sander also helps prevent the sandpaper from loading quickly with sawdust.

At the back of your sander, you can attach a dust bag with a 1-1/4” ID hose.

SANDING

Use a grade of sandpaper that will make ner marks than those already on the

surface. Too coarse a grade will not make the surface smoother while too ne a

grade will remove scratches too slowly, or not at all. Continue using ner grades of

sandpaper until you obtain the desired nish.

When removing old paint, determine how much paint really needs to be removed.

Consider that old paint may well be toxic and will have to be treated with the

respect due any toxic material both on the part of the tool operator and environment.

Wear appropriate breathing protection and dispose carefully of dust or chips

left after sanding.

MAINTENANCE

1. Keep the vents clear of dust and debris. This will help prevent possible electri-

cal shorts and ensure proper cooling.

2. Keep the tool housing clean and free of oil and grease by using mild soap and a

damp (not wet) cloth.

3. Inspect the cord regularly and have it replaced by an authorized repair facility if

it is damaged.

4. Lubrication for this tool is done at the factory and should not be necessary

again under normal use.

5. An authorized repair center should do any repairs, modification, or mainte-

nance that involves disassembling the tool.

6. Any damage to the tool should be corrected at an authorized repair center.

CLEANING

Use mild soap and a damp cloth to clean the sander. Do not use petrol, turpentine,

lacquer, paint thinners which could damage the plastic casing. Do not allow liquids

to get inside the sander. Never immerse the sander in liquid.

OPERATING PROCEDURES

!

6

No. Description No. Description

1 Screw 14 Label

2 Sand paper 15 Left housing

3 Sanding plate 16 Rubber cover

4 Base support 17 Screw

5 Bearing 18 Bearing

6 Bushing 19 Terminal block

7 Bearing 20 Cord clamp

8 Fan 21 Cord guard

9 Rotor 22 Power cord

10 Stator 23 Screw

11 Brush holder 24 Screw

12 Switch cover 25 Right housing

13 Switch 26 Label

PARTS LIST

SCHEMATIC DRAWING

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2425

26

!

WARNING Repairs should be made by an authorized repair center. Do not

this power tool . Contact at

for questions regarding this power tool. 1-866-915-8626

open or disassemble

Table of contents

Other Toolshop Sander manuals