Preface

iv

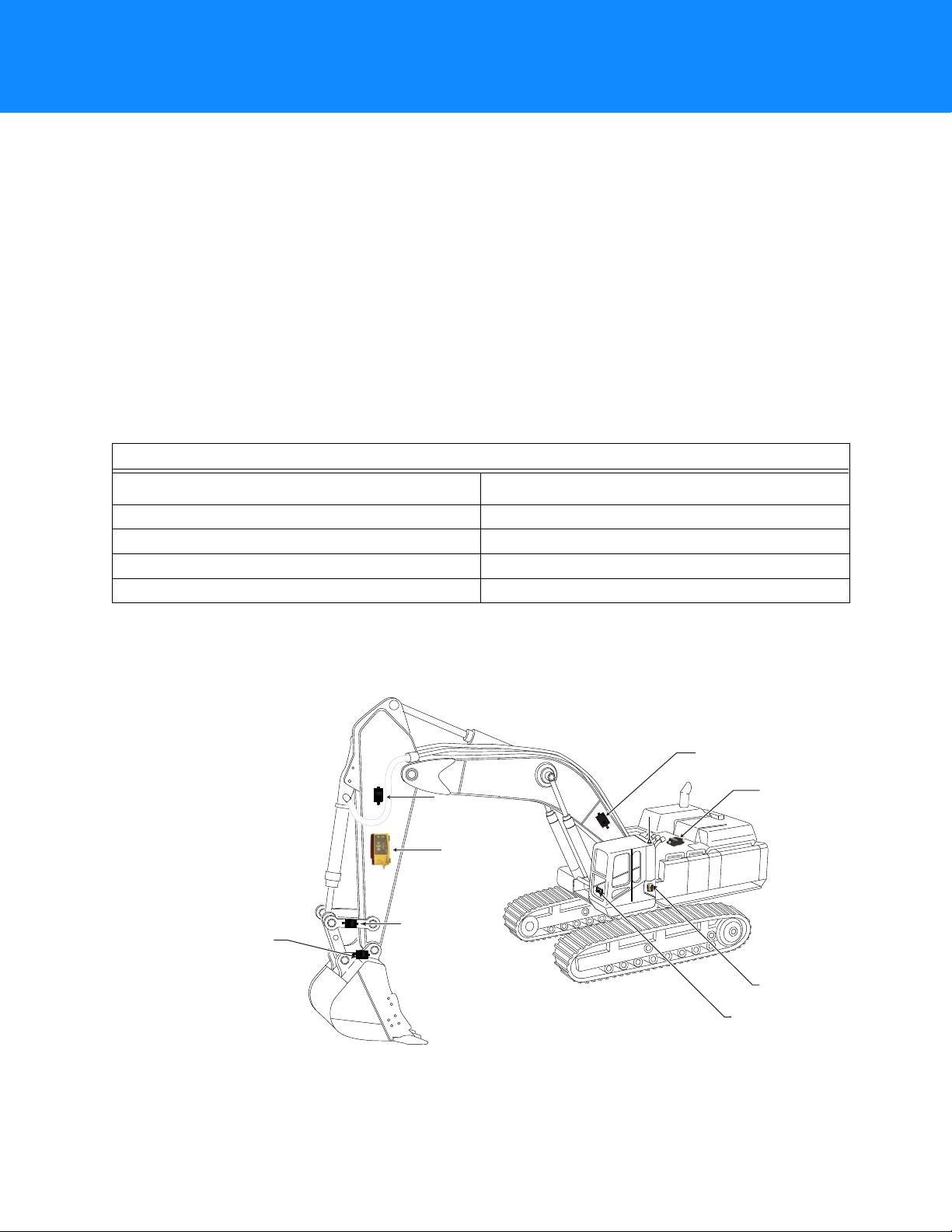

X-52/X-72 2D Excavator Installation and Calibration Manual P/N: 1022461-01

NOR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE

FURNISHING, PERFORMANCE OR USE OF THIS MATERIAL OR THE PRODUCT. SUCH

DISCLAIMED DAMAGES INCLUDE BUT ARE NOT LIMITED TO LOSS OF TIME, LOSS OR

DESTRUCTION OF DATA, LOSS OF PROFIT, SAVINGS OR REVENUE, OR LOSS OF THE

PRODUCT’S USE. IN ADDITION TPS IS NOT RESPONSIBLE OR LIABLE FOR DAMAGES OR

COSTS INCURRED IN CONNECTION WITH OBTAINING SUBSTITUTE PRODUCTS OR

SOFTWARE, CLAIMS BY OTHERS, INCONVENIENCE, OR ANY OTHER COSTS. IN ANY EVENT,

TPS SHALL HAVE NO LIABILITY FOR DAMAGES OR OTHERWISE TO YOU OR ANY OTHER

PERSON OR ENTITY IN EXCESS OF THE PURCHASE PRICE FOR THE PRODUCT.

License Agreement

Use of any computer programs or software supplied by TPS or downloaded from a TPS

website (the “Software”) in connection with the product constitutes acceptance of these

Terms and Conditions in this Manual and an agreement to abide by these Terms and

Conditions. The user is granted a personal, non-exclusive, non-transferable license to use

such Software under the terms stated herein and in any case only with a single product or

single computer. You may not assign or transfer the Software or this license without the

express written consent of TPS. This license is effective until terminated. You may terminate

the license at any time by destroying the Software and Manual. TPS may terminate the license

if you fail to comply with any of the Terms or Conditions. You agree to destroy the Software

and manual upon termination of the use of the product. All ownership, copyright and other

intellectual property rights in and to the Software belong to TPS. If these license terms are

not acceptable, return any unused software and manual.

Confidentiality

This Manual, its contents and the Software (collectively, the “Confidential Information”) are

the confidential and proprietary information of TPS. You agree to treat TPS’ Confidential

Information with a degree of care no less stringent that the degree of care you would use in

safeguarding your own most valuable trade secrets. Nothing in this paragraph shall restrict

you from disclosing Confidential Information to your employees as may be necessary or

appropriate to operate or care for the product. Such employees must also keep the

Confidentiality Information confidential. In the event you become legally compelled to

disclose any of the Confidential Information, you shall give TPS immediate notice so that it

may seek a protective order or other appropriate remedy.

Website; Other Statements

No statement contained at the TPS website (or any other website) or in any other

advertisements or TPS literature or made by an employee or independent contractor of TPS

modifies these Terms and Conditions (including the Software license, warranty and limitation

of liability).

Safety

Improper use of the product can lead to injury to persons or property and/or malfunction of

the product. The product should only be repaired by authorized TPS warranty service centers.

Users should review and heed the safety warnings in an Appendix.