Table of contents

Foreword

................................................................. 1

.................................................................1

Identification numbers ......................................................... 6

Presentation

............................................................ 7

............................................................ 7

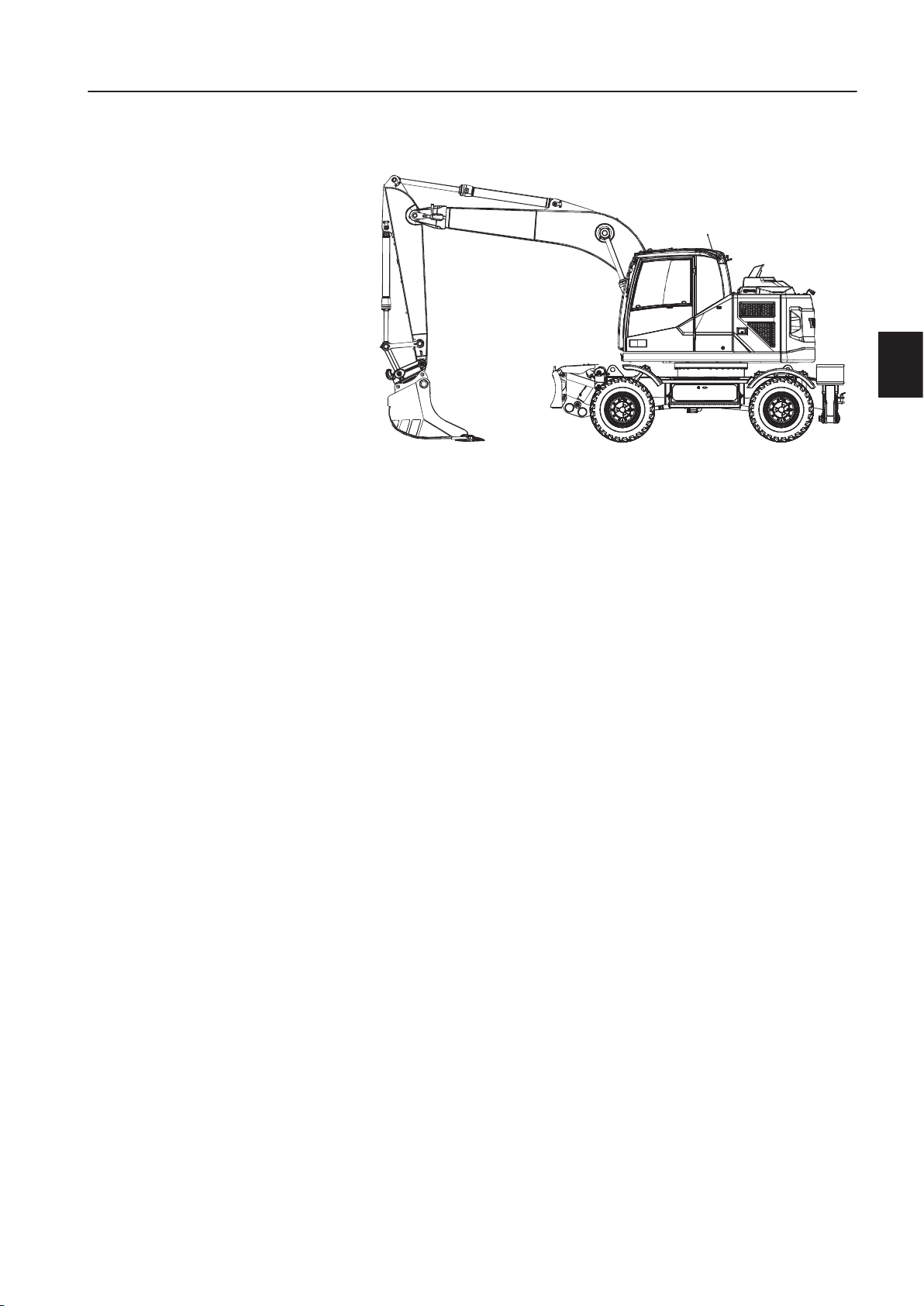

Machine view ..................................................................... 12

CE-marking, EMC-directive ............................................... 13

Communication equipment, installation ............................. 16

Safety components ............................................................ 17

Product plates ................................................................... 18

Information and warning decals ........................................ 19

Instrument panels

.................................................. 27

.................................................. 27

Instrument panel, left ......................................................... 28

Instrument panel, front ...................................................... 32

Display unit ........................................................................ 39

Instrument panel, right ....................................................... 67

Instrument panel, rear ....................................................... 75

Other controls ........................................................ 76

Other controls ........................................................ 76

Controls ............................................................................. 76

Cab .................................................................................... 83

Control lockout system ...................................................... 87

Operator comfort ............................................................... 88

Operating instructions

..........................................

..........................................

117

Safety rules when operating ............................................ 119

Measures before operating ............................................. 126

Starting engine ................................................................ 127

Hydraulic system, warming up ........................................ 131

Operating ......................................................................... 132

Braking ............................................................................ 133

Exhaust aftertreatment system ........................................ 135

Stopping .......................................................................... 144

Parking ............................................................................ 145

Retrieving and towing ...................................................... 147

Attachments, alternative lowering ................................... 151

Transporting machine ...................................................... 154

Operating techniques

..........................................

..........................................

159

Eco driving ....................................................................... 160

Whole-body vibrations ..................................................... 161

Rules for digging ............................................................. 163

Boom Suspension System (BSS) .................................... 165

Working within dangerous areas ..................................... 167

Attachments .................................................................... 173

Attachments, connecting and disconnecting ................... 181

Pressure release ............................................................. 191

Buckets ............................................................................ 192

Offset boom ..................................................................... 197

Hammer ........................................................................... 198

Lifting objects .................................................................. 200

Equipment towing ............................................................ 204

Signalling diagram ........................................................... 211

Table of contents