– While using the machine, do not allow any

persons within the working range.

– Check local regulations and contact Before You

Dig Australia (http://byda.com.au).

• Do not allow other persons to use the machine

before having informed them on the exact operation

and work instructions, and make sure that they

have read and fully understood the operator's

manual.

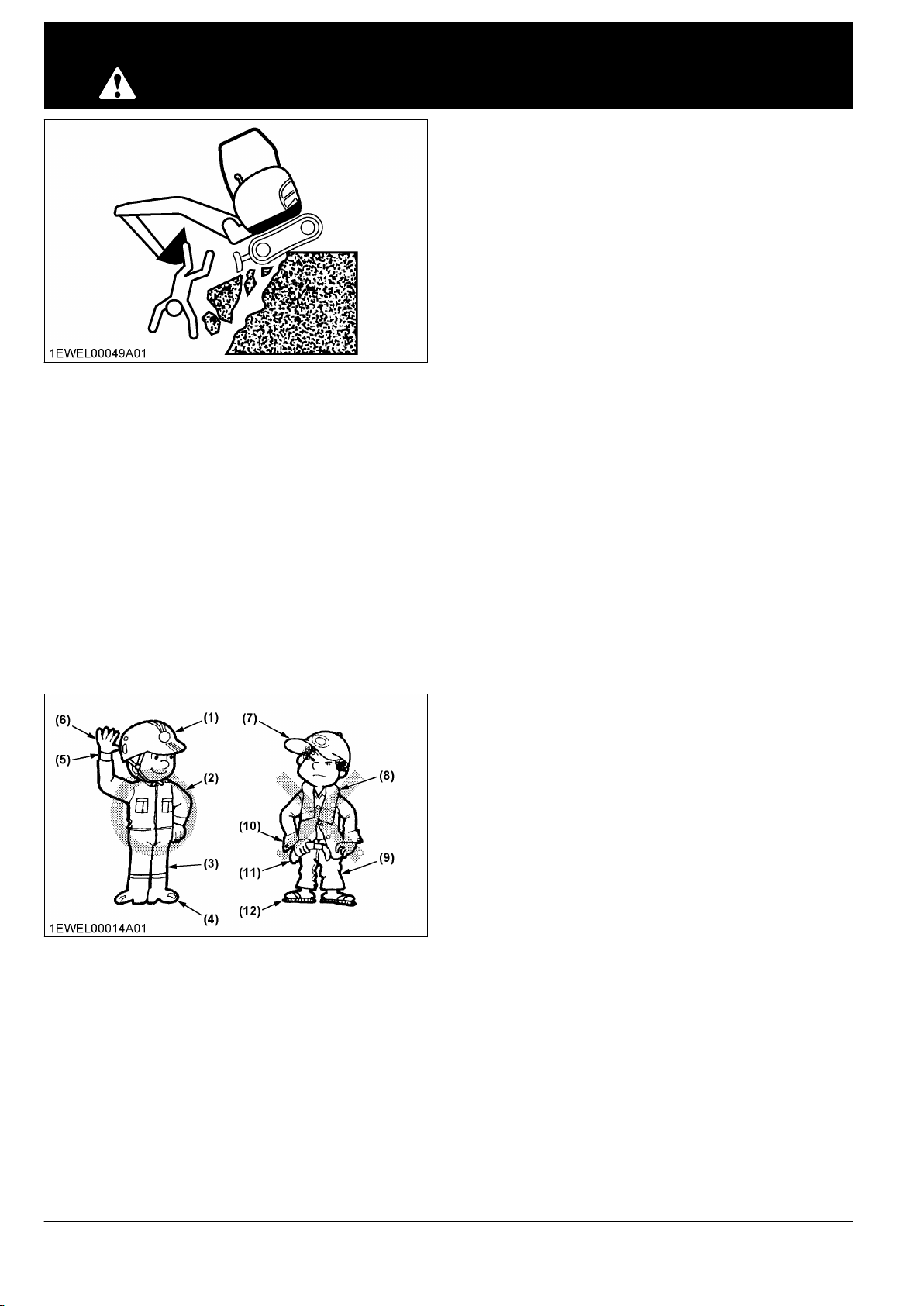

• Do not wear baggy, torn, or oversized clothing

when working with the machine. Clothing can get

caught in rotating parts or control elements,

resulting in accidents or injuries. Wear adequate

safety clothing, such as a safety helmet, safety

shoes, eye protection, ear protection, working

gloves, and so on, as necessary and as prescribed

by law or other standards or regulations.

(1) Helmet

(2) Clothing fit for work

(3) Tight seams

(4) Good grip footwear

(5) Well-fitting cuffs

(6) Working gloves

(7) Soft hat

(8) Towel

(9) Baggy trousers

(10) Loose cuffs of the shirt

(11) Baggy shirt

(12) Sandals or open-toed shoes

• Do not allow passengers to ride on any part of the

machine at any time. The operator must remain in

the machine seat during operation.

• Check mechanical parts for wear, and make sure

that they are correctly adjusted. Replace worn or

damaged parts immediately. Check nuts and bolts

regularly to make sure that they are tightened to the

correct torque.

• Keep your machine clean. Heavy soiling, grease,

dust and grass can cause fires, accidents or

injuries.

• Use only Kubota's authorized attachments.

• Before starting the machine, be absolutely sure that

the machine has been filled with fuel, lubricated,

greased, and undergone all necessary

maintenance.

• Do not modify the machine, otherwise it could lead

to unforeseen safety problems.

2. ROPS

• For your safety, a roll-over protective structure

(ROPS) with a seat belt is installed.

• Always use the seat belt when the machine is

equipped with a ROPS as this combination will

reduce the risk of serious injury or death in case of

machine tip-over or instability.

• Do not modify any structural members of the ROPS

by welding, drilling, bending, grinding or cutting, as

this may weaken the structure.

• If any component is damaged, replace it. Do not

attempt repairs.

• If the ROPS is loosened or removed for any reason,

make sure all parts are reinstalled correctly. Tighten

the mounting bolts to the proper torque.

• The ROPS meets the requirements of ISO 3471.

OPERATING THE EXCAVATOR

1. Starting to operate the machine

• Get into and out of the machine safely. Always face

the machine. Always use handrails and available

steps and keep yourself well balanced. Do not hold

any of the control levers or switches. Do not jump

on or off the machine, whether stationary or in

motion.

• Start and control the machine only from the

operator's seat. The driver should not lean out of

their seat when the engine is running.

• Before starting the engine, make sure that lock

levers are in the LOCK position, all control levers

and pedals are in their “NEUTRAL” positions, and

the seat belt is fastened correctly.

Before starting the engine, make sure that the

control levers, travel lever, pedals, and other control

elements are not stuck and can be moved

smoothly.

If stuck, for example, a lever may fail to return,

possibly putting the user in danger.

If anything wrong is found, immediately pinpoint the

cause and correct it.

• Do not start the engine by jumping the starter

connections.