6

CONTENTS

INTRODUCTION ................................................................................................................1

DISPLAYS FOR SAFE USE ...............................................................................................3

SAFETY CAUTIONS ..........................................................................................................4

MAINTENANCE..................................................................................................................4

ESCAPE CLAUSES............................................................................................................4

WARNING INDICATIONS AND POSITIONS......................................................................5

CONFIGURATION..................................................................................................................7

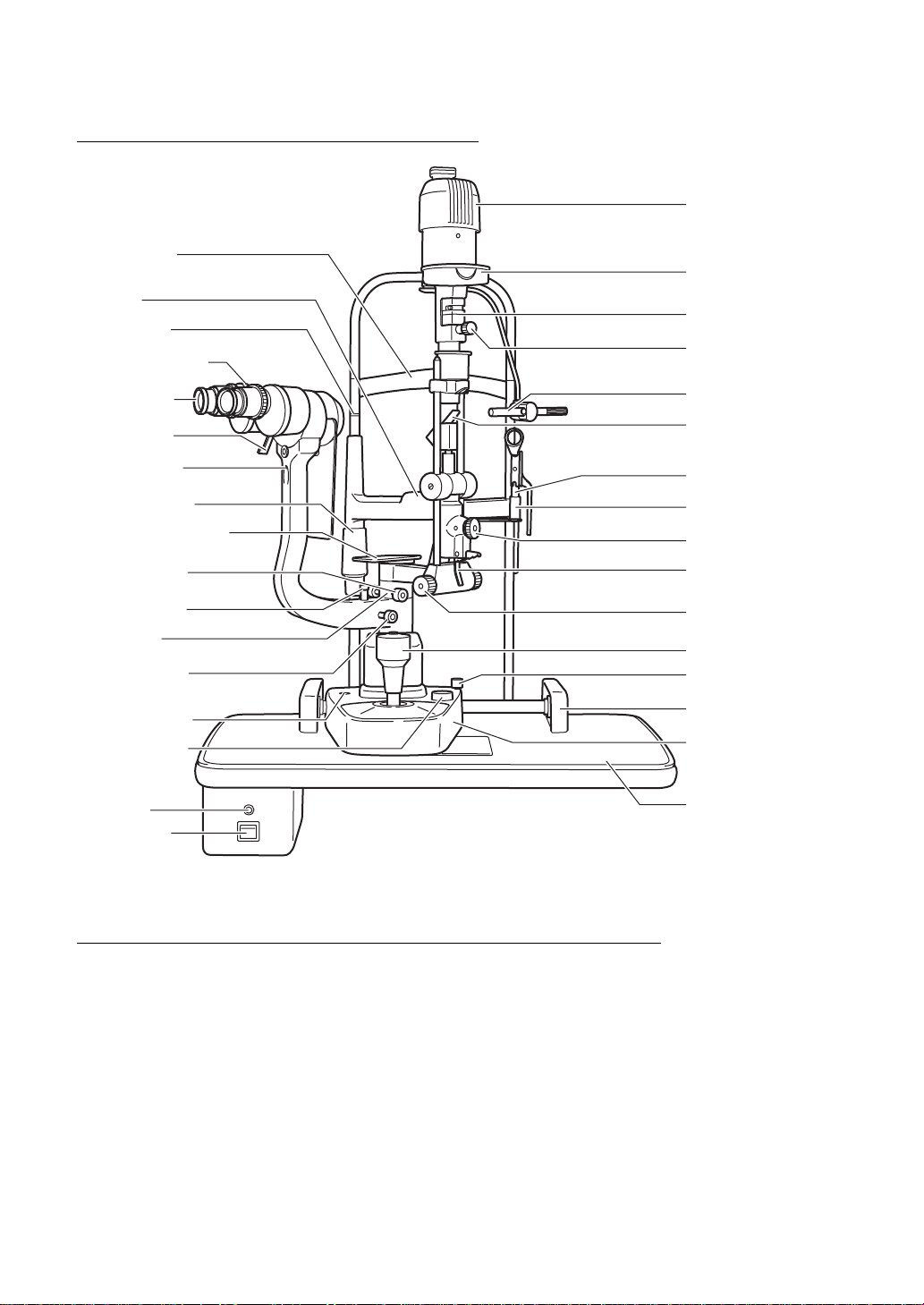

NAMES OF MAIN BODY COMPONENTS .........................................................................7

CONFIGURATION OF PARTS IN CONTACT WITH PATIENT...........................................7

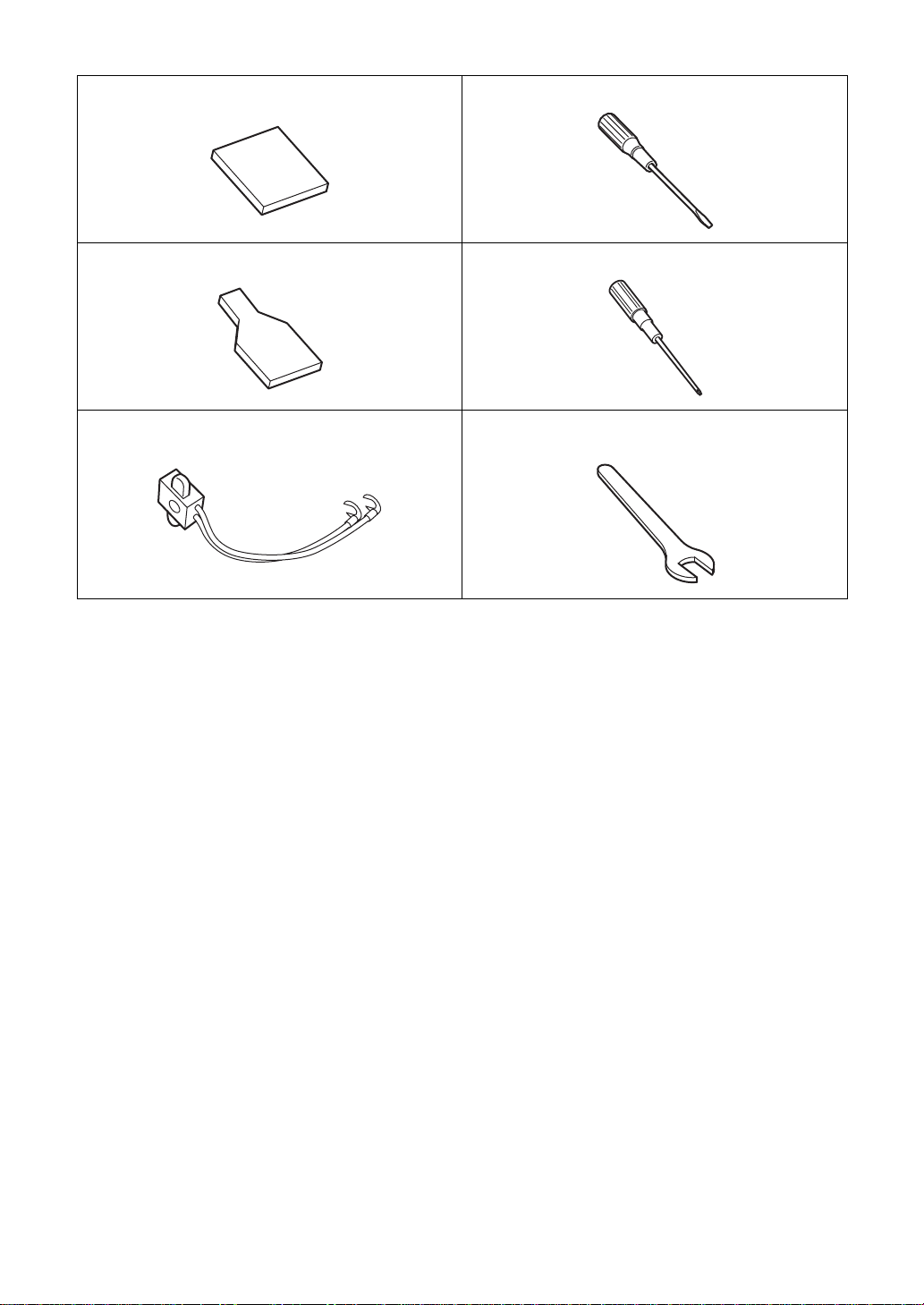

STANDARD ACCESSORIES .............................................................................................8

COMPONENTS.....................................................................................................................10

COMPONENTS................................................................................................................10

ASSEMBLY PROCEDURE ................................................................................................12

ASSEMBLY PROCEDURE...............................................................................................12

CHECKING PROCEDURE...............................................................................................18

OPERATION PROCEDURES ...........................................................................................19

PREPARATION-DIOPTER COMPENSATION AND INTERPUPILLARY

DISTANCE ADJUSTMENT...............................................................................................19

PATIENT POSITION AND FIXATION TARGET................................................................20

BASE OPERATION ..........................................................................................................21

OPERATION OF THE ILLUMINATION UNIT....................................................................22

FUNDUS OBSERVATION WITH THE HRUBY LENS (OPTION).....................................26

TROUBLESHOOTING.........................................................................................................27

TROUBLESHOOTING GUIDE .........................................................................................27

SPECIFICATIONS.................................................................................................................28

ELECTROMAGNETIC COMPATIBILITY..........................................................................30

SYSTEM CLASSIFICATION.............................................................................................34

PURPOSE OF USE..........................................................................................................34

OPERATION PRINCIPLE.................................................................................................34

SHAPE OF PLUG.............................................................................................................35

SYMBOL...........................................................................................................................35

MAINTENANCE.....................................................................................................................36

DAILY CARE.....................................................................................................................36

REPLACING THE BULB...................................................................................................36

REPLACING THE FUSE ..................................................................................................38

REPLACING THE CHINREST PAPER.............................................................................38

ADJUSTMENT OF THE SLIT WIDTH CONTROL KNOB ................................................38

ADJUSTMENT OF THE INCLINATION MOVEMENT ......................................................39

CLEANING........................................................................................................................39

ORDERING SUPPLIES....................................................................................................40

OPTIONAL ACCESSORIES..............................................................................................41

PACHOMETER ATTACHMENT........................................................................................41

10×MEASURING EYEPIECE...........................................................................................41

HRUBY LENS...................................................................................................................42

APPLANATION TONOMETER.........................................................................................42

AUTOMATIC INSTRUMENT TABLE AIT-15.....................................................................42