TOPMAQ GFW4013 User manual

1

Operator’s Manual

Metal Band Saw

MODEL:GFW4013

CAUTION: Read and follow all Safety Rules

and Operating Instructions before First Use

of this Product. Keep this manual with tools.

2

Technical Specification

Attention: Please choose proper power source, voltage and frequency that are shown in the label for your

metal band saw.

Metal band saw GFW4013

Motor Power 400 W S6 30%

Saw Blade 1435 X 12.7 X 0.65 mm

Saw Blade Teeth 8/12 teeth per inch

Cutting Capacity at Square Material 90

º127 X 125 mm

45 º 76x76mm

Cutting Capacity at circular Material 90

º125 mm

45 º 76mm

Cutting Angle Adjustment 0—60 º

Blade Speed 38-80 m/min

SAFETY

WARNING:To avoid electrical hazards, fire hazards, or damage to the tool, use proper circuit protection.

Use a separate electrical circuit for your tools. To avoid shock or fire, replace power cord immediately if it is worn, cut or

damaged in any way.

GENERAL SAFETY INSTRUCTIONS

WARNING:Read carefully these Operating Instructions. Familiarise with the controls and proper use of the

machine. Keep the Operating Instructions for future reference. The warning labels with instructions attached to

the machine provide important information on safe operation.

1. READ and become familiar with the entire Operator’s Manual. LEARN the tool’s application, limitations and possible

hazards.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of checking to see that keys and adjusting wrenches are

removed from the tool before turning ON.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

5. KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

6. MAKE WORKSHOP CHILDPROOF with padlocks.

7. DON’T FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed.

8. USE THE RIGHT TOOL. Do not force tool or attachment to do a job for which it was not designed.

9. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will result in a drop in

line voltage and in loss of power that will cause the tool to overheat.

10. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that may get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS WEAR EYE PROTECTION. Wear goggles for protection against projected chips.

12. DISCONNECT TOOLS before servicing; when changing blade and other part.

13. USE RECOMMENDED ACCESSORIES. Consult the Operator’s Manual for recommended accessories. The use of

improper accessories may cause serious injury.

3

14. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

15. CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function – check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced.

16. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER “OFF”. Don’t leave tool until it comes to a complete

stop.

17. DON’T OVERREACH. Keep proper footing and balance at all times.

18. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

19. DO NOT use power tools in the presence of flammable liquids or gases.

20. NEVER REMOVE GUARD, SAFETY DIVICES OR ART OF THE MACHINE.

21. BE CAREFUL. Pay attention to what you are doing. Work reasonably. Do not use the machine when you are tired.

22. HAVE YOUR MACHINE REPAIRED BY AN EXPERT ONLY!This machine meets the applicable safety provisions. Any

repairs may only be executed by an expert, using original spare parts; otherwise, the user could face a risk of injury.

23. Children and persons not familiarised with the machine and persons with limited physical, sensory and mental skills must

not use the machine.

SPECIFIC SAFETY INSTRUCTIONS FOR THE MACHINE

1. Secure the machine to a bench before operating.

2. The machine must be switched off before inserting material to be cut in the vice or before removing material to be cut

from the vice.

3. Keep your hands and fingers in a safe distance from the running saw blade at all times.

4. The saw blade must not be broken by hand.

5. Safety equipment and guards, etc, must not be removed.

6. Never remove the cutting chips by hand. Use a brush at all times.

7. Never leave the machine when in operation.

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR SPECIFICATIONS

WARNING: To avoid electrical hazards, fire hazards, or damage to the tool, use proper circuit protection. Use a

separate electrical circuit for your tools. To avoid shock or fire, if power cord is worn or cut, or damaged in any way, have it

replaced immediately.

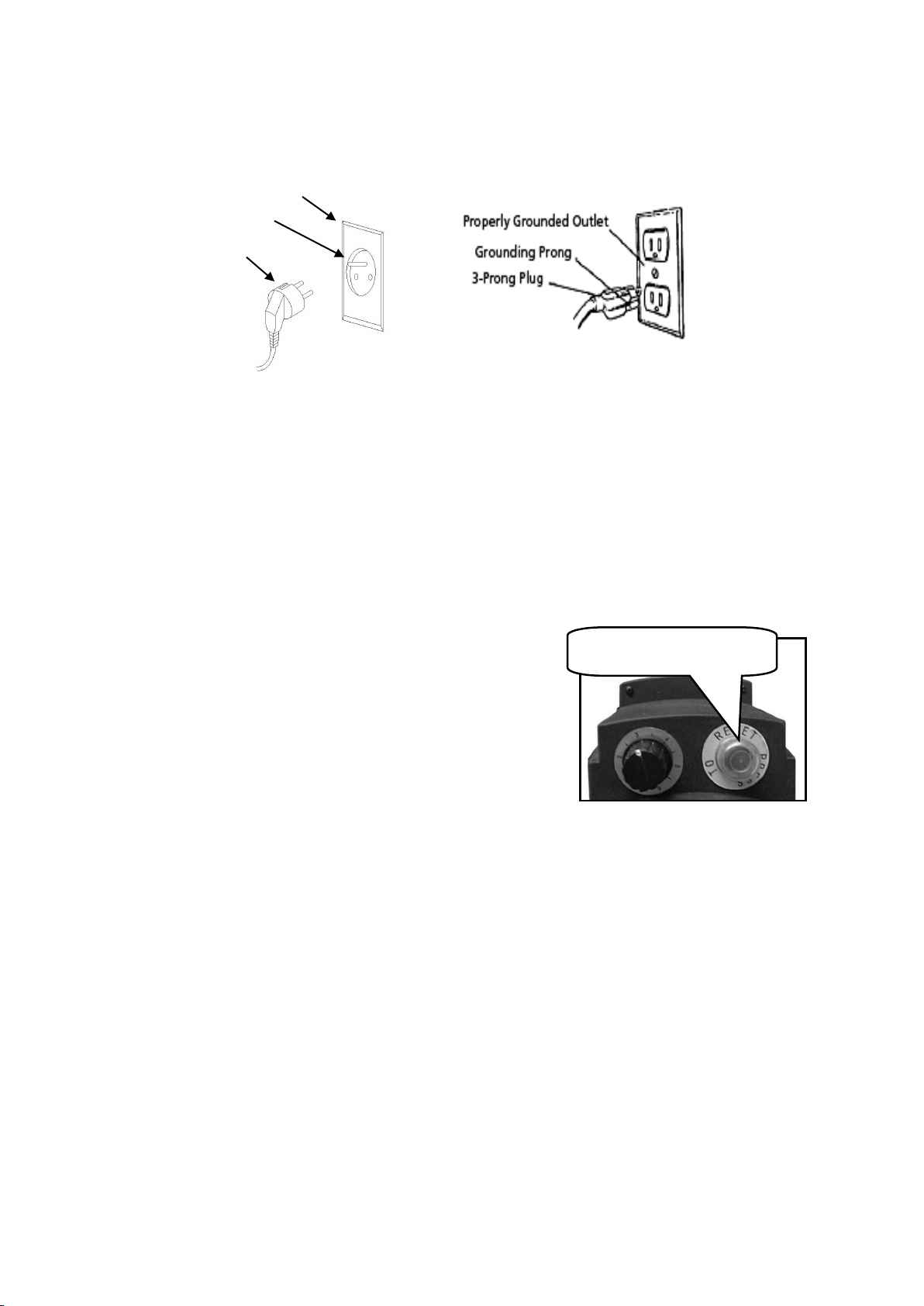

GROUNDING INSTRUCTIONS

WARNING: This tool must be grounded while in use to protect the operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides a path of least resistance for electric current

and reduces the risk of electric shock. This tool is equipped with an electric cord that has an equipment-grounding conductor

and a grounding plug. The plug MUST be plugged into a matching receptacle that is properly installed and grounded in

accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the receptacle, have the proper receptacle installed by a qualified

electrician.

IMPROPER CONNECTION of the equipment-grounding conductor can result in risk of electric shock. The conductor with

green insulation (with or without yellow stripes) is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, DO NOT connects the equipment-grounding conductor to a live terminal.

4

CHECK with a qualified electrician or service person if you do not completely understand the grounding instructions, or if you

are not sure the tool is properly grounded.

Refer to nether picture:

Properly Ground Outlet

Grounding Prong

3-Prong Plug

WARNING: Improper connection of equipment grounding conductor can result in the risk of electrical shock. Equipment

should be grounded while in use to protect operator from electrical shock.

WARNING: This machine is for indoor use only. Do not expose to rain or use in damp locations.

GUIDELINES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line

voltage, resulting in loss of power and cause overheating.

Be sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it. Protect your extension cords from sharp objects, excessive heat and damp or

wet areas.

Attention: There is an overcurrent protection device

in the circuit.

ACCESSORIES AND ATTACHMENTS

RECOMMENDED ACCESSORIES

WARNING: To avoid injury:

• Use only accessories recommended for machine.

• Follow instructions that accompany accessories. Use of improper accessories may cause hazards.

• Use only accessories designed for this machine to avoid injury from thrown broken parts or work pieces.

• Do not use any accessory unless you have completely read the instruction or operator’s manual for that

accessory.

Overcurrent protection

5

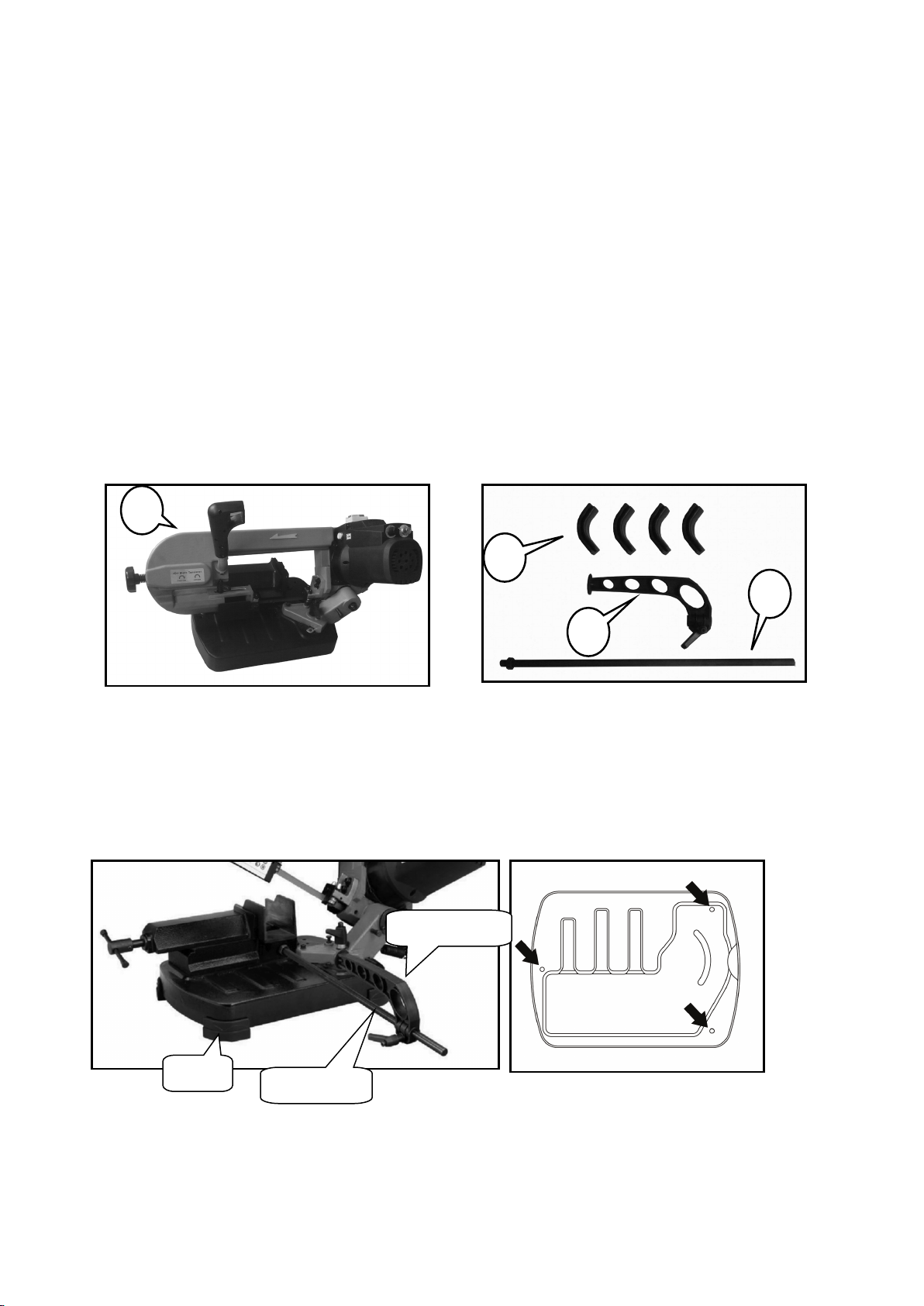

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Carefully unpack the machine and all its parts, and compare against the illustration following.

WARNING:

• To avoid injury from unexpected starting, do not plug the power cord into a power source receptacle during unpacking and

assembly. This cord must remain unplugged whenever you are assembling or adjusting the machine.

• If any part is missing or damaged, do not plug machine in until the missing or damaged part is replaced, and assembly is

complete.

TABLE OF LOOSE PARTS

Unpack carton; check you machine to see parts listed below:

1. Metal band saw X1

2. Foot X4

3. Work stop with lock handle X1

4. Guide rail with hex nut X1

ASSEMBLY AND INSTALLATION

1. Attach four feet to base.

2. Place the machine on a work bench, secure it by using 3 holes provided on the base.

3. Screw the guide rail to the thread hole on vise base. Tighten the nut to fix it,

4. Attach the work stop to the guide rail, secure it by tightening the lock handle

1

2

3

4

Foot

Guide rail

Work stop

6

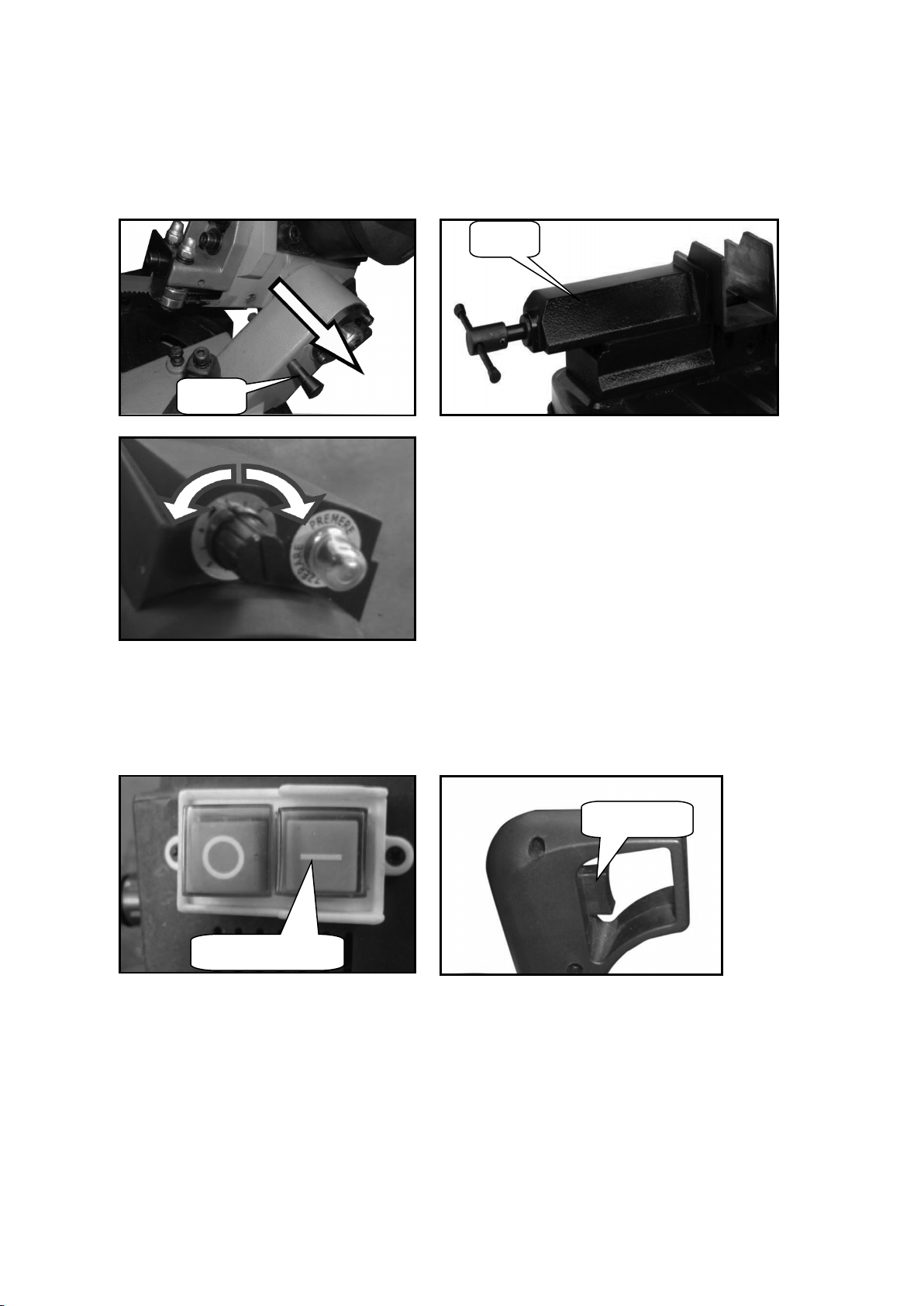

ADJUSTMENTS

1. Positioning the work stop

Use the work stop supplied if you have to do several cuts on

pieces of the same length.

Loosen the lock handle A,place the work stop at the desired

distance from the blade.

Tighten the lock handle Aagain.

CAUTION! Make sure that the length stop does not

interfere with the downward movement of the blade.

2. Cutting angle adjustment

The band saw can cut at an angle varying from 0º

to 60º.

Loosen the lock handle B, turn the swivel support

until the mark on support matches desired angle

on the scale. Then lock the swivel support again

CAUTION! Make sure the lock handle B has

been tightened before turning on the machine.

3. Sliding blade guide

The sliding blade guide must be adjusted before

cutting a different workpiece. If the adjustment is

not done, it would result in an unclean cut.

Loosen the lock handle C, Slide the blade guide to

move it closer to the workpiece then retighten the

lock handle C.

4. Cutting speed

The cutting speed always depends on the material being

cut.

To select the most suitable speed, turn the control knob Dto

increase or decrease the speed as you require.

Example:

Common steel: 40-60m/min

Aluminum, alloy; 80m/min

Pipes/sections: 70-80m/min

A

B

Swivel support

CC

D

7

OPERATION

1. Pull out the pin from the hole in the body and tilt the saw body to upper position.

Use the vice clamping the workpiece,

Adjust the cutting speed.

2. Push the green button to turn on the main switch, using the index finger of your right hand, press the

run button.

Gradually lower the machine body until it comes lightly into contact with the workpiece.

Now begin to apply gradual pressure on the workpiece and complete the cut.

Pin

Vice

Push to turn on

Run button

8

MAINTENANCE

Warning: Turn off the machine and disconnect from the power supply before conducting maintenance

work or settings.

Change the saw blade

Caution! Always wear protective gauntlets before changing saw blade.

Remove the protective casing unscrewing the six screw

Loosen the blade tension, turning the knob E in the anti-clockwise direction.

Extract the blade first from the guides and then from the cast iron pulleys, check to make sure the

blade teeth are facing toward the work piece.

Insert the new blade first between the guides and then into the cast iron pulleys.

Turn the knob E, adjust the blade tension.

Replace the protective casing.

Reposition the blade guides in the correct position for next cut.

Machine care

Usually check the condition of the power supply cords and replace them if they are broken, or even

worse if the internal wires are shown.

Use a brush and a shop vacuum to remove chips and other debris from the machine.

Always keep the machine handgrip clean to prevent accidental slipping during use.

Remove the processing residues from the cutting area and the blade guides whenever necessary.

If you do not intend to use the sawing machine for a long time, clean it and put it in a dry place if

possible. In these cases it is advisable to slacken off the blade so that it is not kept for any reason.

To ensure effective machine operation, check the condition of the blade daily and sharpen it

whenever necessary.

E

9

TROUBLESHOOTHING

PROBLEM

CAUSE

SOLUTION

The motor does not work Defective motor, power cable or

plug

The overload cutout has tripped

Specialized personnel should

check the machine

Reset the overload cutout.

Overload cutout tripped Motor overload caused by

excessive cutting pressure

Motor breakdown

Perform the cut on the piece at

the correct pressure

Specialized personnel should

check the machine

Inaccurate cut squaring Excessive cutting pressure

Incorrect blade tooth in relation to

the workpiece

Incorrect adjustment of the

sliding blade guide

Incorrect cutting speed in relation

to work piece

The workpiece is wrongly

positioned in the vice

Poor blade tension.

Decrease cutting pressure

Chose proper blade for

workpiece

Check blade guide adjustment

Adjust to correct cutting speed

Check workpiece positioning

and clamping in the vice

Check blade tension

The blade tends to protrude

from the guide

Excessive blade tension

Incorrect eccentric blade guide

adjustment

The blade slips on the pulleys,

caused by oil or grease required

for cutting operations

Check blade tension

Check eccentric blade guide

adjustment

Never use any type of lubricant

or coolant for the cutting

operations; specialized personnel

should check and replace the

pulleys, if necessary,

10

ASSEMBLY DIAGRAM

Table of contents

Other TOPMAQ Saw manuals