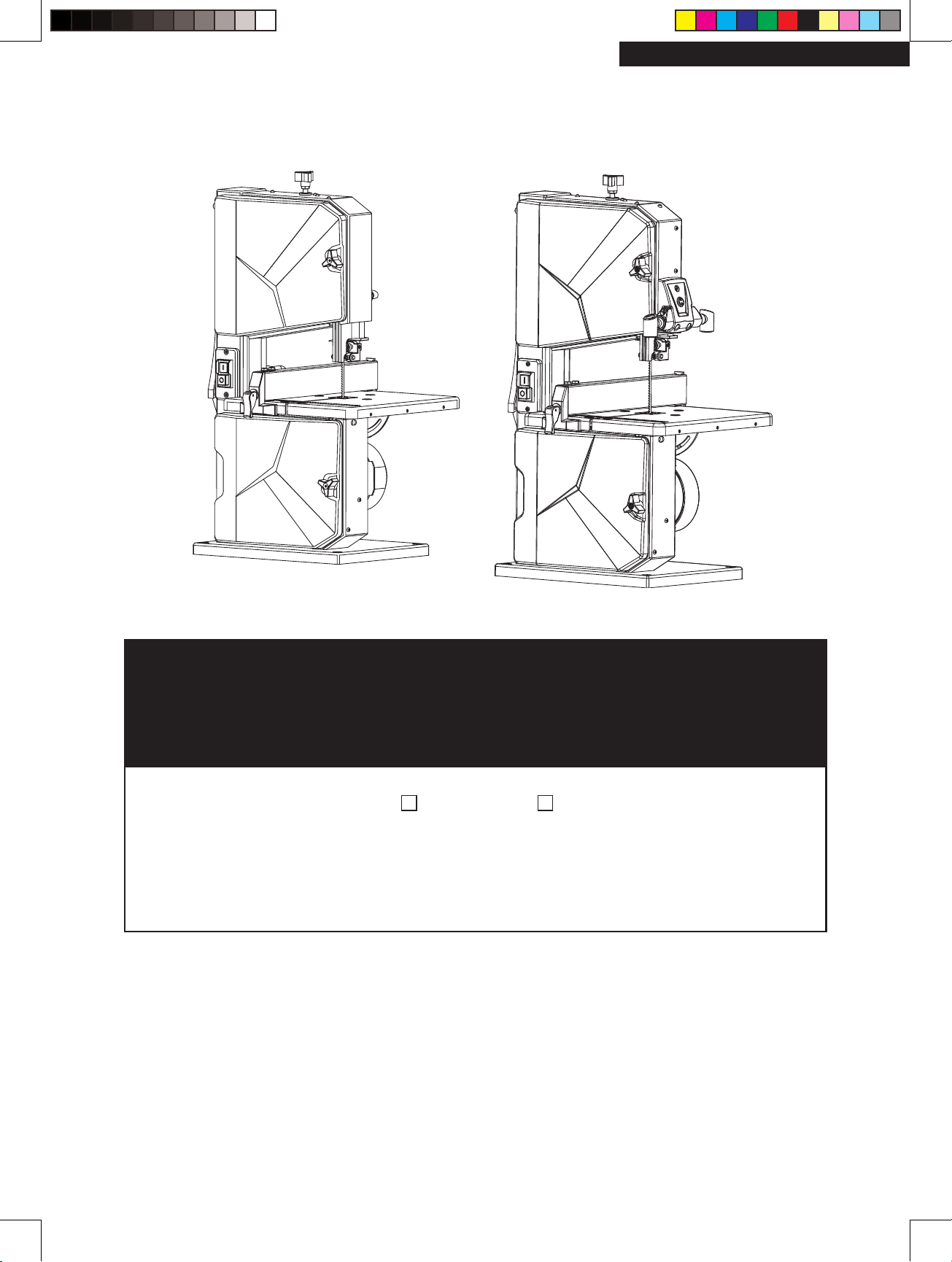

TOPMAQ 65160 User manual

Save This Manual for Future Reference

Original Instructions

Band Saw

Operator’s Manual

MODEL NUMBER : 65160 65160A

SERIAL NUMBER :

Both model number and serial number may be found on the main

label. You should record both of them in a safe place for future use.

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE

OPERATING MACHINE

BAND SAW

2

GB TABLE OF CONTENTS

INTRODUCTION

Introduction 2

Specifications 2

Symbols 3

Safety 3

Specific Safety Rules 4

Contents Supplied 7

Assembly 8

Know your Machine 9

Features & Controls 9

Set Up 11

Operation 12

Maintenance 14

Transport 18

Storage 18

Wiring Diagram 18

Trouble Shooting 19

Parts Schedule 20

Parts List 21

Your new band saw will more than satisfy your

expectations. It has been manufactured under

stringent quality standards to meet superior

performance criteria. You will find it easy and

safe to operate, and with proper care, it will

give you many years of dependable service.

Carefully read through this entire

operator’s manual before using your

new band saw. Take special care to

heed the cautions and warnings.

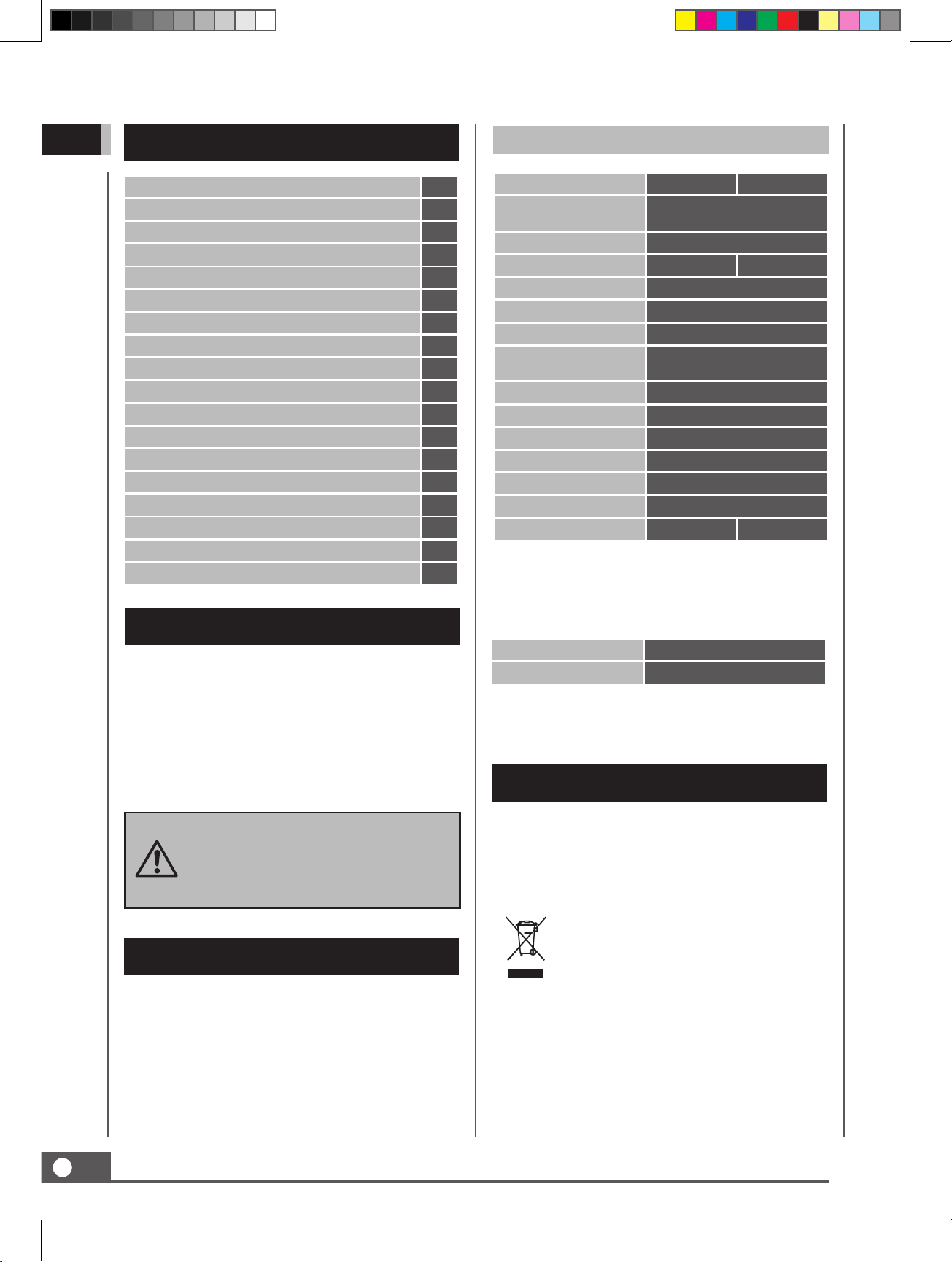

Specifications

Model Number 65160 65160A

AC Motor 230-240V 50Hz, n0

1487 min-1

Power P (S2 15min)* 250W

Lamp None 6.4V DC, 1W

Protection Category IP 20

Safety Class I

Throat Capacity

195 mm

Max. Cutting Height

80 mm @ 90°

45 mm @ 45°

Blade Wheel Dia. 205 mm

Blade Length 1400 mm

Blade Width: 3.5-12 mm

Cutting Speed 950 m/min

Table Size 302×304 mm

Table Tilt 90° - 45°

Weight 16.9 kg 17.5 kg

* S2, Short-time duty. After continuous operation of

15 minutes the machine stops until the device tem-

perature deviates by less than 2 K (2°C) from the room

temperature.

Sound pressure level (LpA) 82.6 db(A)* k=3 db(A)

Sound power level (LwA) 93.6 db(A)* k=3 db(A)

* The noise was measured according to EN 61029-2-

5:2011+A11.

This band saw is designed for operating under

ambient temperatures between +5°C and

40°C and for installation at altitudes no more

than 1000m above M.S.L. The surrounding

humidity should less than 50% at 40°C. It

can be stored or transported under ambient

temperatures between -25°C and 55°C.

APPLICATION CONDITIONS

RECYCLING AND DISPOSAL

This marking indicates that this

product should not be disposed with

other household wastes. To prevent

possible harm to the environment

or human health from uncontrolled

waste disposal, recycle it responsibly

to promote the sustainable reuse of

material resources. To return your

used device, please use the return

and collection systems or check with

your local authority or local stores

for advice of environmental safe

recycling.

BAND SAW 3

GB

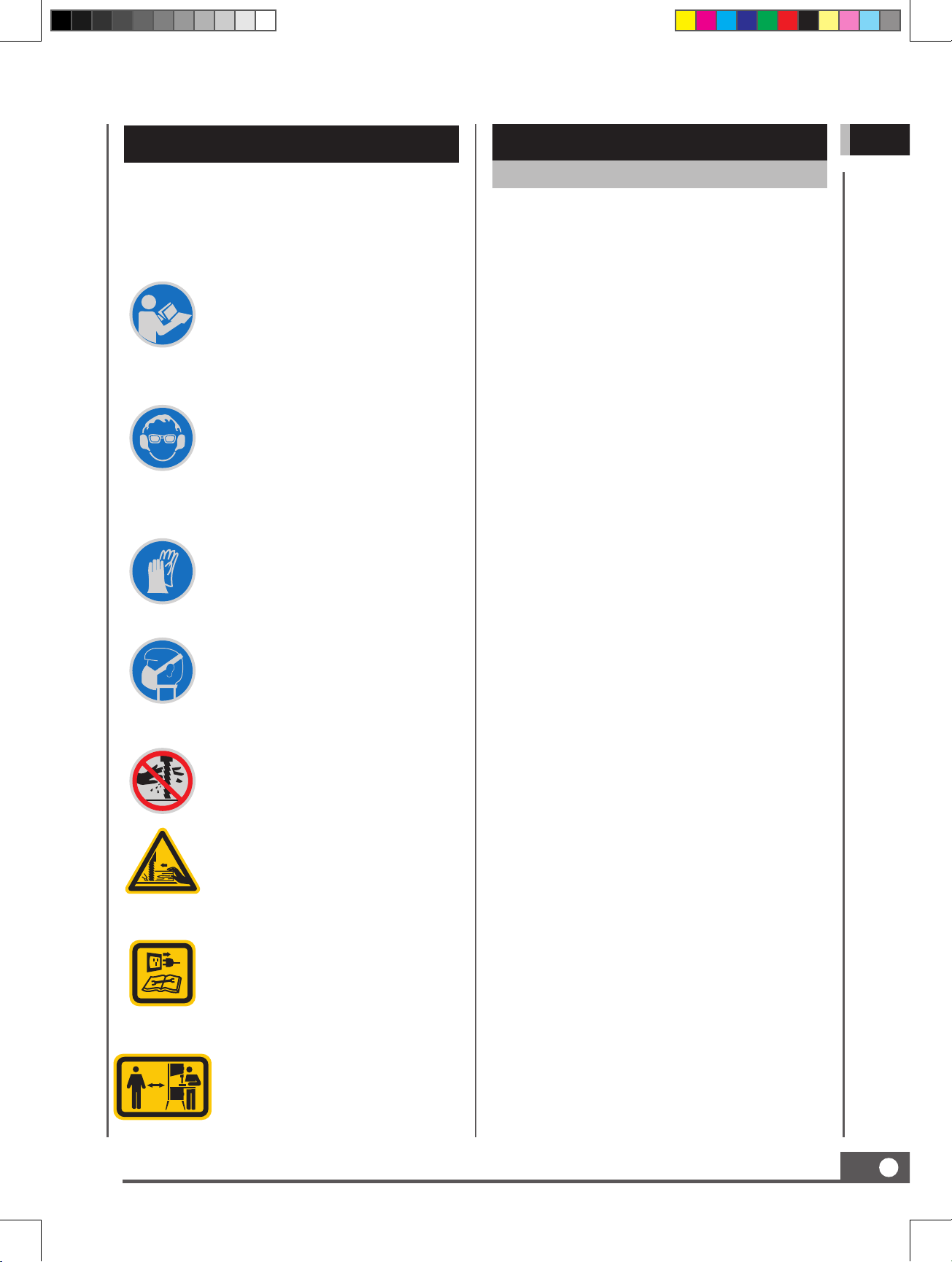

SYMBOLS

The rating plate on your machine may

show symbols. These represent important

information about the product or instructions

on its use.

Read these instructions for use

carefully.

Caution! Wear ear-muffs. The

impact of noise can cause damage

to hearing.

Caution! Wear safety goggles.

Sparks generated during working

or splinters, chips and dust

emitted by the device can cause

loss of sight.

Wear protective gloves.

Caution! Wear a breathing mask.

Dust which is injurious to health

can be generated when working

on wood and other materials.

Never use the device to work on

any materials containing asbestos!

Caution! Risk of injury! Failure

to keep your hands away from

the blade will result in serious

personal injury.

The machine must be

disconnected from the supply

before maintenance! Disconnect

the mains plug prior to the repair,

cleaning, and maintenance of

the saw!

Keep children and bystanders off

and away.

SAFETY

General Safety Rules

Understand your Machine

Read this manual and labels affixed to the

machine to understand its limitations and

potential hazards.

Be thoroughly familiar with the controls and

their proper operation. Know how to stop the

machine and disengage the controls quickly.

Do not attempt to operate the machine until

you fully understand how to properly operate

and maintain the engine and how to avoid

accidental injuries and/or property damage.

If the unit is to be used by someone other than

original purchaser or loaned, rented, or sold,

always provide this manual and any needed

safety training before operation. The user can

prevent and is responsible for accidents or

injuries that may occur to themselves, other

people, and property.

Do not force the machine. Use the correct

machine for your application. The correct

machine will do the job more efficiently and

safer at the rate it was designed.

Personal Safety

warning! The use of any accessory or

attachment other than one recommended in

this instruction manual may present a risk of

personal injury.

Do not permit children to operate this machine

at any time.

Keep children, pets, and other people not

using the unit away from the work area. Be

alert and shut off unit if anyone enters work

area. Keep children under the watchful care of

a responsible adult.

Do not operate the machine while under the

influence of drugs, alcohol, or any medication

that could affect your ability to use it properly.

Dress properly. Wear heavy long pants, boots,

and gloves. Do not wear loose clothing, short

pants, or jewelry of any kind. Secure long hair

so it is above shoulder level. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

BAND SAW

4

GB Protect eyes, face, and head from objects that

may be thrown from the unit. Always wear

safety goggles or safety glasses with side

shields when operating.

Wear appropriate hearing protection. Wear

respiratory protection to avoid the risk of

inhaling harmful dust.

Always keep hands and feet away from all

moving parts during operation. Moving parts

can cut or crush body parts.

Always keep hands and feet away from all

pinch points.

Do not touch parts that might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust, or service.

Stay alert, watch what you are doing, and use

common sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or

similar lightweight footwear. Wear protective

footwear that will protect your feet and

improve your footing on slippery surfaces.

Keep proper footing and balance at all times.

This enables better control of the machine in

unexpected situations.

Inspect your Machine

Check your machine before starting it. Keep

guards in place and in working order. Make

sure all nuts, bolts, etc., are securely tightened.

Never operate the machine when it is in need

of repair or is in poor mechanical condition.

Replace damaged, missing, or failed parts

before using it. Keep the machine in safe

working condition. Regularly check to see that

keys and adjusting wrenches are removed

from the machine area before starting it. A

wrench or a key that is left attached to a

rotating part of the machine may result in

personal injury. Avoid accidental starting.

Be sure the motor switch is off before

transporting the machine or performing any

maintenance or service on the unit.

Transporting or performing maintenance

or service on a machine with its switch on

invites accidents. If the machine should start

to vibrate abnormally, stop the motor and

check immediately for the cause. Vibration is

generally a warning sign of trouble.

Electric Safety

Avoid use of free and inadequately insulated

connections. Connections must be made with

protected material suitable for outdoor use.

Protect yourself from electric shock. Do not

plug or unplug the motor while standing in or

around damp or wet ground. Do not use the

unit in wet or damp areas or expose it to rain.

Prevent body contact with grounded surfaces:

pipes, radiators, ranges, and refrigerator

enclosures. Make sure your fingers do not

touch the plug’s metal prongs when plugging

or unplugging the unit.

Avoid inadvertent starting. Make sure that the

switch is switched off when plugging the plug

into an outlet.

Only use approved and appropriately

identified extension cables for use outdoors.

Only use cable reels in the unrolled state.

Do not use the cable for purposes for which

it is not intended. Do not use the cable to pull

the plug out of the outlet. Protect the cable

from heat, oil and sharp edges.

Never yank the cord to disconnect it from the

socket.

Have your electric tool repaired by a qualified

electrician. This electric tool conforms to the

applicable safety regulations. Repairs may

only be performed by an electrician using

original spare parts. Otherwise accidents can

occur.

Work Area & Store Area

Keep the work area orderly. Disorder in the

work area can lead to accidents.

Take environmental influences into account.

Do not expose electric tools to rain. Do

not use electric tools in a damp or wet

environment. Make sure that the work area

is well-illuminated. Do not use electric tools

where there is a risk of fire or explosion.

Securely store unused electric tools. Unused

electric tools should be stored in a dry,

elevated or closed location out of the reach of

children.

Insure sufficient lighting in the work area and

the area around the machine.

BAND SAW 5

GB

Specific Safety Rules

Intended Use

The band saw is designed to perform

longitudinal and cross cuts on timber or

wood-type materials. To cut round materials

you must use suitable holding devices. The

equipment is to be used only for its prescribed

purpose. Any other use is deemed to be

a case of misuse. The user / operator and

not the manufacturer will be liable for any

damage or injuries of any kind caused as a

result of this. The machine is to be operated

only with suitable saw blades. To use the

machine properly you must also observe the

safety regulations, the assembly instructions

and the operating instructions to be found in

this manual. All persons who use and service

the machine have to be acquainted with

this manual and must be informed about

the machine’s potential hazards. It is also

imperative to observe the accident prevention

regulations in force in your area. The same

applies for the general rules of occupational

health and safety.

Machine Use and Care

The manufacturer shall not be liable for any

changes made to the machine nor for any

damage resulting from such changes. Even

when the machine is used as prescribed it is

still impossible to eliminate certain residual

risk factors. The following hazards may arise

in connection with the machine’s construction

and design:

● Damage to hearing if ear-muffs are not used

as necessary.

● Harmful emissions of wood dust when used

in closed rooms.

● Contact with the blade in the uncovered

cutting zone.

● Injuries (cuts) when changing the blade.

● Injury from catapulted workpieces or parts

of work-pieces.

● Crushed fingers.

● Kickback.

● Tilting of the workpiece due to inadequate

support.

● Touching the blade.

● Catapulting of pieces of timber and

workpieces.

Please note that our equipment has not been

designed for use in commercial, trade or

industrial applications. Our warranty will be

voided if the machine is used in commercial,

trade or industrial businesses or for equivalent

purposes.

Risk of kickback (workpiece is caught by

the band saw blade and thrown against the

operator)! Do not jam workpieces. Cut thin

or thin-walled workpieces only with fine-

toothed saw blades. Always use sharp band

saw blades. If in doubt, check workpiece

for inclusion of foreign matter (e.g. nails

or screws). Cut only stock of dimensions

that allow for safe and secure holding while

cutting. Never cut several workpieces at the

same time, and also no bundles containing

several individual pieces. Risk of personal

injury if individual pieces are caught by the

band saw blade uncontrolled. When cutting

round stock, use a suitable jig to prevent the

workpiece from turning.

Maintain Tools with Care

Keep cutting tools sharp and clean for better

and safer performance.

Follow instruction for lubricating and changing

accessory.

Inspect tool cords periodically and if damaged

have them repaired by an authorized service

facility.

inspect extension cords periodically and

replace if damaged.

Keep handles dry, clean and free from oil and

grease.

Maintenance and Repair

Pull out the mains plug for any adjustment or

repair tasks.

The generation of noise is influenced by

various factors, including the characteristics

of saw blades, condition of saw blade and

electric tool. Use saw blades which were

designed for reduced noise development,

insofar as possible. Maintain the electric

tool and tool attachments regularly and if

necessary, initiate repairs in order to reduce

noise.

BAND SAW

6

GB Report faults on the electric tool, protective

devices or the tool attachment to the person

responsible for safety as soon as they are

discovered.

Check the electric tool for potential damage.

Protective devices and other parts must be

care-fully inspected to ensure that they are

fault-free and function as intended prior to

continued use of the electric tool. Check

whether the moving parts function faultlessly

and do not jam or whether parts are dam-aged.

All parts must be correctly mounted and all

conditions must be fulfilled to ensure fault-

free operation of the electric tool. The moving

protective hood may not be fixed in the open

position. Damaged protective devices and

parts must be properly repaired or replaced

by a recognized workshop, insofar as nothing

different is specified in the operating manual.

Damaged switches must be replaced at a

customer service workshop. Do not use any

faulty or damaged connection cables. Do

not use any electric tool on which the switch

cannot be switched on and off.

Additional safety instructions

● Wear safety gloves whenever you carry out

any maintenance work on the blade!

● When cutting round or irregularly shaped

wood, use a device to stop the workpiece

from twisting.

● When cutting boards in upright position, use

a device to prevent kick-back.

● A dust extraction system designed for an

air velocity of 20 m/s should be connected

in order to comply with woodworking dust

emission values and to ensure reliable

operation.

● Give these safety regulations to all persons

who work on the machine.

● Do not use this saw to cut fire wood.

● The machine is equipped with a safety

switch to prevent it being switched on again

accidentally after a power failure.

● Before you use the machine for the first time,

check that the voltage marked on the rating

plate is the same as your mains voltage.

● If you use a cable reel, the complete cable

has to be pulled off the reel.

● Persons working on the machine should not

be distracted.

● Note the direction of rotation of the motor

and blade.

● Never dismantle the machine's safety

devices or put them out of operation.

● Never cut workpieces which are too small to

hold securely in your hand.

● Never remove loose splinters, chips or

jammed pieces of wood when the saw blade

is running.

● It is imperative to observe the accident

prevention regulations in force in your area

as well as all other generally recognized

rules of safety.

● Note the information published by your

professional associations.

● Adjustable protective devices have to

be adjusted as close as possible to the

workpiece.

● Important! Support long workpieces (e.g.

with a roller table) to prevent them sagging

at the end of a cut.

● Make sure the blade guard (3) is in its lower

position when the saw is being transported.

● Safety guards are not to be used to move or

misuse the machine.

● Blades that are misshapen or damaged in

any way must not be used.

● If the table insert is worn, replace it.

● Never operate the machine if either the

door protecting the blade or the detachable

safety device are open.

● Ensure that the choice of blade and the

selected speed are suitable for the material

to be cut.

● Do not begin cleaning the blade until it has

come to a complete standstill.

● For straight cuts of small workpieces against

the longitudinal limit stop the push stick has

to be used.

BAND SAW 7

GB

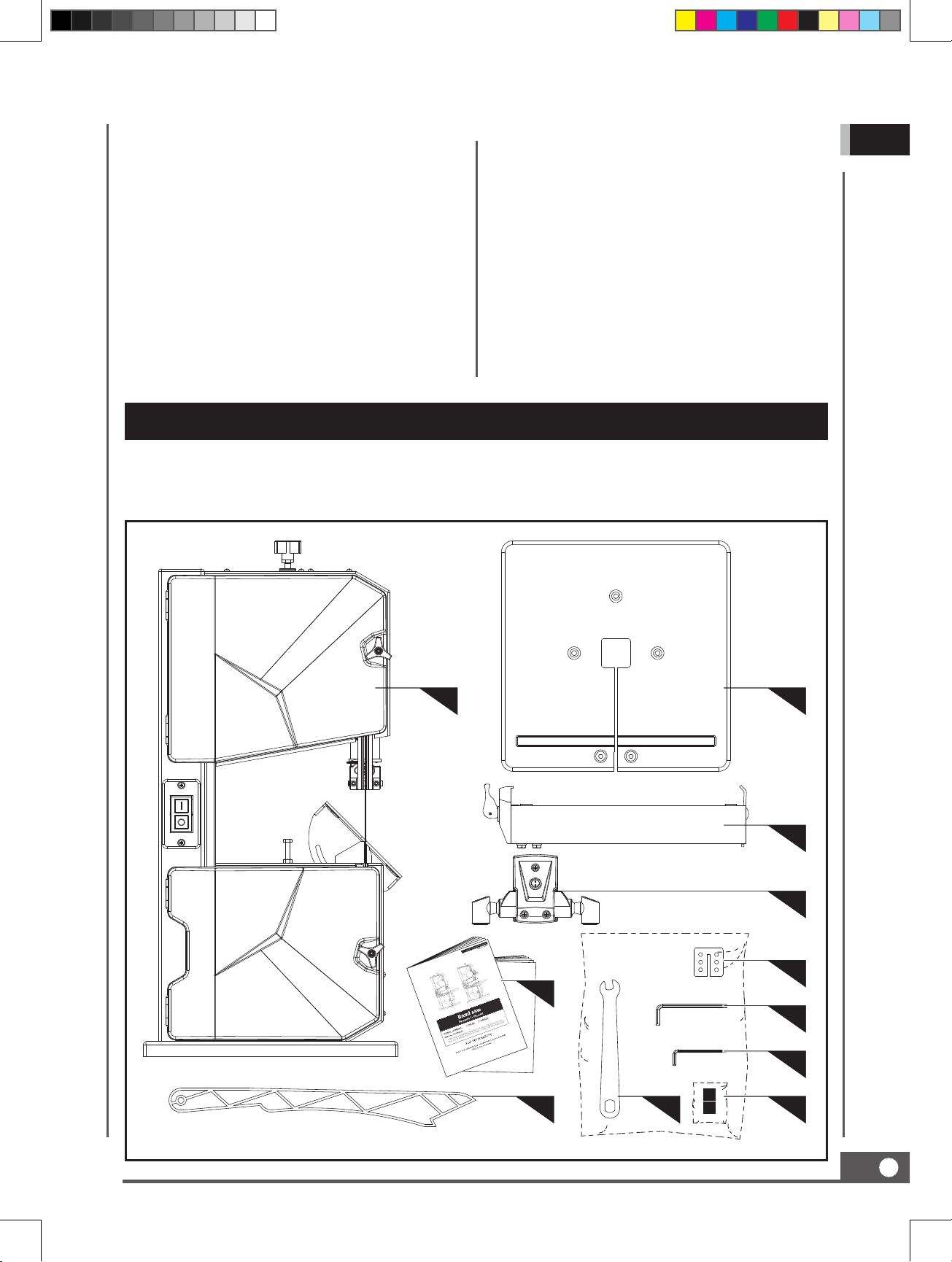

The band saw comes partially assembled and is shipped in carefully packed carton. After all the

parts have been removed from the carton, you should have:

CONTENTS SUPPLIED

4

1 3

2 9

5

6

7

8

11

10

9

A

B

● The band saw blade guard should be in its

lowest position close to the bench during

transport.

● For miter cuts when the table is tilted, the

parallel stop must be positioned on the

lower part of the table.

● When cutting round timber, use a suitable

holding device to prevent the workpiece

turning.

● Never use guards to lift or transport items.

● Ensure that the band saw blade guards are

used and correctly adjusted.

● Keep your hands a safety distance away

from the band saw blade. Use a push stick

for narrow cuts.

● The push stick has to be stored on the

intended device, so that it can be reached

from normal working position and is always

ready to be used.

● In the normal operating position the operator

is in front of the machine.

BAND SAW

8

GB

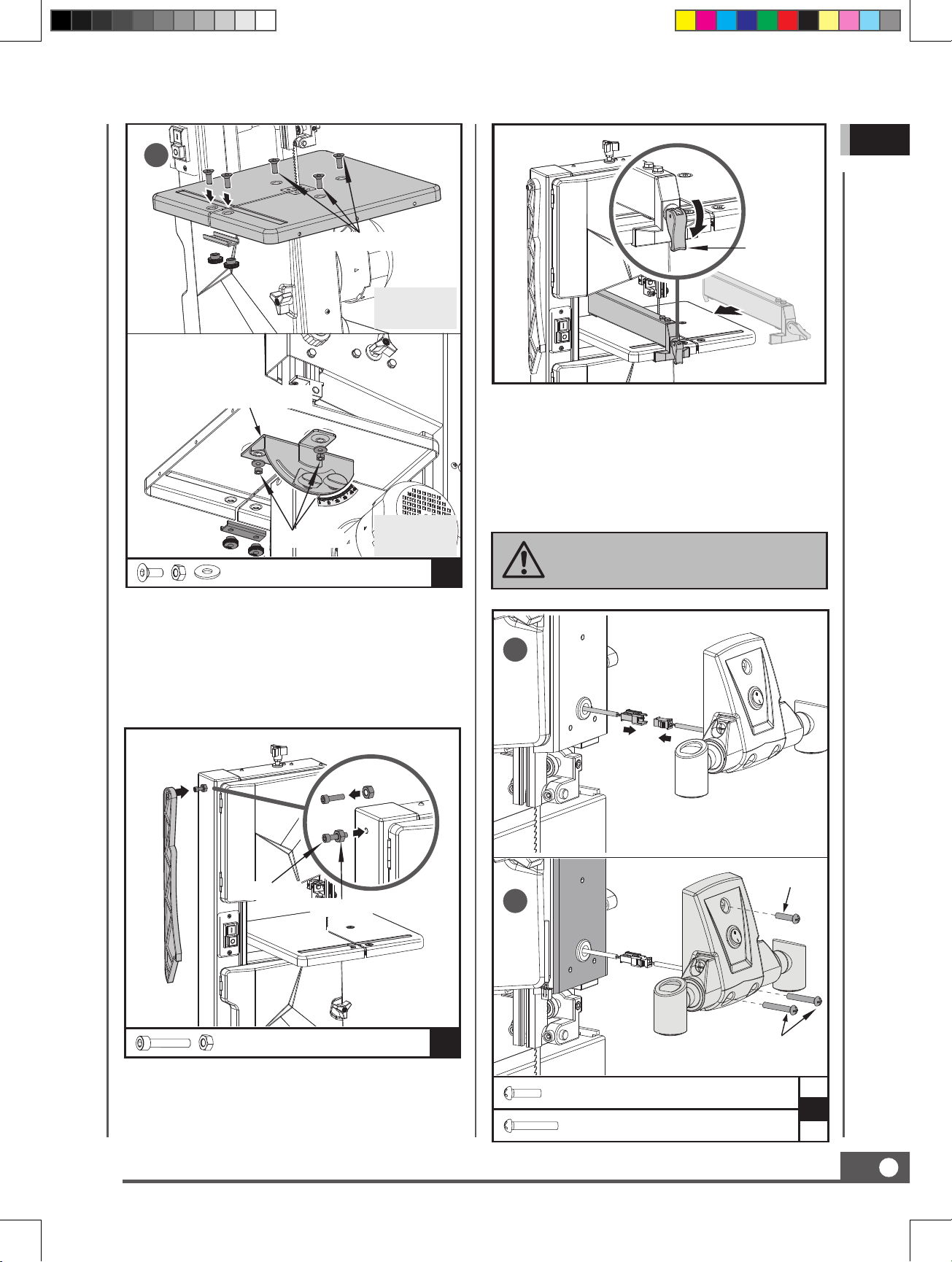

This band saw was partially assembled at the

factory. To assemble your machine follow the

below instructions.

Work Table

1. Remove the two screws, two knurled nuts

and U shape block from the work table.

2. Guide work table over the blade and place

it on the table trunnion. Positon the table

insert on the work table properly.

3. Attach the work table with three each

screws M6×16 to the table trunnion.

4. Fasten the work table with three nuts M6

and three fla t washers.

5. Attach two screws and two knurled nuts

with U shape block that were removed in

step one and fasten.

ASSEMBLY

1

2

3

TOP

VIEW

BOTTOM

VIEW

Work Table

Table Insert

M6 ×16 (×3)

Bench Angle Gauge

M6 Nut (×3)

NOTE: Before fastening the work

table, make sure table be aligned

in two planes. Laterally, in order

for the blade to run dead centre

through the table insert.At right

angles to the blade.

1. Main Machine

2. Push Stick

3. Work Table

4. Rip Fence

5. Table Insert

6. Operator’s Manual

7. Allen Key, 4mm

8. Allen Key, 3mm

9. Blade Key

10. Lamp

11. Hardware Bag

BAND SAW 9

GB

1

2

3

TOP

VIEW

BOTTOM

VIEW

Work Table

Table Insert

M6 ×16 (×3)

Bench Angle Gauge

M6 Nut (×3)

M6 ×16 ×3 A

Locker

Push Stick

1. Fix the screw and nuts on the machine,

leaving room for push stick.

2. Hang the push stick on the screw.

Rip Fence

Clamp the rip fence. It can be used on both

sides of blade.

Lamp

1. Plug the cable connectors together.

2. Align the holes in the unit with the holes in

the rear plate of lamp. Secure and tighten

by using one M4x16 and two M4x25 screws.

M6 ×35 (×1)

M6 Nut (×1)

M6 ×35 ×1 B

1

2

M4 ×25 (×2)

M4 ×16 (×1)

M4 ×16 ×1

B

M4 ×25 ×2

During installation do not get the

cables crushed by the screws.

BAND SAW

10

GB KNOW YOUR MACHINE

Features and Controls

Rip Fence

Setting Knob for Work Table

ON/OFF Switch

Blade

Locking Knob for Blade Guard

Lower Housing Door

Suction Connector

Upper Housing Door

Setting Knob for Blade Tension

Setting Knob for Blade Guard

Work Table

Motor

Door Lock

Door Lock

Power Cord and Plug

Push Stick

Setting Knob for Blade Tracking

Adjustment

Lamp (65160A Only)

ON/OFF Switch for Lamp

BAND SAW 11

GB

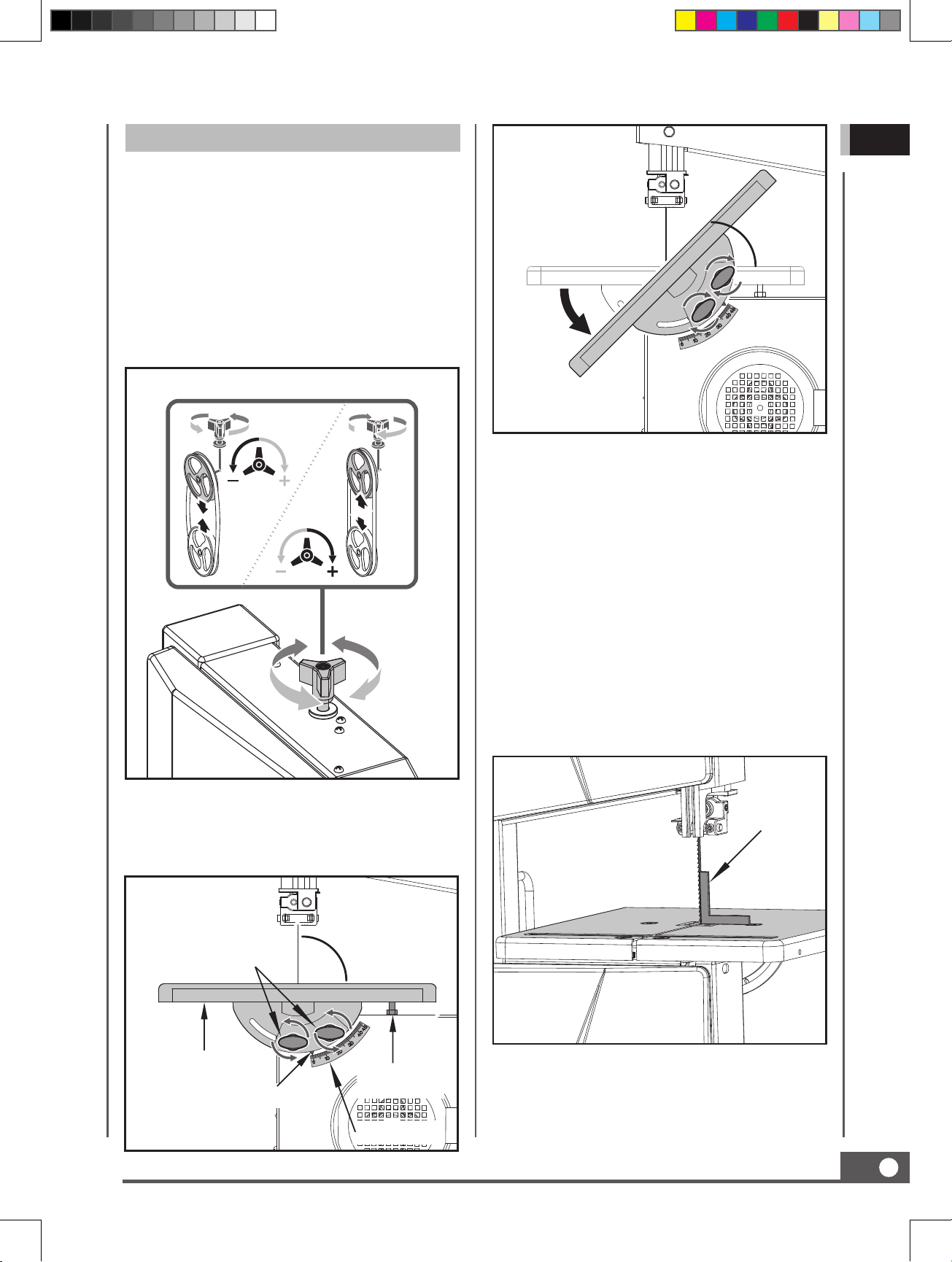

Set Up

Adjusting the Blade Tension

This tracking adjustment is required to have

the blade run dead center on the rubber tyres

of the band saw wheels:

● Turning the setting knob clockwise increases

the blade tension.

● Turning the setting knob counter- clockwise

reduces the blade tension.

Adjusting the Work Table Tilting

After loosening both locking screws, the work

table tilts steplessly through 45° to the blade.

Work Table Alignment

Saw Table Lateral Alignment

1. Loosen the three fastening screws that hold

the lower table trunnion.

2. Align working table so that the blade runs

through the centre of the table insert’s slot.

3. Tighten the three fastening screws again.

Working Table

Angle Scale

Limit Stop

Screw

Pointer

Locking Screw Min: 0°

Max: 45°

Aligning the work table at right angles to the

blade

1. Raise upper blade guide fully. Check band

saw blade tension.

Try Square

BAND SAW

12

GB Adjusting the Blade Guard

The blade guard protects against unintentional

contact with the saw blade and from chips

flying about. In order for the upper blade guard

to provide adequate protection against contact

with the band saw blade, it must always be

set as close as possible against the workpiece

(max. distance 3 mm).

1. Loosen the locking knob.

2. Rotate the setting knob to adjust the blade

guard in the right position, then fasten the

locking knob.

Setting Up the Rip Fence

The rip fence is clamped to the front. It can be

used on both sides of the blade.

2. Loosen locking screws.

3. Using a try square, set the table at right

angles to the blade and tighten the locking

screws again.

4. Loosen locking nut and adjust limit stop

screw until it touches the working table.

5. Tighten locking nut.

Work Table

Limit Stop Screw

Locking Nut

Operation

Start the saw only after the following

preparations are completed:

● The saw is fastened;

● The saw table is installed and

aligned;

●

Safety devices have been checked.

Connect the saw to the mains supply

only afterall ofthe abovepreparations

are completed! Otherwise there is

a risk of an unintentional starting

of the saw, which can cause severe

personal injury.

1

3

2

Locking Knob

3 mm

Setting

Knob

BAND SAW 13

GB

Sawing

1. If necessary, adjust the table tilt.

2. Select rip fence and table tilt for the type of

cutting operation to be carried out.

3. Set upper blade guide 3 mm above the

workpiece.

4. Place workpiece on the working table.

5. Plug in.

6. Start saw.

7. Cut workpiece in a single pass.

8. Switch off if no further cutting is to be done

immediately afterwards.

Danger by jamming workpiece!

When using the rip fence with a

tilted saw table, the rip fence must

be installed on the lower side of the

working table.

Mounting the saw in the stable and flat

supporting surface

1. Drill 4 holes in the supporting surface.

2. Put fixing bolts through the base plate and

secure with nuts.

Supporting Surface

Base Plate

305mm

305mm

220mm

220mm

M6-Bolt (×4)

Ø6.5mm

diameter

hole (×4)

ON/OFF Switch

The saw can be switched on by pressing the

green pushbutton.

The red pushbutton has to be pressed to switch

off the machine.

ON/OFF Switch for Lamp

Press "I" to turn on the lamp.

Press "O" to turn off the lamp

This light switch can only work when the ON/

OFF switch for the product is turned on.

Green “I” button

Red “O” button

Always make a trial cut in a piece

of scrap to verify settings; correct

if necessary before cutting the

workpiece.

“O”

“I”

BAND SAW

14

GB

1M6 ×16 (×2)

2

Warning! Prior to any adjustment,

maintenance or service work

disconnect the mains power plug!

Danger! Risk of injury, even with the

band saw blade at standstill. Wear

gloves when changing blades.

General Maintenance Measures

Keep all safety devices, air vents and the

motor housing free of dirt and dust as far as

possible. Wipe the equipment with a clean

cloth or blow it with compressed air at low

pressure.

We recommend that you clean the device

immediately each time you have finished using

it.

Clean the equipment regularly with a damp

cloth and some soft soap. Do not use cleaning

agents or solvents; these could attack the

plastic parts of the equipment. Ensure that no

water can seep into the device. The ingress of

water into an electric tool increases the risk of

an electric shock.

In order to extend the service life of the tool,

oil the rotary parts once monthly. Do not oil

the motor.

Use only suitable band saw blades.

1. Loosen the 2 knurled screws and remove

the U shape blocker.

2. Open both housing doors.

3. Loosen setting knob until the band saw

blade has slackened.

4. To remove the band saw blade, guide it

through the slot in the working table.

Saw Blade Change

MAINTENANCE

5. Fit fresh band saw blade. Ensure correct

position: the teeth must point towards the

front of the saw (where the doors are).

6. Center band saw blade on the rubber tyres

of the band saw wheels.

7. Tighten setting knob until blade does no

longer slip off the band saw wheels.

8. Close both housing doors.

9. Tension band saw blade;

Align band saw blade and align blade guides;

let saw test run for at least one minute;

Stop saw, unplug and recheck settings.

Machine has suction connector,

user can connect the machine to a

proper suction unit when working.

BAND SAW 15

GB

3

4

Adjusting the Blade Tension

This tracking adjustment is required to have

the blade run dead center on the rubber tyres

of the band saw wheels:

● Turning the setting knob clockwise increases

the blade tension.

● Turning the setting knob counter - clockwise

reduces the blade tension.

Band Saw Blade Alignment

If the band saw blade does not run in the centre

of the rubber tyres, the tracking needs to be

corrected by adjusting the tilt of the upper

band saw wheel:

1. Loosen locking nut.

2. Turn setting knob:

● Turn setting knob clockwise if the band saw

blade runs towards the front of the saw.

● Turn setting knob counter- clockwise if the

band saw blade runs towards the rear of the

saw.

3. Tighten locking nut.

BAND SAW

16

GB

0.5 mm 0.5 mm

1 3

2

Upper Blade Guide Alignment

The upper blade guide consists of:

● a thrust bearing (supports the band saw

blade from the rear),

● two guide pins (providing lateral support).

The bearing and guide pins need to be

readjusted after every band saw blade change

or tracking.

Lower Blade Guide Alignment

The lower blade guide consists of:

● a thrust bearing (supports the band saw

blade from the rear),

● two guide pins (providing lateral support).

Thrust bearing adjustment

1. If necessary, align and tighten the band saw

blade.

2. Loosen the thrust bearing’s locking screw.

3. Adjust thrust bearing position (distance

thrust bearing - band saw blade = 0.5 mm

- if the band saw blade is turned by hand, it

shall not touch the thrust bearing.

Guide pin adjustment

1. Loosen screws.

2. Press guide pins together, keep 0.5 mm

distance between guide pin and the saw

blade.

3. Tighten screws again.

4. Tighten the thrust bearing locking screw.

NOTE: Periodically check all bearings

for wear, if necessary replace both

guide bearings at the same time.

NOTE: Periodically check thrust

bearings and guide pins for wear, if

necessary replace both guide pins

at the same time.

BAND SAW 17

GB

0.5 mm 0.5 mm

Table Insert

Table Insert Replacement

The table insert needs replacement when its

slot has become enlarged or damaged.

1. Remove table insert from saw table (push

up from underneath).

2. Fit new table insert.

Thrust bearing adjustment

1. Loosen the two screws and remove the

under blocks.

2. Loosen the three screws and Remove the

working table from the table trunnion .

3. Loosen the two knobs and remove the

bench angle gauge.

4. Open the lower housing door.

5. Raise upper blade guide fully.

6. If necessary, align and tighten the band saw

blade.

7. Loosen the thrust bearing's locking screw.

8. Adjust thrust bearing position (distance

thrust bearing - band saw blade = 0.5 mm

- if the band saw blade is turned by hand, it

shall not touch the thrust bearing.

Guide pin adjustment

1. Loosen screws.

2. Press guide pins together, keep 0.5 mm

distance between guide pin and the saw

blade.

3. Tighten screws again.

4. Attach the working table to the table

trunnion.

5. Fit the U shape under block to the working

table.

9. Tighten the thrust bearing locking screw.

Bench Angle Gauge

BAND SAW

18

GB

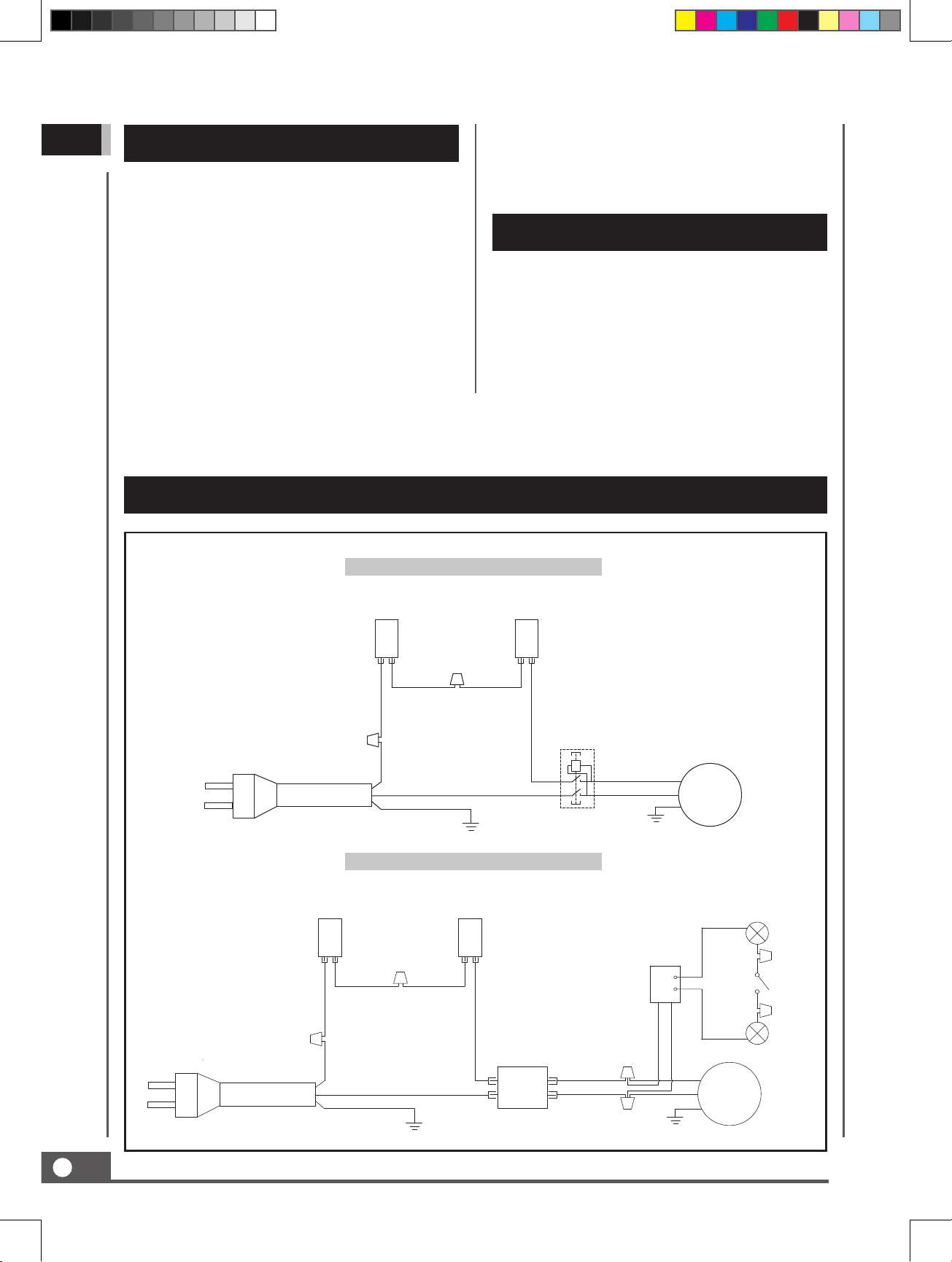

WIRING DIAGRAM

65160

65170

65160A

Micro Switch

(Lower Housing Door)

Micro Switch

(Upper Housing Door)

Micro Switch

(Lower Housing Door)

Micro Switch

(Upper Housing Door)

Close-End Wire

Connector

Close-End Wire

Connector

Power Supply Cord

Motor

Motor

230-240V~ 50Hz

Close-End Wire

Connector

Power Supply Cord

230-240V~ 50Hz

Crown

Crown

Crown

Crown

BlueBlue

Blue

Close-End Wire

Connector

Crown

Crown

Crown

BlueBlue

Blue

Blue

Crown

Blue

U

<

K

c

U

<

K

c

Micro Switch

(Lower Housing Door)

Micro Switch

(Upper Housing Door)

Close-End Wire

Connector Close-End Wire

Connector

Close-End Wire

Connector

Close-End Wire

Connector

Motor

SWITCH

PCB

Lamp

Lamp

Power Supply Cord

230-240V~ 50Hz

Crown

Crown

Crown

Crown

Blue Blue

Red

Crown Blue

Blue

Blue Blue

Store the equipment and accessories in a dark

and dry place at above freezing temperature.

The ideal storage temperature is between 5

and 30°C. Store the electric tool in its original

packaging. Cover the electric tool in order to

protect it from dust and moisture.

STORAGE

1. Turn off the power tool before any transport

and disconnect it from the power supply.

2. Apply the power tool at least with two

people, do not touch the table extensions.

3. Protect the power tool from knocks, bumps

and strong vibrations such as during

transport in vehicles.

4. Secure the power tool against overturning

and sliding.

TRANSPORT 5. Never use the safety devices for handling or

transporting purpose.

BAND SAW 19

GB

TROUBLE SHOOTING

Problem Cause Remedy

Motor does not

work

1. Motor, cable or plug defective,

fuses burnt

2. Housing cover open (limit

switch)

1. Arrange for inspection of the

machine by a specialist. Never repair

the motor yourself. Danger! Check

fuses and replace as necessary

2. Close housing cover exactly

The motor starts

up slowly and does

not reach operating

speed

Voltage too low, coils damaged,

capacitor burnt

Contact the utility provider to check

the voltage

Arrange for inspection of the motor by

a specialist

Arrange for replacement of the

capacitor by a specialist

Motor makes

excessive noise Coils damaged, motor defective Arrange for inspection of the motor by

a specialist

The motor does not

reach its full power

Circuits in the network are

overloaded (lamps, other motors,

etc.)

Do not use any other equipment or

motors on the same circuit

Motor overheats

easily

Overloading of the motor,

insufficient coolinof the motor

Avoid overloading the motor while

cutting, remove dust from the motor in

order to ensure optimal cooling of the

motor

Saw cut is rough

orwavy

Saw blade dull, tooth shape

not appropriate forthe material

thickness

Resharpen saw blade and/or use

suitable saw blade

Workpiece pulls

awayand/or

splinters

Excessive cutting pressure and/

or saw bladenot suitable for use Insert suitable saw blade

Saw blade is not

running straight

1. Guide has been wrongly set

2. Wrong saw blade

1. Set the saw blade guide according

to the operating instructions

2. Select a saw blade according to the

operating instructions

Burn marks appear

on the wood during

the cutting work

1. Blunt saw blade

2. Wrong saw blade

1. Change the saw blade

2. Select a saw blade according to the

operating instructions

Saw blade jams

during cutting work

1. Blunt saw blade

2. Deposits on the saw blade

3. Guide has been set poorly

1. Change the saw blade

2. Clean the saw blade

3. Set the saw blade guide according

to the operating instructions

BAND SAW

20

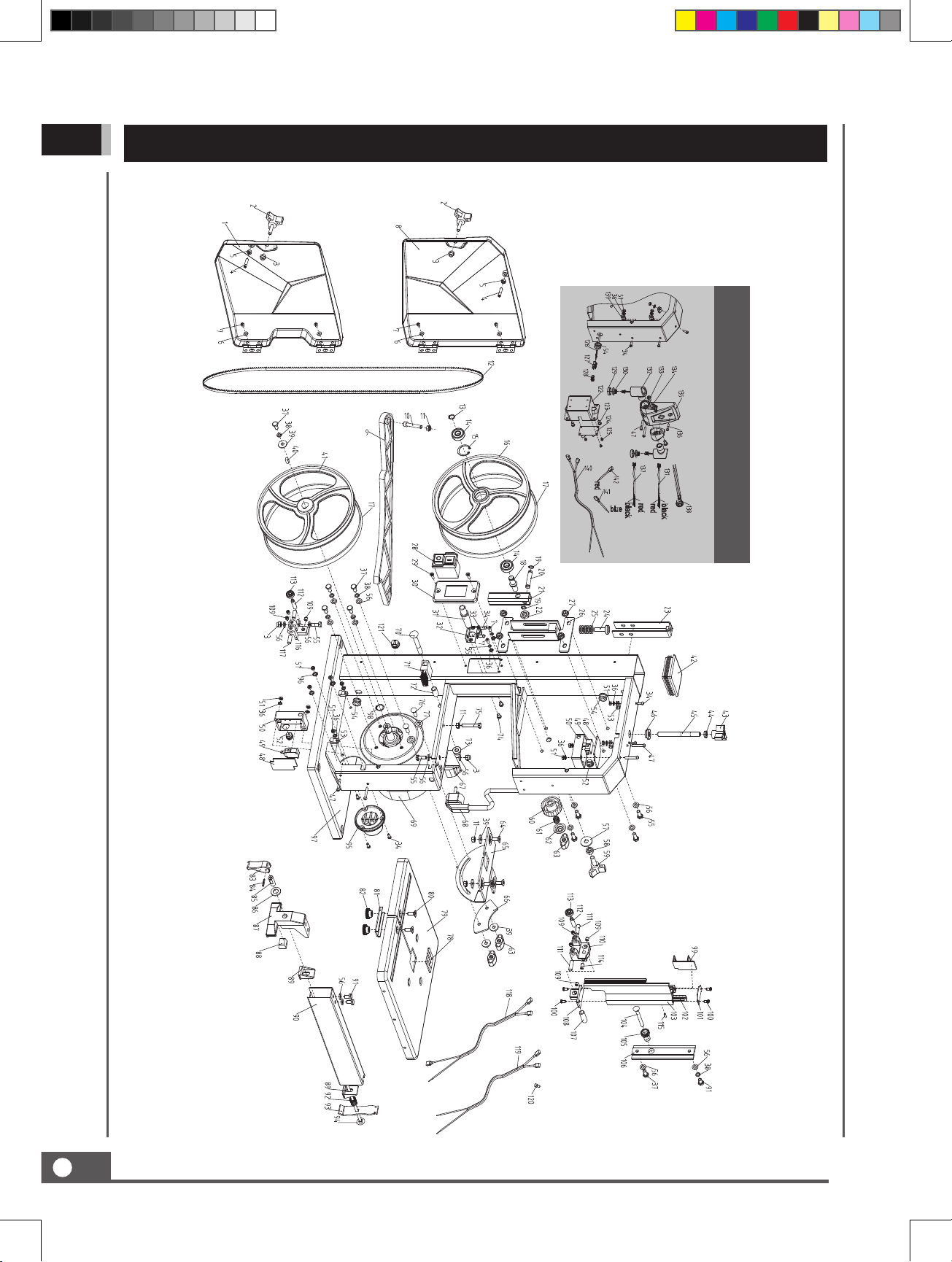

GB PARTS SCHEDULE

65160A ONLY

USED

This manual suits for next models

1

Other TOPMAQ Saw manuals

Popular Saw manuals by other brands

Bosch

Bosch 1678 - 7-1/4" Worm Drive Saw Operating/safety instructions

Clarke

Clarke Woodworker MBS600C Assembly instructions

Parkside

Parkside PHKS 1450 LASER Operation and safety notes

Skil

Skil 3575 Original instructions

Evolution

Evolution EVO180 V2 instruction manual

Shindaiwa

Shindaiwa 490 Owner's/operator's manual