TOPP C160 Guide

INSTALLATION AND USE INSTRUCTIONS

BEFORE INSTALLING AND USING THE ACTUATOR, IT IS

COMPULSORY FOR THE INSTALLER AND THE USER TO READ

AND UNDERSTAND THIS MANUAL IN ALL ITS PARTS.

CHAIN ACTUATOR FOR

WINDOW AUTOMATION C160

COD. 0P5296

VER.0.0 REV.07.18

original instructions

THIS MANUAL IS INTEGRAL PART OF THE ACTUATOR

AND MUST BE PRESERVED FOR FUTURE REFERENCE

UNTIL DEMOLITION OF THE SAME.

C160RWA

C160

3

INDICE

ISTRUZIONI PER L’INSTALLAZIONE E L’USO

C160

3

INDEX

INSTALLATION AND USE INSTRUCTIONS

C160

1- EC DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINE..pag.04

2- GENERAL REMARKS

2.1- General Instructions ..............................................................................................pag.05

2.2- Installer and user....................................................................................................pag.05

2.3- Technical assistance..............................................................................................pag.05

2.4- Reserved rights ....................................................................................................pag.05

2.5- Description of personnel .......................................................................................pag.05

3- TECHNICAL DESCRIPTION

3.1- Actuator Denomination - Dimensions - Technical data..........................................pag.06

3.2- Formulas for the calculation of thrust and tractive force........................................pag.08

3.3- Destination of use..................................................................................................pag.08

3.4- Use limits................................................................................................................pag.08

3.5- Rating plate and “CE” marking .............................................................................pag.08

3.6- Package ................................................................................................................pag.09

3.7- Components and dimensioning..............................................................................pag.11

3.8- Application..............................................................................................................pag.12

4- SAFETY

4.1- General Instructions ..............................................................................................pag.13

4.2- Safety devices ......................................................................................................pag.14

4.2.1- Protection against electric hazard ......................................................................pag.14

4.3- Safety plates..........................................................................................................pag.14

4.4- Residual risks ........................................................................................................pag.14

5- INSTALLATION

5.1- General Instructions...............................................................................................pag.15

5.2- Installation .............................................................................................................pag.15

5.3- Electric connections...............................................................................................pag.15

5.4- Command devices.................................................................................................pag.15

5.5- Correct assembly of the actuator on the window frame.........................................pag.16

5.6- Emergency procedures..........................................................................................pag.17

6- USE AND OPERATION

6.1- Use of the actuator ................................................................................................pag.18

7- MAINTENANCE

7.1- General Instructions ..............................................................................................pag.18

8- DEMOLITION

8.1- General Instructions ..............................................................................................pag.19

9- SPARE PARTS AND ACCESSORIES UPON REQUEST

9.1- General Instructions...............................................................................................pag.19

10- DRAWINGS / INSTALLATION INSTRUCTIONS

10.1- Frame actuator mounting...........................................................................pag.20

10.2- Casement actuator mounting........................................................................pag.49

11.ELECTRICAL WIRING DIAGRAM............................................................pag.54

4

1- EC DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

INSTALLATION AND USE INSTRUCTIONS

ORIGINAL

The undersigned, in the name of and

behalf of the following company

Topp S.r.l.

Via Galvani, 59

36066 Sandrigo (VI)

Italia

herewith declares that the person authorised to compile the technical file is

Name: Bettiati Roberto - Topp S.r.l.

Address: via Galvani,59 36066 Sandrigo (VI)

and that to the partly completed machinery

CHAIN ACTUATOR FOR WINDOW AUTOMATION

RWA CHAIN ACTUATOR FOR WINDOW AUTOMATION

Type: C160

Model: C160/230V - C160/24V RWA - C160/24V Double push point RWA

the following essential requisites of the

2006/42/EC Machinery Directive (including all applicable amendments)

have been applied and fulfilled: Enclosure I: 1.5.1; 1.5.2; 1.5.10; 1.5.11

that the relevant technical documentation is compiled in accordance with part B of Annex VII of the above

mentioned Machinery Directive..

The above identified partly completed machinery is also in conformity with the all the relevant provisions of the

following directives (including all applicable amendments)

EMC Directive 2014/30/EU

RoHS II Directive 2011/65/EU

The following harmonised standards have been applied:

EN 60335-2-103:2015 (applicable parts)

EN 55014-1:2006 + A1:2009 + A2:2011

EN 55014-2:2015

EN 61000-6-2:2005.

EN 61000-6-3:2007 + A1:2011 + AC:2012.

EN 50581:2012

EN 12101-2:2003 (only for RWA): - 7.1 Dual purpose ventilator class "RE1000" -7.2 class "SL 0" - 7.3

class"T(-15)" - 7.4 class "WL1500" - 7.5 class "B300".

and the following technical documents:

EN 62233:2008

The undersigned also undertakes the obligation, in response to a duly reasoned request by the national market

surveillance authorities, to transmit to the a.m. authorities, in electronic or paper format, the relevant technical

documentation on the partly completed machinery.

The above identified partly completed machinery must not be put into service until the final machinery into which

it is to be incorporated has been declared in conformity with the provisions of the above mentioned Machinery

Directive.

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Date: Sandrigo01/02/2018 Signature: Matteo Cavalcante

Amministratore ................................................................

5

GENERAL REMARKS -2

INSTALLATION AND USE INSTRUCTIONS

C160

2.1- GENERAL INSTRUCTIONS

BEFORE INSTALLING AND USING THE ACTUATOR, IT IS COMPULSORY THAT THE INSTALLER AND THE USER

CAREFULLY READ AND UNDERSTAND THIS MANUAL IN ALL ITS PARTS.

THIS MANUAL IS INTEGRAL PART OF THE ACTUATOR AND MUST COMPULSORILY BE PRESERVED FOR FUTURE

REFERENCE.

THE MANUFACTURER HAS NO LIABILITY FOR ANY EVENTUAL DAMAGE TO PERSONS, ANIMALS AND THINGS DUE TO

THE INOBSERVANCE OF THE PRESCRIPTIONS DESCRIBED IN THIS MANUAL.

IN ORDER FOR THE AUTOMATION UNIT TO OPERATE CORRECTLY, WE RECOMMEND CARRYING OUT PERIODICAL

MAINTENANCE ON IT, AS INDICATED IN PAR. 7 OF THIS MANUAL.

THE WARRANTY ON THE ACTUATOR WILL NOT BE HONORED IF PRODUCT IS NOT INSTALLED AND USED ACCORDING TO

THE INSTRUCTIONS PROVIDED AND THE REGULATIONS SHOWN IN THIS INSTRUCTION MANUAL AND IF IT IS USED WITH

NONGENUINE PARTS, ACCESSORIES, SPARE PARTS AND/OR CONTROL/FEEDING UNITS.

2.2- INSTALLER AND USER

THE ACTUATOR INSTALLATION CAN BE PERFORMED EXCLUSIVELY BY COMPETENT AND QUALIFIED TECHNICAL

PERSONNEL SATISFYING THE PROFESSIONAL AND TECHNICAL REQUIREMENTS FORESEEN BY THE LAWS IN FORCE

IN THE COUNTRY OF INSTALLATION.

THE INSTALLATION TECHNICIAN SHALL ACCEPT FULL RESPONSIBILITY FOR ANY INSTALLATION ERRORS AND FOR

ANY FAILURE TO ADHERE TO THE INSTRUCTIONS PROVIDED IN THIS MANUAL. THE INSTALLATION TECHNICIAN

SHALL THEREFORE BE EXCLUSIVELY LIABLE FOR ANY DAMAGES CAUSED TO USERS AND/OR THIRD PARTIES THAT

MAY ARISE AS A RESULT OF INCORRECT INSTALLATION.

THE ACTUATOR CAN BE USED EXCLUSIVELY BY A USER ACTING IN COMPLIANCE WITH THE INSTRUCTIONS

CONTAINED IN THIS MANUAL AND/OR IN THE MANUAL OF THE ACTUATOR CONTROL DEVICE (E.G.: CONTROL UNIT).

2.3- TECHNICAL ASSISTANCE

Contact the installation technician or retailer for assistance.

2.4- RESERVED RIGHTS

The reserved rights on this manual "Installation and use instructions" remain property of the Manufacturer.

Each information herein contained (text, drawings, diagrams, etc.) is reserved.

None part of this manual can be reproduced and disclosed (totally or partially) by any reproduction means (photocopies,

microfilms or other) without written authorization of the Manufacturer.

2.5-DESCRIPTION OF PERSONNEL

USERS MUST NEVER PERFORM OPERATIONS RESERVED FOR MAINTENANCE PEOPLE OR SPECIALISED

TECHNICIANS. THE MANUFACTURER DECLINES ALL LIABILITY FOR DAMAGE DERIVING FROM FAILURE TO OBSERVE

THE ABOVE REQUIREMENTS.

Specialised electrician:

A specialised electrician must be able to install the actuator, start it and operate it both in normal conditions and in the

maintenance mode; he/she is qualified to perform all electrical and mechanical adjustment and maintenance operations.

He/she is allowed to work on live electrical cabinets and junction boxes.

User:

specialised person capable of operating the actuator under normal conditions by using the relative controls. He/she must

also be able to operate with the actuator under “maintenance” in order to perform simple routine maintenance operations

(cleaning), and start or reset the actuator following an unscheduled stop.

6

3- TECHNICAL DESCRIPTION

INSTALLATION AND USE INSTRUCTIONS

C160

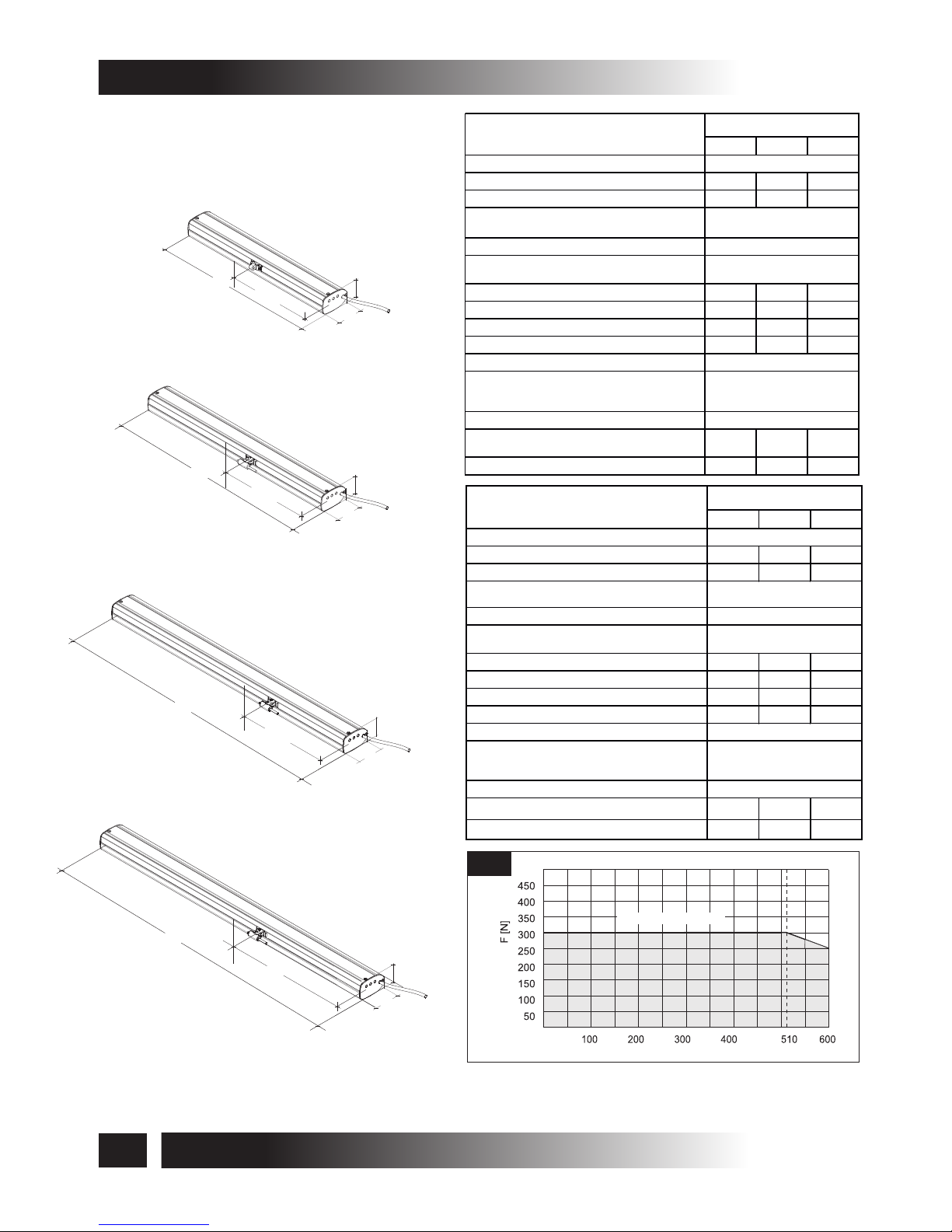

3.1- DENOMINATION – DIMENSIONS

TECHNICAL DATA

C160

stroke 360

230V - 24V

C160

stroke 600

230V - 24V

385

W

H

192.8

W

H

494

202.5

634

W

H

C160

stroke 1000

24V

202.5

C160

stroke 1000

230V

H = 43 mm

W= 68.5 mm

360 600 1000

0,43 A 0,60 A 0,60 A

11 W 15 W 15 W

300 N Fig.A 50 N

200 N 200 N 200N

7,74 10 mm/s 10 mm/s

46,5 s 60s 100s

1,7 kg 1,9 kg 2,5 kg

322 562 962

Stroke ( 1) (mm)

from - 5°C to + 50°C

Electronic for o pening-by

amperometric absorption for

closing

IP30

yes

4 min

24V

Class III

Operating temperature

TECHNICAL DATA

C160 RWA 24V Single push point

Efective stroke bottom hung inward

Type o f service S (3)

Protection degree o f electric devices

Parallel electric co nnection o f mo re

actuators on the same window

Thrust force

Tractive force

Idle translatio n speed

Duration of the idle stro ke (2)

Power supply vo ltage

Absorbed current

Absorbed power with load

Protection against electric sho ck

Limit switch

Gross weight

W

H

740

307

(2) It is considered RWA if the Duration of t he idle stroke is less than or equal to 60 s

/ 600mm Equivalent stroke

(3) Service of limit ed duration according to EN 60034

(1) Tolerance on the precision of limit switch tripping at out put: +/ - 10mm

360 600 1000

0,12A 0,14A 0,14A

28W 22,5W 22,5W

300 Fig.A 50

200 200 185

8mm/s 8mm/s 8mm/s

45s 75s 125s

1,7 kg 1,9 kg 2,8 kg

322 562 962

TECHNICAL DATA

C160 230V Single push point

Power supply vo ltage

Absorbed current

Absorbed po wer with load

Protectio n against electric sho ck

Stroke ( 1) (mm)

from - 5°C to + 50°C

Electronic fo r opening-by

amperometric abso rptio n fo r

closing

IP30

yes

4 min

230V ~ 50Hz

Class II

Duration o f the idle stro ke

Efective stro ke bo tto m hung inward

Gross weight

Operating temperature

Limit switch

Type o f service S (3)

Protectio n degree of electric devices

Parallel electric co nnectio n of mo re

actuators o n the same windo w

Thrust fo rce

Tractive fo rce

Idle translatio n speed

Stroke [mm]

Thrust load actuator [N]

Fig. A

7

INSTALLATION AND USE INSTRUCTIONS

C160

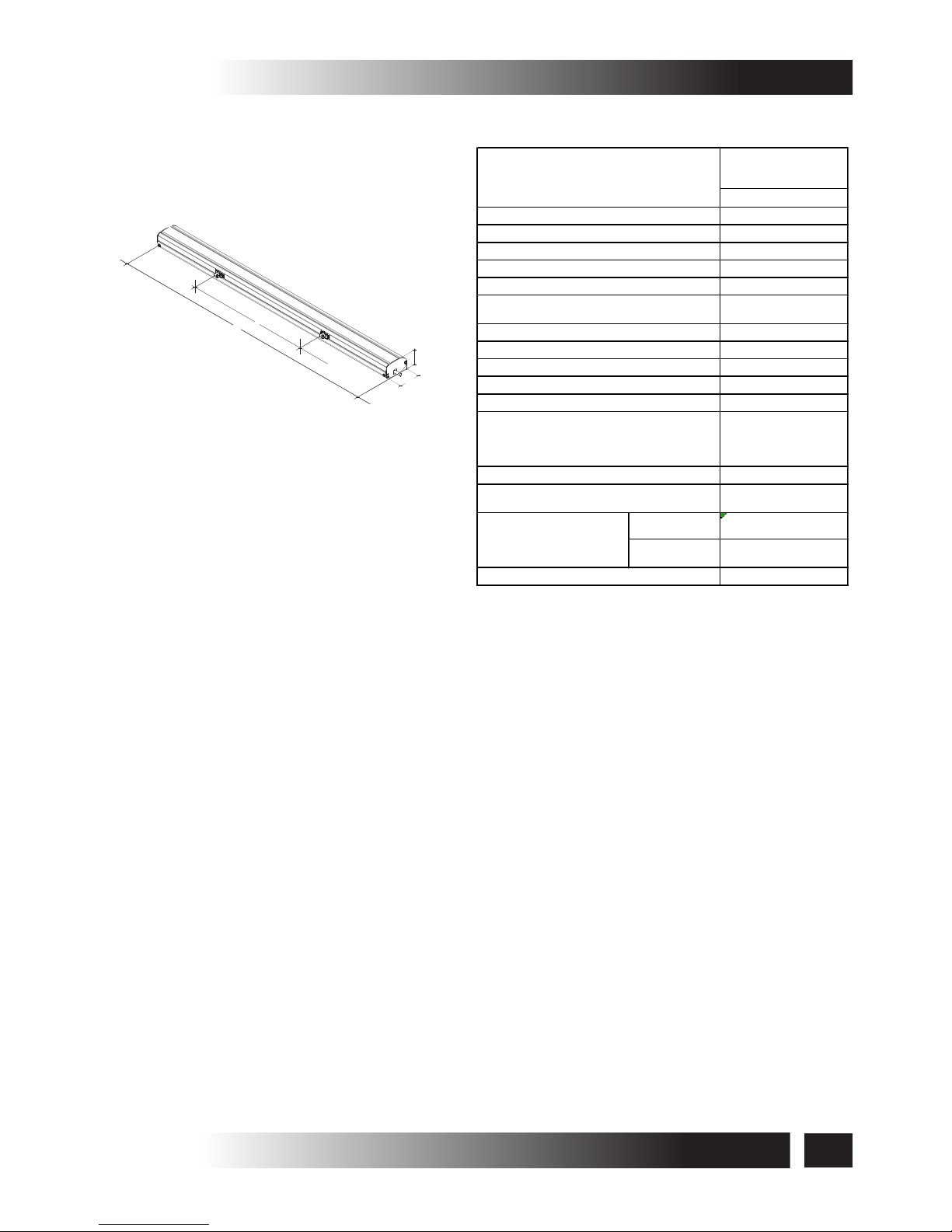

Lt L

W

H

TECHNICAL DESCRIPTION -3

C160

Double push point

stroke 360

24V

H = 43 mm

W= 68.5 mm

Lt; L : variables

(2) It is considered RWA if the Duration of t he idle stroke is less than or equal to 60 s

/ 600mm Equivalent stroke

(3) Service of limit ed duration according to EN 60034

(1) Tolerance on the precision of limit switch tripping at out put: +/ - 10mm

Stroke ( 1) (mm )

360

24V

0,75A

18W

Class III

IP30

yes

400

300

7,5mm/s

48s

4 min

Electronic fo r o pening-by

amperometric abso rptio n

for clo sing

from - 5°C to + 50°C

3,9kg - 7,0 kg

1200<Lt<3000 2

3000<Lt<4000 3

322

Protection degree o f electric devices

Parallel electric co nnectio n of mo re

actuators o n the same windo w

TECHNICAL DATA

C160 RWA 24V Double push point

Power supply vo ltage

Absorbed current

Absorbed po wer with load

Protection against electric sho ck

Thrust force

Tractive force

Idle translatio n speed

Duration o f the idle stro ke (2)

Gross weight

Limit switch

Operating temperature

Type o f service S (3)

Number o f clamps

Efective stroke bo tto m hung inward

3.4- USE LIMITS

The actuator has been designed and manufactured exclusively for the destination of use given in par. 3.3, therefore, any

other type of use is strictly forbidden in order to assure in any moment the safety of the installer and of the user, as well as the

efficiency of the actuator itself.

Check carefully all environmental conditions (temperature, humidity, wind, snow, potential chemical agents, etc.) and

installation settings (misaligned fitting of brackets and attachment to the frame, frictions produced by hinges or gaskets, use

of selfbalancing window stays, etc.) it is recommended that they not exceed the actuator performances shown in par.3.1. If

they do, please find an alternative and more suitable product for your application.

IT IS STRICTLY FORBIDDEN TO INSTALL THE ACTUATOR ON THE EXTERNAL SIDE OF THE WINDOW FRAME SUBJECT

TO ATMOSPHERIC AGENTS (RAIN, SNOW, ETC.).

THE USE OF THE ACTUATOR IN ENVIRONMENTS WITH POTENTIALLY EXPLOSIVE ATMOSPHERE IS STRICTLY

FORBIDDEN.

IT IS COMPULSORY TO KEEP THE PACKAGE AND THE ACTUATOR OUT OF REACH OF CHILDREN.

3.3- DESTINATION OF USE

The actuator has been designed and manufactured to perform, by means of a command device, the opening and closing

of top hinged windows, bottom hinged windows and side hinged windows.

Application RWA: The RWA actuator has been designed and manufactured to perform in case of emergency the opening

of the window for safe discharge of the smoke. It must be installed in windows that opening outside and bottom hinged.

According to EN 12101-2 / 2003.

3.4- FORMULAS FOR THE CALCULATION OF THRUST AND TRACTIVE FORCE

Top hung windows (A) or

bottom hung windows (B)

F= Force necessary for opening or closing

P= Weight of the window (Only movable part)

C= Window opening stroke

H= Window height (Only movable part)

F = (0,54 x P) x ( )

C

H

P

F

H

C

B

P

F

H

C

A

Fig. 1

8

3- TECHNICAL DESCRIPTION

INSTALLATION AND USE INSTRUCTIONS

C160

EX

3.5- RATING PLATE AND “CE” MARKING

The “CE” marking certifies the compliance of the machine with the essential safety and health requirements foreseen by the

product European Directives.

The rating plate is an adhesive plate in polyester, silk-screen printed in black, having the following size: L=24 mm - H=60 mm

It is applied externally on the actuator. The plate bears in readable and indelible way the following data:

• logo and address of the manufacturer

• type and model

• voltage and intensity of power supply (V - A)

• absorbed electric power P (W)

• thrust and tractive force F (N)

•type of service S2 (min)

• idle translation speed (mm/s)

• protection degree (IP)

• “CE” marking

• symbol of WEEE Directive 2002/96/CE

• symbol of double insulation (only for mod. C160/230V)

• serial number

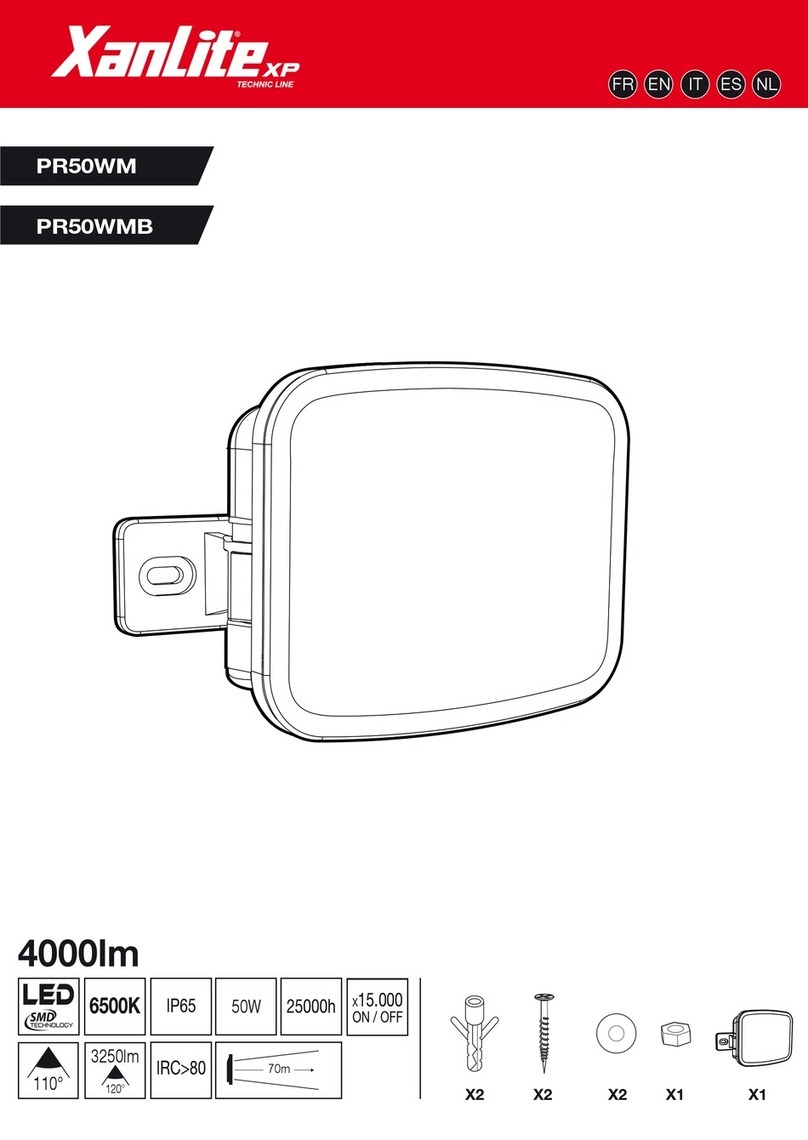

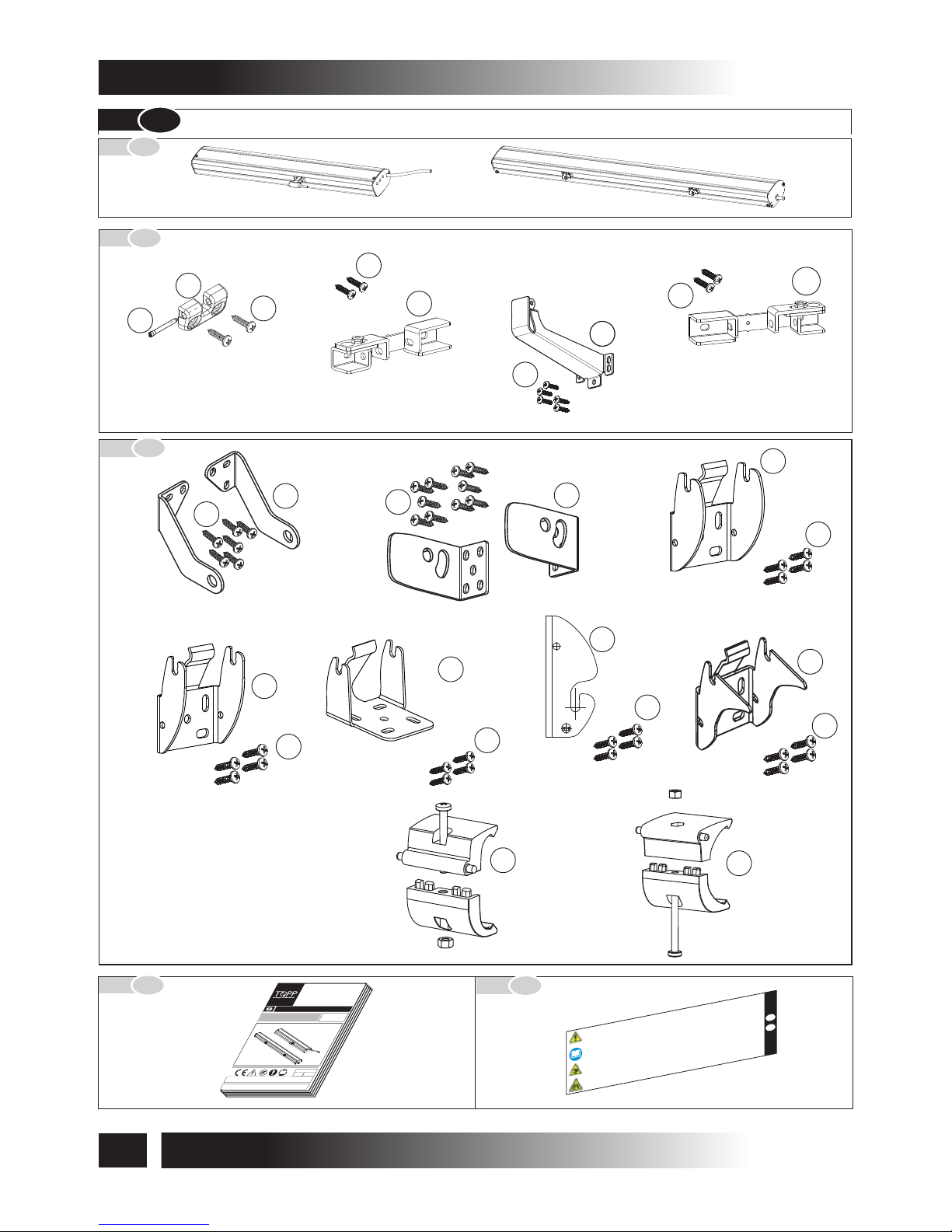

3.6- PACKAGE

Each package of the product (Fig. 2) contains:

1) Actuator equipped with power supply (Ref. A);

2) Window mounting brackets (depending on application) and screws for aluminum (Ref. B);

3) Actuator brackets (depending on application) and screws for aluminum (Ref. C);

4) Installation and use instructions (Ref.D);

5) Safety plate (Ref. E).

MAKE SURE THAT THE ABOVE DESCRIBED COMPONENTS ARE CONTAINED IN THE PACKAGE, AS WELL AS

THAT THE ACTUATOR HAS NOT BEEN DAMAGED DURING TRANSPORT.

SHOULD ANY ANOMALY BE DETECTED, IT IS FORBIDDEN TO INSTALL THE ACTUATOR, AND IT IS

COMPULSORY TO REQUIRE TECHNICAL ASSISTANCE FROM YOUR DEALER OR THE MANUFACTURER.

THE PACKAGING (PAPER, PLASTIC, ETC.) HAS TO BE DISPOSED ACCORDING TO THE LAWS IN FORCE.

9

INSTALLATION AND USE INSTRUCTIONS

C160 TECHNICAL DESCRIPTION -3

10

3- TECHNICAL DESCRIPTION

INSTALLATION AND USE INSTRUCTIONS

C160

MACCHINA AD AVVIAMENTO AU TOMATICO

AUTOMATIC MACHINE

PRIMA DI IN STALLARE E UTILIZZARE L'ATTUATORE È OBBLIG ATORIO CHE L'INS TALLATORE E L'UTILIZZATORE

LEGGANO E COMPRENDANO IN TUTTE LE SUE PARTI IL MANUALE

THE INSTALLER AND USER MUST READ AND UNDERSTAND ALL PARTS OF TH IS MANUAL BEFORE INSTALLING AND

USING T HE ACTUATOR.

PERICOLO ATTENZIONE ALLE MANI

BEWARE OF YO UR HANDS

ATTENZIONE MACCHINA AD AVVIAM ENTO AUTOMATICO CON COMANDO

A DISTANZA

ATTENT ION! AUTOMATIC MACHINE WITH REMOTE CONTROL DEVICE

IT

EN

SB

S3S3

A

S4

SC

SD

SE

SF

M1 M2

SG

S1

P1

S2

Ref.

C

Ref.

B

Ref.

A

Ref.

D

Ref.

E

Fig.

2

SA

V1

V2

V3

V4

VA VB

VC

VD VE

VF

VG

ISTRUZION I PER L’INSTALLAZIONE E L’USO

PRIMA DI INSTALLARE E UTILIZZARE L’ATTUATORE È OBBLIGATORIO CHE

L’INSTALLATORE E L’UTILIZZATORE LEGGANO E COMPRENDANO

IN TUTTE LE SUE PARTI IL PRESENTE MANUALE.

ATTUATORE A CATENA

PER AUTOMAZIONE FINESTRE C160

COD. 0P5295

VER.0.0 REV.03.17

istruzioni originali

IL PRESENTE MANUALE È PARTE INTEGRANTE DELL’ATTUATORE E DEVE

OBBLIGATORIAMENTE ESSERE CONSERVATO

PER FUTURI RIFERIMENTI FINO ALLA DEMOLIZIONE DELLO STESSO.

C160RWA

C160

AF TC Ø4.8x16

AF TC Ø4.2x19

AF TC Ø4.2x19

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

AF TC Ø4.8x16

11

INSTALLATION AND USE INSTRUCTIONS

C160 TECHNICAL DESCRIPTION -3

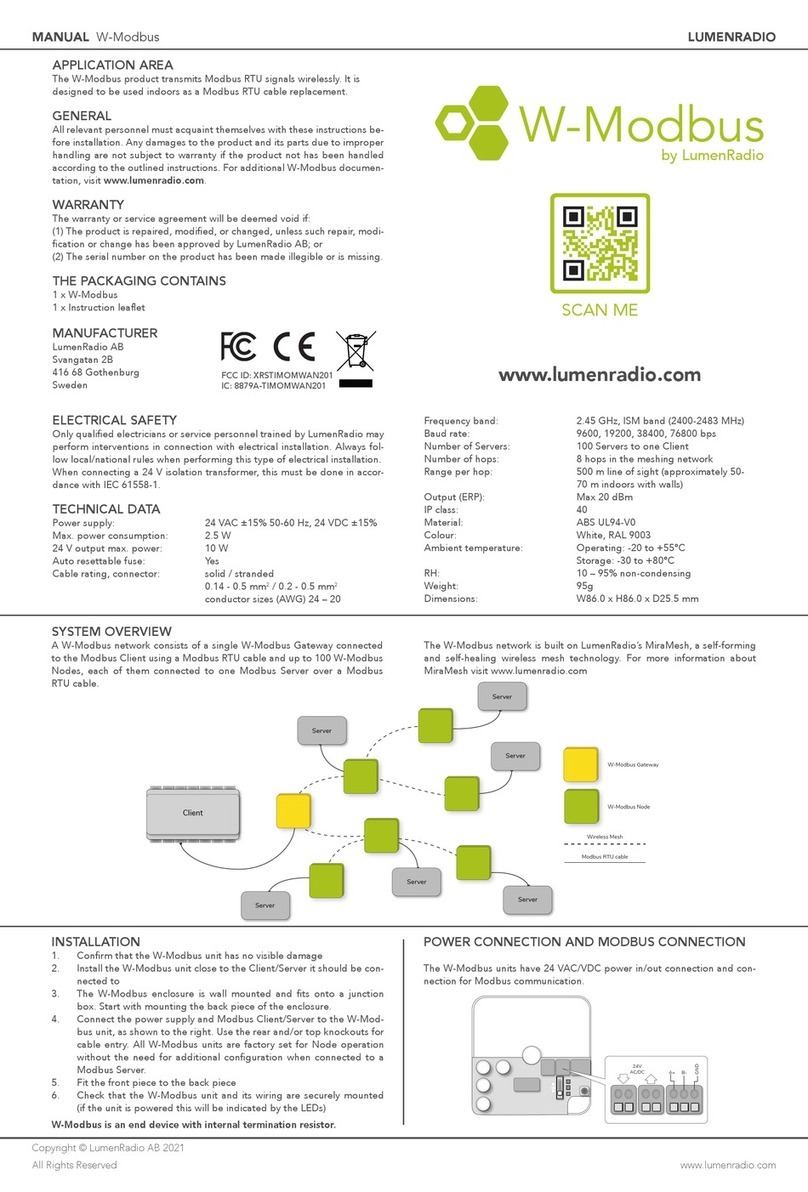

3.7- COMPONENTS AND DIMENSIONING

S1

S2

S4

SC

SD SE

M1 M2

Fig.

3

30

18

26.5

44.5

32.9 50

40

21.4

29

26.9 40

40.7 50

21.4

29

35.7

38 32

95 17.5

18.5

32 38

18.5

95 17.5

24.5

5

6

SA

S3

19

12

13

13

23

23

24

34.1

2.5

9.6 11.6

5.6

118.97

108.5

23

23

SA

16

21

34.5

64

75

SB

30

R2.75

15 6.25

2

13 13

77.5 2.5

18

26.5

44.5

59.5

SF

18

26.5

44.5

59.5

46

25

26

46

57

SG

30

26,5

44,5

18

3030

12

3- TECHNICAL DESCRIPTION

INSTALLATION AND USE INSTRUCTIONS

C160

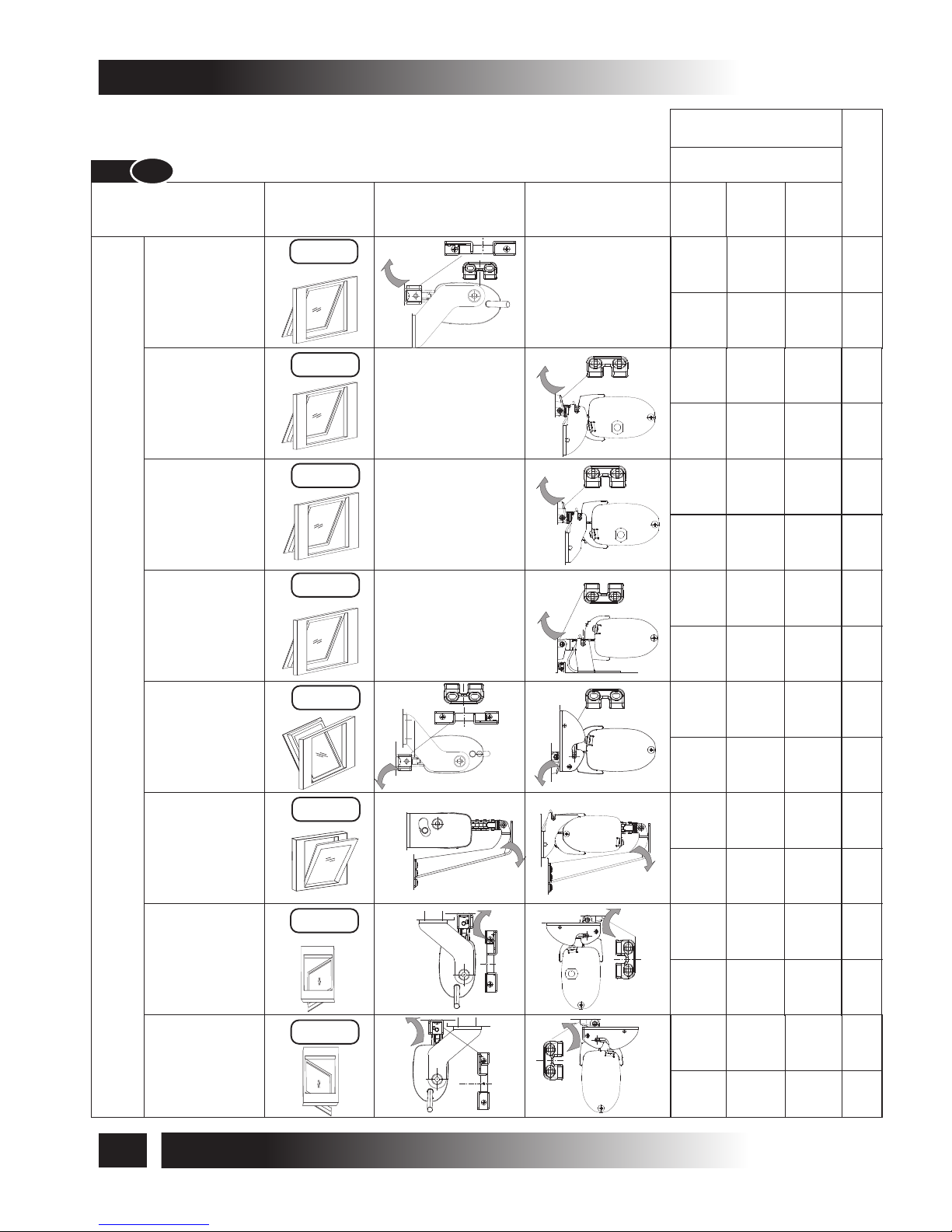

APPLICATION

REF.

Single

push point

Double

push point

TOP HUNG

Outward

opening

SA,S1

SA,S2

A1_1

TOP HUNG

Outward

opening

SC,S1,M1

A1_2

TOP HUNG

Outward

opening

SD,S1,M1

A1_3

TOP HUNG

Outward

opening

SE,S1,M1

A1_4

BOTTOM HUNG

Outward opening

SA,S1

SA,S2

SF,S1,M1

A2

BOTTOM HUNG

Inward opening

SB,S3

SG,S3,M2

A3

SIDE HUNG

Outward opening

LH

SA,S2

SF,S1,M1

A4_1

SIDE HUNG

Outward opening

RH

SA,S4

SF,S1,M1

A4_2

3.8- APPLICATION

ACTUATOR MOUNTING ON THE FRAME

Pag. 20

Pag. 34

Pag. 34

Pag. 34

Pag. 23, 38

Pag. 26, 40

Pag. 28, 43

Pag. 28, 43

Minimun window frame height

mm (1)

stroke mm

360

600

1000

500

600

Sing.

700

Doub.

400

Doub.

500

Doub.

500

600

1000

Sing.

400

Doub.

500

800

1000

Sing.

900

Doub.

500

600

1000

Sing.

700

Doub.

500

600

1000

Sing.

700

Doub.

Push point

Fig.

4

4.1- GENERAL INSTRUCTIONS

OPERATORS MUST BE INFORMED OF ACCIDENT RISKS, SAFETY DEVICES AND THE GENERAL ACCIDENT

PREVENTION REGULATIONS ESTABLISHED BY INTERNATIONAL DIRECTIVES AND BY THE LAW IN FORCE IN THE

COUNTRY OF USE.

ALL OPERATORS MUST STRICTLY COMPLY WITH THE ACCIDENT PREVENTION REGULATIONS IN FORCE IN THE

COUNTRY OF USE.

DO NOT REMOVE OR ALTER THE PLATES PLACED ON THE ACTUATOR BY THE MANUFACTURER.

IF THE WINDOW FRAME IS ACCESSIBLE FROM OR INSTALLED AT A HEIGHT OF LESS THAN 2.5 m FROM THE GROUND,

AND IF IT CAN BE COMMANDED BY AN UNTRAINED USER OR WITH A REMOTE CONTROL DEVICE, FIT AN EMERGENCY

STOP SYSTEM WHICH AUTOMATICALLY CUTS IN TO PREVENT THE RISK OF CRUSHING OR DRAGGING PARTS OF THE

BODY INSERTED BETWEEN THE MOVING AND FIXED PARTS OF THE WINDOW FRAME.

ANY TAMPERING WITH OR UNAUTHORISED REPLACEMENT OF ONE OR MORE PARTS OR COMPONENTS OF THE

ACTUATOR, OR THE USE OF UNORIGINAL ACCESSORIES AND CONSUMABLES, MAY INCREASE THE RISK OF

ACCIDENT AND THUS RELIEVES THE MANUFACTURER OF ALL CIVIL AND PENAL LIABILITY.

13

INSTALLATION AND USE INSTRUCTIONS

C160 TECHNICAL DESCRIPTION -3

C160 SAFETY -4

APPLICATION

REF.

Single

push point

Double

push point

SIDE HUNG

Inward opening

LH

SB,S3

SG,S3,M2

A5_1

SIDE HUNG

Inward opening

RH

SB,S3

SG,S3,M2

A5_2

On the window

Inward opening

SA,S1

SA,S4

B1

On the window

Inward opening

SC,S1,M1

B1

ACTUATOR MOUNTING

ON MOVABLE WINDOWS

ACTUATOR MOUNTING

ON THE FRAME

Pag. 31, 46

Pag. 49

Pag. 52

Pag. 31, 46

Minimun window frame height

mm (1)

stroke mm

360

600

1000

500

800

1000

Sing.

900

Doub.

Push point

500

800

1000

Sing.

900

Doub.

1100

1900

3000

Sing.

1000

Doub.

(1) Distance from the opening edge of the window to the axis of rotation of the window.

Fig.

4

THE MAINTENANCE OPERATIONS INVOLVING THE TOTAL OR PARTIAL DISMOUNTING OF THE ACTUATOR MAY ONLY

BE PERFORMED AFTER DISCONNECTING IT FROM THE POWER SUPPLY.

THIS APPLIANCE MAY NOT BE USED BY PERSONS (CHILDREN INCLUDED) WITH REDUCED PHYSICAL, SENSORIAL OR

MENTAL CAPACITIES, OR INEXPERT PEOPLE, UNLESS THEY ARE SUPERVISED AND TAUGHT HOW TO USE IT BY A

PERSON RESPONSIBLE FOR THEIR SAFETY. CHILDREN MUST BE CONTROLLED TO MAKE SURE THEY DO NOT PLAY

WITH THE APPLIANCE.

DURING HANDLING AND INSTALLATION OF THE PARTS, THE PERSONNEL SHALL BE EQUIPPED WITH SUITABLE

PERSONAL PROTECTION EQUIPMENT (PPE) SO AS TO PERFORM THE WORKS REQUIRED UNDER SAFE CONDITIONS.

14

4- SAFETY

INSTALLATION AND USE INSTRUCTIONS

C160

MACCHINA AD AVVIAMENTO AUTOMATICO

AUTOMATIC MACHINE

PRIMA DI INSTALLARE E UTILIZZARE L'ATTUATORE È OBBLIGATORIO CHE L'INSTALLATORE E

L'UTILIZZATORE LEGGANO E COMPRENDANO IN TUTTE LE SUE PARTI IL MANUALE

THE INSTALLER AND USER MUST READ AND UNDERSTAND ALL PARTS OF THIS MANUAL BEFORE

INSTALLING AND USING THE ACTUATOR.

PERICOLO ATTENZIONE ALLE MANI

BEWARE OF YOUR HANDS

ATTENZIONE MACCHINA AD AVVIAMENTO AUTOMATICO CON COMANDO A DISTANZA

ATTENTION! AUTOMATIC MACHINE WITH REMOTE CONTROL DEVICE

IT

EN

Fig.

5

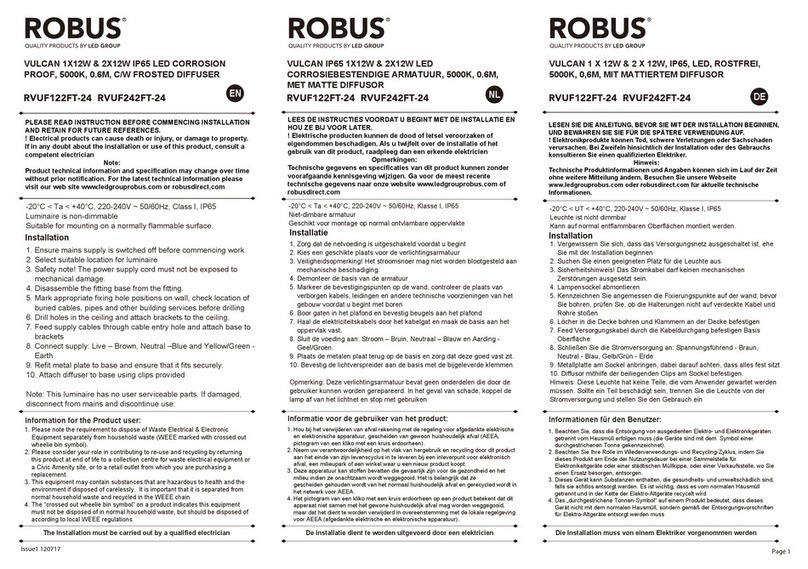

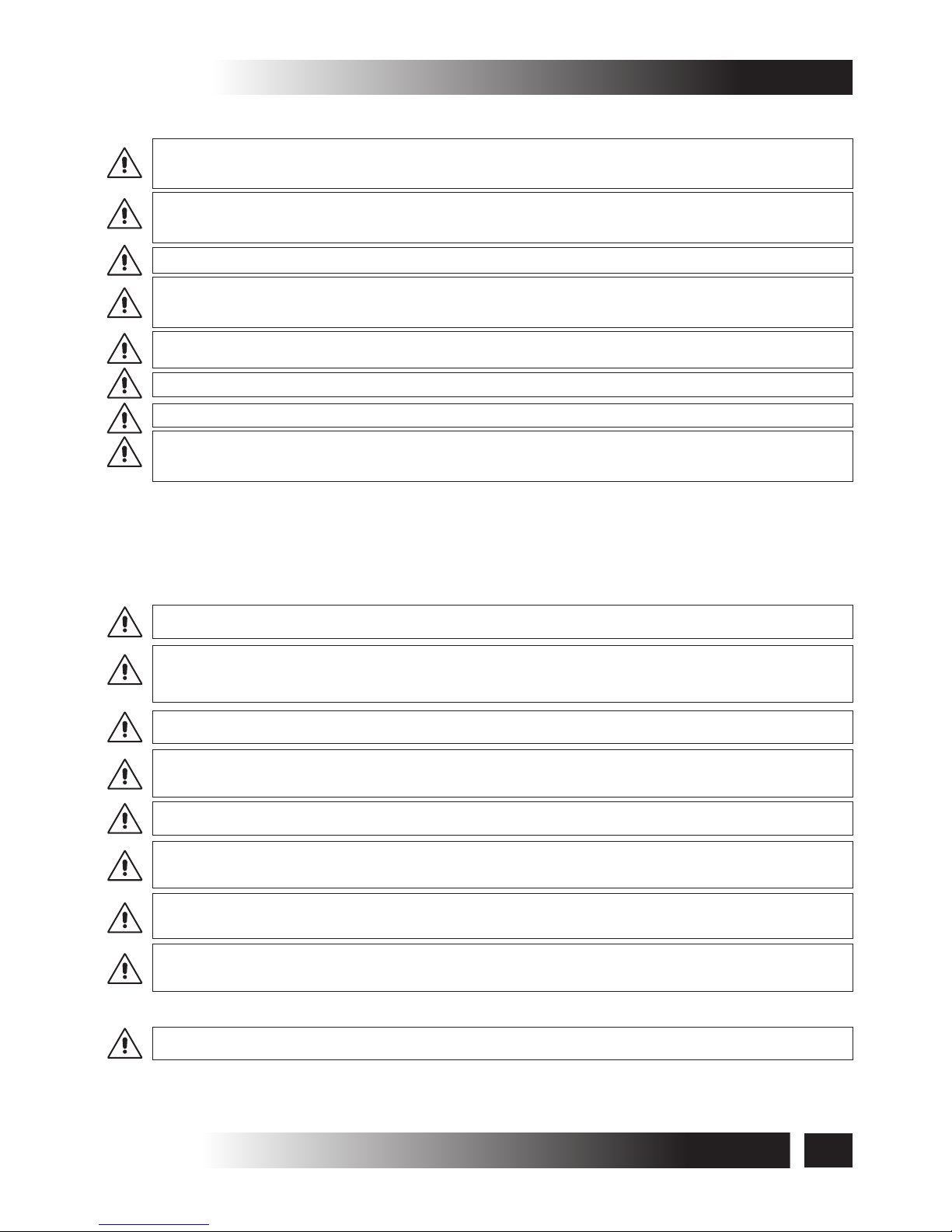

4.3- SAFETY PLATES

IT IS FORBIDDEN TO REMOVE, MOVE, SPOIL OR IN ANYWAY REDUCE THE VISIBILITY OF THE SAFETY PLATES.

FAILURE TO OBSERVE THE ABOVE MAY CAUSE SERIOUS HARM TO PEOPLE AND DAMAGE TO PROPERTY. THE

MANUFACTURER DECLINES ALL LIABILITY FOR ANY DAMAGE CAUSED BY THE FAILURE TO OBSERVE THE ABOVE

REQUIREMENT.

In Fig. 5 illustrates the safety plate: this must applied directly to the outside of the actuator or near it and always in a position

where it can be seen by the installer and/or operator.

4.4- RESIDUAL RISKS

The installer and the user are herewith informed that after the actuator has been installed on the window, the actuator drive

can accidentally generate the following residual risk:

Residual risk: Hazard of squashing or dragging of body parts inserted between the movable and the fix part of the window

frame.

Exposure frequency: Accidental and when the installer or the user decides to perform a wrong voluntary action.

Severity of the damage: Light lesions (usually reversible)

Adopted measures: Before enabling the device, it is compulsory to verify that near the window there are not persons,

animals or things whose safety may be accidentally jeopardized. During actuator operation, it is compulsory to be in a safe

control position assuring visual control on the window movement.

4.2- SAFETY DEVICES

4.2.1- PROTECTION AGAINST ELECTRIC HAZARD

The actuator is protected against electric hazard due to direct and indirect contacts.

The protection measures against direct contacts aim at protecting people against hazards due to contact with active parts,

usually live parts; while the protection measures against indirect contacts aim at protecting people against hazards due to

conducing part, which are usually insulated, but could become live in case of failure (insulation failure).

The adopted protection measures are the following:

1) Insulation of live parts by means of a plastic material body;

2) Enclosure with suitable protection degree;

3)Only for Mod. C160/230 V equipped with double insulation: Protection of passive type given by the use of components

with double insulation, also called components of class II or with equivalent insulation. (It is forbidden to connect the

actuators equipped with double insulation to the earth plant.

15

INSTALLATION AND USE INSTRUCTIONS

C160 INSTALLATION -5

5.1- GENERAL INSTRUCTIONS

THE ACTUATOR INSTALLATION CAN BE PERFORMED EXCLUSIVELY BY COMPETENT AND QUALIFIED TECHNICAL

PERSONNEL SATISFYING THE PROFESSIONAL AND TECHNICAL REQUIREMENTS FORE SEEN BY THE LAWS IN

FORCE IN THE COUNTRY OF INSTALLATION.

THE ACTUATOR PERFORMANCE MUST BE SUFFICIENT TO ASSURE THE CORRECT MOVEMENT OF THE WINDOW. IT IS

COMPULSORY TO VERIFY THE THRUST OR TRACTIVE FORCE ACCORDING TO THE TYPE AND WEIGHT OF THE

WINDOW (PAR. 3.1). IT IS FORBIDDEN TO EXCEED THE LIMITS CONCERNING TECHNICAL DATA (PAR. 3.1).

THE ACTUATOR INSTALLATION MUST BE PERFORMED EXCLUSIVELY WITH CLOSED WINDOW.

BEFORE PERFORMING THE INSTALLATION OF THE ACTUATOR ON BOTTOM HUNG WINDOWS, VERIFY THAT ON BOTH

SIDES OF THE WINDOW TWO COMPASS STROKE LIMIT DEVICES ARE INSTALLED IN ORDER TO AVOID THE

ACCIDENTAL FALL OF THE WINDOW.

FOR CORRECT OPERATION OF THE ACTUATOR, THE WINDOW FRAME MUST HAVE A MINIMUM HEIGHT VALUE

INCLUDED IN THE RANGE STATED IN PAR 3.8.

VERIFY THAT DISTANCE “D” BETWEEN THE ACTUATOR SHELL AND THE CHAIN END IS GREATER THAN 5 mm.

THE FITTING SURFACE FOR THE BRACKETS MUST BE PERFECTLY FLAT AND/OR SMOOTH.

CHECK THE ADEQUACY OF THE WINDOW AND THE SUITABILITY OF THE MATERIALS OF THE WINDOW AND/OR FRAME

ON WHICH THE ACTUATOR WILL BE FASTENED. AND IT MUST ENSURE A GOOD SUPPORT OF THE ACTUATOR-

WINDOW ASSEMBLY DURING THE MOVEMENT.

5.3- ELECTRIC CONNECTIONS

THE CONNECTION OF MODEL C160/24V HAS TO BE CARRIED OUT WITH VERY LOW VOLTAGE SAFETY FEEDER

PROTECTED AGAINST SHORT CIRCUIT.

THE ELECTRIC CONNECTION OF THE ACTUATOR (PAR.11) CAN BE PERFORMED ONLY BY COMPETENT AND

QUALIFIED TECHNICAL PERSONNEL FORESEEN BY THE LAW IN FORCE IN THE COUNTRY OF INSTALLATION WHO

CAN ISSUE TO THE CUSTOMER A DECLARATION OF CONFORMITY FOR THE CONNECTION AND/OR PLANT CARRIED

OUT.

BEFORE PERFORMING THE ELECTRIC CONNECTION OF THE ACTUATOR, VERIFY THE CORRECT INSTALLATION ON THE

WINDOW

THE MAINS TO WHICH THE ACTUATOR IS CONNECTED MUST COMPLY WITH THE REQUIREMENTS OF THE LAWS IN

FORCE IN THE COUNTRY OF INSTALLATION, AS WELL AS SATISFY THE TECHNICAL FEATURES GIVEN IN PAR.3.1 AND

ON THE RATING PLATE AND THE “CE” MARKING.

THE SECTION OF THE MAINS CABLES MUST BE PROPERLY SIZED ACCORDING TO THE ABSORBED ELECTRIC POWER

(SEE RATING PLATE AND “CE” MARKING).

ANY TYPE OF ELECTRIC MATERIAL (PLUG, CABLE, TERMINALS, ETC.) USED FOR THE CONNECTION MUST BE

SUITABLE FOR THE USE, WITH “CE” MARKING, AND COMPLYING WITH THE REQUIREMENTS FORESEEN BY THE LAWS

IN FORCE IN THE COUNTRY OF INSTALLATION.

TO ASSURE AN EFFICIENT SEPARATION FROM THE MAINS, IT IS COMPULSORY TO INSTALL UPSTREAM OF THE

DEVICE A TEMPORARY BIPOLAR SWITCH (PUSHBUTTON) OF APPROVED TYPE. UPSTREAM OF THE COMMAND LINE,

IT IS COMPULSORY TO INSTALL AN UNIPOLAR MAIN SWITCH WITH OPENING OF CONTACTS OF AT LEAST 3 mm.

BEFORE MAKING ANY ELECTRICAL CONNECTIONS ON THE ACTUATOR, MAKE SURE THE POWER SUPPLY CABLE IS

NOT DAMAGED. IF THE CABLE IS DAMAGED, THEN IT MUST BE REPLACED BY THE MANUFACTURER THROUGH THE

TECHNICAL ASSISTANCE SERVICE OR BY TECHNICAL OPERATORS.

5.4- COMMAND DEVICES

THE CONTROL DEVICES USED TO DRIVE THE ACTUATOR MUST ASSURE THE SAFETY CONDITIONS FORESEEN BY

THE LAWS IN FORCE IN THE COUNTRY OF USE.

According to the different type of installations, the actuators can be driven by the following control devices:

1) MANUAL PUSH-BUTTON:

Bipolar switch button with central OFF position, with biased-off switch;

5.2- INSTALLATION

Perform the installation as described in Chapter 10 : DRAWINGS / INSTALLATION INSTRUCTIONS.

16

5- INSTALLATION

INSTALLATION AND USE INSTRUCTIONS

C160

2) OPTIONAL: CONTROL AND FEEDING UNIT:

TOPP microprocessor control units (e.g.: Mod. TF, etc.) controlling the single actuator or more than one actuator

simultaneously by means of one or more manual pushbuttons, an infrared remote control or a 433 Mhz radio control.

To these control units, it is possible to connect rain sensors (RDC - 12V), wind sensor (RW) and brightness sensor.

TO ASSURE A CORRECT OPERATION OF THE ACTUATOR, THE COMMAND AND FEEDING UNITS EVENTUALLY USED

HAVE TO PROVIDE POWER SUPPLY TO THE ACTUATOR FOR MAX. 120 sec.

BEFORE OPERATING THE ACTUATOR, THE USER MUST COMPULSORILY VERIFY THAT NEAR AND/OR UNDER THE

WINDOW THERE ARE NOT ANY PERSON, ANIMAL AND THING WHOSE SAFETY MAY BE ACCIDENTALLY JEOPARDISED

(SEE PAR. 4).

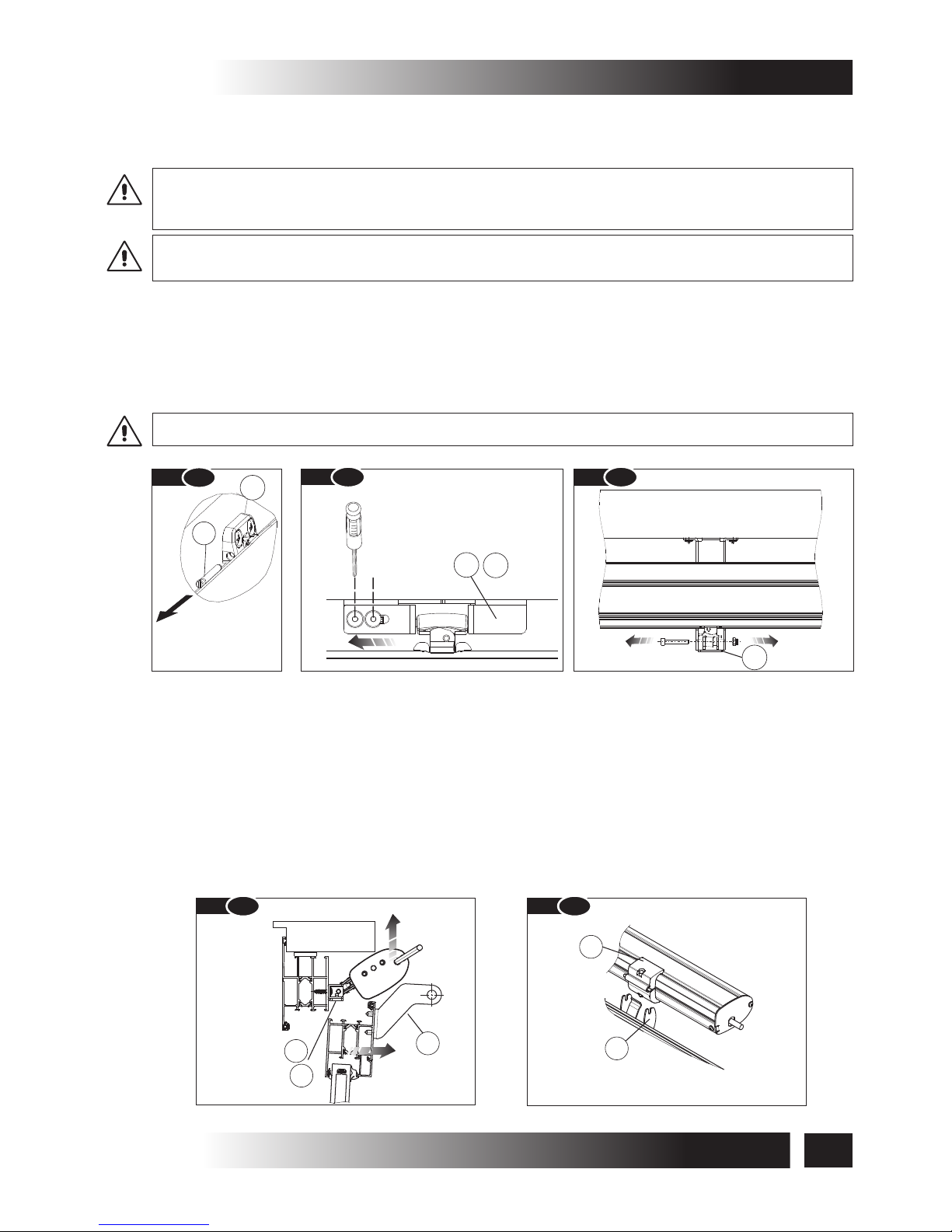

5.5-CORRECT ASSEMBLY OF THE ACTUATOR ON THE WINDOW FRAME

THE CORRECT ADJUSTMENT OF THE WINDOW FRAME CLOSING ASSURES THE LIFE AND THE TIGHTNESS OF THE

SEALS, AS WELL AS THE GOOD OPERATION OF THE ACTUATOR.

1) With open window frame, verify that the stroke is some centimetre lower than the stroke limited by window frame

mechanical limit devices;

VERIFY THAT THE CHAIN COUPLING (A) IS ON THE SAME AXIS OF THE CHAIN END (B). OTHERWISE, LOOSEN THE

TIGHTENING SCREWS AND POSITION CORRECTLY. WHEN THE DEVICES ARE NOT COAXIAL, DAMAGES TO THE

ACTUATOR AND THE WINDOW FRAME MAY ARISE (FIG. 6a- 6b).

2) Verify that the two support brackets of the actuator are aligned to each other and the four tightening screws are well

tightened. Between the two brackets and the actuator there must not be any clearance.

Fig.

6a

NO

Fig.

6b

A

B

B

NO

YES

A

YES

17

INSTALLATION AND USE INSTRUCTIONS

C160 INSTALLATION-5

5.6- EMERGENCY PROCEDURES

Should it be necessary to close the window manually, due to power supply failure or mechanism block, follow these

instructions:

BEFORE PERFORMING ANY TYPE OF TRIPPING ON THE ACTUATOR AND ON THE WINDOW, IT IS COMPULSORY TO

DISCONNECT THE POWER SUPPLY OF THE ACTUATOR AND TO PUT ON “0” THE EVENTUAL SWITCHES OF THE

CONTROL

DEVICES.

IT IS COMPULSORY TO PADLOCK THE MAIN SWITCH OF THE DISCONNECTION DEVICE INSTALLED ON THE MAINS IN

ORDER TO AVOID ANY UNEXPECTED START. IF THE MAIN SWITCH CANNOT BE PADLOCKED, IT IS COMPULSORY TO

PLACE A SIGN FORBIDDING THE ENABLING.

EMERGENCY PROCEDURES – For Applications with frame actuator mounting :

Opening S1: Fig. 7- Remove P1 from S1 bracket completely, until the chain end is released.

Opening S2 (S4): Fig. 8- Slacken off both bolts (Ref. 1,2) with a 2.5mm hex wrench, move the square plate aside and

extract the actuator (pull out the shorter shaft side first).

Opening S3: Fig. 9- Bottom hung – inward opening: with a 3 mm Allen key and 7 mm hex wrench unscrew the nut , remove

the pin until the chain end is released.

SHOULD IT BE IMPOSSIBLE TO CARRY OUT THE ABOVE MENTIONED MANOEUVRES, EXTRACT THE ACTUATOR FROM

THE BRACKETS PROVIDING CONNECTION TO THE FRAME BY UNSCREWING THE PROPER SCREWS.

EMERGENCY PROCEDURES – For applications with casement actuator mounting:

1) Remove the actuator from the window: For single push point actuator (Fig. 9a): loosen the two screws that secure the

actuator to the bracket "SA"; for two push point (Fig. 9b): unfasten the clamps "M1" from the bracket "SC";

2)Move actuator upwards;

3)Open the window just enough and then proceed to pull out the chain terminal from S1 or S4 bracket, described bellow:

• Opening S1: Fig. 7- Remove P1 from S1 bracket completely, until the chain end is released.

• Opening S4: Fig. 8- Slacken off both frame mount bolts with a 2.5mm hex wrench, move the square plate aside and extract

the actuator (pull out the shorter shaft side first).

1

2

S1

Fig. 9

Fig. 8

Fig. 7

S2 S4

S3

P1

Fig. 9a Fig. 9b

SA SC

M1

S1

S4

18

6- USE AND OPERATION

INSTALLATION AND USE INSTRUCTIONS

C160

7- MAINTENANCE

6.1- USE OF THE ACTUATOR

THE ACTUATOR CAN BE USED EXCLUSIVELY BY AN USER ACTING IN COMPLIANCE WITH THE INSTRUCTIONS

CONTAINED IN THIS MANUAL AND/OR IN THE MANUAL OF THE ACTUATOR CONTROL DEVICE (e.g.: WIND AND RAIN

CONTROL UNIT).

BEFORE USING THE ACTUATOR, IT IS COMPULSORY FOR THE USER TO READ AND UNDERSTAND IN ALL ITS PARTS

THIS MANUAL, AS WELL AS THE EVENTUAL MANUAL OF THE INSTALLED CONTROL DEVICE TYPE.

BEFORE OPERATING THE ACTUATOR, THE USER MUST COMPULSORILY VERIFY THAT NEAR AND/OR UNDER THE

WINDOW THERE ARE NOT ANY PERSON, ANIMAL AND THING WHOSE SAFETY MAY BE ACCIDENTALLY JEOPARDISED

(SEE PAR. 4).

DURING THE OPERATION OF THE ACTUATOR CONTROL DEVICE, THE USER HAS TO COMPULSORY OCCUPY A SAFE

CONTROL POSITION ASSURING VISUAL CONTROL ON THE WINDOW MOVEMENT.

IT IS COMPULSORY TO VERIFY CONSTANTLY IN TIME THE FUNCTIONAL EFFICIENCY AND THE RATED PERFORMANCE

OF THE ACTUATOR, OF THE WINDOW FRAME WHERE IT IS INSTALLED AND OF THE ELECTRIC PLANT, PERFORMING

WHEN NECESSARY INTERVENTIONS OF ROUTINE OR SUPPLEMENTARY MAINTENANCE ASSURING OPERATION

CONDITIONS COMPLYING WITH SAFETY REGULATIONS.

LL ABOVE MENTIONED INTERVENTIONS CAN BE PERFORMED ONLY BY COMPETENT AND QUALIFIED TECHNICAL

PERSONNEL MEETING THE PROFESSIONAL AND TECHNICAL REQUIREMENTS FORESEEN BY THE LAW IN FORCE IN

THE COUNTRY OF INSTALLATION.

IN ORDER FOR THE AUTOMATION UNIT TO OPERATE CORRECTLY, WE RECOMMEND CARRYING OUT PERIODICAL

MAINTENANCE ON IT, AS INDICATED IN PAR. 7.1 OF THIS MANUAL.

TOPP INFORMS THE USER THAT, IN ACCORDANCE WITH ART. 8 OF MINISTERIAL DECREE NO. 38 OF 22.1.2008, THE

OWNER OF THE SYSTEM IS RESPONSIBLE FOR ADOPTING ALL NECESSARY MEASURES TO MAINTAIN THE SAFETY

FEATURES SET OUT IN APPLICABLE LEGISLATION, OBSERVING THE INSTRUCTIONS FOR MAINTENANCE AND USE

PROVIDED BY THE MANUFACTURER OF THE DEVICE AND BY THE COMPANY THAT CARRIED OUT THE INSTALLATION.

The use of the actuator allows to control automatically the opening and closing of the window according to the type of control

device installed (see par. 5.4).

7.1- GENERAL INSTRUCTIONS

IF THE ACTUATOR WORKS INCORRECTLY, CONTACT THE MANUFACTURER.

ANY WORK ON THE ACTUATOR (E.G.: POWER CABLE, ETC.) OR ITS COMPONENTS MAY ONLY BE CARRIED OUT BY

PERSONNEL QUALIFIED BY THE MANUFACTURER. TOPP DECLINES ALL LIABILITY FOR WORK PERFORMED BY

UNAUTHORISED PEOPLE.

THE MAINTENANCE OPERATIONS INVOLVING THE TOTAL OR PARTIAL DISMOUNTING OF THE ACTUATOR MAY ONLY

BE PERFORMED AFTER DISCONNECTING IT FROM THE POWER SUPPLY.

The actuator incorporates components that do not require significant routine or extraordinary maintenance operations.

The recommended maintenance activities should in any case involve the periodical execution (every 6 mounths) of at least

the following operations: that the actuator assembly components are clean, the replacement of components that show

signs of superficial damage such as injuries, cracks, discoloration, etc., the fixing systems (brackets and screws) are tight,

the window frame is not deformed and the seals are tight, and check the cables and connectors.

This maintenance activity may be carried out either by TOPP, in accordance with a specific agreement made with the user,

or by the installation technician or by other competent and qualified technical personnel in possession of all legal

requirements.

C160 USO E FUNZIONAMENTO -6

C160 DEMOLITION / DISPOSAL -8

USO E FUNZIONAMENTO -6SPARE PARTS AND ACCESSORIES UPON REQUEST -9

19

INSTALLATION AND USE INSTRUCTIONS

8.1-GENERAL INSTRUCTIONS

THE DEMOLITION OF THE ACTUATOR MUST OCCUR IN COMPLIANCE WITH THE LAWS IN FORCE ON ENVIRONMENT

PROTECTION.

DIFFERENTIATE THE PARTS MAKING UP THE ACTUATOR ACCORDING TO THEIR DIFFERENT MATERIAL TYPE

(PLASTIC, ALUMINIUM, ETC.).

9.1- GENERAL INSTRUCTIONS

THE USE OF “NON-ORIGINAL” SPARE PARTS AND ACCESSORIES WHICH MAY ENDANGER THE SAFETY AND THE

EFFICIENCY OF THE ACTUATOR IS FORBIDDEN..

ORIGINAL SPARE PARTS AND ACCESSORIES HAVE TO BE REQUESTED EXCLUSIVELY TO YOUR DEALER OR TO THE

MANUFACTURER STATING TYPE, MODEL, SERIAL NUMBER, AND YEAR OF CONSTRUCTION OF THE ACTUATOR.

IN CASE OF REPLACEMENT OF THE POWER SUPPLY CABLE, IT IS NECESSARY TO USE A CABLE TYPE HOS-VVF 3 x 0.75

FOR THE C160/230V AND TYPE Si HF Fg4G4 2 x 0.75 FOR THE C160/24V.

THE REPLACEMENT CAN BE PERFORMED EXCLUSIVELY BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL

MEETING THE PROFESSIONAL AND TECHNICAL REQUIREMENTS FORESEEN BY THE LAWS IN FORCE IN THE COUNTRY OF

INSTALLATION.

20

10- DRAWINGS / INSTALLATION INSTRUCTIONS

INSTALLATION AND USE INSTRUCTIONS

C160

Stroke 360

24V - 230V

Standard

Stroke 600

24V - 230V

Standard

A1_1

A1_1

10.1- Actuator mounting on the frame

TOP HUNG

Outward opening

TOP HUNG

Outward opening

Casement

Frame

Overlap

C

A

B

Casement

Frame

Overlap

C

A

B

SA,S1

SA,S2

24.5

X

L1=184.3 L2=183.7

368

16

SA

S1

392

X

L1=194 L2=283

477

16 16

32

38

SA

S2

501

C

SA

V2

VA

A

B

XS2

X

C

SA

V1

VA S1

B

A

This manual suits for next models

1

Table of contents