Tork Craft RT001 User manual

RT001

ROUTER TABLE W/FENCE & FEATHER

BOARD

Made in China to Tork Craft specifications

Instruction manual

Introduction

Thank you for purchasing the Tork Craft™ router table. This instruction

manual will assist you with safety instructions and how to assemble and

use the router table.

The router table is designed to convert a portable plunge router into a

stationary router. It is designed for small routers that only use a 1/4” or

8mm collet with a base diameter smaller than 150mm.

Parts of the router table

1. Extension table

2. Table top

3. Legs

4. Dust extraction port

5. Vertical fence

6. Miter fence

7. Chip guard

2 | P a g e

Safety instructions

Before using the router table, please make sure that the following is installed correctly:

The table top, legs and extension tables are correctly assembled.

All fittings and bolts are tightened.

The mounting plates to secure the router underneath the table is secured in place.

The cutter is correctly installed in the router.

The working area is free from sawdust and debris..

It is advised not to use the router table as a workbench.

The best finish is achieved by making use of the vertical fence to assist in guiding the wood along the router bit.

It is dangerous to use the router table to cut profiles freehand when a router bit is not equipped with a bearing.

Make use of support table or roller stands to support long lengths of wood.

Do not use the router table as a stepping ladder.

Safely store away the router table when it is not in use.

Always feed the wood against the router bit’s rotation.

Always make sure that your hands are kept at a safe distance away from the router bit when in use.

Unplug the router when the cutter is changed.

Care should be taken when handling router bits, as the cutting edges are very sharp.

The largest router diameter to be used with the router table is Ø41mm.

Make sure that the locking lever is released on the router before adjusting the height.

Never do height adjustments while the router is switched on.

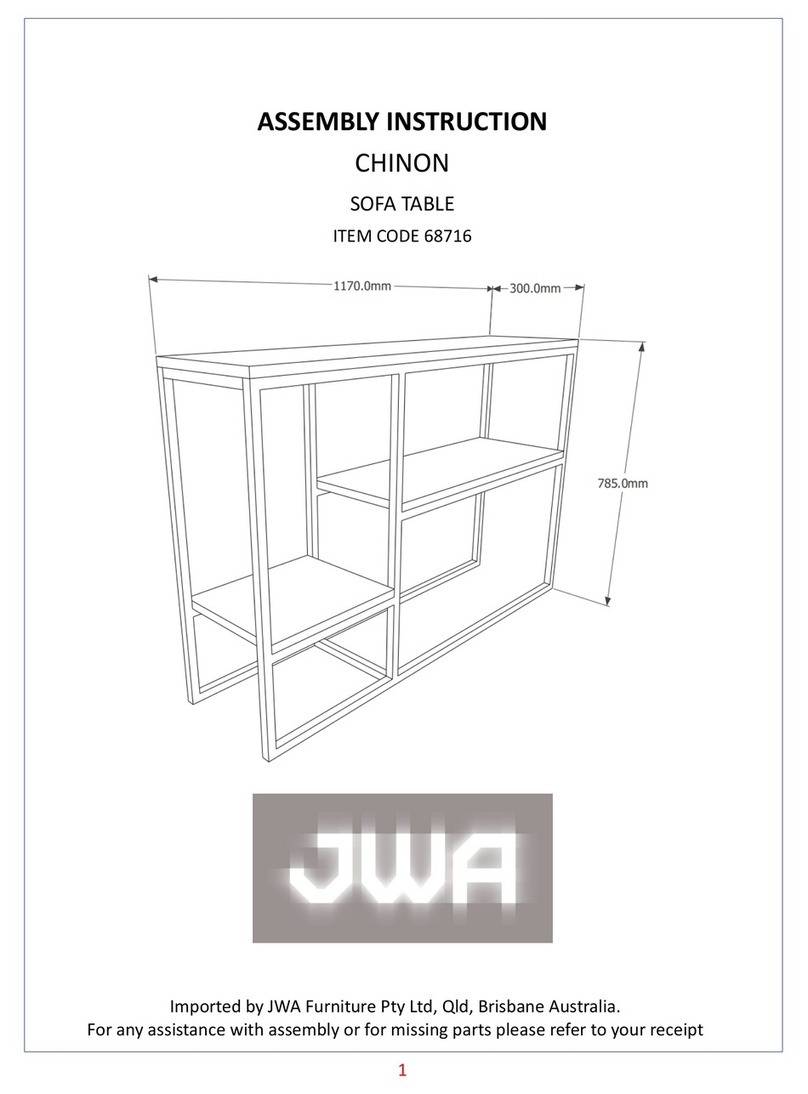

Parts inside of the box

Feather boards with parts to

attach it to the table and

vertical fences.

Table inserts to provide a better clearance

between the router bit and the router table.

Mounting plates used to secure

the router onto the router table.

3 | P a g e

(x16) screw bolts with washers and

nuts used to secure the table

extension and legs to the router

table.

The legs used to support the router table. The narrow end of each leg includes

(x2) 3mm diameter holes to secure the router table to a workbench.

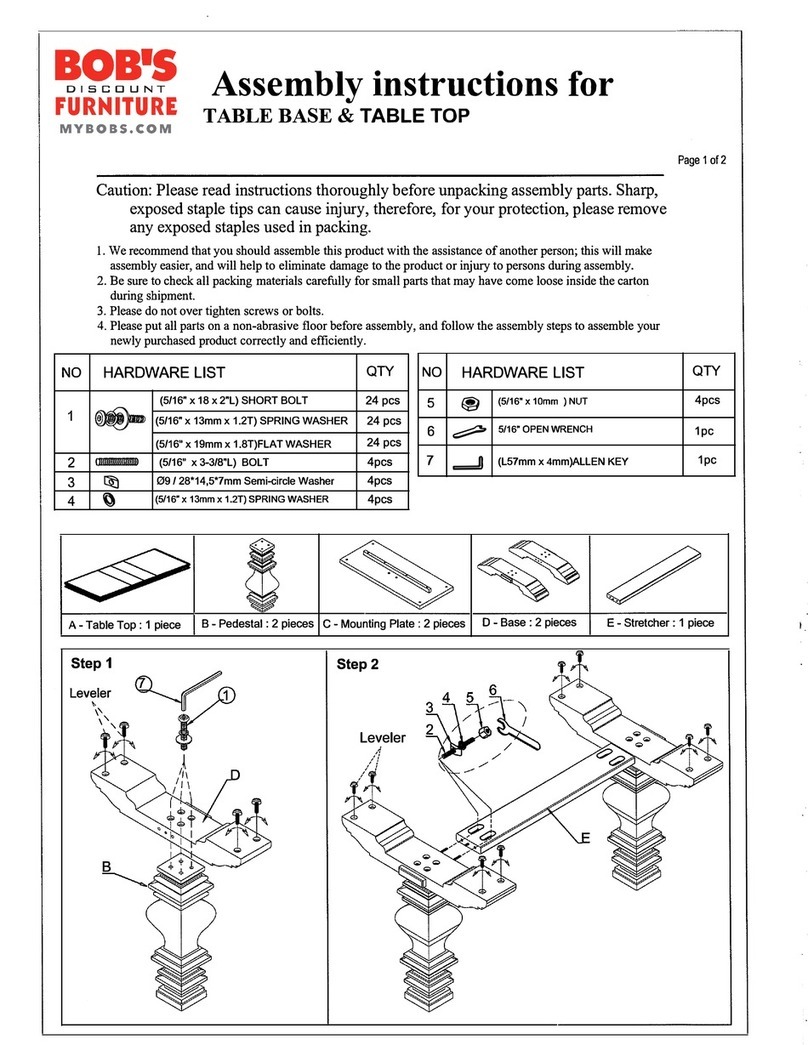

The miter fence is

used to support

end-grain cuts in

wood at specific

angles.

The vertical fences includes the dust extraction port as well as an

offset fence for edge planing.

Knobs and bolts used

to secure the vertical

fences on the router

table.

Router table with a recessed guide to allow

the miter fence to slide in it.

Table extensions are used to help support longer lengths of wood.

A few tools are required to assemble the router table:

A Philips #2 screwdriver

8mm combination wrench

Cordless drill to secure legs on workbench.

4 | P a g e

Assemby and setup of the router table

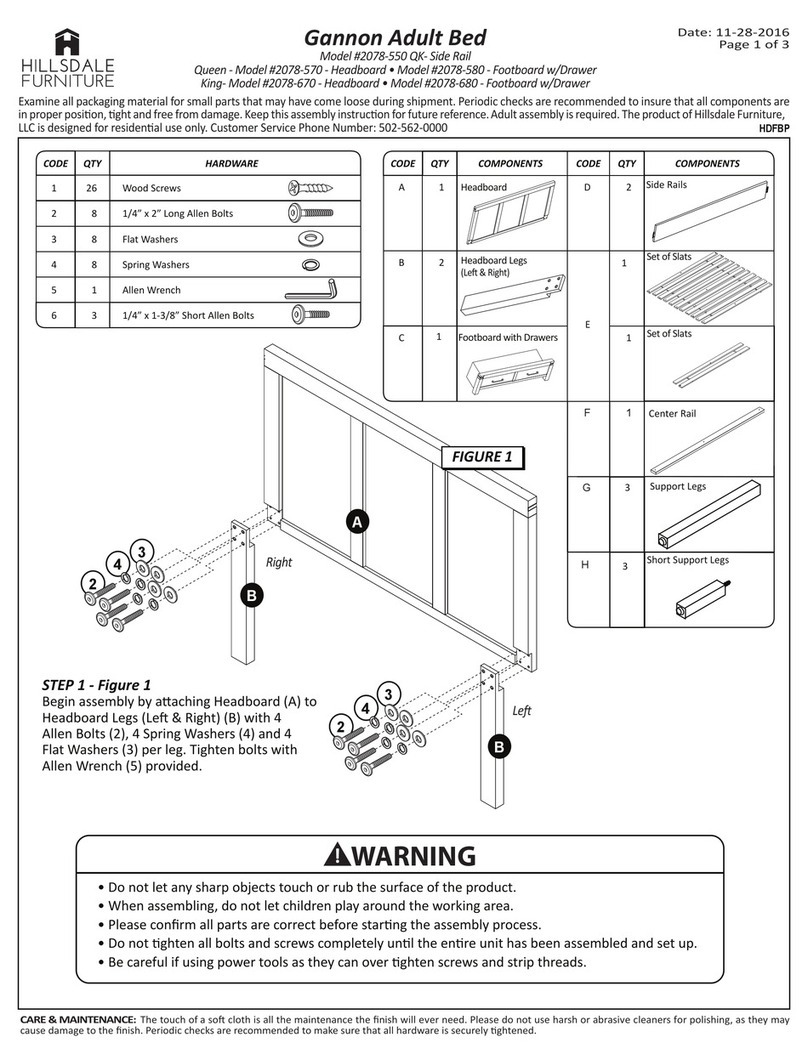

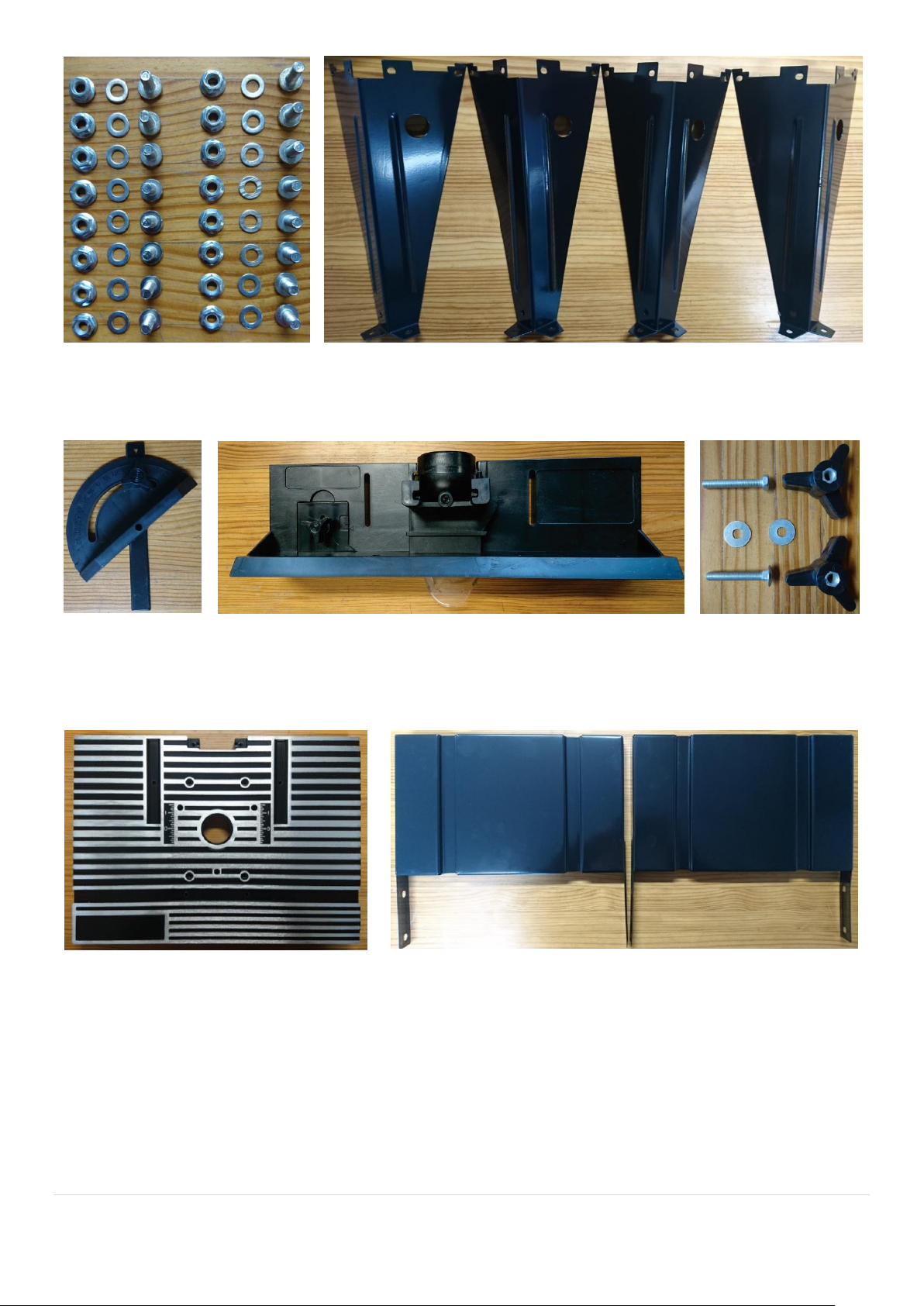

Step 1: Assembly of the router table, table extensions and the legs

Use a flat surface (floor or workbench) and position the router table

and table extensions upside down. Connect the extensions on either

end of the router table. Position the legs on either corner of the router

table and use the (x16) short bolts, washers and nuts to attach the legs

and the table extensions to the router table.

The Phillips screwdriver and the combination wrench will be required to

secure the bolts.

Step 2: Align and secure the router to the router table

The underside of the router table is manufactured to have a 150mm

diameter space available to position and center the router base to the

table. It is important that the opening in the base of the router is

centered with the opening in the table. Position the router correctly and

secure it in place with the mounting plates. At least two mounting

plates should be used.

The assembled router table parts should look like this when it is flipped

over.

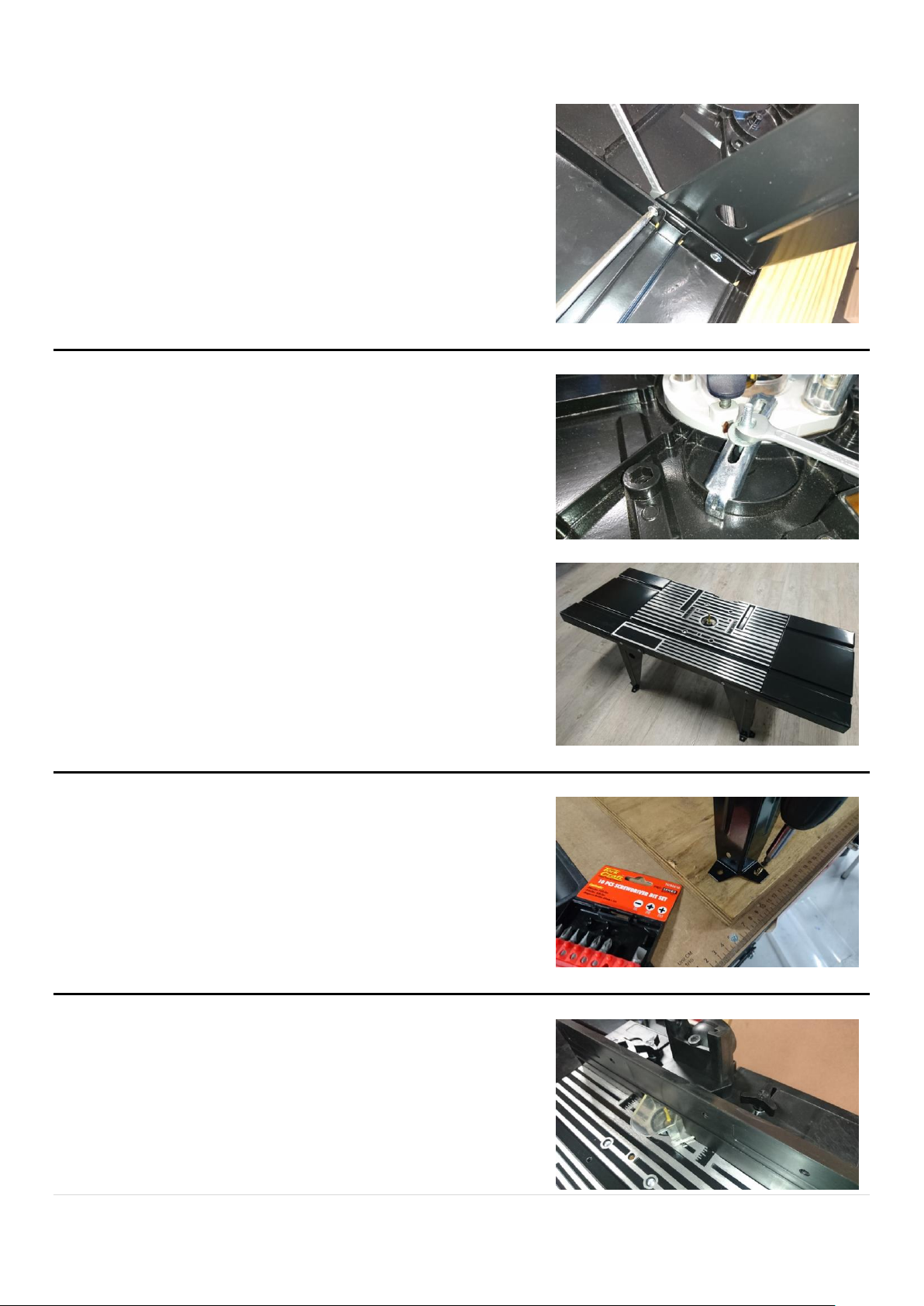

Step 3: Securing the legs to a workbench

Short chipboard screws can be used to secure the legs to a table or a

workbench. We recommend the Tork Craft workbench TCWS001.

Step 4: Installing the vertical fence to the router table

The knobs and bolts are used to install the vertical fence on the router

table.

5 | P a g e

The vertical fence has a built-in offset fence that is only used when the

entire thickness of the wood is profiled. The offset can be adjusted by

using this scale.

The scale should be positioned to the 0 marking when the thickness of

the wood is partially profiled.

The edge of the offset fence should be aligned correctly to the edge of

the router bit, otherwise the cutter will snipe the end of the wood.

This alignment can be achieved by using a straight edge such as a

steel ruler.

For added safety, a chip guard is installed in the vertical fence to help

assist in chip clearing. It is spring loaded and will retract when wood is

pushed along the fence.

Remember to use the correct table insert to increase the table surface

around the router bit.

Step 5: Fitting the feather boards

The feather boards are used to apply feeding pressure. Two are fitted

on the vertical fence with bolts and wing nuts. One is fitted on the router

table with two knobs.

The pressure of the feather boards will apply feeding pressure and it

only allows movement in one direction, preventing kickback.

Inside diameter on table insert

Maximum outside diameter on router bit

13mm

10mm

20mm

16mm

25mm

22mm

32mm

28mm

38mm

35mm

Table of contents