Tormach PSG 612 User manual

QUESTIONS OR COMMENTS?

PLEASE EMAIL US AT:

SUPPORT@TORMACH.COM

OPERATOR MANUAL

TORMACH

PSG 612

2AXIS SEMIAUTOMATIC

PERSONAL SURFACE GRINDER

TORMACH.COM

© 2018 Tormach, Inc. All rights reserved.

UM10159_PSG612_Operators_Manual_0718A

1. Scope of Documentation 2

Customer Service 2

About the PSG 612 2

Intended Use 2

Product Features 2

Components 3

Tool Box Inventory 4

Specifications 5

2. Risks of Machinery 6

Basic Machine Safety 6

Operating Safety 6

Electrical Safety 7

For Lifting 7

For Assembly 7

3. Installation 8

Unpacking 8

Assembly 8

Protecting from Rust 8

Lubrication 8

4. Grinder Operation 11

Control Modes and Power Controls 11

Speed and Feed 11

Wheel On/Wheel Off 11

Start/Stop 11

E-Stop 11

Power Mains 11

Powering Up the Machine 12

Using the Magnetic Chuck 12

5. Working With Wheels 13

Adjusting Table Flags 13

Installing a Grinding Wheel 13

Ring Test 14

Replacing the Hub on a Grinding Wheel 14

Wheel Balancing 15

Dressing a Wheel 16

6. Machine Maintenance 17

Backlash Adjustment 17

Gib Screw Adjustment 17

Changing /Cleaning Air Filters 17

Replacing Fuse 18

Replacing the Y Axis Belt 18

Machine Storage 19

7. Electrical Cabinet Components 20

8. Exploded Views 21

9. Troubleshooting 27

10. Warranty 30

11. Index 32

TABLE OF CONTENTS

UM10159_PSG612_OPERATORS_MANUAL_0718A PB 1UM10159_PSG612_OPERATORS_MANUAL_0718A

The purpose of this manual is to help the reader

understand how to prepare for, operate, and maintain the

Tormach 2-Axis Semi-Automac Personal Surface Grinder

PSG 612.

While the reader may not have an inmate understanding

of the Tormach 2-Axis Semi-Automac Personal

Surface Grinder PSG 612, we assume they have a basic

understanding of how to operate this type of machine.

As with all machinery of this nature, learning the nuances

of operaon is a process that happens through training

and experience. If you are not an experienced operator of

this type of machinery, read through this enre manual,

then learn more from an experienced operator, schooling,

or research before aempng operaons. Following this

advice will help you avoid serious personal injury and get

the best results from your work.

Tormach intends to be as accurate as possible in creang

technical documentaon. That said, periodically manuals

are updated to add or remove content to improve the

overall accuracy and usability. We use an alpha-numeric

revision control method that is idened in the footer of

each page. For example, 0413B is the second update to the

document in the month of April 2013.

The current version of the manual is made available

in electronic format on hp://www.tormach.com/

documents.html. Tormach values customer feedback as it

relates to documentaon. If you have feedback, posive or

construcve, please send an email to

CUSTOMER SERVICE

Tormach provides technical support through mulple

channels. The quickest ways to receive technical support

and the answers you need are through one of the methods

listed below:

• This manual: always the rst place to check

• tormach.com/support

• Email: [email protected]

• Telephone: 608-849-8381

• Fax: 209-885-4534

ABOUT THE PSG 612

Intended Use

The Tormach 2-Axis Semi-Automac Personal Surface

Grinder PSG 612 is a 6” X 12” semi-automac personal

surface grinder. It is intended for use as a general purpose

surface grinder for grinding ferrous materials including cast

iron, mild steel, and alloy steels. Grinding other materials

may be possible, but may require specialized grinding

wheels and or specialized grinding techniques. Tormach

limits support and warranty when products are used

outside the scope of a product’s intended purpose.

All applicable warranes for this equipment are voided

through modicaon to the equipment or use outside

of the Intended Use. Individuals or companies involved

with modifying the equipment or applying the products

assume all consequent liability. Refer to the warranty and

liability secons at the end of this manual for addional

informaon.

Product Features

A surface grinder allows you to smooth the surface of

metallic work pieces, ulizing a semi-automac table that

moves on a horizontal plane and a grinding wheel that

moves along a vercal axis. By mounng a work piece to

the table with a magnec chuck, then moving the table

and the grinding wheel during the grinding process,

extremely small amounts of material can be removed to

create high-tolerance at surfaces.

The PSG 612 is equipped with easy-to-reach front-mounted

handwheels for controlling table movement to posion the

wheel manually.

The table travels in the longitudinal direcon (X) on a

hydrodynamic (oil lm) slideways table, driven by a rack-

and-pinion mechanism. Vercal (Z) travel is driven by a

manually-operated leadscrew with a counterweight for

controlled posioning. Crossfeed travel (Y) is driven by a

leadscrew. Both X and Y are automac and can also be

posioned manually.

The stand doubles as a storage cabinet where you can keep

the necessary tools and extra grinding wheels right where

you need them.

SCOPE OF DOCUMENTATION

UM10159_PSG612_OPERATORS_MANUAL_0718A 23UM10159_PSG612_OPERATORS_MANUAL_0718A

Components

1. Control Panel

2. Power Disconnect

3. Table Jog Handwheel

4. Storage Cabinet

5. Cross Feed Handwheel

6. Table Flags (X)*

7. Shield Plate

8. Grinding Wheel

9. Vercal Adjustment Handwheel

10. Emergency Stop Buon

* Table Flags (Y) (Not Shown)

WARNING: SERIOUS PERSONAL

INJURY COULD OCCUR IF YOU

CONNECT THE MACHINE TO POWER

BEFORE COMPLETING THE SETUP

PROCESS. DO NOT CONNECT POWER

UNTIL INSTRUCTED TO DO SO LATER IN THIS

MANUAL.

WARNING: UNTRAINED USERS HAVE

AN INCREASED RISK OF SERIOUSLY

INJURING THEMSELVES WITH THIS

MACHINE. DO NOT OPERATE THIS

MACHINE UNTIL YOU HAVE

UNDERSTOOD THIS ENTIRE MANUAL AND

RECEIVED PROPER TRAINING.

1

2

4

6

5

3

7

8

9

10

UM10159_PSG612_OPERATORS_MANUAL_0718A 23UM10159_PSG612_OPERATORS_MANUAL_0718A

Tool Box Inventory

Qty Part

1 Metal Tool Box

(Not Shown)

1 Cabinet Lock Keys

1 Balancing Arbor

1 Adjustable Spanner Wrench

1 Diamond Dresser

(in Protecve Case)

1 Diamond Dresser Base

3 Hex Wrenches

4 Machine Foot Assemblies

(Feet, Studs, Nuts and Washers)

1 Grinding Wheel Hubs

2 Auxiliary Clamps and

Bolts w/Nuts

1 Adjustable End Wrench

1 Dual Open End Wrench

1 Spindle Wrench

2 Screwdriver

UM10159_PSG612_OPERATORS_MANUAL_0718A 45UM10159_PSG612_OPERATORS_MANUAL_0718A

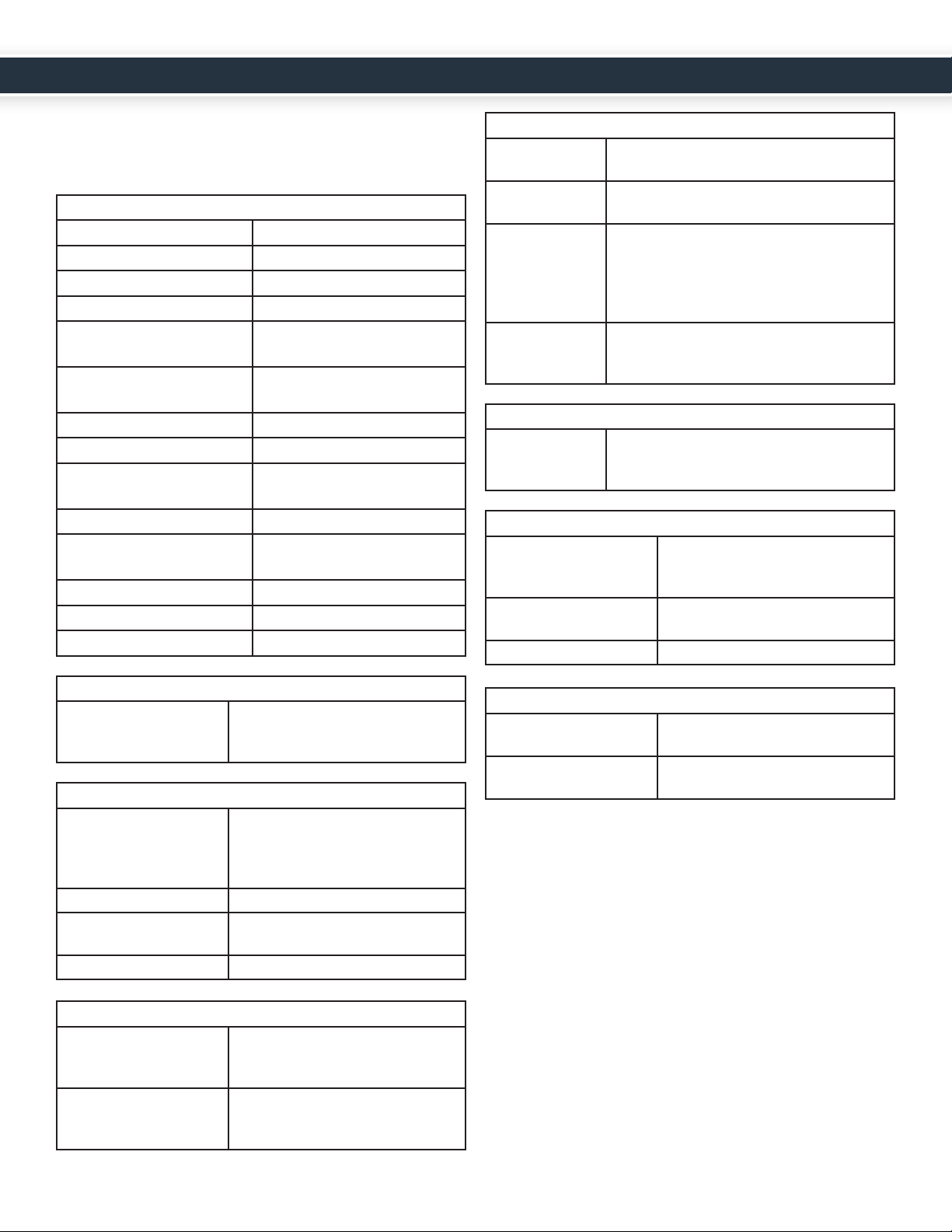

Specifications

Product Dimensions:

Dimensions/Weight:

Table Size 6” X 12”

Table Slots 1 Slot: 1/2” X 15 1/2” T

Longitudinal Max Travel 13 7/8”

Cross Feed Max Travel 8 1/4”

Min / Max Distance to

Spindle Center

3” min, 12” max

Maximum Working Height

(Above Table)

8 3/4”

Elevaon (Z) Graduaon 0.001”

Floor to Table Height 40”

Space Required for Full

Range of Movement

51” W X 66” H X 30” D

Stand Footprint 24” X 24”

Approximate Shipping

Weight

530 lbs.

Weight 400 lbs.

Crate Dimensions 43 1/2” W X 66” H X 30” D

Max Workpiece 400 lbs.

Power:

Power Requirements Single Phase, 110-123 V, 50/60 Hz

8 Amp Peak / 4 Amp Connuous

15 A Breaker Recommended

Spindle:

Spindle Motor Industrial Grade 3/4 HP TEFC

Single Phase, 115 V 60 Hz

7 Amp Peak

Inducon Motor

Wheel Size 7” X 1 1/4” X 1/2” Hub

Wheel RPM 3450 RPM (@60 Hz) providing 6300

SFM

Spindle Bearing P6

Iron:

Frame and Table Cast Iron with Hand-Scraped

Hydrodynamic Dovetailed Slide

Ways and Tapered Adjustment Gibs

Slide Way Surfaces Low Fricon PTFE-lled Acetyl

Bonded Sliding Surface, Similar to

Turcite® or Rulon®

Moon:

Feedrate 0-45 /min Longitudinal (X)

0-24 /min Cross Feed (Y)

Axis Drives NEMA 34 Stepper Motors with Leadshine®

High Performance Microstepping Drivers

Moon Longitudinal: Rack and Pinion (Automac)

Cross: Leadscrew w/ An-backlash Nut

(Automac or Manual)

Vercal: Leadscrew w/ An-Backlash Nut

(Manual)

Vercal

Handwheel

Graduaon

0.0005” (0.012mm)

Control:

Operator

Console

Wheel On/O, Speed and Cross Feed

Control, Power On, E-Stop, 4-Mode

Automac Feed

Other Features:

Paint 2-Part Copolymer Enamel,

Cross-linked Acrylic /Modied

Amino Resin

Stand Sheet Metal With Storage Cabinet

and Adjustable Footpads

Lubricaon Single Shot Distribuon, 7 Points

1 Year Warranty:

Standard Warranty 12 Month Tormach Standard

Warranty

Extended Warranty 12 Month Oponal Extended

Warranty, Renewable Yearly

Any machine tool is potenally dangerous. Grinding

wheels are brile and can burst without warning. The

combinaon of a loose or misaligned work piece with the

UM10159_PSG612_OPERATORS_MANUAL_0718A 45UM10159_PSG612_OPERATORS_MANUAL_0718A

inera of a spindle motor and grinding wheel will usually

result in damage to both work and the machine. If loose

hair, clothing, gloves, or jewelry gets caught by a rotang

piece the results can be disastrous. It is the operator’s

responsibility to ensure for his own personal safety, as well

as the safety of bystanders, should such an incident occur.

This manual tries to give you guidance on safety

precauons and techniques, but because we do not know

the details of your workshop or other local condions

we cannot accept responsibility for the performance of

your machine or any damage or injury caused by its use.

It is your responsibility to ensure that you understand the

implicaons of what you are doing and to comply with any

legislaon and codes of pracce applicable to your country

or state.

Operang all machinery and machining equipment can

be dangerous or relavely safe depending on how it is

installed and maintained, and the operator’s experience,

common sense, risk awareness, working condions, and

use of personal protecve equipment (safety glasses,

respirators, etc.).

The owner of this machinery or equipment is ulmately

responsible for its safe use. This responsibility includes

proper installaon in a safe environment, personnel

training and usage authorizaon, regular inspecon and

maintenance, manual availability and comprehension,

applicaon of safety devices, integrity of cung tools or

accessories, and the usage of approved personal protecve

equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will

not be held liable for injury or property damage from

negligence, improper training, machine modicaons, or

misuse. Failure to read, understand, and follow the manual

and safety labels may result in serious personal injury,

including amputaon, broken bones, electrocuon, or

death.

The symbols used in this manual to idenfy hazard levels

are dened as follows:

WARNING: INDICATES A

POTENTIALLY HAZARDOUS

SITUATION THAT, IF NOT AVOIDED,

COULD RESULT IN SERIOUS INJURY

OR DEATH.

CAUTION: INDICATES A POTENTIALLY

HAZARDOUS SITUATION THAT, IF

NOT AVOIDED, COULD RESULT IN

INJURY. CAUTIONS ARE ALSO USED

TO DRAW ATTENTION TO UNSAFE

PRACTICES OR ADVERSE OPERATING

CONDITIONS.

Note: Indicates supplemental informaon and

instrucons on proper operang condions/

techniques.

BASIC MACHINE SAFETY

Operating Safety

Safe operaon of the machinery depends on its proper use

and precauons taken by each operator.

Read and understand this manual. Be certain every

operator understands the proper operaon and safety

requirements before using the machine.

1. Do not operate this machine without knowing the

funcon of every control key, buon, knob or handle.

Refer to the manual or contact Tormach if any funcon

is not understood.

2. Never operate this machine with unbalanced or

damaged grinding wheels.

3. Protect your eyes. Wear approved safety glasses (with

side shields) at all mes.

4. Ear protecon should be used on any operaons that

exceed sound levels of 85dBa.

5. Never wear rings, watches, long sleeves, neckes,

jewelry or other loose items when operang or

working around the machine. Long hair should be

bound or kept under a hat.

6. Do not wear gloves while operang the machine.

Gloves are easily caught in moving parts or cung

tools.

7. Never operate the machine aer consuming alcoholic

beverages or taking strong medicaon.

8. Protect your hands. Stop the machine spindle and

ensure that the computer control is stopped before

RISKS OF MACHINERY

UM10159_PSG612_OPERATORS_MANUAL_0718A 67UM10159_PSG612_OPERATORS_MANUAL_0718A

you:

a. Change tools;

b. Change parts or adjust the work piece;

c. Clear away chips or debris – always use a chip

scraper or brush;

d. Make an adjustment to the part, xture, or take

measurements;

9. Keep work area well lit. Ask for addional light if

needed.

10. Use proper grinding wheels for the job.

11. Chips and dust from certain materials (e.g.,

magnesium) can be ammable. Fine dust from

normally non-ammable materials can be ammable

or even explosive.

12. Chips and dust from certain materials can be toxic.

Vapors from certain overheated materials can be toxic.

Always check a Materials Safety Data Sheet (MSDS) of

suspect materials. Refuse machining work requests of

unknown materials.

13. If you are in any doubt you must seek guidance from a

professionally qualied expert rather than risk injury to

yourself or to others.

14. Always stop the grinder and check to ensure the

machine is in stop mode before adjusng the tool or

work piece.

15. Use adequate safeguarding around the operang

envelope.

It is the responsibility of the employer to provide and

ensure point of operaon safeguarding per the following:

• OSHA 1910.212 - General Requirements for All

Machines

• ANSI B11.09-2010 Safety Requirements for Grinding

Machines

• ANSI B11.TR3-2000 Risk Assessment and Risk

Reducon - A Guideline to Esmate, Evaluate, and

Reduce Risks Associated with Machine Tools

ELECTRICAL SAFETY

Power Input: The power input should be

unplugged before working in the electrical

cabinet.

Grounding: Power inputs must be grounded.

During installaon it is not enough to assume that the

ground line of a wall outlet is properly grounded. Check

connuity between the machine frame and true earth

ground (water pipe or similar) to ensure a good ground

connecon.

Electrical Panel: NEVER operate the grinder with the

cabinet door open.

Retained Electrical Power: Electronic devices within the

electrical cabinet may retain dangerous electrical voltages

aer the power has been removed.

Electrical Service: Certain service and troubleshoong

operaons require access to the electrical cabinet while

the electrical power is on. Only qualied electrical

technicians should perform such operaons.

In preparaon for installing the Tormach 2-Axis Semi-

Automac Personal Surface Grinder PSG 612 Surface

Grinder you will need to idenfy a workspace that is large

enough to accommodate the machine foot print. Select a

workspace that is relavely level and away from exposure

to moisture or vibraons.

CAUTION: TORMACH STRONGLY

RECOMMENDS INSTALLATION AND

ASSEMBLY BE COMPLETED WITH THE

ASSISTANCE OF ANOTHER PERSON.

REQUIRED TOOLS AND ITEMS

During the installaon process you will need the following

items:

For Lifting

• A forkli, engine hoist, or other mechanical liing

device rated for the weight of the machine.

• A chain or clevis rated for at least 1500 pounds.

For Assembly

• Machine Foot Assemblies (Included)

• Crowbar

• Level

UNPACKING

The Tormach PSG 612 will arrive in a shipping crate or

pallet jack designed to be moved with a forkli at the base.

UM10159_PSG612_OPERATORS_MANUAL_0718A 67UM10159_PSG612_OPERATORS_MANUAL_0718A

Tormach recommends leaving the machine bolted to the

crate unl it is moved to the installaon locaon.

Note: If you noce any transport damage to the

shipping container or machine, please call Tormach

Customer Service at 1-608-849-8381 before

proceeding with the installaon instrucons.

CAUTION: DO NOT APPLY ANY FORCE

TO THE TABLE WHILE MOVING THE

MACHINE UNLESS THE RODS AND

STRAPS USED DURING SHIPPING ARE

IN PLACE. THE TABLE IS A SLIDING

MECHANISM HELD IN PLACE BY ITS OWN WEIGHT

AND A CROSS FEED SCREW. TILTING THE TABLE IN

AN UPRIGHT POSITION CAN DAMAGE THE CROSS

FEED SCREW.

ASSEMBLY

1. Using a crowbar, remove the sides of the shipping

crate.

2. With the grinder base sll connected to the base of

the crate, reach underneath the crate to un-thread and

remove the four bolts and washers used to secure the

base to the crate.

3. Temporarily remove the X table: Remove the X table

ags and carefully li the table o of the machine

saddle. This provides beer balance when liing the

machine from the liing point.

4. Connect the chain or clevis to the eye bolt located at

the top of the grinder.

5. Using the forkli or mechanical liing device, carefully

li the grinder up from the base of the crate.

6. Pull the base of the crate out and away from the

grinder.

7. Thread the stud, nut, and washer onto the machine

foot and screw the machine foot assembly into

the boom of the grinder cabinet as shown in the

following photo.

8. Slowly lower the machine to the ground at its desired

locaon and replace the table and table ags.

9. Level the machine, adjusng the posion of each

machine foot assembly as necessary.

PROTECTING FROM RUST

Exposed iron and steel surfaces should always be protected

from rust and corrosive environments. If your grinder will

be unused for more than a couple days, you should mist

the surfaces with light water repellent oil such as WD-40.

INITIAL LUBRICATION

The X-axis has a bonded layer of plasc compound, a

composion of Acetyl and PTFE similar to Turcite®. This

is state of the art technology for oil lubricated slideways

and superior to plain ground surfaces or hardened and

chromed surfaces.

When properly maintained, sliding surfaces will last for a

long me. If you use the oil lubricaon system properly the

slideways are not normally maintenance items.

The central lubricaon pump should be lled with quality

way oil. We recommend Perkins Perlube WL-68 (Tormach

Part Number 31386). Other acceptable alternaves

are Tonna 68 (Shell), Vactra No. 2 (Mobil), Way-lube

68 (Sunoco), WayLube 68 (Texaco), Febis 68 (Esso) or

equivalent oil.

INSTALLATION

UM10159_PSG612_OPERATORS_MANUAL_0718A 89UM10159_PSG612_OPERATORS_MANUAL_0718A

A shot of lubricaon should be given for each 4 hours of

operaon and aer the machine has stood unused for

more than 48 hours.

Always make certain that the lubricaon oil is clean. The

oil is delivered to 7 points throughout the machine. This

includes (reference the Lubricaon Schemac on the next

page):

• X-Front

• X-Back

• Y-Right

• Y-Le

• X-Drive Sha

• Z-Ways

• Y-Leadscrew

These are some of the most crical and expensive

mechanical parts of the machine. Any dirt or foreign

material suspended in the oil is going to be delivered

directly to these parts and can dramacally shorten the

eecve life of the machine.

Be sure to clean o the cover and surrounding area before

relling the oil reservoir. The strainer at the top of the

reservoir is only a screen; it is not a lter.

Your PSG 612 comes standard with a single shot manual

oil pump. An oponal Automac Oiler is also available

(Tormach Part Number 31373).

Notes:

• The pump is spring loaded, where the spring

force creates a very light hydraulic pressure. You

can get the oil out quicker by pushing a bit, but

apply too much force and you can pop o one of

the oil lines.

• You will have a more uniform distribuon of oil

if the machine is moving when the hydraulic

pressure is applied.

• The pump sucks up oil from the reservoir on the

pull stroke and delivers it to the machine on the

push stroke. If at some point the oil pump seems

to move much easier on the push stroke then

make certain that you do not have a broken oil

line.

• Extreme axis posions can expose the oil

distribuon channels that are cut into the way

support saddle surfaces. If the pump is used in

those posions the hydraulic force of the oil will

not apply it throughout the machine as intended.

Instead the oil will simply squirt out at the point

where the oil channel is exposed.

• Aer a long period of inacvity or in cold

condions the oil system may become clogged.

See Tormach Service Bullen SB0031 – Flushing

the Lubricaon System in the Event of a Clog.

UM10159_PSG612_OPERATORS_MANUAL_0718A 89UM10159_PSG612_OPERATORS_MANUAL_0718A

P-18

P-19

P-20

P-21

Elbow (31311)

Nut (31310)

Ferrule (31309)

Manifold Orifice (31370)

Gib Orifice (31408)

Nut and Ferrule Bundle (31409)

4mm Nylon Tubing (31304)

PUMP

(31302 or 31373)

Left Side

Y Lead

Screw

X Front

Y Right

Y Left

X Drive

Short

Z Ways

Protective Metal Sheath (31306)

Compression Fittings

Large XY

manifold

(34709)

X Back

P-1

P-2

P-3

P-4

(33954)

UM10159_PSG612_OPERATORS_MANUAL_0718A 10 11 UM10159_PSG612_OPERATORS_MANUAL_0718A

CONTROL MODES AND POWER

CONTROLS

Speed and Feed

The speed and feed knobs are used to control the moon

of the work table. Speed controls X-axis moon and Feed

controls how far the table moves in the Y-axis. Turn the

knobs in a clockwise direcon to increase speed or feed.

Wheel On/Wheel Off

The Wheel On and Wheel O buons turn the grinding

wheel on and o, respecvely. Wheel O will not stop the

X- or Y-axis.

1. Mode Select Button

Push this buon to switch between grinding modes. Each mode

has a green LED below the mode symbol to indicate the mode is

acve. The machine will not change feed modes while in moon.

2. Feed at Both Ends The grinder feeds in the Y-axis at each end of the X-axis stroke.

3. Feed at Left End Only The grinder feeds in the Y-axis at the le end of each X-axis stroke.

4. Continuous Feed The Y-axis is in connuous feed at set feed.

5. No Feed Use this feed for plunge grinding. No Y-axis moon.

Start/Stop

The Start/Stop buon starts and stops table moon.

E-Stop

The E-Stop buon supplies power to the machine. Rotate

to power up

Main Power Disconnect

The Power Mains switch (located on the side of the control

panel) completely disconnects the machine from an

electrical power source.

Speed

Feed

GRINDER OPERATION

UM10159_PSG612_OPERATORS_MANUAL_0718A 10 11 UM10159_PSG612_OPERATORS_MANUAL_0718A

POWERING UP THE MACHINE

1. Connect the main power cord to an approved IEC wall

outlet.

2. Turn the main disconnect located on the side of the

cabinet to on.

3. Rotate the red emergency (E-stop) knob located on the

electrical box.

4. All of the LED lights on the control panel will blink

once, indicang power to the machine.

5. If either of the LED lights for the speed or feed buon

is acve (red), the table is outside the dened range of

moon and the table is tripping a proximity switch.

6. Manually adjust the table in the X- or Y- direcon if

necessary. The table should move freely.

7. When the table locaon is within the limits, the red

LED lights will turn o.

8. Select the desired grinder operaon mode by pushing

the Mode Select buon unl the LED light to that

operaon turns green.

9. Press/toggle the black start buon to start and stop

table moon. The E-Stop buon should be used in

emergency situaons and to completely terminate

power to the machine.

USING THE MAGNETIC CHUCK

To install the Magnec Chuck (Tormach Part Number

33210) for workholding:

1. Locate the auxiliary clamps with bolts and nuts

(included in the tool box).

2. Wipe the table surface clean, removing any debris or

material.

3. Place the magnec chuck on the grinding surface.

4. Insert the bolts in the T-slots located on either side of

the magnec chuck.

5. Lower the clamps down onto the bolts and then

slide the xture into the grooves on each side of the

magnec chuck.

6. Slide the washer and nut down onto the top of the

bolts and ghten.

7. Insert the wrench into the slot on the front face of the

magnec chuck. Rotate the wrench to the direcon

of “on” or “o” to acvate or deacvate the magnec

eld.

UM10159_PSG612_OPERATORS_MANUAL_0718A 12 13 UM10159_PSG612_OPERATORS_MANUAL_0718A

ADJUSTING TABLE FLAGS

Adjust the distance between the X-axis and Y-axis table

ags to the size of the part being ground.

To set the X-axis and Y-axis travel limits, move the table

ags to the desired locaon by loosening and sliding the

thumbscrews.

Note: Dierent table speeds will produce dierent

amounts of overtravel. As an example, with slow

table movement the table will stop quicker in a

smaller distance than when the table speed is faster.

You may need to adjust the table ags if you change

your table speed.

Note: The thumbscrews must remain on opposite

sides of the proximity switch located in the center

of the grinding surface under the table guard. If

both screws (table ags) are moved to either side

of the proximity switch, the table will not run. If the

proximity switch is defecve, the LEDs will not light.

Keep the travel flags on opposite sides of the

proximity switch located under the table guard.

INSTALLING A GRINDING WHEEL

CAUTION: NEVER INSTALL A

GRINDING WHEEL THAT HAS NOT

BEEN PROPERLY BALANCED.

There are many reasons for changing the grinding wheel.

These include changing the type of material that is being

ground or changing the grit type of the wheel itself (for

example, from ne to course). Over me the grinding

wheel will experience wear and will need to be replaced.

1. Remove the three socket head cap screws that hold

the wheel guard cover.

2. Set the wheel guard cover to the side.

3. Using the spanner wrench, remove the spindle nut.

Note: The spindle nut is a le-hand thread.

WORKING WITH WHEELS

UM10159_PSG612_OPERATORS_MANUAL_0718A 12 13 UM10159_PSG612_OPERATORS_MANUAL_0718A

4. Firmly grasp the grinding wheel with one hand and

remove the hub. If the wheel spins freely, you will

need to hold the wheel in one hand while you insert

the spindle wrench in the slot on the back side of the

spindle motor.

Note: You may need to lightly tap the hub in order to

remove the tapered hub from the spindle sha.

5. Pull the hub and wheel back and away from the

grinder.

6. Ensure the inside of the hub is clean and free from

debris. A clean nger works best for this job.

7. Also ensure the spindle taper is wiped clean.

8. Gently place the new wheel onto the spindle and

install the nut, keeping in mind it is a le-hand thread.

9. Hold the wheel in one hand and ghten it down with a

spanner wrench.

Note: You may need to re-insert the spindle wrench

in the slot on the back side of the spindle motor. Do

not over ghten.

10. Replace the cover and the socket head cap screws.

RING TEST

Lightly tap the circumference of the grinding wheel with

a metal object (a wrench works ne). Listen for consistent

ringing sounds. There should be no dead tones as you tap

in several locaons around the wheel.

CAUTION: THE GRINDING WHEEL

SHOULD BE PROPERLY BALANCED

AND DRESSED BEFORE FIRST USE.

UM10159_PSG612_OPERATORS_MANUAL_0718A 14 15 UM10159_PSG612_OPERATORS_MANUAL_0718A

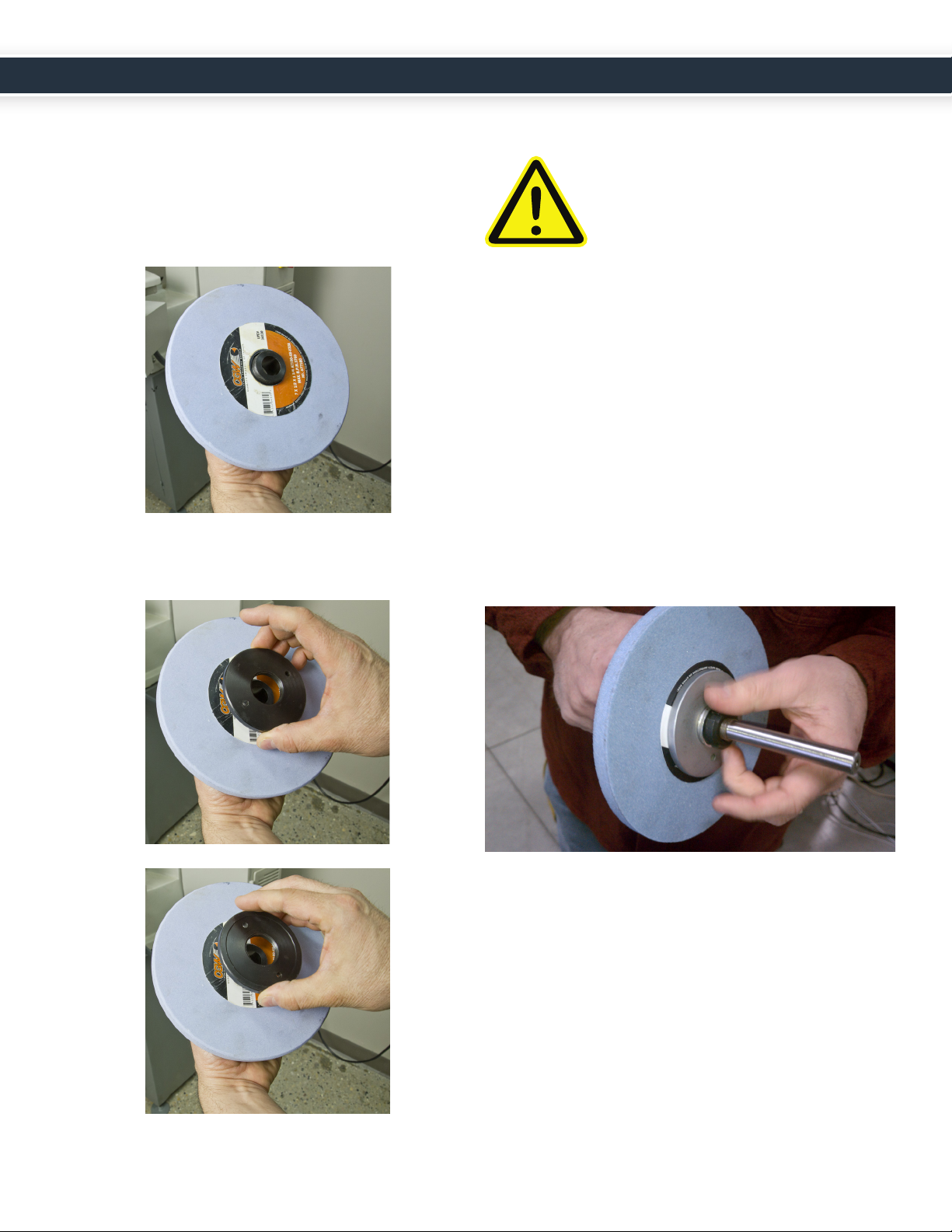

REPLACING THE HUB ON A

GRINDING WHEEL

1. Insert the wheel onto the hub with the product label

facing out/up so that the wheel is resng at against

the back shoulder of the hub.

2. While holding the back of the hub, screw the nut onto

the hub (again note the le handed threads). Make

sure that the “ledge” side of the hub is facing the

wheel.

Correct

Incorrect

3. Tighten the hub nut using the spanner wrench.

CAUTION: OVER TIGHTENING THE

HUB NUT CAN DAMAGE THE

GRINDING WHEEL.

WHEEL BALANCING

For more informaon on balancing a wheel, go to

tormach.com/support and watch our video, Surface

Grinder Basics: How to Balance a Grinding Wheel.

To eliminate vibraon of the grinding wheel during

normal operaon, the grinding weight should be properly

balanced on the wheel hub.

1. To adjust the balance, remove the wheel and hub from

the grinder.

2. Thread the wheel hub onto the balancing arbor and

secure it in place with the washer and nut included

with the accessory kit.

3. Using a level surface and two equally sized resng

blocks (1-2-3 blocks work ne for this task), rest the

balancing arbor on the plates with the wheel between

the plates as shown.

UM10159_PSG612_OPERATORS_MANUAL_0718A 14 15 UM10159_PSG612_OPERATORS_MANUAL_0718A

4. Spin the arbor in either direcon and set it on the

blocks as show in the above photo. When you let go

of the arbor, the wheel should remain at rest. If the

wheel is not balanced, it will rotate. Repeat this step

several mes.

5. If necessary, adjust the balancing weights on the inside

side of the wheel hub using a at head screwdriver,

moving the weights away from the direcon of the

“heavy spot.”

DRESSING A WHEEL

For more informaon on dressing a wheel, go to

tormach.com/support and watch our video, Surface

Grinder Basics: Grinding Wheel Dressing with an Opcal

Wheel Dresser.

1. When facing the machine, place the wheel dresser

onto the surface grinder magnet with the pointed

diamond p on center.

2. Turn the grinding wheel on in staonary moon and

turn the feed and speed knobs full to the le (in the o

posion) to eliminate table moon.

3. Carefully feed the grinding wheel down onto the

diamond using the vercal adjustment handwheel

(Z-axis downfeed) unl contact is made between the

p and the grinding wheel surface.

4. Turn the table jog handwheel (Y-axis crossfeed) and

slowly move the diamond p across wheel surface and

dress unl the wheel achieves the desired nish.

Note: Reference the Control Modes secon for a

denion of the control modes and instrucons on

switching between modes of operaon.

UM10159_PSG612_OPERATORS_MANUAL_0718A 16 17 UM10159_PSG612_OPERATORS_MANUAL_0718A

BACKLASH ADJUSTMENT

Over the course of normal operaon, the PSG 612 may

need backlash adjustment on the Y-axis crossfeed and

(less frequently) on the Z-axis downfeed. If you noce

lost moon in Y- or Z- adjust the backlash adjustment set

screws as follows:

1. Manually move the table in the Y- or Z- direcon so

that it reaches the edge of travel.

2. Using an Allen wrench, manually ghten both set

screws, ensuring the screws are ghtened evenly.

Note: The set screws are located to the le and the

right of the lead screw as shown:

Set Screw Adjustment on the Y-Axis

Set Screw Adjustment on the Z-Axis

GIB SCREW ADJUSTMENT

The slide ways are hand scraped as part of the

manufacturing process. This means that the Z axis saddle

is ed to the column. They are scraped in as a set

and neither the saddle nor the column can be had as a

replacement component. Likewise, the base, XY saddle,

and machine table are scraped in as a set.

The slide ways have tapered gib plates (also hand scraped),

where the posion of the Gib Plate controls the ghtness

and fricon in a slide way.

Like the backlash adjustment on lead screws, the gib

screws on the Y- and Z-axes can loosen over the course of

normal operaon.

1. If you noce the table is wobbling, manually ghten

the gib screw with a at head screwdriver unl you

feel resistance as you move the axis.

2. Back o 1/8 turn.

Note: You may want to manually ghten the gib

screws before rst use, as the grinder may have

experienced excess vibraon during transit.

CHANGING/CLEANING AIR

FILTERS

1. Remove the enre air lter panel from the side of the

control panel.

2. Using a screwdriver, open the front panel cover and

remove the air lter.

MACHINE MAINTENANCE

UM10159_PSG612_OPERATORS_MANUAL_0718A 16 17 UM10159_PSG612_OPERATORS_MANUAL_0718A

3. Wash the air lter with mild soapy water and air dry.

Reassemble the panel and place it into posion on the

control panel.

REPLACING FUSE

Note: While 32A is the fuse holder rang, the Tor-

mach PSG612 is rated for a 15A fuse. Replacement

fuses should be 15A.

WARNING: UNPLUG THE MACHINE

BEFORE REPLACING FUSE.

1. Pull down on the tab at the top of the fuse box.

2. Open the housing and carefully pull the fuse out

of the box.

3. Insert a replacement 15A fuse.

REPLACING THE YAXIS BELT

1. Remove the two cover guard screws.

2. Li and remove the cover guard.

3. Move the table fully to the le.

4. Remove the ve motor cover screws.

UM10159_PSG612_OPERATORS_MANUAL_0718A 18 19 UM10159_PSG612_OPERATORS_MANUAL_0718A

Table of contents

Popular Grinder manuals by other brands

Hitachi

Hitachi G 18SH2 Technical data and service manual

EINHELL

EINHELL TC-AG 115/1 Original operating instructions

Chicago Pneumatic

Chicago Pneumatic RediPower RP9105QB Operator's manual

Makita

Makita DGA508RFE instruction manual

Ingersoll-Rand

Ingersoll-Rand AG Series Product information

Makita

Makita 9005B instruction manual