Toro 23522 User manual

FormNo.3412-299RevA

BrushCutter

ModelNo.23522—SerialNo.400000000andUp

ModelNo.33522—SerialNo.400000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3412-299*A

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Introduction

Thismachineisdesignedtolevelbrush,tallweeds,saplings,

smalltreesandheavyvegetationupto1.8m(6feet)talland

5.1cm(2inches)indiameter.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

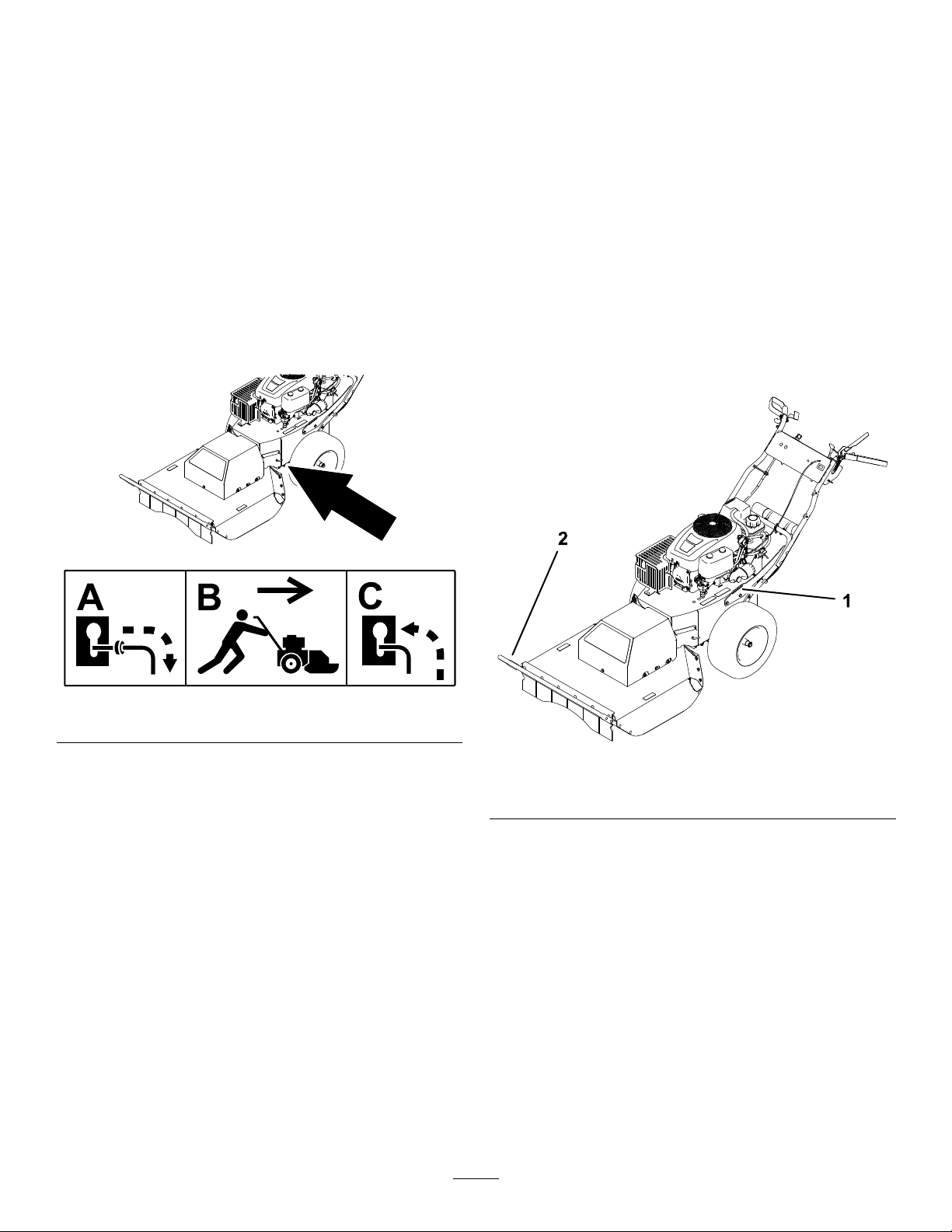

g186622

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

1InstallingtheHandle.............................................8

2ConnectingtheNegativeBatteryCable....................8

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................11

BeforeOperation......................................................12

BeforeOperationSafety..........................................12

RecommendedFuel................................................12

UsingStabilizer/Conditioner...................................12

FillingtheFuelTank...............................................13

CheckingtheEngine-OilLevel.................................13

ThinkSafetyFirst...................................................13

DuringOperation.....................................................13

DuringOperatingSafety..........................................13

OperatingtheIgnitionSwitch..................................14

StartingandShuttingOfftheEngine.........................14

OperatingtheTractionControl................................14

OperatingtheBlade-ControlClutch..........................15

AfterOperation........................................................15

AfterOperationSafety............................................15

MovingaNonfunctioningMachine...........................16

TransportingtheMachine........................................16

Maintenance.................................................................17

RecommendedMaintenanceSchedule(s)......................17

MaintenanceSafety.................................................17

EngineMaintenance..................................................18

EngineSafety.........................................................18

ServicingtheAirCleaner.........................................18

ServicingtheEngineOil..........................................19

ServicingtheSparkPlug..........................................21

FuelSystemMaintenance...........................................22

ReplacingtheIn-LineFuelFilter...............................22

ElectricalSystemMaintenance....................................23

ElectricalSystemSafety...........................................23

RemovingtheBattery.............................................23

ChargingtheBattery...............................................24

InstallingtheBattery...............................................24

ServicingaReplacementBattery...............................24

DriveSystemMaintenance.........................................25

CheckingtheTirePressure......................................25

CoolingSystemMaintenance......................................25

CleaningtheEngineScreen......................................25

CleaningtheEngine-CoolingFinsand

Shrouds.............................................................25

BeltMaintenance......................................................26

InspectingtheBelts................................................26

ReplacingtheTransmissionBelt...............................26

ReplacingtheMowerBelt........................................26

MowerMaintenance...................................................27

BladeSafety...........................................................27

BeforeInspectingorServicingtheBlade....................27

InspectingtheBlade...............................................27

CheckingforaBentBlade........................................28

RemovingtheBlade................................................28

SharpeningtheBlade..............................................29

InstallingtheBlade.................................................29

Cleaning...................................................................30

RemovingDebrisfromtheMachine..........................30

Storage........................................................................30

StoringtheMachine................................................30

Troubleshooting...........................................................31

3

Safety

ThismachinehasbeendesignedinaccordancewithEN

12733.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’sManual

beforestartingtheengine.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

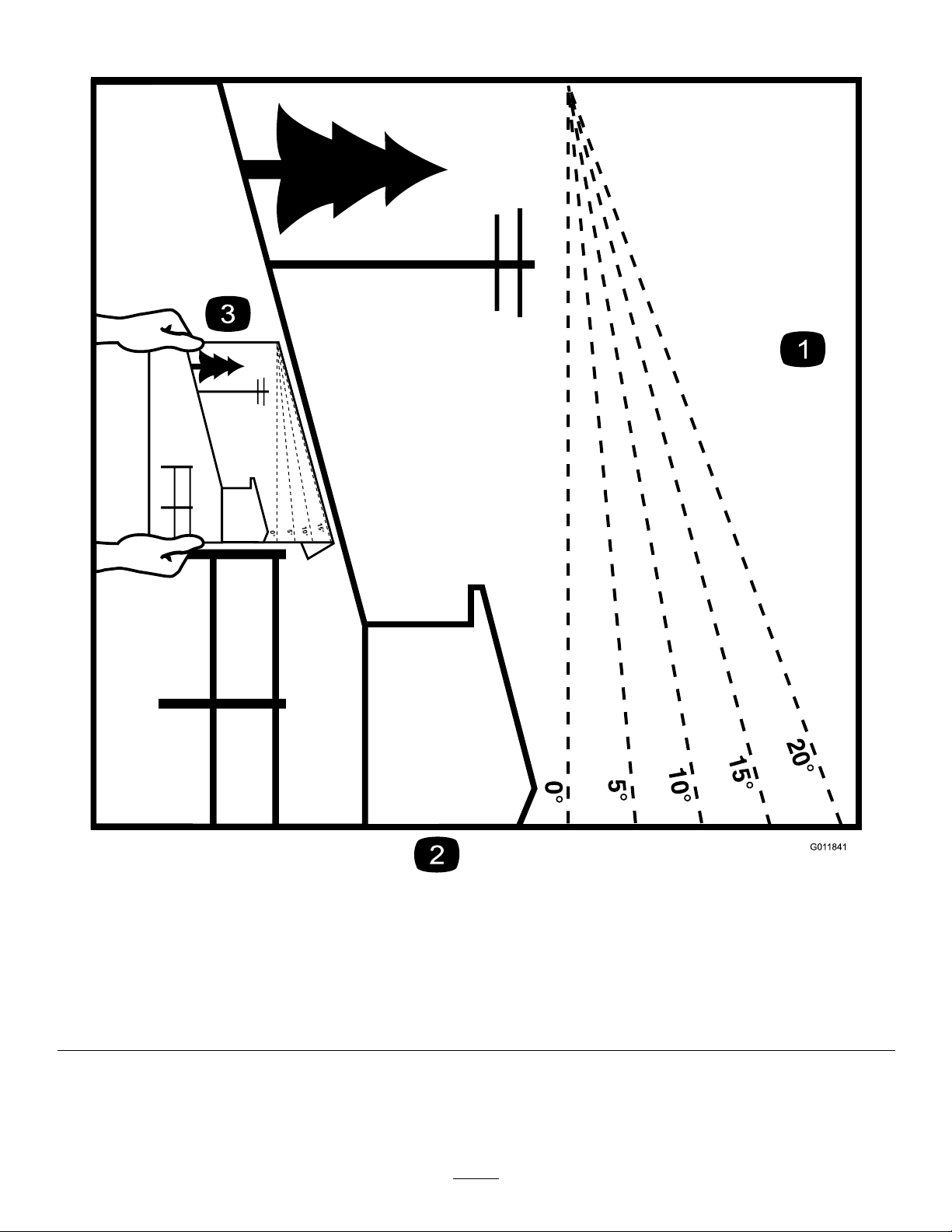

SlopeIndicator

G01 1841

g011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal115-9625

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

decal117-2718

117-2718

decal130-9670

130-9670

1.Severinghazardofhandorfoot;mowerblade—keepaway

frommovingparts;keepallguardsandshieldsinplace.

decal136-4635

136-4635

decal136-4646

136-4646

1.Whenthemachinehas

power,disengagethe

bypassandtransportthe

machinenormally.

3.Whenthemachinehasno

power,engagethebypass

andpushthemachineto

transportit.

2.ReadtheOperator's

Manual.

6

decal132-4005

132-4005

1.Cuttingbladecontrol6.Warning—alloperator'sshouldbe

trainedbeforeoperatingthemachine.

11.Warning—shutofftheengine,

disconnectthesparkplug,andreadthe

Operator'sManualbeforeperforming

maintenance.

2.Choke7.Thrownobjecthazard—shutoffthe

engineandpickupdebrisbefore

operating.

12.Warning—hearingprotectionmustbe

worn.

3.Fastenginespeed8.Warning—keepawayfrommoving

parts;keepallguardsandcoversin

place.

13.Tractiondrivecontrol

4.Slowenginespeed9.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machine.

5.Warning—readtheOperator’sManual.10.Warning—shutofftheenginebefore

leavingtheoperatorposition.

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Cabletie1

Handlebolt4

Nut(5/16inch)4

Slotted-headbolt(#10)2

1

Locknut(#10)2

Installthehandle.

2Nopartsrequired–Connectthenegativebatterycable.

1

InstallingtheHandle

Partsneededforthisprocedure:

1Cabletie

4Handlebolt

4Nut(5/16inch)

2Slotted-headbolt(#10)

2Locknut(#10)

Procedure

1.Installtheupperhandletubestothelowerhandleand

bracesusing2handleboltsand2nuts(5/16inch)on

bothsidesofthemachine(Figure4).

g194930

Figure4

Leftsideshown

1.Upperhandletube4.Nut(5/16inch)

2.Handlebolt5.Brace

3.Lowerhandle

2.Securethethrottlecableoverthelowerhandleusinga

cabletie(Figure5).

g195541

Figure5

1.Operator’sManualtube4.Slotted-headbolt(2)

2.Clamp(2)5.Cabletie

3.Throttlecable6.Locknut(2)

3.SlidetheclampsontotheOperator’sManualtubeand

installitontopofthelowerhandleusing2slotted-head

boltsand2locknuts(Figure5).

8

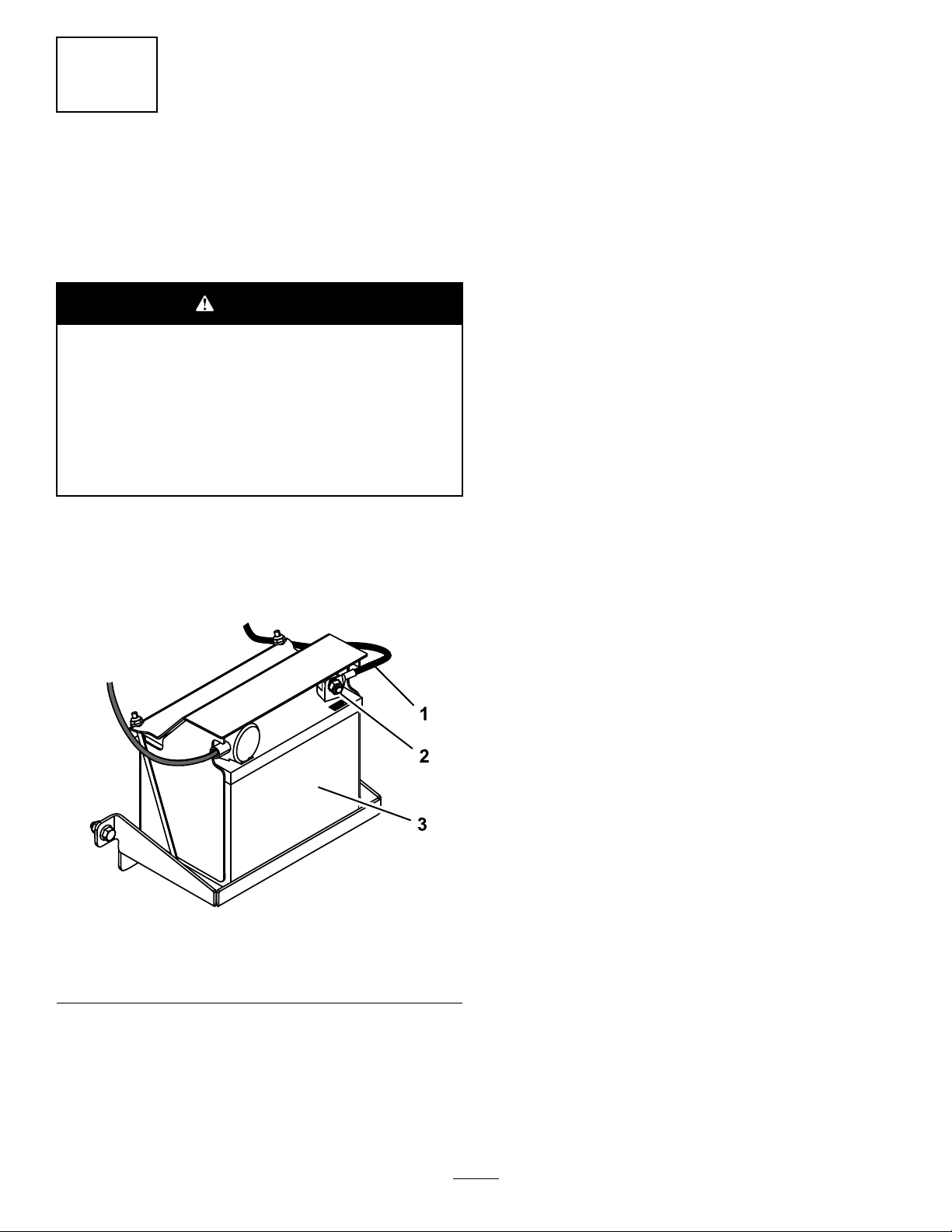

2

ConnectingtheNegative

BatteryCable

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Removetheplasticcapfromthenegativebattery

terminal.

2.Connectthenegativebatterycabletothenegative(-)

batterypostusingtheboltandnutattachedtothe

cable(Figure6).

g195546

Figure6

1.Negativebatterycable3.Battery

2.Boltandnut

9

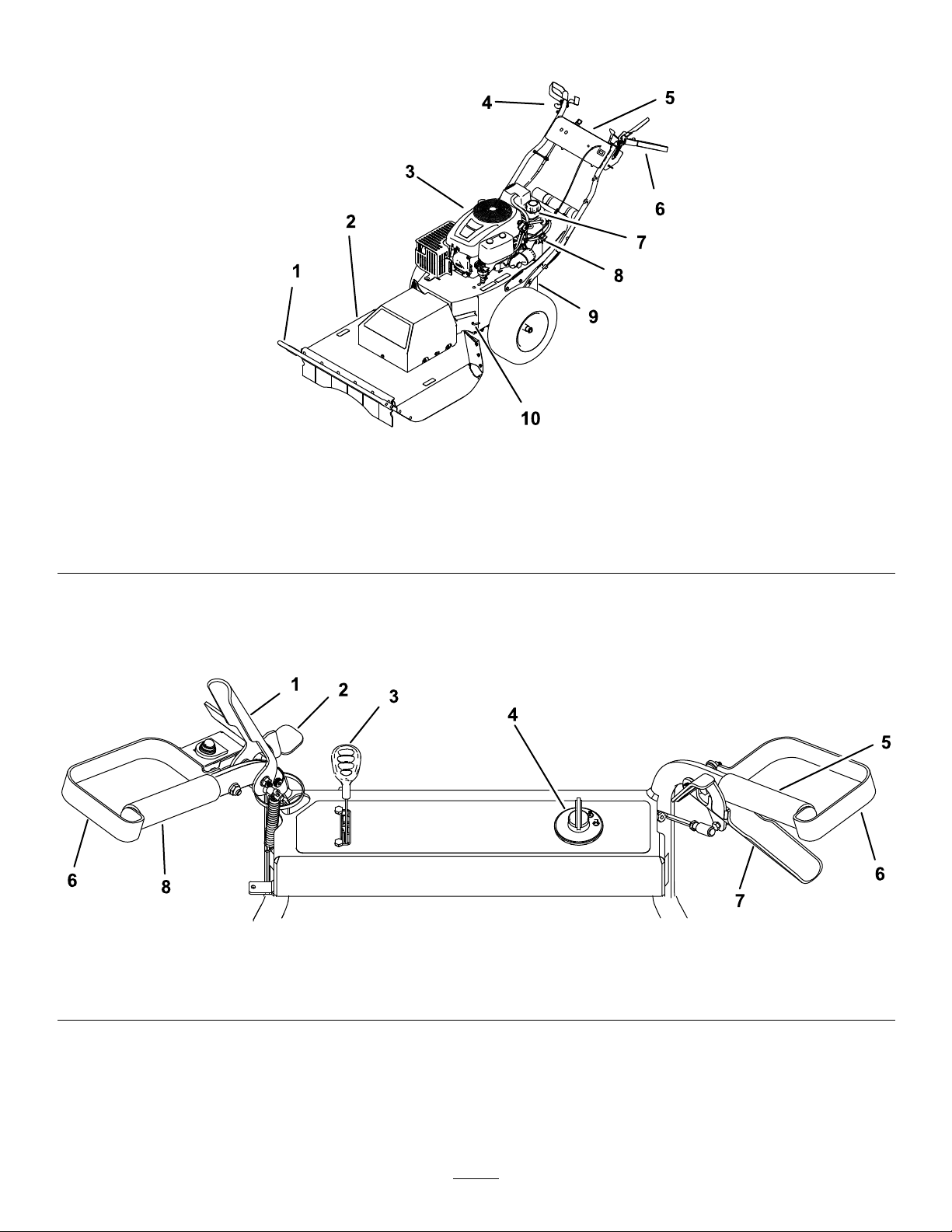

ProductOverview

g186623

Figure7

1.Brushbar4.Righthandgripandtraction

control

7.Fuel-tankcap10.Bypasslever

2.Cutterdeck5.Controlpanel8.Fuel-shutoffvalve

3.Engine6.Lefthandgripand

blade-controlclutch

9.Parkingbrake

Controls

Becomefamiliarwithallthecontrols(Figure7andFigure8)beforeyoustarttheengineandoperatethemachine.

g186771

Figure8

1.Blade-controlclutch3.Throttle/chokecontrol5.Righthandgrip7.Tractioncontrol

2.Safetylatch4.Ignitionswitch6.Handguard8.Lefthandgrip

10

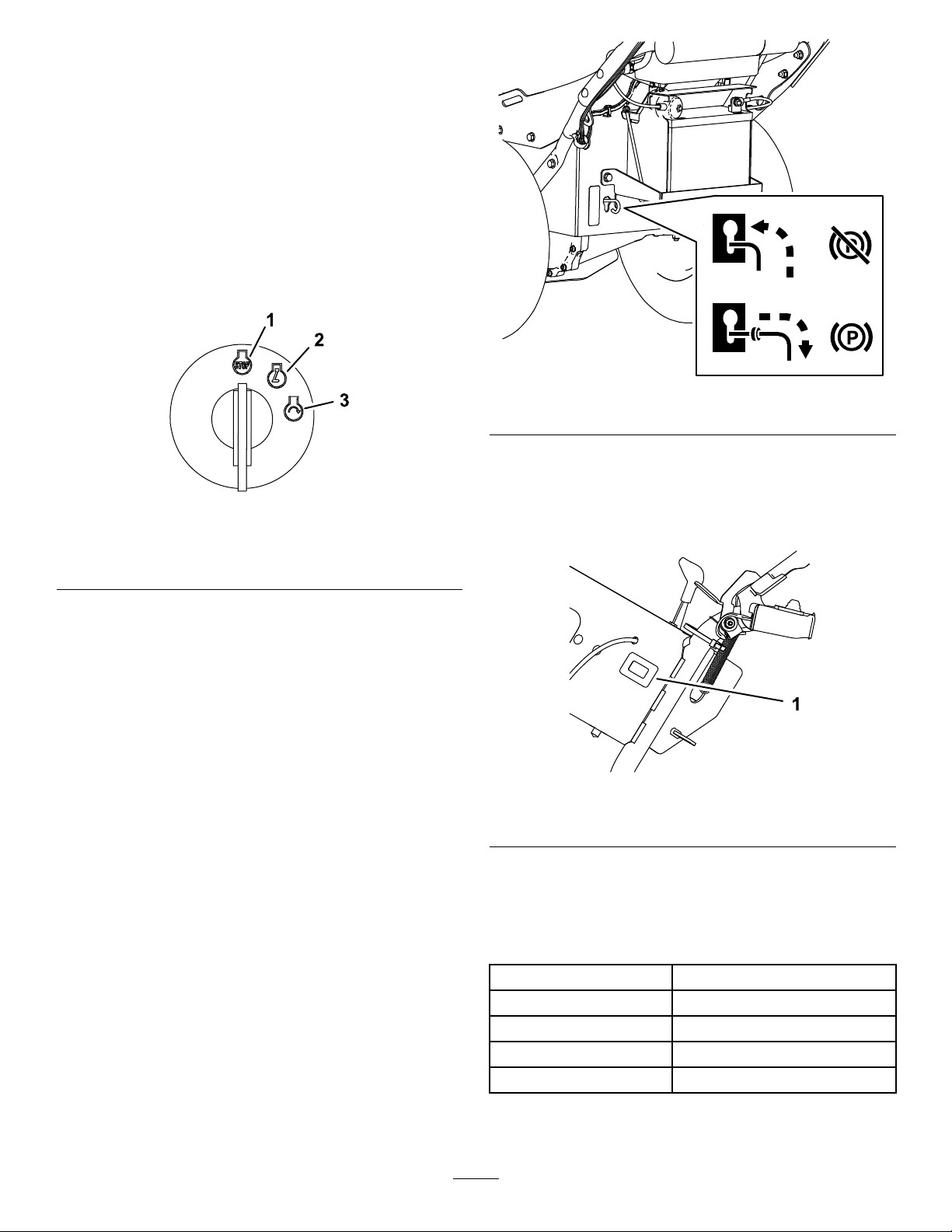

Blade-ControlClutch

Usetheblade-controlclutchtoengageanddisengagethe

mowerblade.

IgnitionSwitch

Theignitionswitchhas3positions:OFF,RUN,andSTART.

ThekeyturnstoSTARTandmovesbacktoRUNuponrelease.

TurningthekeytotheOFF(“STOP”)positionshutsoffthe

engine;however,alwaysremovethekeyfromtheignition

switchwhenleavingthemachinetopreventsomeonefrom

accidentallystartingtheengineandtopreventthebattery

frominadvertentlydraining(Figure9).

g192199

Figure9

1.Offposition3.Startposition

2.Runposition

Throttle/ChokeLever

Thethrottleandchokecontrolsarecombinedinto1control

lever.Thethrottlecontrolstheenginespeedandhasa

continuous-variablesettingfromSLOWtoFAST.Engagethe

chokebymovingtheleverpasttheFASTsettinguntilitstops

TractionControl

Usethetractioncontroltomovethemachineforwardand

rearwardwithcontinuouslyvariablespeed.

Fuel-ShutoffValve

Closethefuel-shutoffvalvefortransport,maintenance,and

storage.

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

ParkingBrake

Theparkingbrakeislocatednearthebattery.Toengagethe

parkingbrake,pulltheleveroutwardthroughthekeyholeand

downtolockitinplace(Figure10).Todisengagetheparking

brake,liftuptheleverandpushitinwardthroughthekeyhole.

g195543

Figure10

HourMeter

Thehourmeterdisplaysthenumberofhoursofoperation

thathavebeenloggedonthemachine(Figure11).

g186773

Figure11

1.Hourmeter

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Length227cm(89inches)

Width88cm(35inches)

Height101cm(40inches)

Weight171kg(376lb)

Cuttingwidth71cm(28inches)

11

Operation

BeforeOperation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperationSafety

GeneralSafety

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevicesareinplaceand

workingproperly.

•Alwaysinspectthemachinetoensurethattheblade,blade

bolts,andcuttingassemblyarenotwornordamaged.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow .

FuelSafety

DANGER

Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachinedirectlyon

thegroundbeforelling,notinavehicleoron

anobject.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

12

FillingtheFuelTank

1.Parkthemachineonalevelsurfaceandshutoffthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit(Figure

7).

4.Addfueltothefueltankuntiltheleveloffuelisatthe

bottomofthellerneck.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page19).

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossfromextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

G009027

12

g009027

Figure12

1.Weareyeprotection.2.Wearhearingprotection.

DuringOperation

DuringOperatingSafety

GeneralSafety

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;thicklypaddedgloves;

andhearingprotection.Tiebacklonghair,secureloose

clothing,anddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Thebladeissharp;contactingthebladecanresultin

seriouspersonalinjury.Shutofftheengineandwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

•Whenyoureleasetheblade-controlclutch,theblade

shouldstopwithin7seconds.Ifnot,stopusingyour

machineimmediatelyandcontactanAuthorizedService

Dealer.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflightning.

•Wetgrassorleavescancauseseriousinjuryifyouslipand

contacttheblade.Avoidmowinginwetconditions.

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview .

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslip-and-fall

accident.

•Shutoffthemachineandinspectthebladeafterstriking

anobjectorifthereisanabnormalvibrationinthe

machine.Makeallnecessaryrepairsbeforeresuming

operation.

•Beforeleavingtheoperatingposition,shutofftheengine,

andwaitforallmovingpartstostop.

•Iftheenginehasbeenrunningthemuferwillbehotand

canseverelyburnyou.Keepawayfromthehotmufer.

•UseaccessoriesandattachmentsapprovedbytheThe

Toro®Companyonly.

SlopeSafety

•Usethemachineacrossthefaceofslopes;neverupand

down.Useextremecautionwhenchangingdirectionon

slopes.

•Donotusethemachineonexcessivelysteepslopes.Poor

footingcouldcauseaslip-and-fallaccident.

•Usethemachinewithcautionneardrop-offs,ditches,

orembankments.

13

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheSTARTposition(Figure13).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failureto

followtheseinstructionscanburnoutthestarter

motor.

Note:Youmayneedmultipleattemptstostartthe

enginewhenyoustartitthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

g192135

Figure13

2.TurntheignitionkeytotheSTOPpositiontoshutoff

theengine.

StartingandShuttingOffthe

Engine

StartingtheEngine

1.MovethethrottleleverforwardpasttheFASTposition

andholditagainsttheforwardstoptoactivatethe

choke.

2.TurntheignitionswitchtotheSTARTposition.

3.Whentheenginestarts,releasethekeyandmovethe

throttleleverbacktotheFASTposition.

ShuttingOfftheEngine

1.Releasetheblade-controlclutchtodisengagetheblade.

2.TurntheignitionswitchtotheOFFpositionand

removethekey.

OperatingtheTractionControl

Tomovethemachineforward,squeezethetractioncontrol

towardthehandgrip(Figure13).

Tomovethemachinerearward,pushthethumbpaddownto

movethetractioncontrolawayfromthehandgrip(Figure

13).

Themoreyoumovethetractioncontrolineitherdirection,

thefasterthemachinemovesinthatdirection.

Todisengagethetractiondrive,releasethetractioncontrol.

g186864

Figure14

1.Tractioncontrol2.Thumbpad

14

OperatingtheBlade-Control

Clutch

Thismachineiscapableofcuttingbrushandsaplingsupto

1.8m(6feet)talland5.1cm(2inches)indiameter.The

cuttingdeckpivotstofollowthegroundcontourasyoumove

themachine.

Toengagetheblade,useyourrighthandtoopenthesafety

latchandthenuseyourlefthandtosqueezetheblade-control

clutchtothelefthandle(Figure14).

Todisengagetheblade,releasetheblade-controlclutch.

g188811

Figure15

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelpprevent

res.Cleanupoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

HaulingSafety

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Securethemachinefromrolling.

15

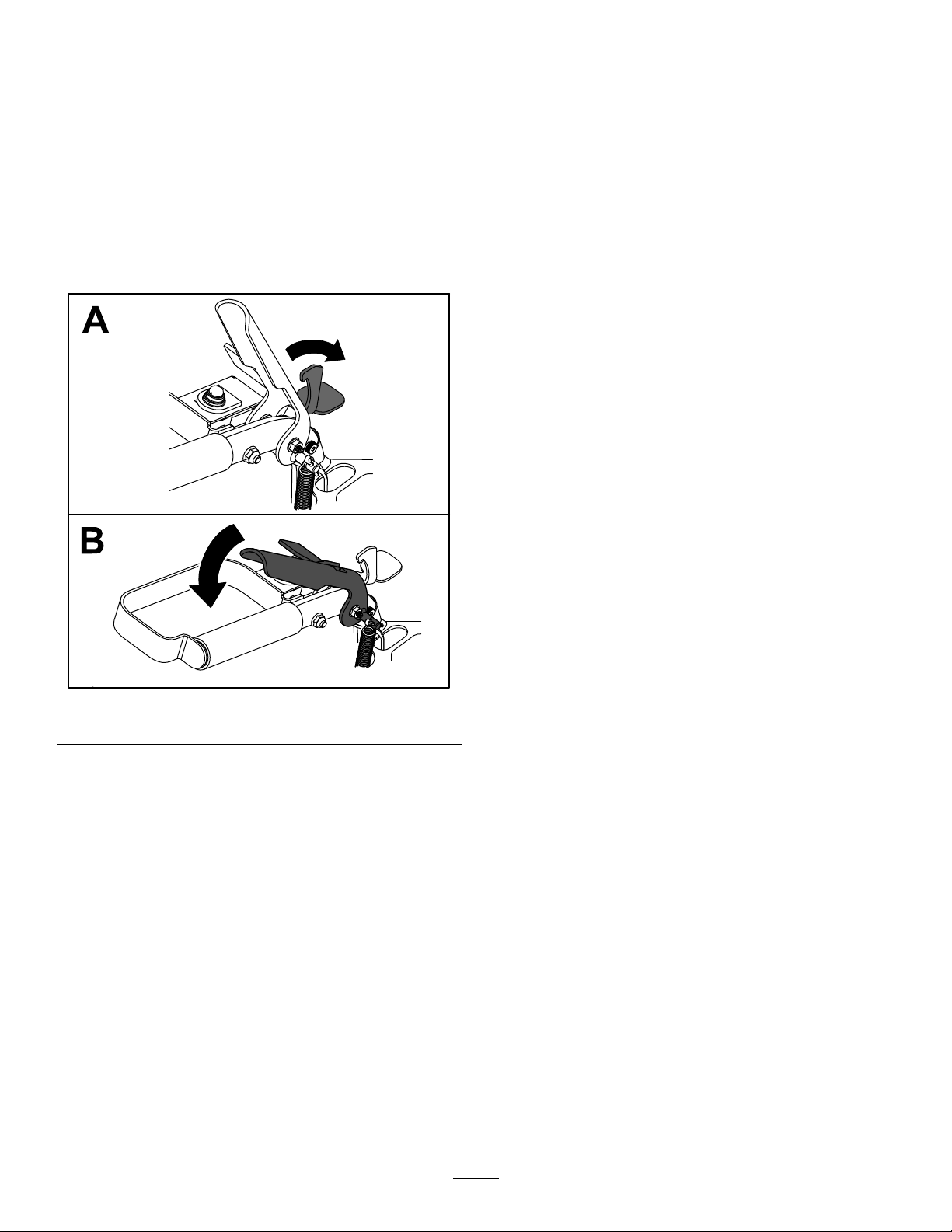

MovingaNonfunctioning

Machine

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlclutch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey,andwaitforallmovingpartstostop.

3.Movethebypassleveroutwardthroughthekeyhole

anddowntolockitinplace.

4.Disengagetheparkingbrake.

5.Pushthemachineasrequired.

6.Engagetheparkingbrake.

7.Movethebypassleverupandinwardthroughthe

keyholetodisengagethebypass.

g188886

g188887

Figure16

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,engagetheparking

brake,andclosethefuelvalve.

5.Usethebrushbarand2tie-downloopsonthemachine

tosecurelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure17).

g188889

Figure17

1.Lefttie-downloop2.Brushbar

16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

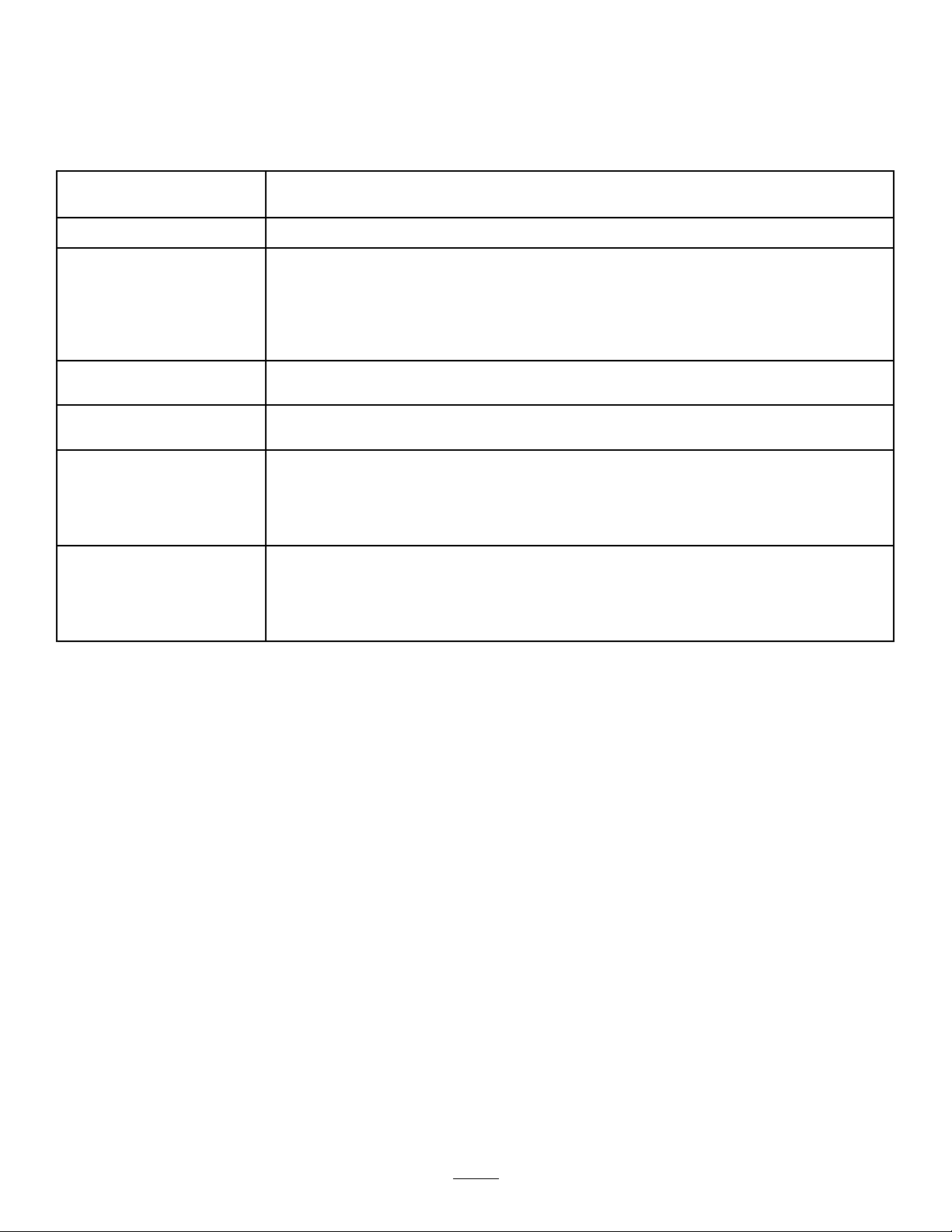

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Changetheengineoilandlter.

Beforeeachuseordaily

•Cleanandchecktheair-cleanerfoamandpaperelements.

•Checktheengine-oillevel.

•Inspecttheconditionofthetires.

•Cleantheengineair-intakescreen.

•Inspecttheblade.

•Removedebrisfromthemachine.

Every25hours•Checktirepressure.

•Checkthebeltsforwear/cracks.

Every50hours•Replacetheair-cleanerfoamandpaperelements.

•Checkthesparkplug.

Every100hours

•Changetheengineoilandlter(changeitmoreoftenunderaheavyloadorin

hightemperatures).

•Replacethesparkplug.

•Replacethein-linefuellter.

•Cleantheengine-coolingnsandshrouds.

Beforestorage

•Chargethebatteryanddisconnectbatterycables.

•Changetheengineoilandlter.

•Servicetheaircleaner.

•Emptythefueltank.

•Lubricateinsidetheenginecylinder.

MaintenanceSafety

•Disconnectthespark-plugwirefromthesparkplugbeforeperforminganymaintenanceprocedure.

•Wearglovesandeyeprotectionwhenservicingthemachine.

•Thebladeissharp;contactingthebladecanresultinseriouspersonalinjury.Weargloveswhenservicingtheblade.

•Nevertamperwithsafetydevices.Checktheirproperoperationregularly.

•Tippingthemachinemaycausethefueltoleak.Fuelisammableandexplosive,andcancausepersonalinjury.Runthe

enginedryorremovethefuelwithahandpump;neversiphonthefuel.

17

EngineMaintenance

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theair-cleanerfoamandpaperelements.

Every50hours—Replacetheair-cleanerfoamand

paperelements.

Note:Servicetheaircleanermorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Parkthemachineonalevelsurface,shutofftheengine,

waitforallmovingpartstostop,andremovethekey

fromtheignitionswitchbeforeleavingtheoperating

position.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

3.Removetheair-cleanercoverbyunscrewingthe2

knobs(Figure18).

G017862

g017862

Figure18

1.Air-cleanercover2.Knobs

4.Removethe2nutssecuringthelterassemblytothe

housing(Figure19).

g037326

Figure19

1.Foamelement3.Nuts

2.Paperelement

5.Carefullyremovethefoamandpaper-lterelements

fromtheair-cleanerhousing.

6.Separatethefoamandpaperelements.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

4.Installthefoamelementontoacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,andblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

Important:Donotcleanthepaperelementwith

liquids,suchassolvents,gasoline,orkerosene.

Replacethepaperelementifitisdamagedor

cannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofalldirt,dust,

anddebris.

18

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaper-aircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure19).

2.Installthefoamandpaperlterintotheair-cleaner

housing.

3.Securethelterassemblytothehousingusingthe2

nuts(Figure19).

4.Installtheair-cleanercover,andtightenthe2knobs

(Figure18).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,or

higher)

CrankcaseCapacity:1.4L(48oz)whenyouchangethe

lter.

Viscosity:Seethetablebelow .

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

g029683

Figure20

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoiland

runtheengine;enginedamagemayresult.

1.Parkthemachineonalevelsurface,shutofftheengine,

waitforallmovingpartstostop,andremovethekey

fromtheignitionswitchbeforeleavingtheoperating

position.

2.Checktheengine-oillevel(Figure21).

B

A

CDE

G029368

FG H

I J K

g029368

Figure21

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenunderaheavy

loadorinhightemperatures).

Note:Changetheengine-oilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Parkthemachineonalevelsurface,shutofftheengine,

waitforallmovingpartstostop,andremovethekey

fromtheignitionswitchbeforeleavingtheoperating

position.

2.Draintheoilfromtheengine(Figure22).

19

B

A

C

E F

D

GH

g029369

g029369

Figure22

3.Removetheengine-oillter(Figure23).Aftertheoilis

drained,installanewoillter.

Note:Ensurethenewoil-ltergaskettouchesthe

engine,andthenanextra3/4turniscompleted.

B

A

C D

EF

3/4

g027477

g027477

Figure23

4.Slowlypourapproximately80%ofthespecied

amountofoilintothellhole(Figure24).

5.Allow3to5minutesfortheoiltosettle,thencheck

theoillevel(Figure24).

20

Other manuals for 23522

1

This manual suits for next models

1

Table of contents

Other Toro Brush Cutter manuals

Popular Brush Cutter manuals by other brands

McCulloch

McCulloch MAC 250 L instruction manual

Makita

Makita RBC413U instruction manual

Tonino Lamborghini

Tonino Lamborghini PB 43SB TL Translation of the original operating instructions

Bosch

Bosch AHS 45-26 Original instructions

Maruyama

Maruyama B420H Owner's/operator's manual

AS MOTOR

AS MOTOR 620KM user manual