Toro 38701 User manual

FormNo.3439-892RevB

PowerBroom

ModelNo.38701—SerialNo.400000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3439-892*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnow,dust,anddirtfrompaved

surfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties,aswellasthatchfromgrass.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g325100

Figure1

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeIndicator...................................................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................7

Controls.............................................................7

Specications....................................................8

Attachments/Accessories...................................8

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

FillingtheFuelTank............................................9

CheckingtheSweepingPath..............................9

AdjustingtheBroomHeight..............................10

DuringOperation.................................................10

DuringOperationSafety...................................10

OperatingtheEngine.........................................11

DrivingtheMachine..........................................13

OperatingtheBroom........................................14

AdjustingtheBroomSideAngle........................15

UsingtheAlternateCasterLocation..................16

ClearingaCloggedBroom................................16

AfterOperation....................................................16

AfterOperationSafety......................................16

PreventingFreeze-upafterUse........................17

TransportingtheMachine.................................17

Maintenance...........................................................18

RecommendedMaintenanceSchedule(s)...........18

MaintenanceSafety..........................................18

PreparingforMaintenance...............................18

Lubrication........................................................19

EngineMaintenance.........................................19

FuelSystemMaintenance................................22

DriveSystemMaintenance...............................23

BroomMaintenance.........................................24

BeltMaintenance..............................................26

ChassisMaintenance.......................................30

Storage...................................................................30

StorageSafety..................................................30

PreparingtheMachineforStorage...................30

RemovingtheMachinefromStorage................31

Troubleshooting......................................................32

Safety

Thismachinehasbeendesignedinaccordancewith

ANSI/OPEIB71.3andANSIB71.4specications.

Thisproductiscapableofinjuringhandsandfeetand

ofthrowingobjects.Failuretoobservethefollowing

safetyinstructionscouldresultinseriousinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

GeneralSafety

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

•Ensurethateveryoneusingthisproductknows

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

•Releasethebroom-drivelever,traction-drivelever,

shutofftheengine,andwaitforallmovingparts

tostopwheneveryouleavetheoperatingposition

foranyreason.

•Donotputyourhandsorfeetnearorunder

movingpartsonthemachine.Keepclearofthe

dischargeopeningatalltimes.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepbystanders,especiallysmallchildren,outof

theoperatingarea.

•Neverallowchildrentooperatethemachine.

3

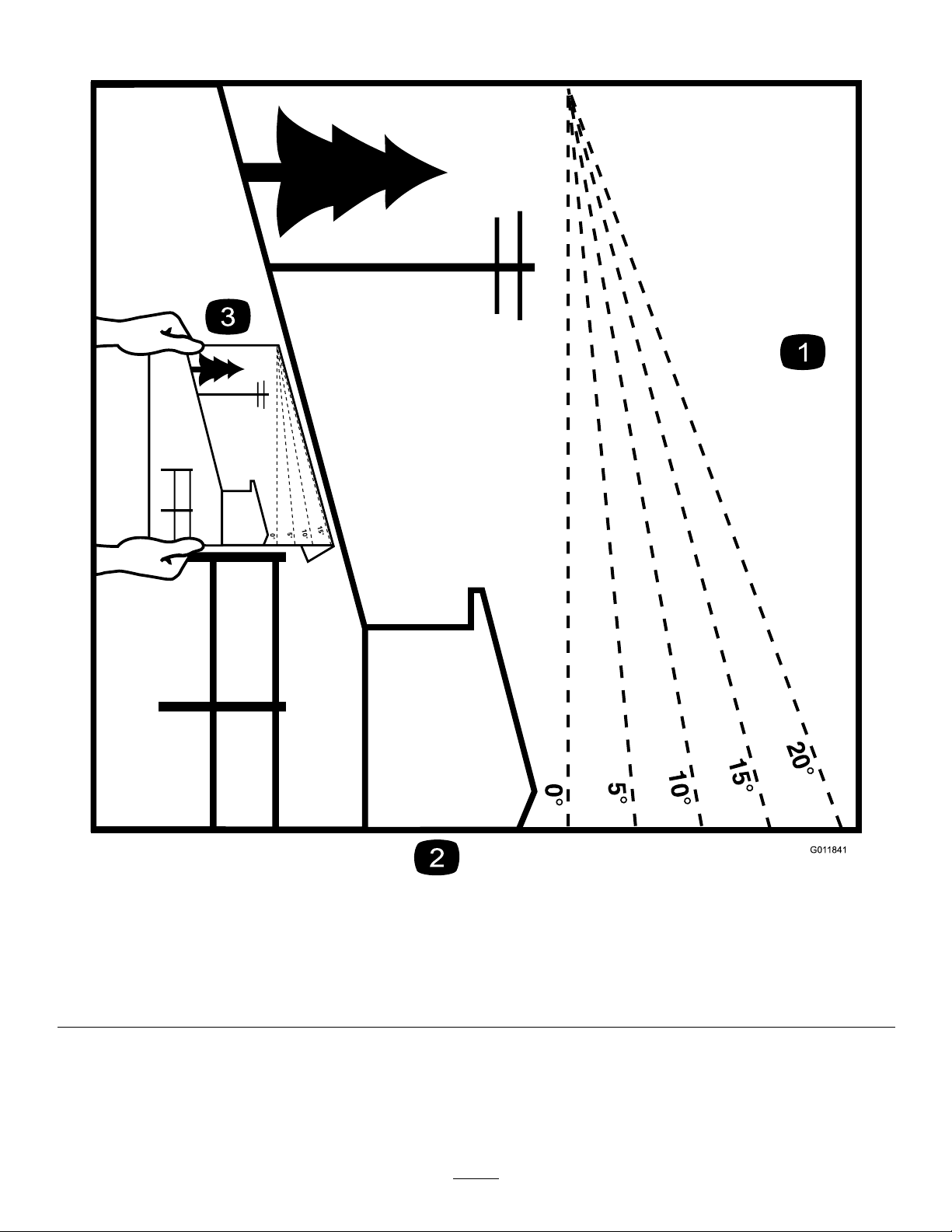

SlopeIndicator

g011841

Figure3

1.Themaximumslopeyoucansafelyoperatethemachineonis10°.Usetheslopeindicatortodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan10°.Foldalongtheappropriatelinetomatchthe

recommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

decal115-2903

115-2903

1.Grease

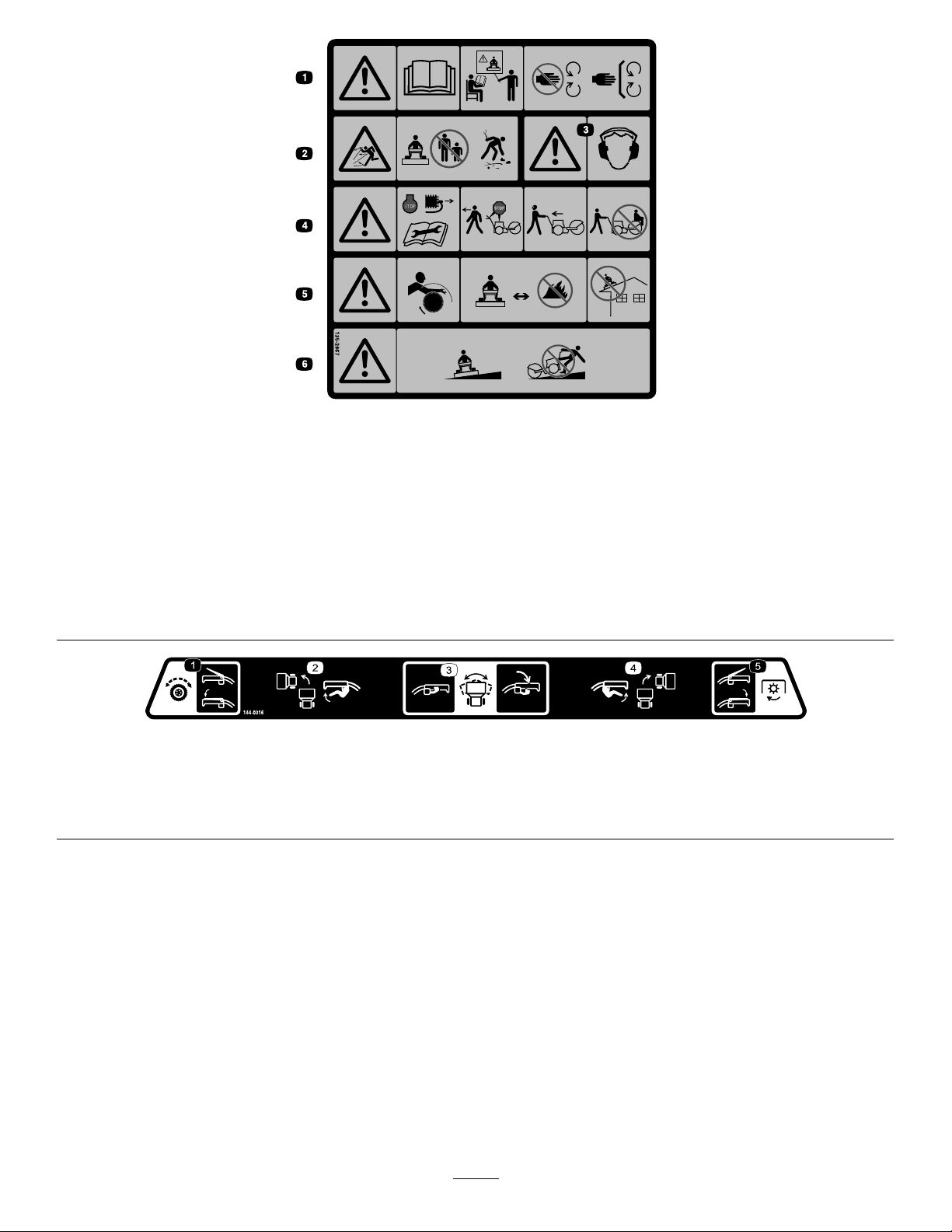

decal116-8140

116-8140

1.Thrownobjecthazard—Do

notoperatewhenpeople

andpetsareinthearea.

2.Warning—Entanglement

hazard—stayclearofthe

rotatingbroom.

decal133-8062

133-8062

5

decal135-2867

135-2867

1.Warning-ReadtheOperator’sManual.DoNotoperatethis

machineunlessyouaretrained.Stayawayfrommoving

parts;keepallguardsinplace.

4.Warning-Stopengineandremovesparkplugbeforeadjusting,

servicing,orcleaningmachineandattachments.Before

leavingtheoperator’sposition,disengagebroom,traction

drive,andstopengine.Lookbehindandtothesidebefore

changingdirections.DoNotcarrypassengers.

2.Thrownobjecthazard-DoNotoperatewhenpeopleandpets

areinthearea;pickupobjectsthatcouldbethrownbybroom.

5.Warning-Entanglementhazard-stayclearofrotatingbroom.

Broombristleswillmeltorburn-keepawayfromextreme

heatorame.DoNotoperateonanyrooforotherelevated

surface.

3.Warning-Wearhearingprotection.6.Warning-Operateacrossslopesnotupanddown.Use

extremecautionwhenoperatingonslopes.

decal144-0316

144-0316

1.Engagethetraction-controllevertoactivatethetractiondrive.4.Engagetheright-turnlevertoturnright.

2.Engagetheleft-turnlevertoturnleft.5.EngagethePTOlevertoactivatethePTO.

3.Engagethebroom-anglelevertoadjustthebroom.

6

ProductOverview

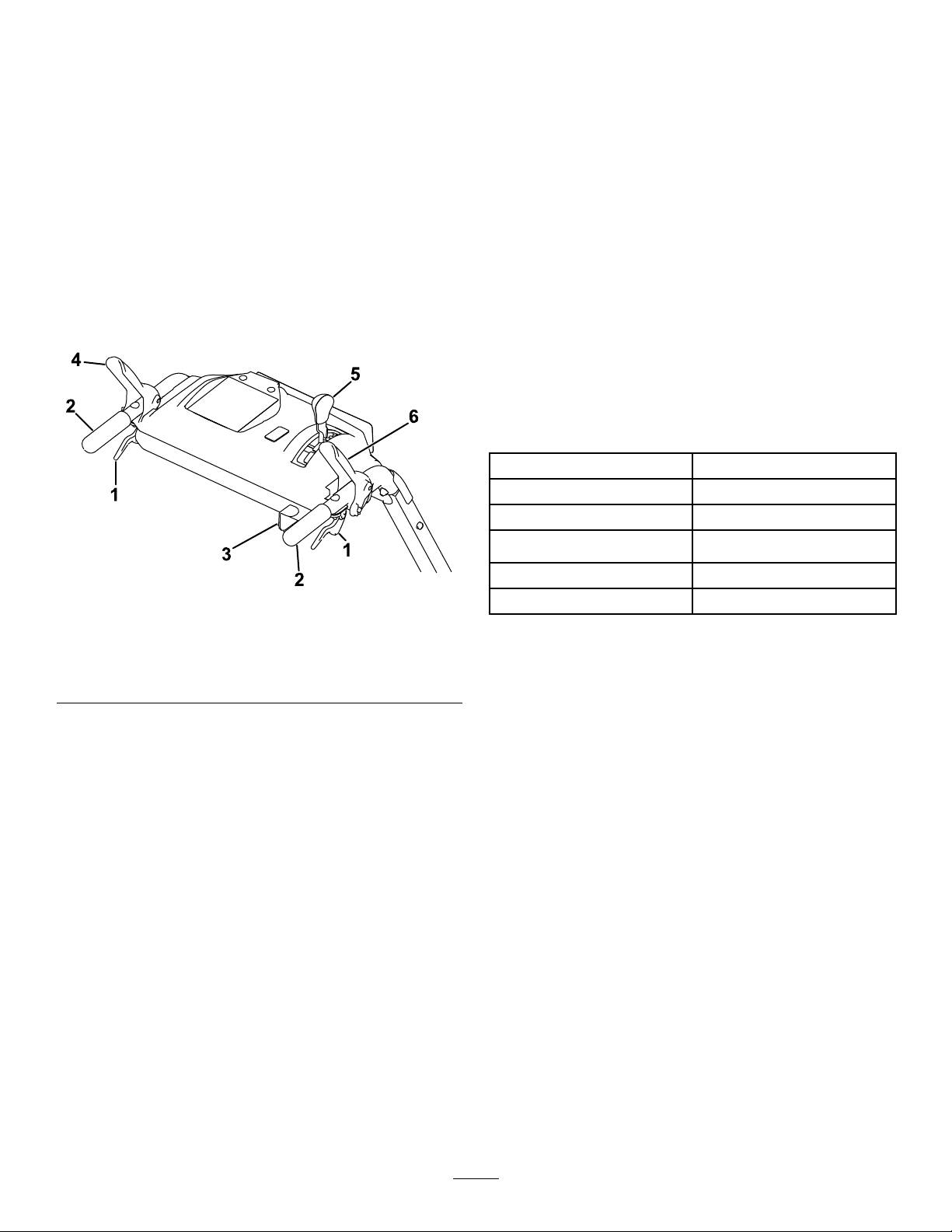

g325102

Figure4

1.Wheel-clutchlever6.Traction-drivelever

2.Broom-anglelever7.Fuel-tankcap

3.Broom-drivelever8.Broomandhood

4.Speed-selectorlever9.Broom-height-adjustment

pin

5.Handbargrip

Controls

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

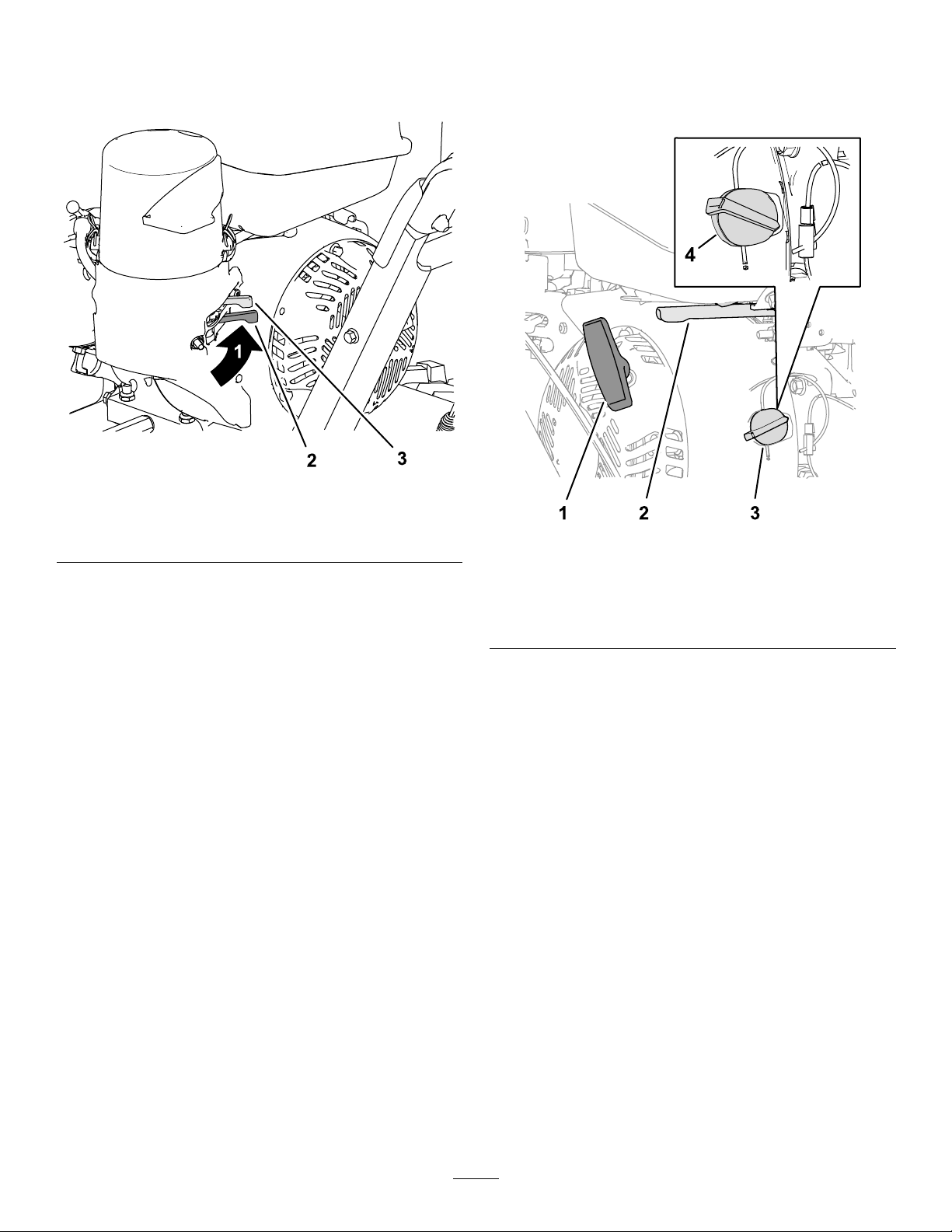

ChokeControl

Thechokecontrolisthetopleverlocatedontherear,

leftsideoftheengineabovethefuel-shutoffvalve

(Figure5).

Thechokeisusedtoaidinstartingacoldengine.

MovetheleverlefttotheONpositionforacoldstart.

DonotrunawarmenginewiththechokeintheON

position.

g326826

Figure5

1.Chokecontrol4.Recoil-starthandle

2.Fuel-shutoffvalve5.EngineOn/Offswitch

3.Throttlecontrol

Fuel-ShutoffValve

Usethefuel-shutoffvalvetoshutoffthefuelwhen

youwillnotusethemachineforafewdays,parkthe

machineinsideabuilding,ortransportthemachineto

andfromthejobsite(Figure5).

Movethelevertothelefttoshutoffthefuel.Movethe

levertotherighttoturnonthefuel.

ThrottleControl

Thethrottlecontrolislocatedontherear,rightsideof

theengineandbelowthefueltank(Figure5).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottlecontroltotheleftincreasestheengine

speed,andmovingitrightdecreasestheengine

speed.

EngineOn/OffSwitch

Locatedontherightsideoftheengine(Figure5).

RotatetheswitchclockwisetotheONposition

beforestartingtheengine.Rotatetheswitch

counterclockwisetotheOFFpositiontoshotoffthe

engine.

7

Wheel-ClutchLevers

Thewheel-clutchleversarelocatedbelowtheright

andlefthandles.

Thewheelclutchleversallowthedrivetomomentarily

disengageto1orbothwheelswiththetraction-drive

leversqueezed.Thisallowsforeasierturningand

maneuveringthemachine(Figure6).

Note:Squeezingbothwheelclutchlevers

simultaneouslydisengagesthedrivetobothwheels

(free-wheeling).Thisenablesyoutomanuallymove

themachinebackwardwithoutstoppingtoshiftitinto

areversegear.Italsoallowsyoutomaneuverand

transportthemachinemoreeasilywhentheengine

isnotrunning.

g325105

Figure6

1.Wheel-clutchlever4.Traction-drivelever

2.Handle5.Speed-selectorlever

3.Broom-anglelever6.Broom-drivelever

Broom-DriveLever

Thebroom-driveleverislocatedabovetheright

handle(Figure6).

Toengagethebroom,squeezethelevertothehandle.

Todisengagethebroom,releasetherightlever.

Traction-DriveLever

Thetraction-driveleverislocatedabovetheleft

handle(Figure6).

Thetraction-drivelevercontrolstheforwardand

reversemotionofthemachine.T oengagethetraction

drive,squeezethelevertothehandle.

Note:Holdingdownthetraction-driveleveragainst

thehandleengagesthetractiondrivetobothwheels.

Speed-SelectorLever

Thespeed-selectionleverislocatedonthemain

consolepanel(Figure6).

Thespeedselectorhas6forwardand2reverse

settings.Tochangespeeds,releasethetraction-drive

lever,andshiftthespeed-selectorlevertothedesired

setting.Theleverlocksinanotchateachspeed

setting.

Broom-AngleLever

Thebroom-angleleverislocatedattherighthandle

(Figure6).

Thebroom-anglelevercontrolstheanglelock.The

broomanglecanbelockedinto3positions:straight

ahead,orangledtotheleftorright19°.

Specications

Width118cm(46.5inches)

Length185.5cm(73inches)

Height105.5cm(41.5inches)

Weight151kg(333lb)

Enginespeed(noload)Fullspeed:3600±100rpm

Fueltankcapacity4.1L(1.0USgallon)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedToro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

8

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection;alsoweara

respiratorordustmaskindustyconditions.Tie

backlonghair,securelooseclothing,anddonot

wearloosejewelry.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

•Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

FillingtheFuelTank

TypeUnleadedgasoline

Minimumoctanerating87(US)or91(research

octane;outsidetheUS)

EthanolNomorethan10%byvolume

MethanolNone

MTBE(methyltertiarybutyl

ether)

Lessthan15%byvolume

OilDonotaddtothefuel

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

FillthefueltankasshowninFigure7;donotllabove

thebottomofthefueltankneck.

g216203

Figure7

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,addfuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizer/conditioner

manufacturer.

CheckingtheSweeping

Path

Abroomsweepswiththetipsofitsbristles.Whenyou

applytoomuchdownwardpressure,thebroomno

longerusesitstips;thebroomisnowworkingwiththe

sidesofthebristles.Thislimitstheickingactionof

thebristlesandsweepingeffectiveness,decreasing

theservicelifeofthebroom.

1.Drivethemachinetoaat,dustyareaandstop

themachine.

2.Withtheenginerunning,movethethrottle

midwaybetweentheSLOWandFASTpositions.

3.Squeezethebroom-drivecontrol,andallowthe

broomtorotatefor30seconds.

4.Releasethebroom-drivecontrol,shutoffthe

engine,andwaitforallmovingpartstostop.

5.Checktheareasweptbythebroom.The

broom-sweepareashouldequalthefullbroom

widthandamaximumdepthof51to102mm(2

to4inches).

9

g017922

Figure8

1.51to102mm(2to4

inches)maximumdepth

3.Sweptarea

2.Fullbroomwidth

6.Ifthebroom-sweepareaistoolarge,toosmall,

oruneven,adjustthebroomheight;referto

AdjustingtheBroomHeight(page10).

AdjustingtheBroomHeight

1.Drivetoaat,dustyareaandstopthemachine.

2.Ensurethatthebroom-driveleverisreleased,

shutofftheengine,andwaitforallmovingparts

tostop.

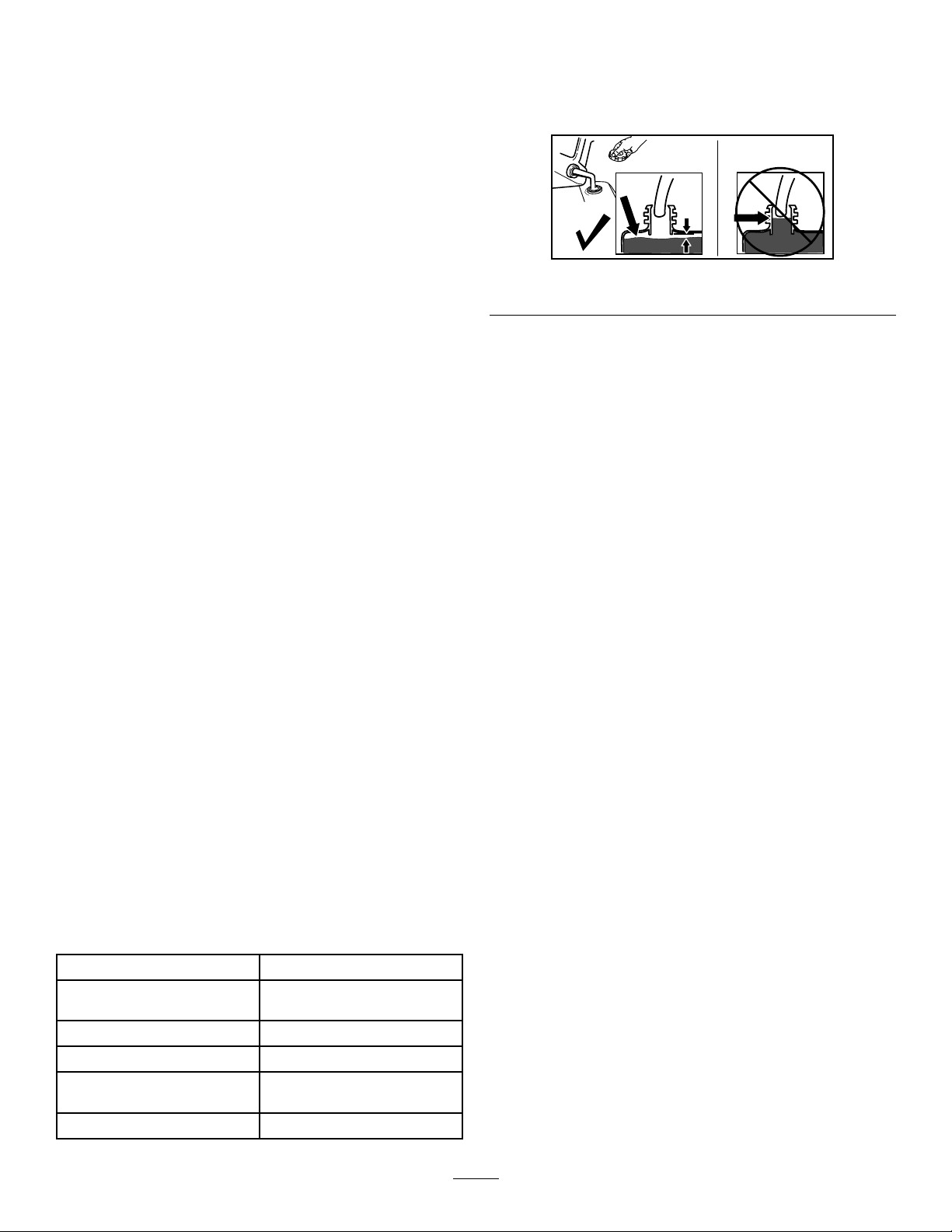

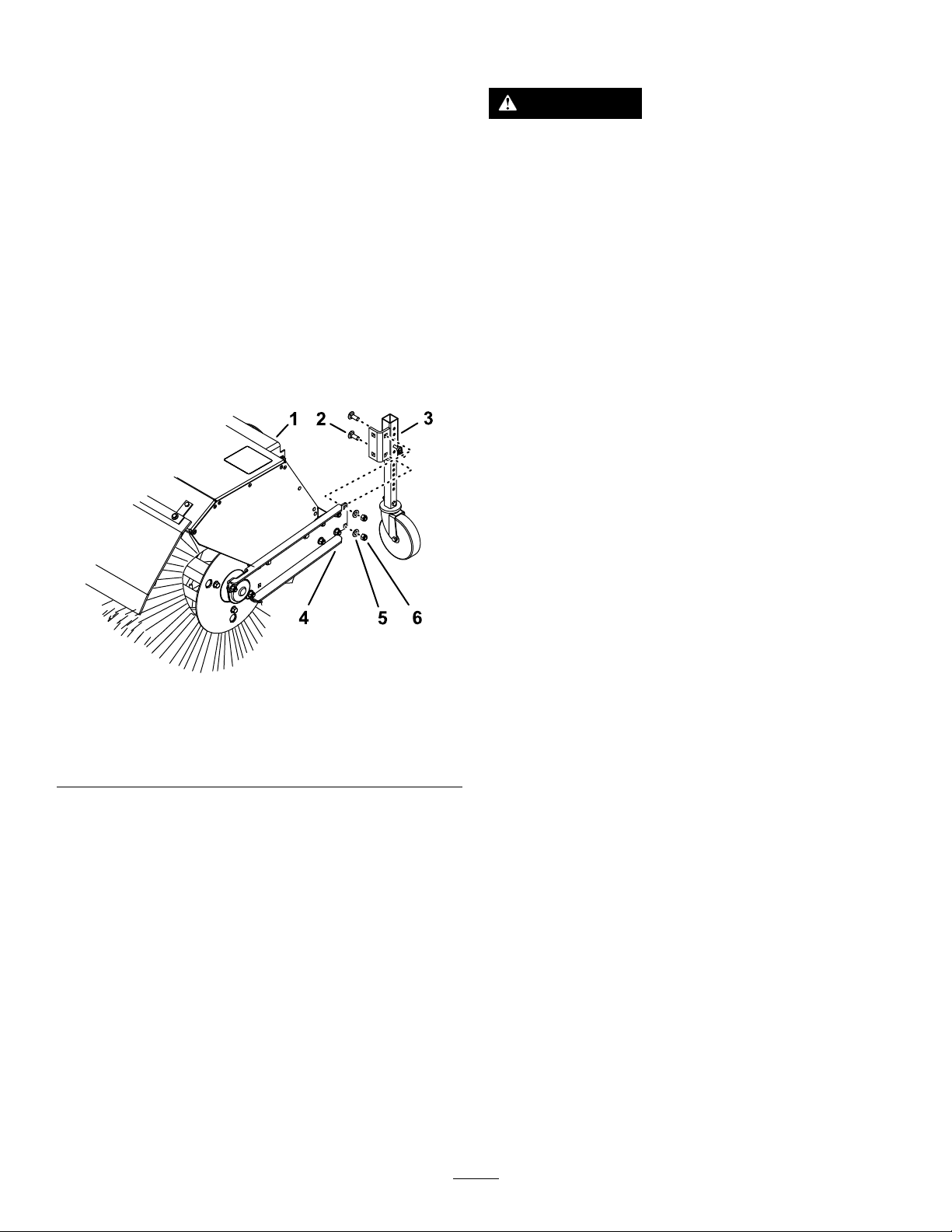

3.Toadjustthebroomheight,removeandretain

thepinfromtheadjustersleeveandwheeltube

ofthecaster(Figure9).

g030413

Figure9

1.Caster-wheeltube3.Pin

2.Positionstoachieve3mm

(1/8inch)increments

4.Adjustersleeve

4.Raiseorlowerthecasterwheeltubetoadjust

theareasweptbythebroomasstatedin

CheckingtheSweepingPath(page9).

Note:Selectanyholecombinationthatisin

alignmenttoplaceandlatchtheretainingpin;

matchthesamepositionontheotherside.

5.Forneradjustment,slidetheadjustersleeve1

pinholeupordownonthecasterwheeltube

toadjustthebroomheightin3mm(1/8inch)

increments(Figure9).Repeatsteps3through5

fortheothercasterwheel.

•Toraisethebroomin3mm(1/8inch)

increments,slightlyraisetheadjustersleeve

andinsertthepinintothenextpinholebelow

thecurrentholeused.

•Tolowerthebroomin3mm(1/8inch)

increments,slightlylowertheadjustersleeve

andinsertthepinintothenextpinhole

abovethecurrentholeused.

6.Whenthebroomheightisadjusted,secure

thepinoneachcasterwheel,andcheckthe

broom-sweeparea;refertoCheckingthe

SweepingPath(page9).

DuringOperation

DuringOperationSafety

GeneralSafety

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Donotclearsnow,dirt,orthatchacrossthefaceof

slopes.Exerciseextremecautionwhenchanging

directiononslopes.Donotattempttoclearsteep

slopes.

10

•Donotoperatethemachinenearglassenclosures,

automobiles,windowwells,dropoffs,etc.without

properlyadjustingthebroomdischargeangle.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

•Lookbehindandusecarewhenbackingupthe

machine.

•Exerciseextremecautionwhenoperatingthe

machineonorcrossinggraveldrives,walks,or

roads.Stayalertforhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

andinspectthemachinefordamage.Repairany

damagebeforestartingthemachine.

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors,exceptwhen

startingitandformovingthemachineinoroutof

thebuilding;exhaustfumesaredangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnow,dirt,orthatchattoofast

ofarate.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeuncloggingthe

broomhousing,andwhenmakinganyrepairs,

adjustments,orinspections.

•Beforeclearingthebroom,parkthemachine

onlevelground,shutofftheengine,waitfor

allmovingpartstostop,anddisconnectthe

spark-plugwire(s).Sharpobjectscanbecome

entangledinthebristles.Wearglovesanduse

cautionwhencleaningoutthebroomofforeign

objects;donotuseyourbarehands.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.

•Useonlyattachmentsandaccessoriesapproved

bythemanufacturerofthemachine.

OperatingtheEngine

PositioningtheAir-CleanerCover

forColdorWarmAirTemperature

Important:Runningtheenginewiththe

air-cleanercoverpositionedforcold-weather

operationinnormalconditionscandamagethe

engine.

Theair-cleanercoverhas2positions:thecoldor

normal,ambientairpositions:

Adjusttheair-cleanercoverasfollows:

•Whenoperatinginacoldambientaircondition

(coldairtemperatureandhumidity)—positionthe

air-cleanercoverwithsnowakedecalfacingout

(Figure10).

Note:Usethispositionifyourmachineexhibits

carburetoricing.Symptomsincludetheengine

runsroughatidleorlowspeed,anditdischarges

blackorwhitesmokeintheexhaust.

•Whenoperatinginanormalambientair

condition—positiontheair-cleanercoverwithsun

decalfacingout(Figure10).

Note:Usethispositionifyourmachineisnot

exhibitingcarburetoricing.

g326835

Figure10

1.Normalambientair

position

2.Coldambientairposition

11

OpeningtheFuel-ShutoffValve

Movethefuel-shutoffvalvelocatedbelowthechoke,

totherighttoturnonfuel(Figure11).

g325099

Figure11

1.FUELONposition3.Choke

2.Fuel-shutoffvalve

StartingtheEngine

1.Ontherightsideoftheengine,rotatetheengine

On/OffswitchclockwisetotheONposition

(Figure12).

g325098

Figure12

1.Recoil-starthandle3.Engineswitch(OFF

position)

2.Throttle4.Engineswitch(ON

position)

2.Ontherear,leftsideoftheengine,movethe

chokelevertothelefttotheONposition.On

awarmengine,leavethechokeintheOFF

position(Figure11).

3.PlacethethrottlemidwaybetweentheSLOW

andFASTpositionslocatedonrear,rightsideof

theengine(Figure12).

4.Slowlypulltherecoil-starthandleuntilyoufeel

resistanceandthenstop(Figure12).

5.Allowtheropeoftherecoil-starthandletoretract

andthensharplypullthehandlestraightout.

Note:Allowtheropetoretractslowly.

6.Allowtheenginetowarmupforseveralminutes,

thenmovethechoketowardtheOFFposition

(Figure11).

StoppingtheEngine

1.Releasethebroom-driveleverandthe

traction-drivelever.

2.PlacethethrottlemidwaybetweentheSLOW

andFASTpositions(Figure12).

12

3.Allowtheenginetorunforaminimumof15

seconds,thenturntheengineOn/Offswitchto

theOFFpositiontostoptheengine(Figure12).

4.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

5.Usethefuel-shutoffvalvetoshutofffuelwhen

youwillnotusethemachineforafewdays,park

themachineinsideabuilding,ortransportthe

machinetoandfromthejobsite(Figure11).

DrivingtheMachine

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthe

tractionleverisdisengaged,checkandadjustthe

tractioncable;refertoCheckingtheBroomDrive

Adjustment(page25)andAdjustingtheTraction

Cable(page24),orcontactyourAuthorized

ServiceDealer.

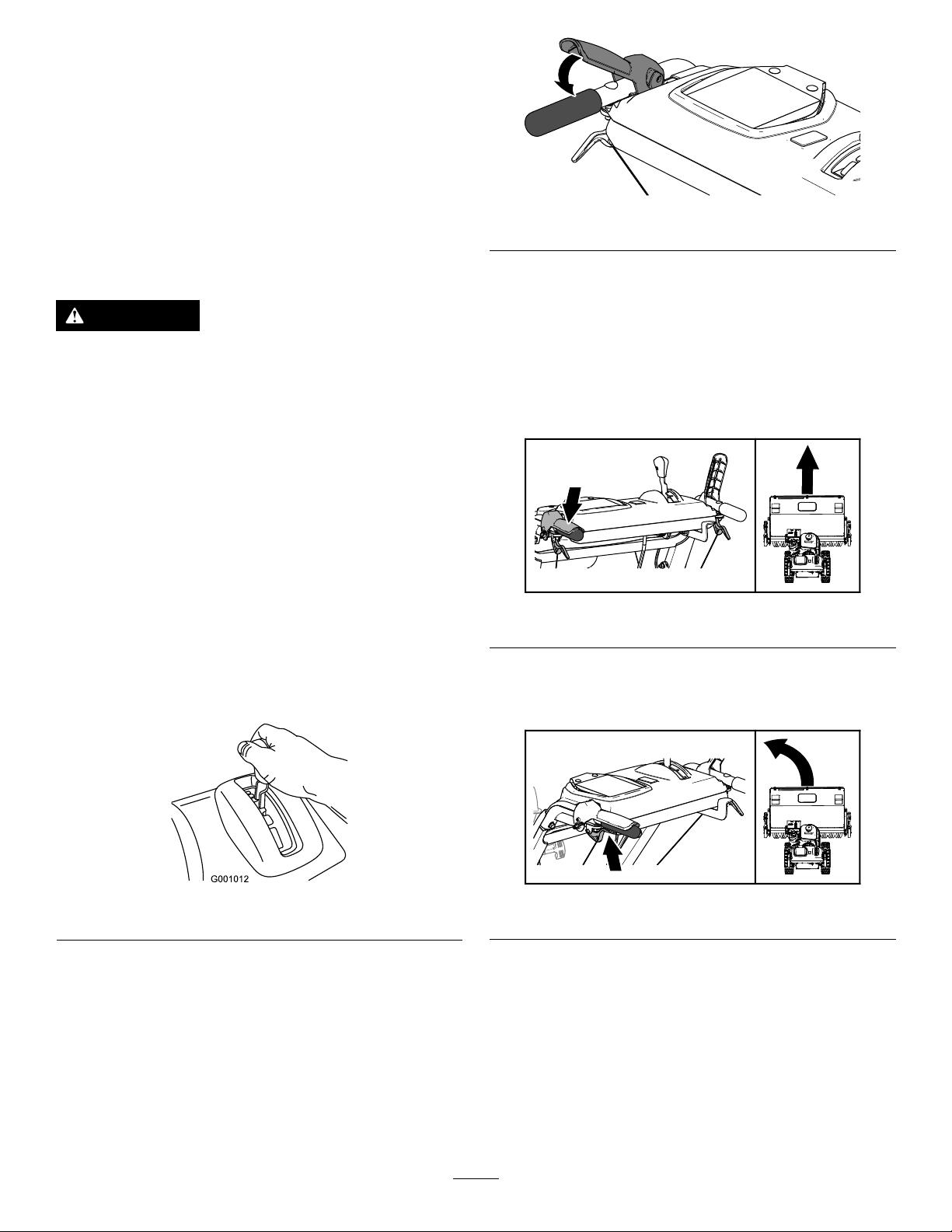

DrivingForward

1.Placethespeedselectorlevertothedesired

forwardposition,makingsurethatitlocksinthe

notch(Figure13).

g001012

Figure13

Note:Ifthegroundspeedistoofast,debrisor

snowwillpileupinfrontofthebroomcausing

thebroomtoplowinsteadofsweep.Thiscan

damagethebristlesandthedriveline.

2.Slowlysqueezethetraction-drivelevertothe

lefthandle(Figure14).

Note:Holddownthetraction-driveleveragainst

thehandletoengagethetractiondriveforboth

wheels.

g326524

Figure14

3.Tostopthetractiondrive,releasethe

traction-drivelever.

4.Usethewheelclutchesleversasfollows:

Note:

•Todrivestraight,squeezethetraction-drive

leverbutdonotsqueezethewheel-clutch

levers(Figure15).

g326528

Figure15

•Toturnleft,squeezethetraction-drivelever

andsqueezetheleftwheel-clutchlever

(Figure16).

g326521

Figure16

Note:Whenyoucompletetheturn,release

thewheel-clutchlever.Thetractiondrive

engagesbothwheels.

•Toturnright,squeezethetraction-drivelever

andsqueezetherightwheel-clutchlever

(Figure17).

13

g326522

Figure17

Note:Whenyoucompletetheturn,release

thewheel-clutchlever.Thetractiondrive

engagesbothwheels.

•Momentarilysqueezeandreleasetheleft

orrightwheel-clutchlevertomakesteering

adjustmentsandkeepthemachinemoving

inastraightline,especiallyindeepsnow.

5.Toshutoffthetractiondrive,releasethe

traction-drivelever.

DrivingtheMachineRearward

1.Placethespeed-selectorleverintothedesired

reverse-speedrange,makingsurethatthe

speedselectorlocksinthenotch.

2.Tomoverearward,engagethetractiondrive

andslowlysqueezethelefttractionlevertothe

handle.

Note:Momentarilysqueezingandreleasingthe

leftorrightwheel-clutchleverallowsforsteering

adjustmentstokeepthemachinegoingina

straightline.

Note:Toturnright,squeezetheright

wheel-clutchlevertowardthehandle.This

disengagesthedrivetotherightwheelwhilethe

leftwheelcontinuesdriving,andthemachine

turnstotheright.

Note:Similarly,squeezingtheleftwheel-clutch

leverturnsthemachinetotheleft.

Note:Squeezingbothwheel-clutchlevers

simultaneouslydisengagesthedrivetobothwheels.

Thisenablesyoutomovethemachinerearward

withoutstoppingtoshiftitintoareversegear.Italso

allowsyoutomaneuverandtransportthemachine

moreeasilywhentheengineisnotrunning.

PivotingtheMachinewiththe

EngineShutoff

Squeezebothwheel-clutchleverssimultaneouslyand

pivotthemachine(Figure18).

g326520

Figure18

OperatingtheBroom

DANGER

Whenthemachineisinoperation,contact

withrotatingormovingpartswillseverely

injurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

•Staybehindthehandlesandawayfromthe

broomwhileoperatingthemachine.

•Keepface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

14

WARNING

Contactwitharotatingbroomcanresult

inseriouspersonalinjuryordeathtothe

operatororbystanders.

•Toremoveanobstructionfromthebroom;

refertoClearingaCloggedBroom(page

16).

•Donotoperatethemachineifthebroom

driveleverisnotfunctioningproperly.

ContactyourAuthorizedServiceDealer.

WARNING

Therotatingbroomcanthrowstonesand

otherforeignobjects,causingserious

personalinjurytoyouorbystanders.

•Keeptheworkingareaclearandfreeofall

objectsthatthebroomcouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

CAUTION

Whenthebroomisengaged,itmaydrivethe

machineinthereversedirection.Ifthebroom

heightisadjustedtoolow,themachinemay

movemoreforcefullyinthereversedirection,

causinginjuryand/orpropertydamage.

Carefullycheckthebroomheightandadjust

itproperlyorcontactyourAuthorizedService

Dealer.

1.SettheenginethrottletotheFASTposition.

2.Placethespeedselectorleverintothedesired

positionandslowlysqueezethelefthand

tractiondrivelever.

Important:Makesurethatthetractiondrive

isengagedbeforeoperatingthebroom;

otherwise,thebroommaydrivethemachine

inthereversedirection.

3.Engagethebroombyslowlysqueezingtheright

broomlevertothehandle(Figure19).

g326523

Figure19

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalower

gear.

•Ifthefrontofthemachineridesup,shift

themachineintoalowergear.Ifthefront

continuestorideup,liftthehandles.

4.Tostopthebroom,releasetherightlever.

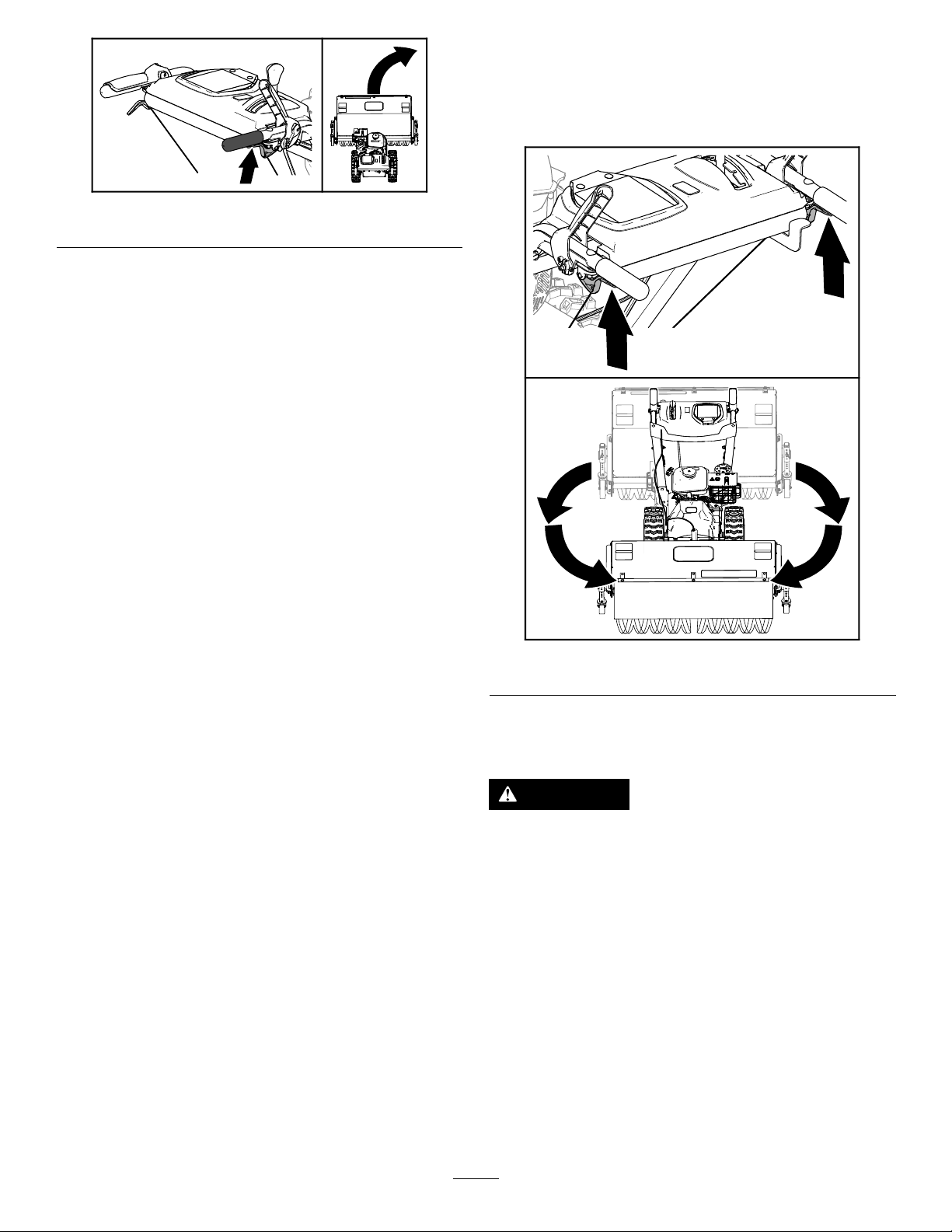

AdjustingtheBroomSide

Angle

1.Disengagethebroomandshutofftheengine.

2.Waitforallmovingpartstostop.

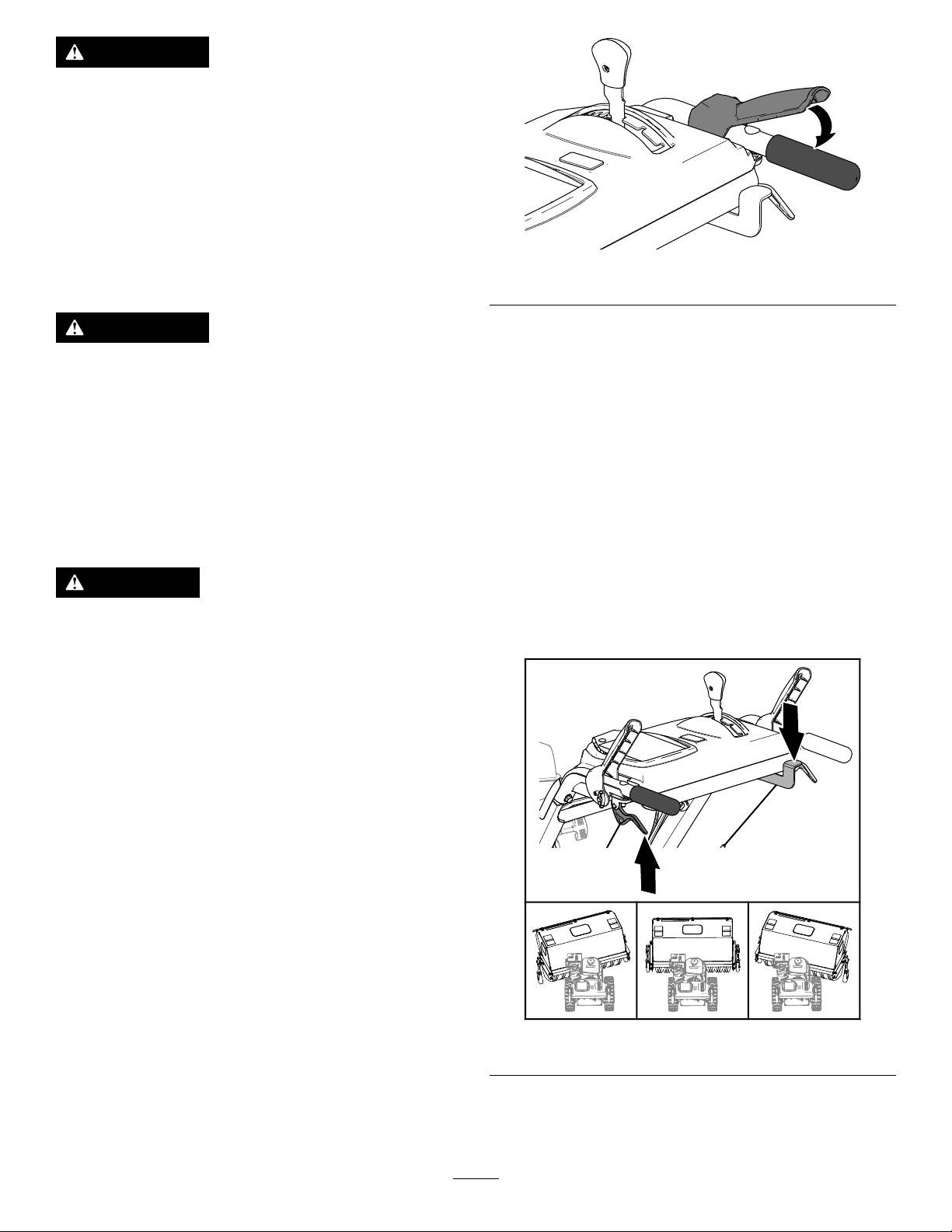

3.Pushtheleverdownwiththethumbofyourright

hand(Figure20).

g326519

Figure20

4.Squeezetheleftwheel-clutchlevertothehandle

(Figure20)andpushthebroomhousingto

followingpositions.

15

•19°totheleft

•Straightahead

•19°totheright

5.Oncethebroomispositioned,releasethe

broomanglelever.

Important:Ensurethatthebroomlocksinto

placeatoneofthe3positions.

6.Releasetheleftwheel-clutchlever.

UsingtheAlternateCaster

Location

Whenworkinginsnow,movethecastersfromthe

frontofthebroomarmtothebackthebroomhood

(Figure21).

g326877

Figure21

1.Broomhood4.Broomarm

2.Carriagebolt5.Washer

3.Casterbracket6.Locknut

1.Supportthebroom.

2.Removethe2locknuts,2washers,and2

carriagebolts(Figure21)thatsecurethecaster

brackettothebroomarm.

3.Atthebackofthebroomhood,aligntheholesin

thecasterbracketwiththeholesontheinboard

sideofthebroomarm(Figure21).

4.Securethecasterbrackettothebroomarmwith

the2locknuts,2washers,and2carriagebolts

(Figure21).

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseserious

injury.

Shutofftheengineandallowallrotatingparts

tostopbeforecleaningthebroom.

•Ifthebroombecomesclogged,stayinthe

operatingpositionandreleasethetraction-drive

lever.Whileengagingthebroom,pushdownon

thehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary.

•Ifyoucannotunclogthebroombybumpingthe

frontofthemachine,dothefollowing:

–Parkthemachineonlevelground.shutoffthe

engine,waitforallmovingpartstostop,and

disconnectthespark-plugwire.

–Sharpobjectscanbecomeentangledin

bristles.Useglovesandcautionwhen

removingforeignobjectsfromthebroom;do

notuseyourhands.

AfterOperation

AfterOperationSafety

GeneralSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertotheStoragesectionforimportant

information.

•Whenoperatinginsnowyconditions,runthe

machineforafewminutesafterremovingsnowto

preventfreeze-upofthebroomandhousing.

•Whencleaning,repairing,orinspectingthe

machine,ensurethattherotarybroomandall

movingpartshavestopped.Disconnectthe

spark-plugwireandkeepitawayfromtheplugto

preventaccidentalstarting.

•Disengagethepowertotherotarybroomwhen

transportingorstoringthemachine.

16

PreventingFreeze-upafter

Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.Ifyou

havedifcultyoperatinganycontrolorpart,start

theengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Engagethebroomtoclearanyremainingsnow

frominsidethehousing.Shutofftheengineand

waitforallmovingpartstostop,anddisconnect

thespark-plugwire.Removeallice,snow,orother

debrisfromthemachine.

•Connectthespark-plugwire.Withtheengine

switchintheOFFposition,pulltherecoil-starter

handleseveraltimestopreventtherecoilstarter

fromfreezingup.

TransportingtheMachine

WARNING

Usingrampsthatarenotstrongenoughor

properlysupportedtoloadthemachineonto

thetransportvehiclecouldbedangerous.The

rampscouldcollapse,causingthemachineto

fall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepyourfeetandlegsoutfromunderthe

machinewhenloadingandunloading.

PreparingtoTransportthe

Machine

Performthefollowingbeforetransportingthemachine:

•Closethefuel-shutoffvalve.

•Useaheavy-dutytrailertotransportthemachine.

Placethemachineineitheraforwardorreverse

gear,thenblockthewheels.

•Securelyfastenthemachinetothetrailerwith

straps,chains,cables,orropes.

•Ensurethatthetrailerhasallthenecessary

lightingandmarkingasrequiredbylaw.

17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

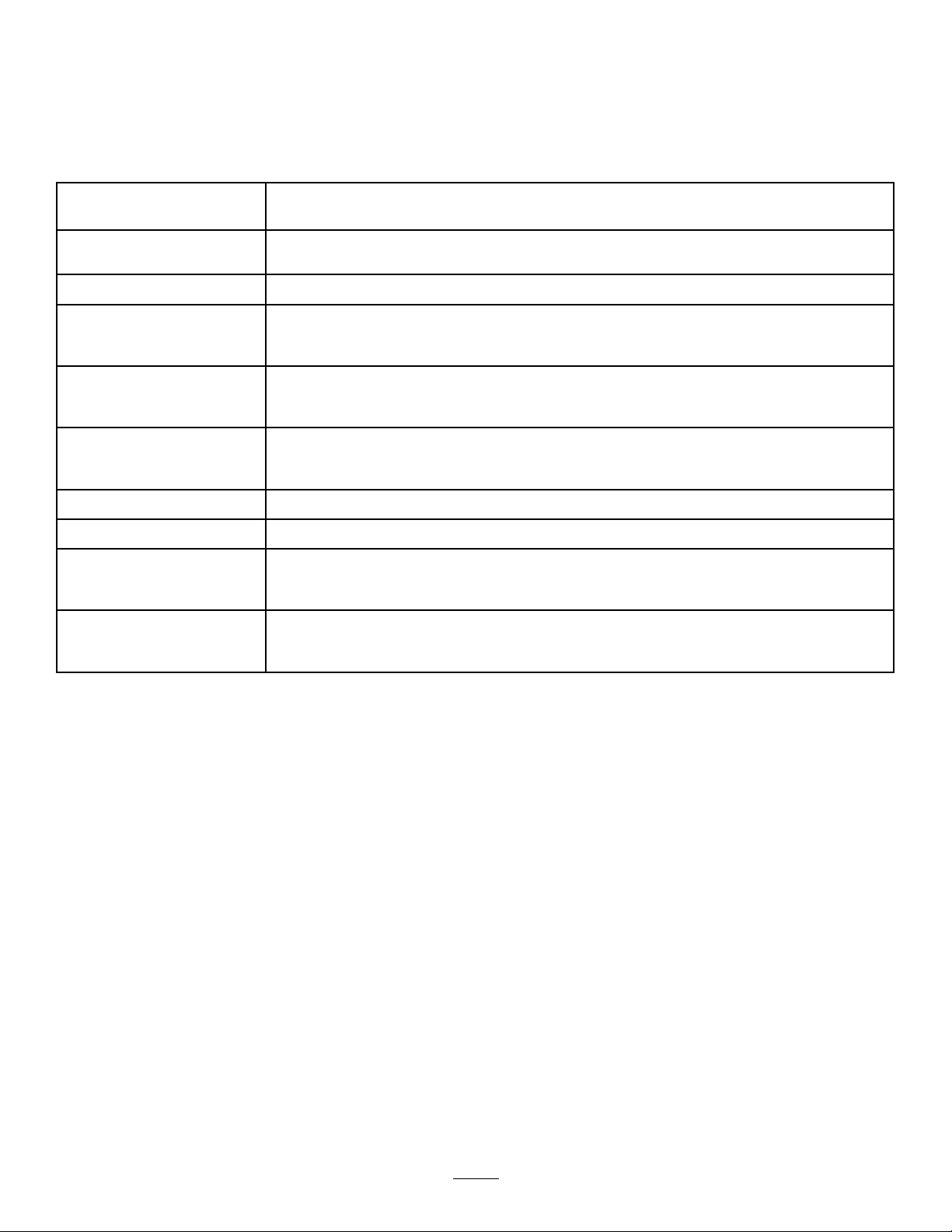

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst2hours•Checkthetractioncableadjustmentandcorrectitifnecessary.

•Checkthebroomdriveadjustmentandcorrectitifnecessary.

Aftertherst5hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevel.

•Checkthebroom-shaftshearpin.

•Checkforloosehardware.

Every50hours

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checkthetireairpressure.

•Checktheconditionofthebelts.

Every100hours

•Lubricatethebroom-angle-lockpin.

•Changetheengineoil(morefrequentlyinsevereconditions).

•Checkthesparkplug.

Every200hours•Replacethefoampre-cleaner.

Every300hours•Replacethepaperairlter(morefrequentlyindustyconditions).

Yearly

•Lubricatethehexshaft.

•Checkthetractioncableadjustmentandcorrectitifnecessary.

•Checkthebroomdriveadjustmentandcorrectitifnecessary.

Yearlyorbeforestorage

•Drainthefuelsystemandruntheengineoutthefuelattheendoftheoperating

season.

•Checkthetireairpressure.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.Forengine

adjustments,repairs,orwarrantyservicenotcoveredinthismanual,contacttheauthorizedengine

servicedealer.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeservicing,adjusting,orcleaningthe

machine,shutofftheengineandwaitforall

movingpartstostop.Ifmajorrepairsareever

needed,contactyourAuthorizedServiceDealer.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandallowittocool.

3.Disconnectthespark-plugwirefromthespark

plugandkeepthewireawayfromtheplug,to

preventaccidentalstarting(Figure22).

18

g023810

Figure22

1.Spark-plugwire

Lubrication

LubricatingtheBroom-Angle-Lock

PinandtheHexShaft

ServiceInterval:Every100hours

Yearly

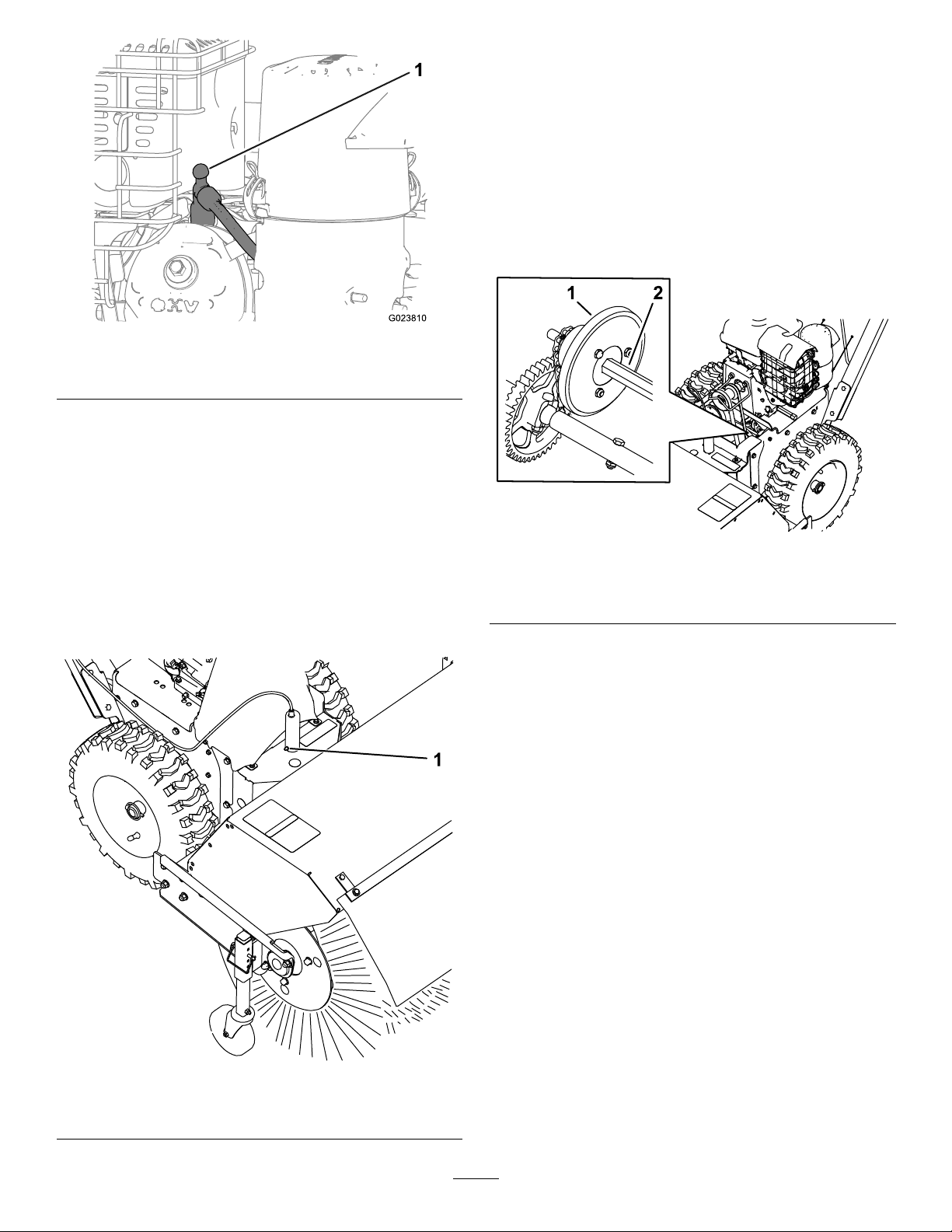

1.Lubricatethebroom-angle-lockpinttingwith

No.2lithiumgrease(Figure23).

g325097

Figure23

1.Broom-angle-lockpin

2.Removethebeltcoverandtheengineshield.

3.Movethespeed-selectorlevertotheR2position.

4.Dipalong,clean,small-tippedpaintbrushin

automotiveengineoilandlightlylubricatethe

hexshaft(Figure24).

Important:Donotgetoilontherubber

wheelorthealuminumfriction-driveplateas

thetractiondrivewillslip(Figure24).

Note:Rockthemachineforwardandrearward

torotatethehexshaft.

g325104

Figure24

1.Aluminumfriction-drive

plate

2.Hexshaft

5.Movethespeedselectorlevertoposition6.

6.Lubricatetheotherendofthehexshaft.

7.Movethespeedselectorleverforwardand

rearwardafewtimes.

8.Installthebeltcoverandtheengineshield.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanthefoam

pre-cleaner(morefrequentlyin

dustyconditions).

Every200hours—Replacethefoam

pre-cleaner.

Every300hours—Replacethepaperairlter

(morefrequentlyindustyconditions).

Important:Donotoperatetheenginewithoutthe

airlterassembly;extremeenginedamagemay

occur.

1.Releasethelatchesonthecoverfortheair

cleaner.

19

2.Removethecoverandcleanitthoroughly

(Figure25).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

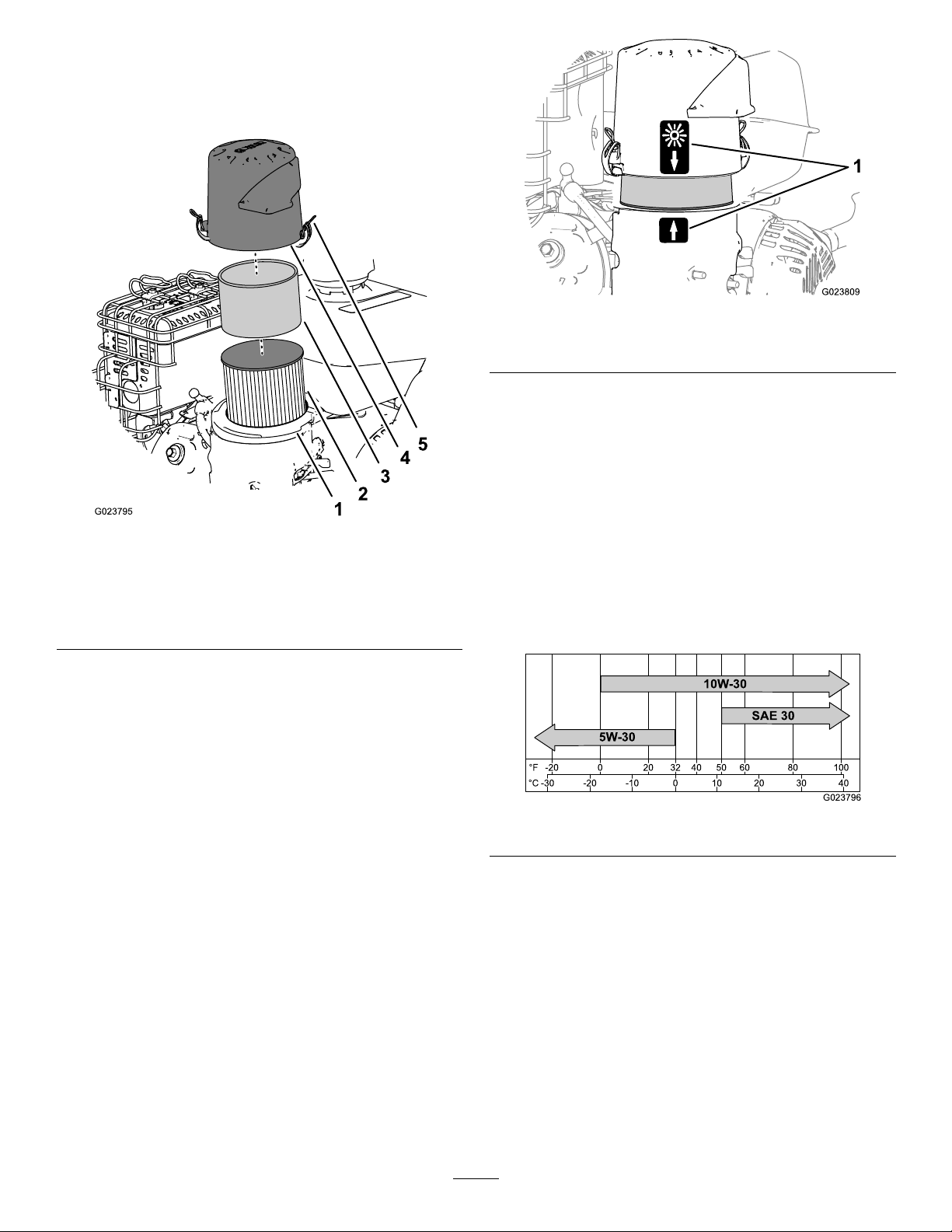

g023795

Figure25

1.Air-lterbase4.Cover

2.Paperairlter5.Latchontheair-cleaner

cover(2)

3.Foampre-cleaner

3.Removethefoampre-cleaner,washitwitha

milddetergentandwater,andthenblotitdry

(Figure25).

4.Removeandinspectthepaperairlter(Figure

25);discarditifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

5.Wipedirtawayfromthebaseandthecoverwith

amoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

6.Installthefoampre-cleanerontothepaperair

lter(Figure25).

Note:Useanewpaperairlterifyoudiscarded

theoldone.

7.Installtheairlterassemblytotheair-lterbase

(Figure25).

8.Alignthearrowdecalontheair-cleanercover

andthearrowdecalonthebase(Figure26).

g023809

Figure26

1.Alignment-arrowdecal(normalambientairpositionshown)

9.Securetheair-ltercovertothebasewiththe

latches.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

EngineOilType:T oro4–CyclePremiumEngineOil

Usehigh-qualitydetergentoils(includingsynthetic)

ofAPI(AmericanPetroleumInstitute)serviceclass

SJorhigher.Selecttheviscositybasedontheair

temperatureattimeofoperationasshowninthetable

below.

g023796

Figure27

Checktheoillevelwhentheengineiscold.

1.Cleantheareaaroundthedipstick.

2.Removethedipstickandreadtheoillevel

(Figure28).

20

Table of contents

Other Toro Floor Machine manuals