Toro 23740 User manual

FormNo.3378-184RevA

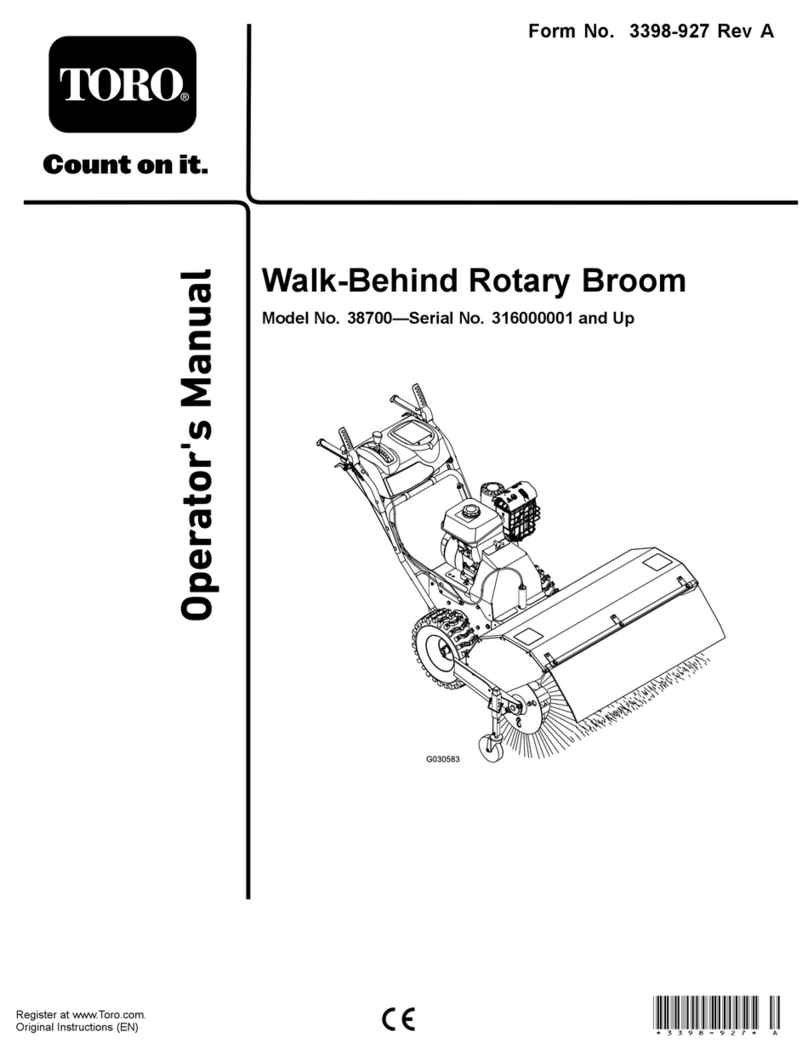

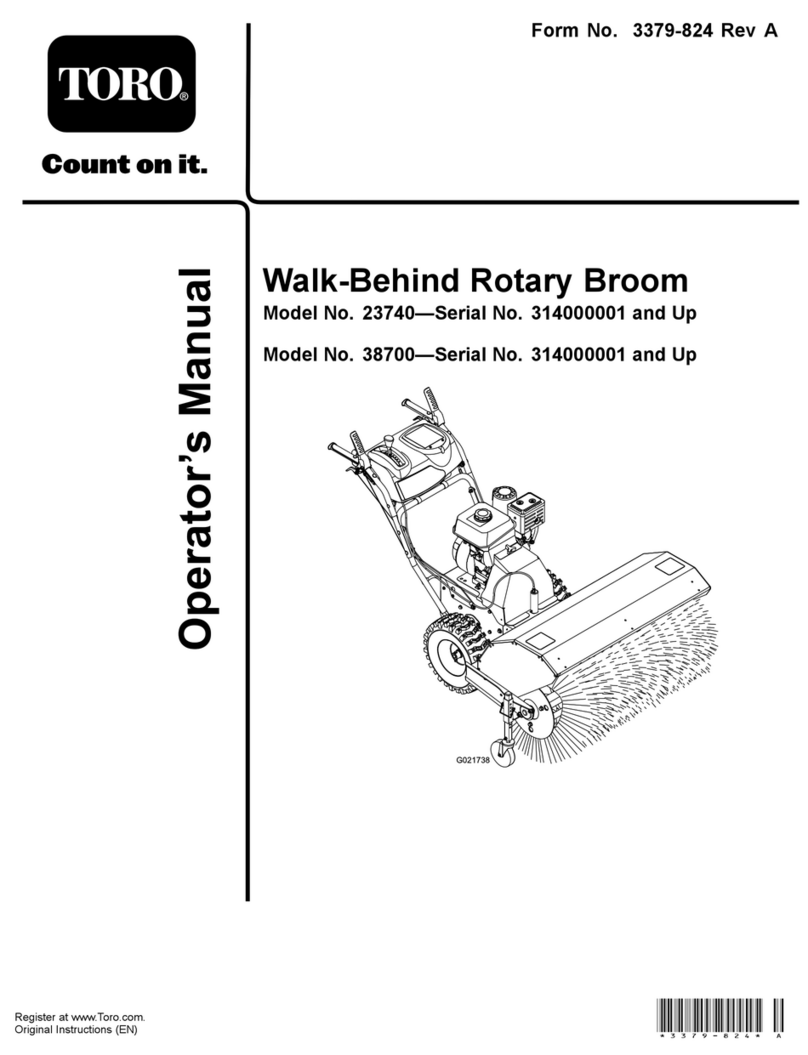

Walk-BehindRotaryBroom

ModelNo.23740—SerialNo.313000001andUp

ModelNo.38700—SerialNo.313000001andUp

G021738

Registeratwww.Toro.com.

OriginalInstructions(EN)*3378-184*A

ReplacementEngineOwner’sManualsmaybeordered

throughtheenginemanufacturer.

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnotequipped

withasparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCode(CPRC)Section4442

touseoroperatethisengineonanyforest-covered,

brush-covered,orgrass-coveredlandasdenedinCPRC

4126.Otherstatesorfederalareasmayhavesimilarlaws.

Toacquireasparkarresterforyourunit,seeyourEngine

ServiceDealer.

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnow,dust,anddirtfrom

pavedsurfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties,aswellasthatchfromgrass.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

Operation...............................................................4

ClearingaCloggedBroom........................................5

MaintenanceandStorage..........................................5

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................10

Attachments/Accessories........................................10

Operation....................................................................10

OperatingInstructions............................................10

TransportingtheMachine........................................14

Maintenance.................................................................15

RecommendedMaintenanceSchedule(s)......................15

CheckingtheEngineOilLevel.................................16

CheckingtheTractionCable....................................16

CheckingforLooseHardware..................................16

ChangingtheEngineOil.........................................16

CheckingtheTirePressure......................................16

CheckingtheConditionoftheBelts..........................16

LubricatingtheBroomAngleLockPinandHex

Shaft.................................................................16

CheckingtheSparkPlug..........................................17

CheckingtheBroomCable......................................17

CheckingtheBroomShaftShearPin.........................17

CheckingtheBroomSegments.................................18

AdjustingtheTractionCable....................................18

AdjustingtheBroomDrive......................................18

AdjustingtheWheelClutchCable.............................19

Storage........................................................................19

PreparingtheMachineforStorage............................19

RemovingtheMachinefromStorage.........................20

Troubleshooting...........................................................21

3

Safety

Readandunderstandthecontentsofthismanualbefore

theengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.Toreducethispotential,

complywiththefollowingsafetyinstructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren,andpets.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatinginreverse.

Preparation

•Thoroughlyinspecttheareawherethemachineistobe

usedandremovealldoormats,sleds,boards,wires,and

otherforeignobjects.

•Donotoperatethemachinewithoutwearingappropriate

garments.Wearfootwearwhichwillimprovefootingon

slipperysurfaces.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Fillfueltankoutdoorswithextremecare.Neverll

fueltankindoors.

–Replacegasolinecapssecurelyandwipeupspilled

fuel.

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwherespecicallyrecommendedby

manufacturer).

•Letengineandmachineadjusttooutdoortemperatures

beforestartingtoclearsnow.

•Theoperationofanypoweredmachinecanresultin

foreignobjectsbeingthrownintotheeyes.Alwayswear

safetyglassesoreyeshieldsduringoperationorwhile

performinganadjustmentorrepair.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,remove

thewirefromthespark-plug,thoroughlyinspectthe

machineforanydamage,andrepairthedamagebefore

restartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthebroomhousing,and

whenmakinganyrepairs,adjustments,orinspections.

•Whencleaning,repairing,orinspecting,makecertain

therotarybroomandallmovingpartshavestopped.

Disconnectthespark-plugwire,andkeepthewireaway

fromtheplugtopreventaccidentalstarting.

•Donotruntheengineindoors,exceptwhenstartingit

andformovingthemachineinoroutofthebuilding.

Opentheoutsidedoors;exhaustfumesaredangerous.

•Donotclearsnow,dirt,orthatchacrossthefaceof

slopes.Exerciseextremecautionwhenchangingdirection

onslopes.Donotattempttoclearsteepslopes.

•Neveroperatethemachinewithoutproperguards,plates,

orothersafetyprotectivedevicesinplace.

•Neveroperatethemachinenearglassenclosures,

automobiles,windowwells,drop-offs,etc.withoutproper

adjustmentofthesnowdischargeangle.Keepchildren

andpetsaway.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnow,dirt,orthatchattoofastarate.

•Neveroperatethemachineathightransportspeedson

slipperysurfaces.Usecarewhenreversing.

•Neverdirectdischargeatbystandersorallowanyonein

frontofthemachine.

•Disengagepowertotherotarybroomwhenmachineis

transportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofmachine(suchaswheelweights,

counterweights,cabs,etc.).

•Neveroperatethemachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

4

•Neveroperatethemachinewithoutgoodvisibilityor

light.

•Takeallpossibleprecautionswhenleavingthemachine

unattended.Shiftintoneutral,settheparkingbrake,stop

theengineandremovethekey.

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseseriousinjury.

Alwaysusecautionwhencleaningthebroom.

Toclearthebroom:

•Parkthemachineonlevelground.Stopengine,wait

forallmovingpartstostop,andremovethesparkplug

wire(s).

•Sharpobjectscanbecomeentangledinbristles.Use

glovesandcautionwhencleaningoutthebroomof

foreignobjects;notbarehands.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltankinsidea

buildingwhereignitionsourcesarepresentsuchashot

waterandspaceheaters,clothesdryers,etc.Allowthe

enginetocoolbeforestoringinanyenclosure.

•Alwaysrefertoowner’sguideinstructionsforimportant

detailsifthemachineistobestoredforanextended

period.

•Maintainorreplacesafetyandinstructionslabels,as

necessary.

•Whenoperatinginsnowconditions,runthemachinea

fewminutesafterthrowingsnowtopreventfreeze-upof

thecollector/impeller.

5

SlopeIndicator

G01 1841

Figure3

1.Themaximumslopeyoucansafelyoperatethemachineonis10°.Usetheslopeindicatortodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan10°.Foldalongtheappropriatelinetomatchthe

recommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

SafetyandInstructional

Decals

Important:Safetyandinstructiondecalsarelocated

nearareasofpotentialdanger.Replacedamageddecals.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-2903

1.Grease

116-8140

1.Thrownobjecthazard-Do

Notoperatewhenpeople

andpetsareinthearea.

2.Warning-Entanglement

hazard-stayclearof

rotatingbroom.

116-8505

1.Explosion/Firehazard–ReadtheOperator’sManual.Stop

enginebeforellingfueltank.Leave5/8inch(16mm)attop

oftankforfuelexpansion-DoNotoverlltank.

117–2718

106-4525

Reorderpartno.112-6633

1.Fast3.Slow

2.Forwardspeeds4.Reversespeeds

7

116-7370

1.Warning-ReadtheOperator’sManual.DoNotoperatethis

machineunlessyouaretrained.Stayawayfrommoving

parts;keepallguardsinplace.

4.Warning-Stopengineandremovesparkplugbeforeadjusting,

servicing,orcleaningmachineandattachments.Before

leavingtheoperator’sposition,disengagebroom,traction

drive,andstopengine.Lookbehindandtothesidebefore

changingdirections.DoNotcarrypassengers.

2.Thrownobjecthazard-DoNotoperatewhenpeopleandpets

areinthearea;pickupobjectsthatcouldbethrownbybroom.

5.Warning-Entanglementhazard-stayclearofrotatingbroom.

Broombristleswillmeltorburn-keepawayfromextreme

heatorame.DoNotoperateonanyrooforotherelevated

surface.

3.Warning-Wearhearingprotection.6.Warning-DoNotoperateonslopesgreaterthan10degrees.

Useextremecautionwhenoperatingonslopes;operate

acrossslopesnotupanddown.

126–0017

1.Engagetheleftturnlever

toturnleft.

4.EngagethePTOleverto

activatethePTO.

2.Engagethetraction

controllevertoactivate

thetractiondrive.

5.Engagetherightturnlever

toturnright.

3.Engagethebroomangle

levertoadjustthebroom.

8

ProductOverview

G021739

Figure4

1.Wheelclutchlever6.Tractiondrivelever

2.Handle7.Fuelcap

3.Broomanglelever8.Broom

4.Broomdrivelever9.Broomheightadjustment

pin

5.Speedselectorlever

Controls

Determinetheleftandrightsidesofthemachinefromthe

normaloperatingposition.

ChokeControl

Thechokecontrolisthetopleverlocatedontherearleft

handsideoftheengineabovethefuelshut-offvalve.

Thechokeisusedtoaidinstartingacoldengine.Movethe

leverlefttotheOnpositionforacoldstart.Donotruna

warmenginewiththechokeintheOnposition.

ThrottleControl

Thethrottlecontrolislocatedontherearrighthandside

oftheengine.

Thethrottleisusedtocontrolenginespeed.Movingthe

throttlecontroltotheleftwillincreaseenginespeedand

movingitrightwilldecreaseenginespeed.

EngineOn/OffSwitch

Locatedontherighthandsideoftheengine.

RotatetheswitchclockwisetotheOnpositionbeforestarting

theengine.RotatetheswitchcounterclockwisetotheOff

positiontokilltheengine.

FuelShut-OffValve

Thefuelshut-offvalveisthelowerleverlocatedonthe

rearlefthandsideoftheenginebelowthechoke.Thefuel

shut-offvalveshutsofftheowoffuelwhenthemachinewill

notbeusedforafewdays,whenparkinginsideabuilding,

andduringtransporttoandfromthejob.

Movethelevertothelefttoshutofffuel.Movethelever

totherighttoturnonfuel.

WheelClutchLevers

Locatedbelowtherighthandandlefthandhandles.

Thewheelclutchleversallowthedrivetomomentarily

disengagetooneorbothwheelswiththetractiondrivelever

stillengaged.Thisallowseasierturningandmaneuvering

themachine(Figure5).

Squeezingbothwheelclutchleverssimultaneouslydisengages

thedrivetobothwheels(free-wheeling).Thisenablesyouto

manuallymovethemachinebackwardwithoutstoppingto

shiftitintoareversegear.Italsoallowsyoutomaneuver

andtransportthemachinemoreeasilywhentheengineis

notrunning.

Figure5

1.Wheelclutchlever4.Tractiondrivelever

2.Handle5.Speedselectorlever

3.Broomanglelever6.Broomdrivelever

BroomDriveLever

Locatedabovetherighthandhandle(Figure5).

Toengagethebroom,squeezethelevertothehandle.To

disengagethebroom,releasetherighthandlever.

TractionDriveLever

Locatedabovethelefthandhandle(Figure5).

Thetractiondrivelevercontrolstheforwardandreverse

motionofthemachine.Toengagethetractiondrive,squeeze

thelevertothehandle.

9

Note:Holdingdownthetractiondriveleveragainstthe

handleengagesthetractiondrivetobothwheels.

SpeedSelectorLever

Locatedonthemainconsolepanel(Figure5).

Thespeedselectorhas6forwardand2reversesettings.To

changespeeds,releasethetractiondriveleverandshiftthe

speedselectorlevertothedesiredsetting.Theleverlocksina

notchateachspeedsetting.

BroomAngleLever

Locatedontherighthandhandle(Figure5).

Thebroomcanbelockedintothreepositions;straightahead,

orangledtotheleftorright19°.

Specications

Width118cm(46.5inches)

Length185.5cm(73inches)

Height105.5cm(41.5inches)

Weight146.5kg(323lbs)

Enginerpm(noload)Fullspeed:3600±100rpm

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

Operation

OperatingInstructions

OpentheFuelShut-OffValve

Movethefuelshut-offvalvelocatedbelowthechoke,tothe

righttoturnonfuel.

StartingtheEngine

1.Ontherighthandsideoftheengine,rotatetheengine

On/OffswitchclockwisetotheOnposition.

2.Ontherearlefthandsideoftheengine,movethe

chokelevertothelefttotheOnposition.Onawarm

engine,leavethechokeintheOffposition.

3.PlacethethrottlemidwaybetweentheSlowandFast

positionslocatedonrearrighthandsideoftheengine.

4.Slowlypulltheenginerecoilhandleuntilyoufeel

resistanceandthenstop.Allowtherecoilhandleto

returnandthensharplypullitstraightout.Allowthe

ropetoreturnslowly.

5.Allowtheenginetowarmupforseveralminutes,then

movethechoketowardtheOffposition.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.PlacethethrottlemidwaybetweentheSlowandFast

positions.

3.Allowtheenginetorunforaminimumof15seconds,

thenturntheengineOn/OffswitchtotheOffposition

tostoptheengine.

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

5.Closethefuelshut-offvalvebymovingittotheleft

whenthemachinewillnotbeinuseforafewdays,

whentransporting,orwhentheunitisparkedinsidea

building.

DrivingtheMachine

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable

(refertoCheckingtheTractionCable(page16)and

10

AdjustingtheTractionCable(page18))orcontactyour

authorizedTorodealer.

DrivingForward

1.Placethespeedselectorlevertothedesiredforward

position,makingsureitlocksinthenotch(Figure6).

Figure6

Note:Ifthegroundspeedistoofast,debrisorsnow

willpileupinfrontofthebroomcausingthebroom

tobulldozeinsteadofsweep.Thiscandamagethe

bristlesandthedriveline.

2.Slowlysqueezethelefthandtractiondrivelevertothe

handle(Figure7).

Note:Holdingdownthetractiondriveleveragainst

thehandleengagesthetractiondrivetobothwheels.

Figure7

3.Tostopthetractiondrive,releasethetractiondrive

lever.

4.Tomoveforward,engagethetractiondriveandslowly

squeezethelefthandtractionlevertothehandle

(Figure8).Momentarilysqueezingandreleasingthe

leftorrightwheelclutchleverallowsforsteering

adjustmentstokeepthemachinegoinginastraight

line,especiallyindeepsnow.

Toturnright,liftupontherightwheelclutchlever

andsqueezeittowardthehandle.Thisdisengagesthe

drivetotherightwheelwhiletheleftwheelcontinues

driving,andthemachineturnstotheright.

Figure8

Note:Similarly,squeezingtheleftwheelclutchlever

turnsthemachinetotheleft.

Whenyoucompletetheturn,releasethewheelclutch

lever.Thedriveengagesbothwheels(Figure9).

Figure9

5.Tostopthetractiondrive,releasethetractiondrive

lever.

DrivingRearward

1.Placethespeedselectorlevertothedesiredrearward

position,makingsureitlocksinthenotch.

2.Tomoverearward,engagethetractiondriveandslowly

squeezethelefthandtractionlevertothehandle.

Momentarilysqueezingandreleasingtheleftorright

wheelclutchleverallowsforsteeringadjustmentsto

keepthemachinegoinginastraightline.

Toturnright,squeezetherightwheelclutchlever

towardthehandle.Thisdisengagesthedrivetothe

rightwheelwhiletheleftwheelcontinuesdriving,and

themachineturnstotheright.

Note:Similarly,squeezingtheleftwheelclutchlever

turnsthemachinetotheleft.

Squeezingbothwheelclutchleverssimultaneouslydisengages

thedrivetobothwheels.Thisenablesmachinetobemoved

rearwardwithoutstoppingtoshiftitintoareversegear.It

alsoallowsyoutomaneuverandtransportthemachinemore

easilywhentheengineisnotrunning.

11

OperatingtheBroom

DANGER

Whenthemachineisinoperation,contactwith

rotatingormovingpartswillseverelyinjurehands

andfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Staybehindthehandlesandawayfromthe

broomwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

WARNING

Contactwitharotatingbroomcanresultin

seriouspersonalinjuryordeathtotheoperatoror

bystanders.

•Toremoveanobstructionfromthebroom;refer

toClearingaCloggedBroom(page13).

•Donotoperatethemachineifthebroomdrive

leverisnotfunctioningproperly.Contactyour

authorizedTorodealer.

WARNING

Therotatingbroomcanthrowstonesandother

foreignobjects,causingseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheworkingareaclearandfreeofall

objectsthatthebroomcouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

CAUTION

Whenthebroomisengaged,itmaydrivetheunit

inthereversedirection.Ifthebroomheightis

adjustedtoolow,themachinemaymovemore

forcefullyinthereversedirection,causinginjury

and/orpropertydamage.

Carefullycheckthebroomheightandadjustit

properlyorcontactyourauthorizedTorodealer.

1.SettheenginethrottletotheFastposition.

2.Placethespeedselectorleverintothedesiredposition

andslowlysqueezethelefthandtractiondrivelever.

Important:Makesurethetractiondriveis

engagedbeforeoperatingthebroom;otherwise

thebroommaydrivetheunitinthereverse

direction.

3.Toengagethebroom,slowlysqueezetherighthand

broomlevertothehandle(Figure10).

Figure10

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinues

torideup,liftuponthehandles.

4.Tostopthebroom,releasetherighthandlever.

CheckingtheSweepingPath

Abroomsweepswiththetipsofitsbristles.Whentoomuch

downpressureisapplied,thebroomisnolongerusingits

tips;thebroomisnowworkingwiththesidesofthebristles.

Thislimitstheickingactionofthebristles,sweeping

effectiveness,andcandecreasebroomlife.

1.Drivetoaatdustyareaandstopthemachine.

2.Withtheenginerunningmovethethrottlemidway

betweenSlowandFast.Engagethebroomandallow

thebroomtosweepforapproximately30seconds.

3.Disengagethebroomandstoptheengine.

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

5.TurntheengineOn/OffswitchtotheOffposition.

6.Makesuretheareasweptequalsthelengthofthe

broomandamaximumwidthof51-102mm(2-4

inches).

12

Figure11

1.51-102mm(2–4inches)

maximumwidth

3.Sweptarea

2.Lengthofbroom

7.Adjustthebroomheightifnecessary.

AdjustingtheBroomHeight

1.Drivetoaatdustyareaandstopthemachine.

2.Disengagethebroomandstoptheengine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

4.TurntheengineOn/OffswitchtotheOffposition.

5.Toadjustthebroomheight,removeandretainthepin

fromtheadjustersleeveandcasterwheeltube.

6.Raiseorlowerthecasterwheeltubetoachievethe

sweepareaasstatedinCheckingtheSweepingPath

(page12).Selectanyholecombinationthatisin

alignmenttoplaceandlatchtheretainingpin;match

thesamepositionontheotherside.

7.Fornetuningadjustments,slidetheadjustersleeve

onepinholeupordownonthecasterwheeltubeto

adjustthebroomheightin3mm(1/8inch)increments

(Figure12).Repeatfortheothercasterwheel.

Figure12

1.Casterwheeltube3.Pin

2.Positionstoachieve3mm

(1/8inch)increments

4.Adjustersleeve

•Toraisethebroomin3mm(1/8inch)increments,

slightlyraisetheadjustersleeveandinsertthepin

intothenextpinholebelowthecurrentholeused.

•Tolowerthebroomin3mm(1/8inch)increments,

slightlylowertheadjustersleeveandinsertthepin

intothenextpinholeabovethecurrentholeused.

8.Oncethedesiredheightisreached,securethepinon

eachcasterwheel.Recheckthesweepingarea.

AdjustingBroomSideAngle

1.Disengagethebroomandstoptheengine.

2.Waitforallmovingpartstostop.

3.Pushtheleverdownusingtherighthandthumb

(Figure5).

4.Squeezetheleftwheelclutchlevertothehandleand

pushthebroomhousingtothedesiredangle;the

broomcanrotate19°totherightorleft,orstraight

ahead.

5.Oncethebroomispositioned,releasethebroomangle

lever.Releasetheleftwheelclutchleverandmakesure

thebroomislockedintoplace.

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseseriousinjury.

Alwaysusecautionwhencleaningthebroom.

•Ifthebroombecomesclogged,stayintheoperating

positionandreleasethelefthandtractiondrivelever.

Whileengagingthebroom,pushdownonthehandlesto

raisethefrontofthemachineafewcentimeters(inches)

offthepavement.Thenliftthehandlesquicklytobump

13

thefrontofthemachineonthepavement.Repeatif

necessary.

•Ifyoucannotunclogthebroombybumpingthefront

ofthemachine:

–Parkthemachineonlevelground.Stoptheengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Sharpobjectscanbecomeentangledinbristles.Use

glovesandcautionwhencleaningoutthebroomof

foreignobjects;notbarehands.

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

•Afterusingthemachine,lettheenginerunforafew

minutestopreventmovingpartsfromfreezing.Engage

thebroomtoclearanyremainingsnowfrominsidethe

housing.Stoptheengineandwaitforallmovingpartsto

stop,andremovethesparkplugwire(s).Removeallice,

snow,orotherdebrisfromthemachine.

•Reconnectsparkplugwire(s).Withtheengineswitchin

theOffposition,pulltherecoilstarterhandleseveral

timestopreventtherecoilstarterfromfreezingup.

TransportingtheMachine

WARNING

Loadingthemachineontoatrailerwithoutstrong

enoughorproperlysupportedrampscouldbe

dangerous.Therampscouldcollapsecausingthe

unittofall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothetruck

ortrailer.

•Keepfeetandlegsoutfromundertheunitwhen

loadingandunloading.

•Ifnecessary,useassistancewhenloading.

Besurethefuelshut-offvalveisclosed.

Useaheavydutytrailertotransportthemachine.Placethe

machineineitheraforwardorreversegear,thenblockthe

wheels.

Securelyfastenthemachinetothetrailerwithstraps,chains,

cables,orropes.

Besurethatthetrailerhasallnecessarylightingandmarking

asrequiredbylaw.

14

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst2hours•Checkthetractioncable.

•Checkthebroomcable.

Aftertherst5hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevel.

•Checkforloosehardware.

•Checkthebroomshaftshearpin.

Every50hours•Checkthetirepressure.

•Checktheconditionofthebelts.

Every100hours•Changetheengineoil(morefrequentlyinsevereconditions).

•Lubricatethebroomanglelockpin.

Every160hours•Checkthesparkplug.

Yearly

•Checkthetractioncable.

•Lubricatethehexshaft.

•Checkthebroomcable.

Yearlyorbeforestorage

•Checktheairpressureinthedrivetiresandinatethemto116–137kPa(17–20psi).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•Haveanauthorizedservicedealerinspectandreplacethetractiondrivebelt,if

necessary.

Important:Youcanndmoreinformationaboutmaintainingandservicingyourmachineatwww.Toro.com.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.Forengineadjustments,

repairs,orwarrantyservicenotcoveredinthismanual,contactanAuthorizedKohlerServicingDealer.

15

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

EngineOilType:Toro4–CyclePremiumEngineOil

1.Turnofftheengineandwaitforallmovingpartsto

stop.Makesuretheunitisonalevelsurface.

2.Checktheoilleveloncetheengineiscold.

3.Cleantheareaaroundthedipstick.Removethedipstick

andwipetheoiloff.Insertthedipstickaccordingto

theenginemanufacturer'srecommendations.Remove

thedipstickandreadtheoillevel.

4.Iftheoillevelislow,wipeofftheareaaroundtheoil

llcap,removethecapandlltotheFullmarkon

thedipstick.Toro4-CyclePremiumEngineOilis

recommended;refertotheEngineOwner'smanualfor

anacceptablealternative.

Note:Donotoverll.

Note:Donotoperatetheenginewiththeoillevelbelowthe

LoworAddmarkonthedipstick,orovertheFullmark.

CheckingtheTractionCable

ServiceInterval:Aftertherst2hours

Yearly

1.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

2.Withthetractionleverdisengaged,checkthepininthe

elongatedslotintheleftsideofthemachineabovethe

tire(Figure13).Thereshouldbeagapof6mm(1/4

inch)fromthefrontoftheslottothefrontedgeof

thepin.Ifadjustmentisnecessary,seeAdjustingthe

TractionCable(page18).

Figure13

1.Pin2.6mm(1/4inch)

CheckingforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

2.Visuallyinspectthemachineforanyloosehardwareor

anyotherpossibleproblem.Tightenthehardwareor

correcttheproblembeforeoperating.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(morefrequentlyinsevere

conditions).

1.Turnofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Draintheoilwhiletheengineiswarmfromoperation.

4.Placeapanunderdrainttingandremovetheoildrain

plug.Allowtheoiltodrainandreplacetheoildrain

plug.

5.Cleanaroundtheoilllcapandremovethecap.Fill

tothespeciedcapacityandreplacethecap.Usethe

oilrecommendedintheCheckingtheEngineOilLevel

(page16)section.Donotoverll.

6.Starttheengineandcheckforleaks.Stoptheengine

andrechecktheoillevel.

7.Wipeupanyspilledoilfromtheenginedeckmounting

surfaces.

CheckingtheTirePressure

ServiceInterval:Every50hours

1.Turnofftheengine,waitforallmovingpartstostop,

andleaveengineswitchintheOffposition.

2.Checkthetirepressureinthedrivetires.

3.Inatethedrivetiresto117-138kPa(17-20psi).

CheckingtheConditionofthe

Belts

ServiceInterval:Every50hours

1.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

2.Removethebeltcoverandengineshieldtocheckthe

beltcondition.

LubricatingtheBroomAngle

LockPinandHexShaft

ServiceInterval:Every100hours

Yearly

1.Turnofftheengine,waitforallmovingpartstostop,

andleavetheengineswitchintheOffposition.

16

2.LubricatethebroomanglelockpinttingwithNGLI

grade#2multi-purposegungrease.

Figure14

1.Broomanglelockpin

3.Removethebeltcoverandengineshield.

4.MovethespeedselectorlevertopositionR2.

5.Dipalong,clean,smalltippedpaintbrushin

automotiveengineoilandlightlylubricatethehex

shaft.Rockthemachineforwardandrearwardto

rotatethehexshaft.

Important:Donotgetoilontherubberwheelor

thealuminumfrictiondriveplateasthetraction

drivewillslip(Figure15).

Figure15

1.Aluminumfrictiondrive

plate

2.Hexshaft

6.Movethespeedselectorlevertoposition6.

7.Lubricatetheotherendofthehexshaft.

8.Movethespeedselectorleverforwardandrearward

afewtimes.

9.Installthebeltcoverandengineshield.

CheckingtheSparkPlug

ServiceInterval:Every160hours

Removethesparkplug,checktheconditionandresetthegap,

orreplacewithanewplug.SeeyourEngineOwner'sManual.

CheckingtheBroomCable

ServiceInterval:Aftertherst2hours

Yearly

1.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

2.Removethebeltcoverandengineshield.

3.Withthebroomleverdisengaged,ensurethegap

betweenthebroomclutchassemblyandthetabis3.2

mm(1/8inch).Ifthebroomisnotproperlyadjusted,

seeAdjustingtheBroomDrive(page18).

Figure16

1.Broomclutchassembly3.3.2mm(1/8inch)

2.Tab

CheckingtheBroomShaft

ShearPin

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

3.Checktheshearpinlocatedonthebroomshafton

eithersideofthegearbox.

17

Figure17

1.Nut2.Shearpin

4.Iftheshearpinisdamaged,removethepinandreplace

withaTororecommendedpin.Securethepinwith

anut.

CheckingtheBroomSegments

1.Movethemachinetoalevelsurface.

2.Turnofftheengine,waitforallmovingpartstostop,

andremovethesparkplugwire(s).

3.Raisethebroombyresettingthecasterpositions.

4.Onbothsidesoftheunit,removeandretaintheouter

bearinghousinghardware.

5.Manuallypullthepowerunitrearwardtoremovethe

broomassemblyfromtheunit.

6.Supportthesplinedshaftoneithersideofthegearbox.

7.Standthebroomcoreassemblyonendsothe

removableendretainerplateisfacingupward.

Figure18

1.Hardware4.Supportshaft

2.Endretainerplate5.Alignmentngers

3.Broomsegment

8.Removeandretainthehardwarefromtheendretainer

plate.

9.Removethedamagedbroomsegment(s).Installthe

newsegment(s)bystaggeringthemetalringalignment

ngersasshowninFigure18.

Important:Damagemayoccurtothebroom

assemblyifthebroomsegmentsarenotproperly

installed.

10.Installthebroomassemblyontotheunit.

Important:Makesurethebearingsetscrewsare

tightenedbeforeoperatingthebroom.

AdjustingtheTractionCable

Ifthemachinedoesnotdriveintheforwardorreversespeeds

oritdriveswhenyoureleasethetractionlever,adjustthe

tractioncable.

Withthetractionleverdisengaged,checkthepininthe

elongatedslotintheleftsideofthemachineabovethetire.

Thereshouldbeagapof6mm(1/4inch)fromthefrontof

theslottothefrontedgeofthepin(CheckingtheTraction

Cable(page16)).

Ifthelefthandtractioncableisnotproperlyadjusted,do

thefollowingsteps:

1.Loosenthejamnut.

2.Loosenortightentheturnbuckletoadjustthepinuntil

itisthepropergapfromthefrontedgeoftheslot.

3.Tightenthejamnut(Figure19).

3

g019016

Figure19

1.Jamnut2.Turnbuckle

AdjustingtheBroomDrive

Ifthebroomcableisnotproperlyadjusted(seeCheckingthe

BroomCable(page17)),dothefollowingsteps:

1.Loosenthejamnut(Figure20).

18

Figure20

1.Jamnut2.Turnbuckle

2.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure20).

3.Adjusttheturnbuckleuntilthegapbetweenthebroom

clutchassemblyandthetabis3.2mm(1/8inch)

(Figure16).

4.Tightenthejamnut.

5.Ifthebroomcableisproperlyadjustedbutaproblem

remains,contactyourauthorizedservicedealer.

AdjustingtheWheelClutch

Cable

1.Squeezetheleverfully,thencheckthegapbetweenthe

bottomofthehandleandthewheelclutchleverend.

Figure21

Note:Thegapshouldbeapproximatelythethickness

ofapencil(6mmor1/4inch).Ifitisgreater,loosen

thecableclampnut,slidethecablejacketupslightly,

tightenthecableclampnut,andcheckthegapagain.

2.Repeatfortheothercable.

Storage

WARNING

•Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor

Storage

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

freshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Loosenthehoseclampthatsecuresthefuellinetothe

valveandslidethefuellineoffthefuelshutoffvalve.

4.Openthefuelshutoffvalveandallowthefueltodrain

outofthefueltankintoanapprovedfuelcontainer.

5.Installthefuellineontothefuelshutoffvalveand

secureitwithahoseclamp.

6.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

7.Primetheengineandstartitagain.

8.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

9.Stoptheengineandallowittocool.

10.Removetheignitionkey.

11.Disconnectthesparkplugwire.

12.Removethesparkplug,add1oz.(30ml)ofoilthrough

thesparkplughole,andpullthestarterropeslowly

severaltimestodistributeoilthroughoutthecylinder

topreventcylindercorrosionduringtheoff-season.

13.Looselyinstallthesparkplug.

14.Disposeofanyunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyourautomobile.

Note:Donotstorestabilizedfuelformorethan

90days.

15.Cleanthemachinethoroughly.

16.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedServiceDealer.Sandaffectedareasbefore

painting,andusearustpreventativetopreventthe

metalpartsfromrusting.

17.Tightenallloosescrews,bolts,andlocknuts.Repairor

replaceanydamagedparts.

18.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheenginetocool

beforestoringitinanyenclosure.

19

RemovingtheMachinefrom

Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

2.Installthesparkplugbyhandandthentorqueitto

20.4N-m(15ft-lb).

3.Connectthesparkplugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule.

20

Other manuals for 23740

1

This manual suits for next models

1

Table of contents

Other Toro Floor Machine manuals

Popular Floor Machine manuals by other brands

Kärcher

Kärcher FP 306 manual

Tornado

Tornado PS Series 98220 Operation & maintenance manual

Schwarze Industries

Schwarze Industries A7 TORNADO SE product manual

Metabo

Metabo W 18 LTX 115 Original instructions

Jon-Don

Jon-Don Prospector PE220 Information & operating instructions

PBU

PBU 08006B Operator's manual

Mytee

Mytee HP100 Grand Prix user manual

Nilfisk-Advance

Nilfisk-Advance Handy 2-in-1 user manual

COMAC

COMAC SIMPLA 55BT Daily maintenance

Tornado

Tornado ExSELLerate Series Dealer Training Guide

Windsor

Windsor 10080480 operating instructions

Advance acoustic

Advance acoustic Advenger 56601000 Instructions for use