ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Introduction

Thisvehicleisintendedtobeprimarilyused

off-highwaytotransportpeople.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyou,yourpassengers,andbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DistributororToroCustomerServiceandhavethe

modelandserialnumbersofyourproductready.

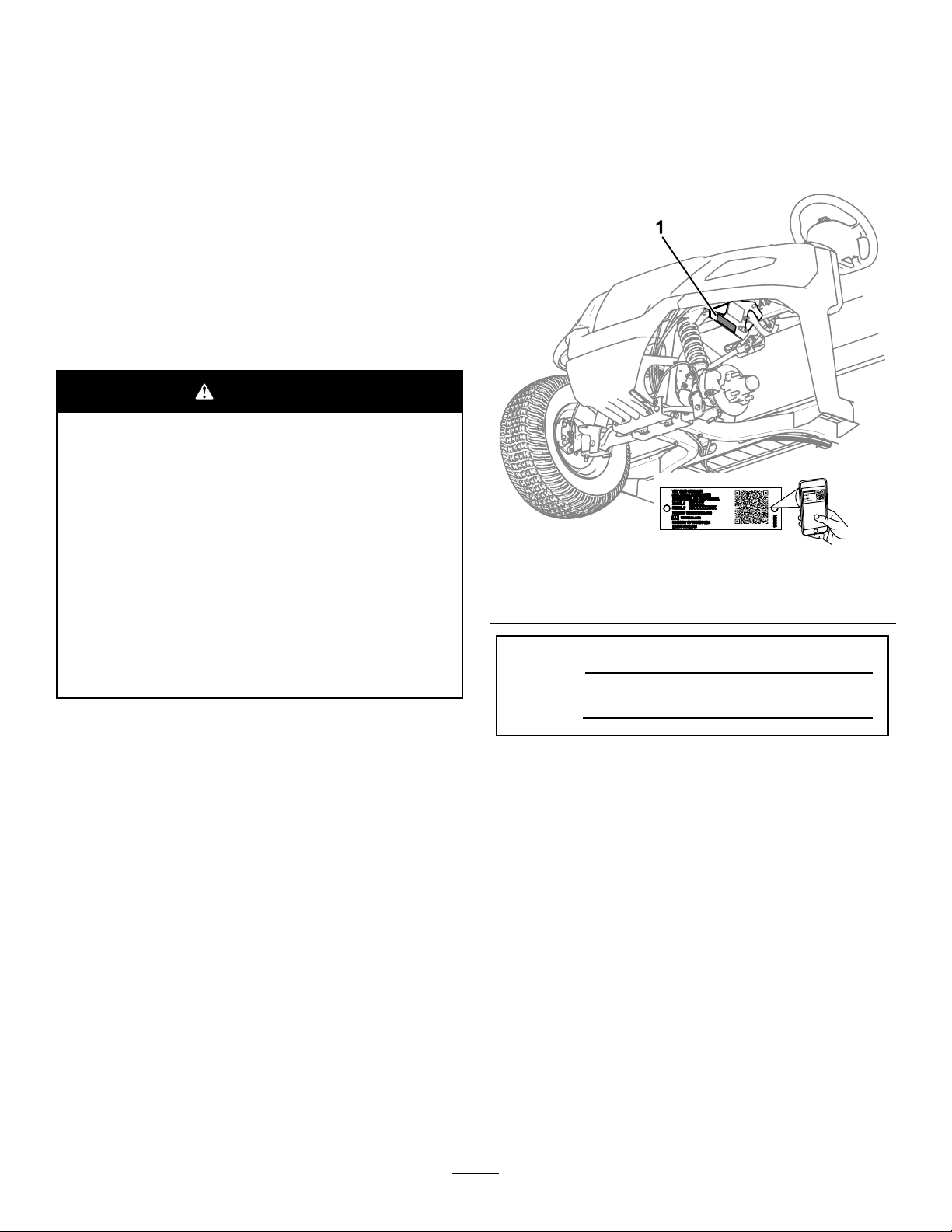

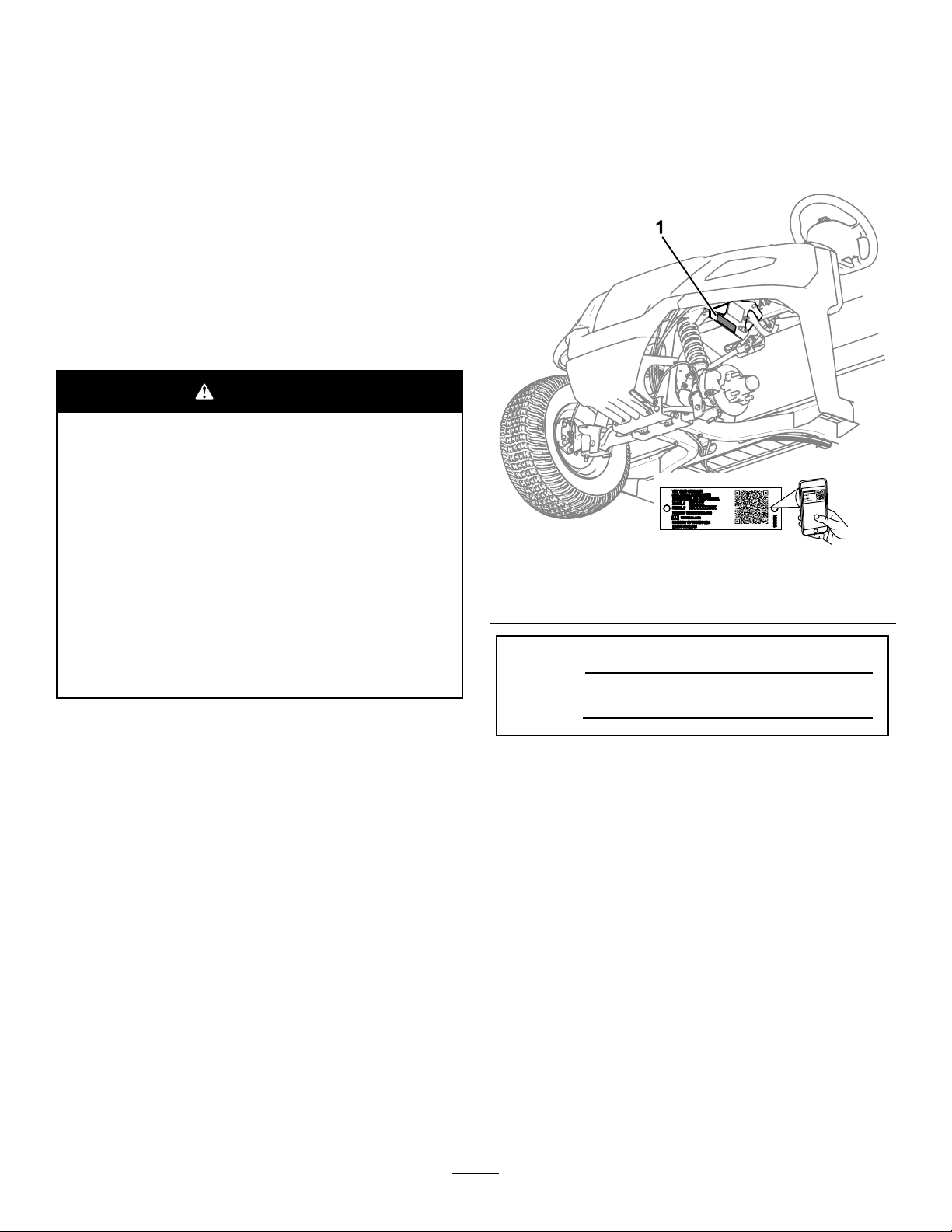

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g405906

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

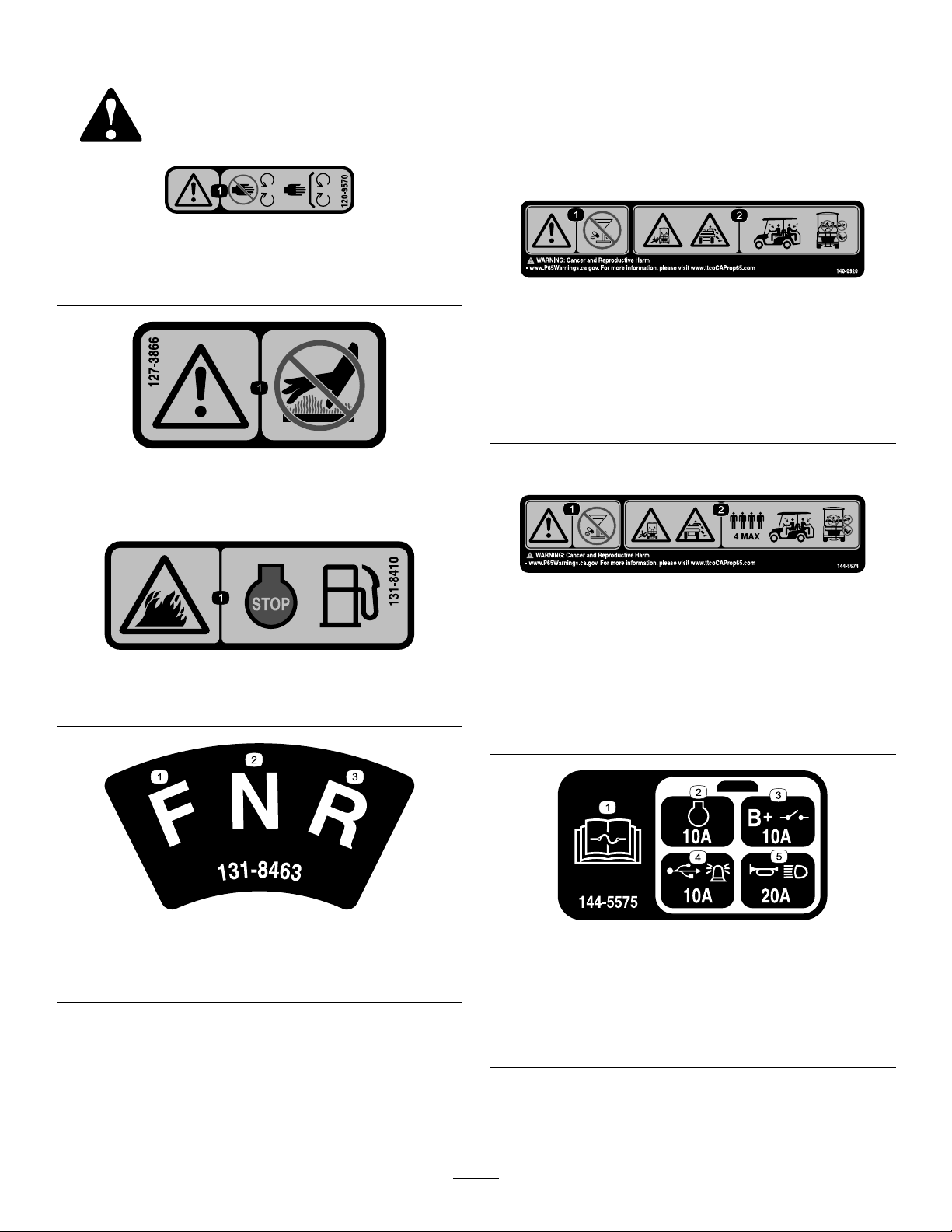

Thesafety-alertsymbol(Figure2)appearsbothin

thismanualandonthemachinetoidentifyimportant

safetymessagesthatyoumustfollowtoavoid

accidents.Thissymbolwillappearwiththeword

Danger,Warning,orCaution.

•Dangerindicatesanimminentlyhazardous

situationwhich,ifnotavoided,willresultindeath

orseriousinjury.

•Warningindicatesapotentiallyhazardous

situationwhich,ifnotavoided,couldresultin

deathorseriousinjury.

•Cautionindicatesapotentiallyhazardoussituation

which,ifnotavoided,mayresultinminoror

moderateinjury.

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved