Workman GTX GasolinePage 1 −2Safety

Safety Instructions

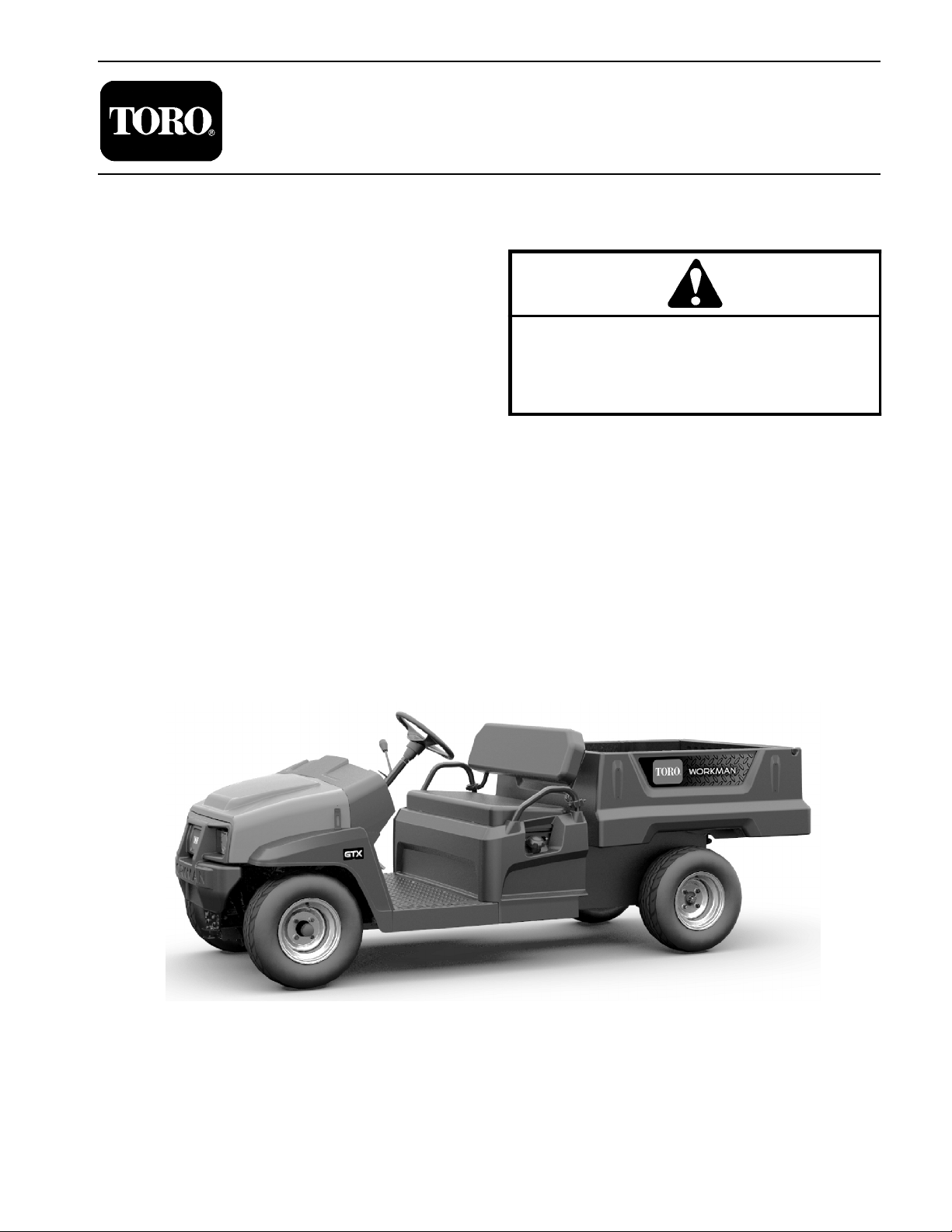

The Workman GTX vehicles are designed and tested to

offer safe service when operated and maintained pro-

perly. Although hazard control and accident prevention

partially are dependent upon the design and configura-

tion of the machine, these factors are also dependent

upon the awareness, concern and proper training of the

personnel involved in the operation, transport, mainte-

nance and storage of the machine. Improper use or

maintenance of the machine can result in injury or

death.

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUC-

TION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

WARNING

To reduce the potential for injury or death, com-

ply with the following safety instructions.

WARNING

The Workman GTX is an off−highway vehicle

only. It is not designed, equipped or manufac-

tured for use on public streets, roads or high-

ways.

Supervisor’s Responsibilities

1. Make sure operators are thoroughly trained and fa-

miliar with the Operator’s Manual and all labels on the

vehicle.

2. Be sure to establish your own special procedures

and work rules for unusual operating conditions (e.g.

slopes too steep for vehicle operation).

Before Operating

1. Read and understand the contents of the Operator’s

Manual and Operator’s DVD before starting and operat-

ing the vehicle. Become familiar with the controls and

know how to stop the vehicle and engine quickly. Addi-

tional copies of the Operator’s Manual are available on

the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the ve-

hicle. Also, tighten any loose nuts, bolts or screws to en-

sure vehicle is in safe operating condition.

3. Since fuel used in Workman vehicles is highly flam-

mable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove vehicle fuel tank cap while engine

is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill

the fuel tank.

E. Clean up any spilled fuel.