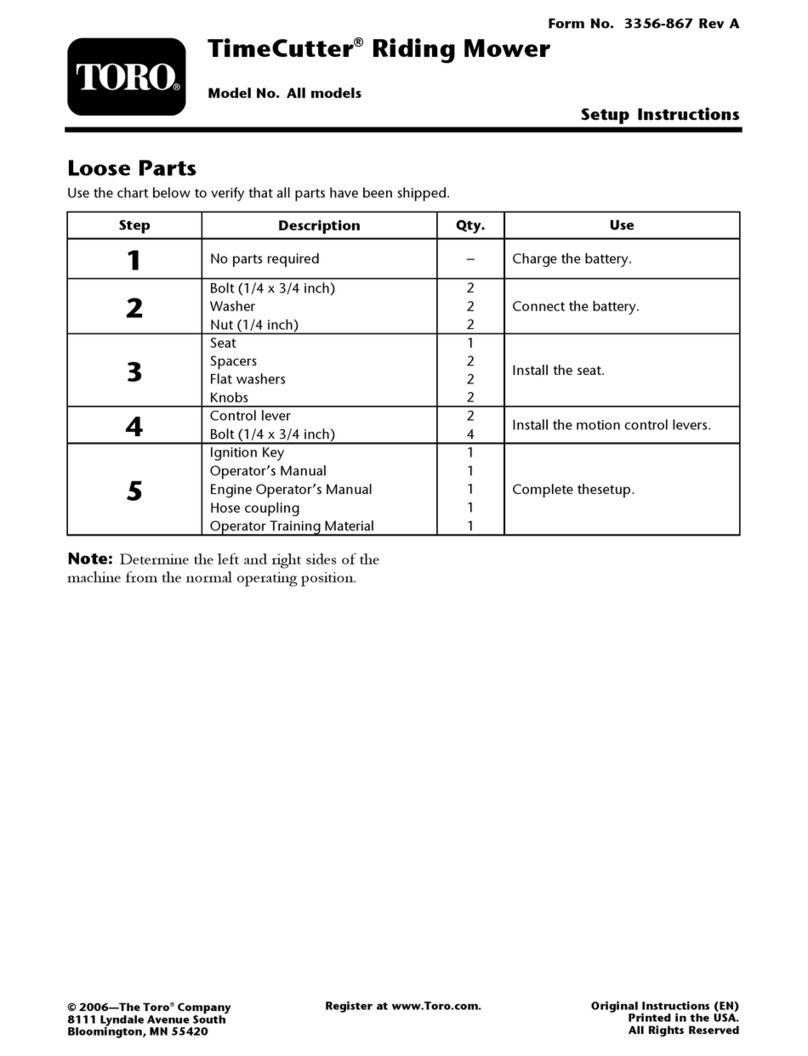

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperuseormaintenanceofthisequipmentcan

resultininjuryordeath.Toreducethepotentialfor

injuryordeath,complywiththefollowingsafety

instructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitOperator’sManualbeforeoperatingthe

verticutters.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingtheverticutters.

•Neverallowchildrentooperatethetractionunitorthe

verticutters.Donotallowadultstooperatethetraction

unitortheverticutterswithoutproperinstruction.Only

trainedoperatorswhohavereadthisOperator’sManual

shouldoperatetheverticutters.

•Neveroperatetheverticutterswhentired,ill,orunderthe

inuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,a

safetydevice,oradecalisillegibleordamaged,repairor

replaceitbeforeresumingoperation.Also,tightenany

loosenuts,bolts,andscrewstoensurethattheverticutters

areinsafeoperatingcondition.

•Alwayswearsubstantial,slip-resistantfootwear.Always

wearlongpants.Wearingsafetyglassesandsafetyshoes

isadvisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Tiebacklonghair.Donotwearjewelry.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythereelbladesofthecuttingunit.Keep

allbystandersawayfromtheworkingarea.

•Iftheverticutterbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

theverticutterfordamagedparts.Repairanydamage

beforestartingandoperatingtheverticutter.

•Lowertheverticutterstotheground,settheparking

brake,shutofftheengine,andremovethekeyfrom

theignitionswitchwheneveryouleavethemachine

unattended.

•Besurethattheverticuttersareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

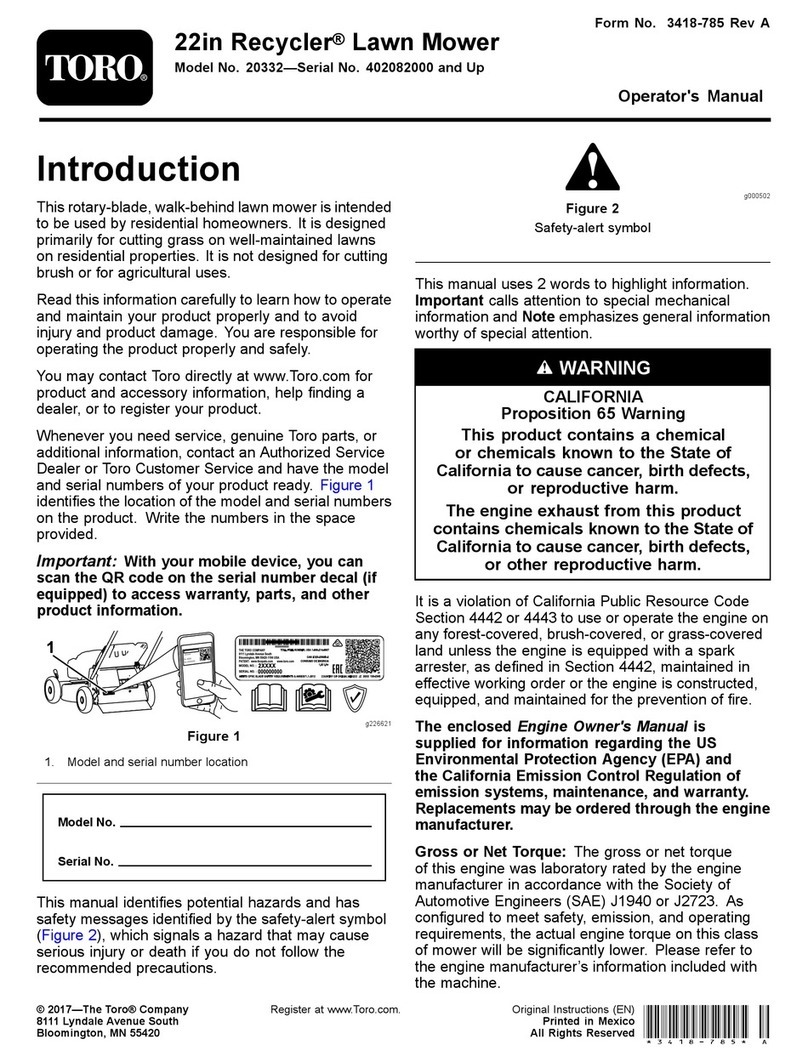

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6688

1.Warning—readthe

Operator’sManualbefore

performingmaintenance.

2.Cuttinghazardofhandor

foot—shutofftheengine

andwaitforallmoving

partstostop.

3