stoppedbecausetheseareascouldbehotenough

tocauseburns.

•Stayclearoftherotatingscreenatthesideofthe

enginetopreventdirectcontactwithyourbodyor

clothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately,turntheengineoff,

waitforallmotiontostop,andinspectthemachine

fordamage.Adamagedreelorbedknifemustbe

repairedorreplacedbeforeoperationiscontinued.

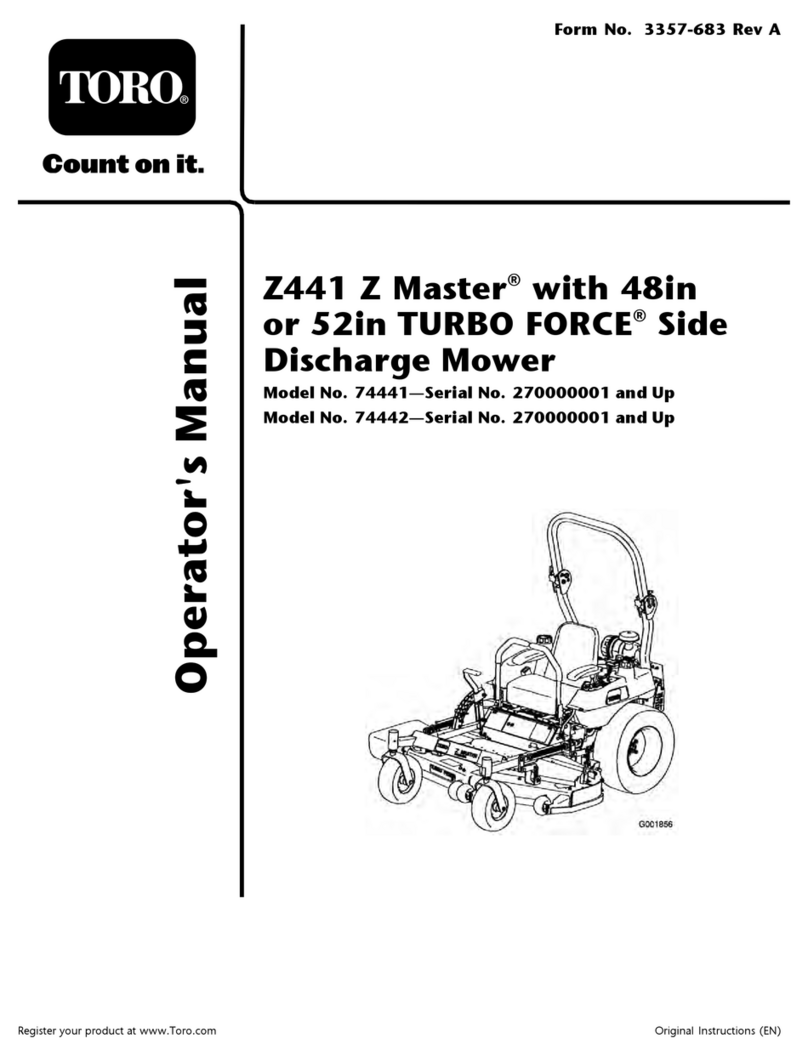

•Beforegettingoffoftheseat,movethefunctional

controllevertoneutral(N),raisethecuttingunits

andwaitforthereelstostopspinning.Setthe

parkingbrake.Stoptheengineandremovethekey

fromtheignitionswitch.

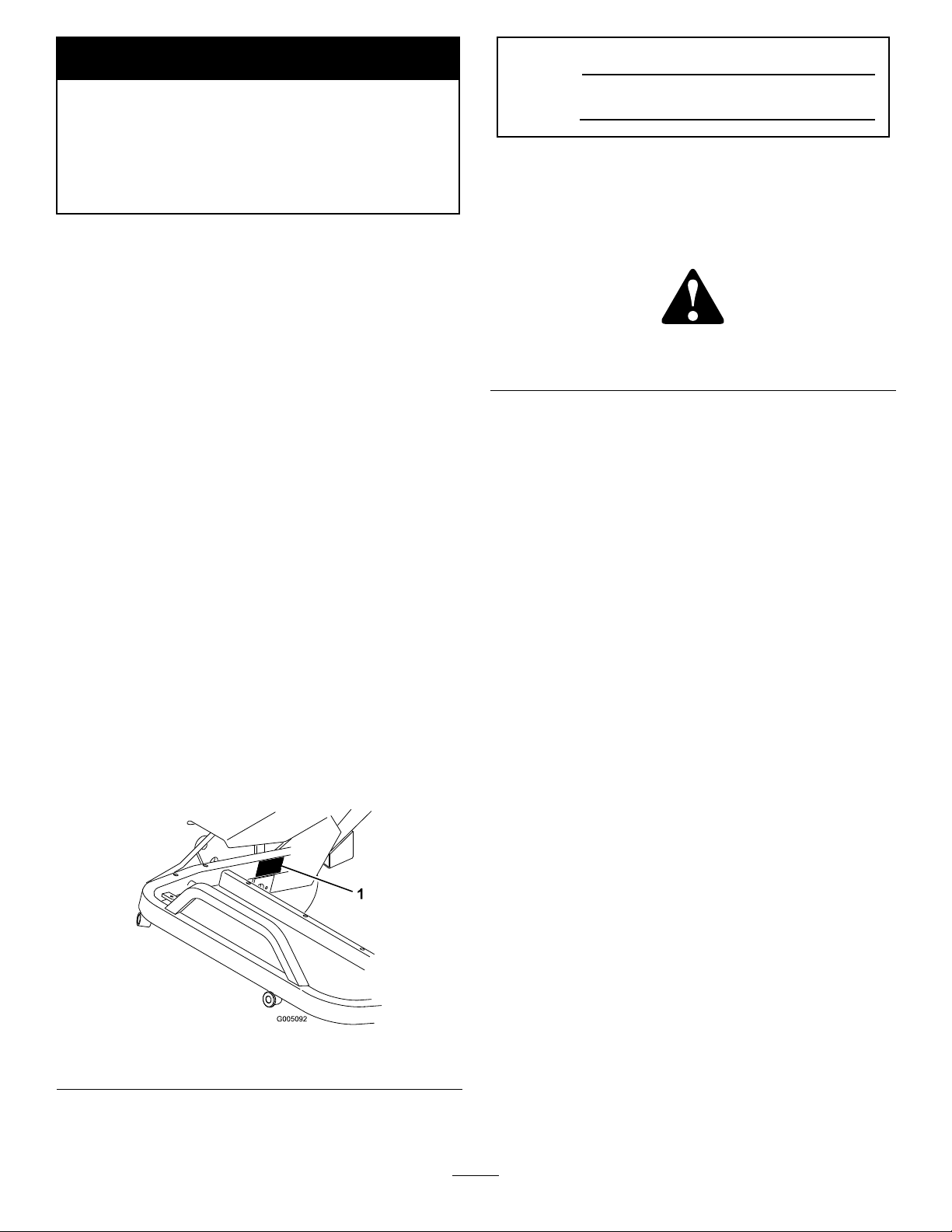

•Traverseslopescarefully.Donotstartorstop

suddenlywhentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowto

driveonhillsides.Failuretousecautiononslopesor

hillsmaycauselossofcontrolandcausethemachine

totiporroll,possiblyresultinginpersonalinjury

ordeath.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

•Wheneverthemachineisleftunattended,make

surethecuttingunitsarefullyraised,thereelsare

notspinning,thekeyisremovedfromtheignition

switch,andtheparkingbrakeisset.

MaintenanceandStorage

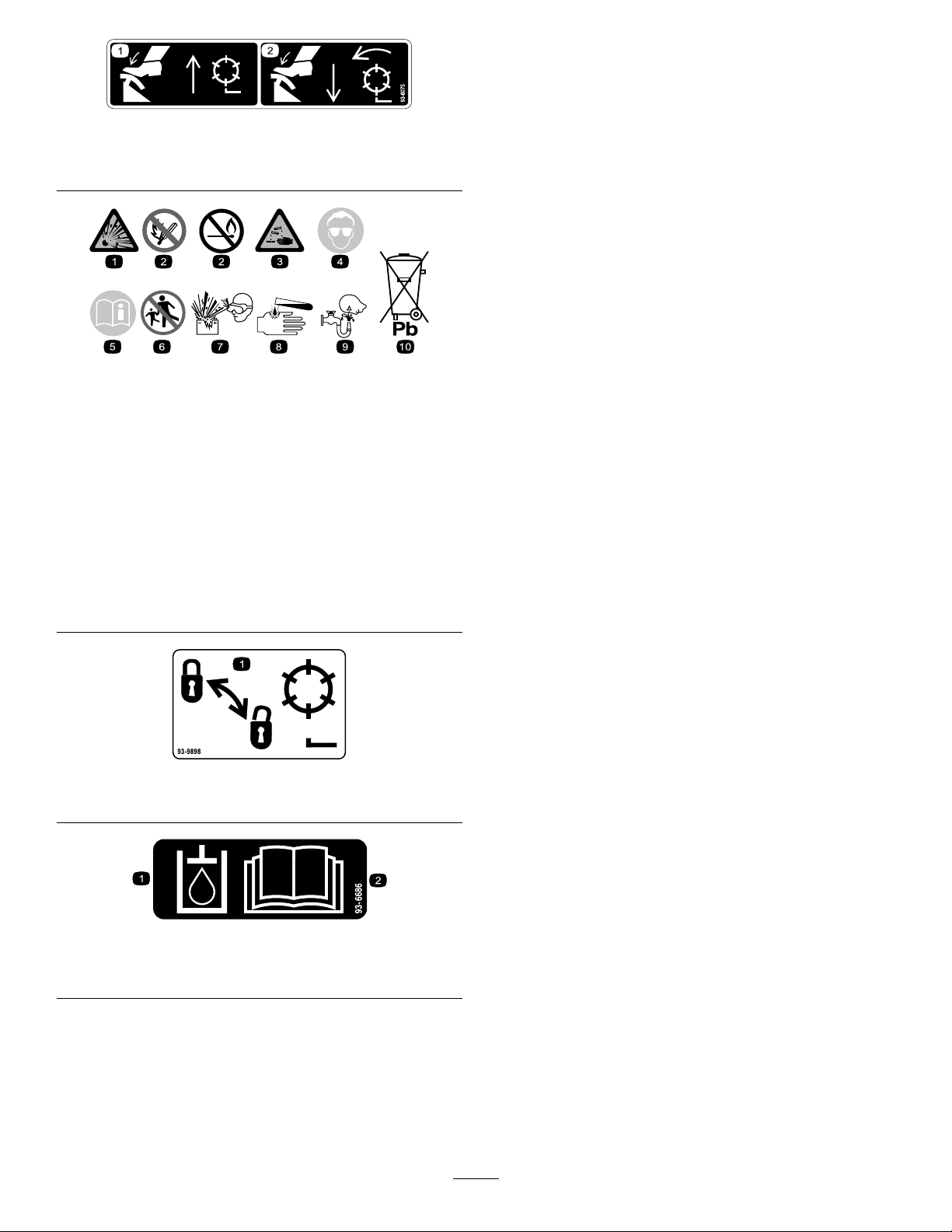

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

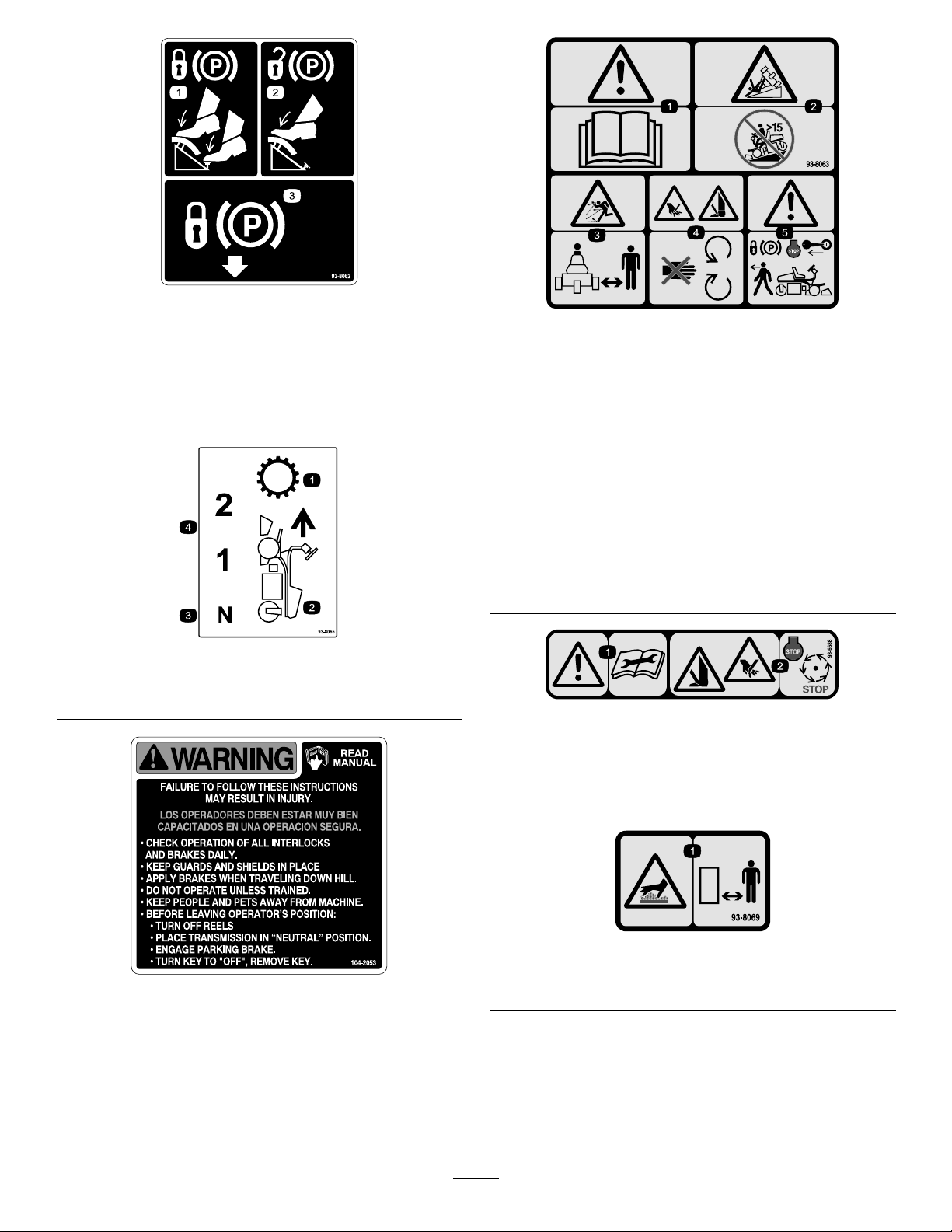

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts,especially

thescreenatthesideoftheengine.Keepeveryone

away.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer..

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Toassureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof86dBA,basedonmeasurementsof

identicalmachinesperISO11201andEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

2.5m/s2,basedonmeasurementsofidenticalmachines

perEN1033andEN836.

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s2,basedonmeasurementsofidentical

machinesperEN1032andEN836.

6