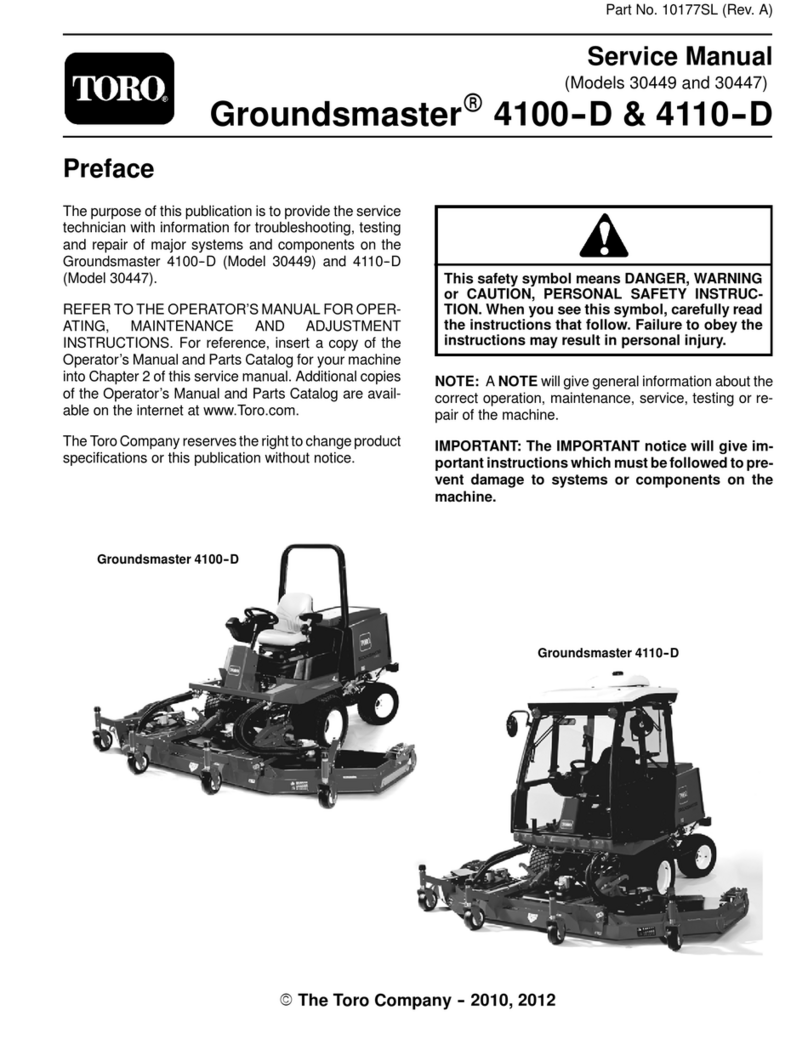

Traction Unit

Engine: Peugeot, four-cycle, four-cylinder, 1.9 liter (1,900

cc) displacement, liquid-cooled diesel engine. 23.5:1

compression ratio. Low idle—1,500 rpm, high idle—3,000

rpm. Oil capacity is 5.3 qts. with filter.

Cooling System: Capacity is 3.5 gal. of 50/50 mixture of

Peugeot recommended anti-freeze.

Fuel System: Capacity is 53 liter (14 gallon) of #1 or #2

diesel fuel.

Hydraulic System: Reservoir capacity is 24.6 liters (6.5

gallon). Replaceable spin-on filter element.

Traction System: Ground speed: Low Range; 0–10.5 kmh,

0–6.5 mph (0–5.5 mph. with mechanical speed limiter

interlock) forward and 0–4.8 kmh, 0–3 mph reverse. High

Range): 0–24.1 kmh, 0–15 mph (0–20 kmh, 0–12.4 m.p.h.

with mechanical speed limiter interlock) forward and 0–8

kmh, 0–5 mph reverse.

Front Axle: Two-speed axle. Separate mowing and

transport selections for faster and more efficient machine

operation. Lubricated with SAE 80–90 weight, EP gear

lubrication. Capacity is 128 oz.

Rear Axles: Two-Wheel Drive—The large diameter wheel

spindles are designed for durability and long wear, yet

provide superior stability and maneuverability. Four-Wheel

Drive , Heavy-duty, agricultural type. Lubricated with SAE

80–90 weight, EP gear lubrication. Capacity is 2.4 kg (80 oz).

Tires/Wheels: Front tires: (2) 26 x 12.0-12, 8 ply. Rear

tires: (2) 20 x 10.0-10, 6 ply. Tire pressure 138 kPa (20 psi).

Seat:Adjustable fore and aft travel and weight.

Diagnostic System: Test ports for: forward and reverse

traction (2-wheel drive), front and rear axle motors (4 wheel

drive), lift and counterbalance circuit, steering circuit and

charge circuit.

Steering System: Automotive type, full power.

Brakes:Totally enclosed, non asbestos, dry multi-disc

individual wheel and parking brakes on the front traction

wheels.

SPECIFICATIONS

9

Electrical System: 12-volt battery with 530 cold cranking

Amps @ –18°C (0° F). 55-amp alternator, ammeter, starter,

key switch and automatic temperature controlled glow plug

controller. Separately-fused run, deck and

instrument/accessory circuits.

Interlock System: Stops the engine if operator gets off the

seat while the cutting deck drive switch is engaged or the

traction pedal is forward or reverse. Prevents the engine from

starting unless the traction pedal is in neutral and the cutting

deck is disengaged. Prevents the cutting deck from operating

unless the axle shift is in LO range.

Warning Lights:

Glow plug indicator

Engine oil pressure warning

Engine coolant temperature warning

Charge indicator

Indicators:

Engine coolant temperature gauge

Fuel gauge

Hour meter

The Cutting Unit

Type: 320 cm (126 inch) width of cut, seven-blade, front-

mounted rotary. 137 cm (54 inch) width of cut, three-blade

center section. Two 94 cm (36 inch) width of cut wings; 229

cm (90 in.) width of cut with one wing up. Rear discharge

with even dispersion over the entire width of cut.

Mowing Rate: Mows up to #8 acres/hr. at 10.5 kmh (6.5

mph).

Trimability: Trims on both sides.

Height-of-Cut: Adjustable from 2.5–12.7 cm (1–5 inches) in

1.2 cm (0.5 inch) increments.

Blades: Seven 48 cm (19 inches) long, 6 mm (1/4”) thick,

and 64 mm (2-1/2 in.) wide, heat treated steel blades.

Belt Idlers: Self-tensioning permanently lubricated idlers.

Wing Decks:Wings can be hydraulically raised from the

operator’s seat for transport or cutting with either wing and

center deck or center deck only. Wings cut from level to 15°

up and down. Further lift disengages the blade and applies a

blade brake.