TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

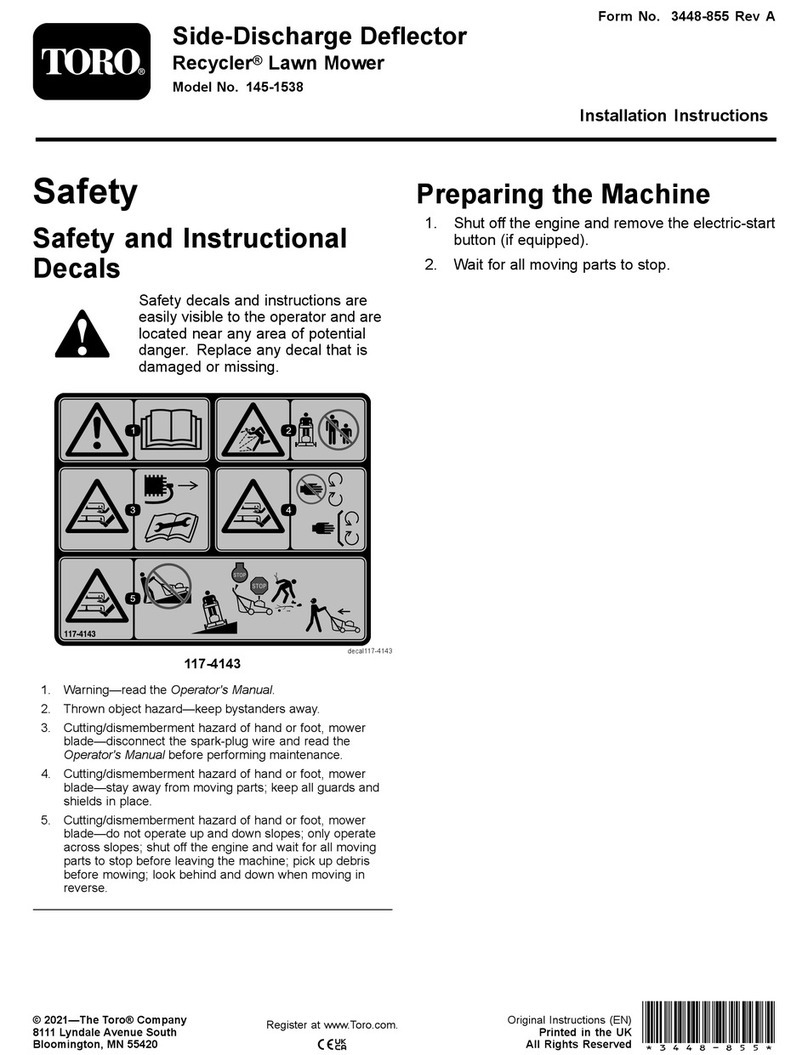

SafetyandInstructionalDecals....................................................................1–8

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–7

ShopSupplies............................................................................................2–13

SpecialT ools..............................................................................................2–15

Chapter3:Troubleshooting.............................................................................3–1

GEARS–TheSystematicApproachtoDening,DiagnosingandSolving

Problems......................................................................................................3–2

GeneralHydraulicSystemProblems............................................................3–3

TractionCircuitProblems..............................................................................3–4

PTOProblems..............................................................................................3–6

Lift/LowerCircuitProblems...........................................................................3–7

SteeringCircuitProblems.............................................................................3–8

StartingProblems.........................................................................................3–9

GeneralRunandTransportProblems.........................................................3–11

CuttingDeck(PTO)OperatingProblems....................................................3–12

CuttingDeckLift/LowerProblems...............................................................3–14

OperatorAdvisories....................................................................................3–16

UsingtheInfoCenterDisplayforTroubleshooting.......................................3–21

MachineFaults...........................................................................................3–23

EngineFaults..............................................................................................3–27

FactorsThatCanAffectQualityofCutandClippingDispersion...................3–29

Chapter4:YanmarDieselEngine....................................................................4–1

GeneralInformation.....................................................................................4–2

ServiceandRepairs...................................................................................4–11

Chapter5:HydraulicSystem...........................................................................5–1

GeneralInformation.....................................................................................5–3

HydraulicSchematic...................................................................................5–12

HydraulicFlowDiagrams............................................................................5–13

Testing........................................................................................................5–36

Adjustments...............................................................................................5–72

ServiceandRepairs...................................................................................5–73

Chapter6:ElectricalSystem...........................................................................6–1

GeneralInformation.....................................................................................6–3

ElectricalSystemOperation..........................................................................6–7

InfoCenterDisplay........................................................................................6–9

Adjustments................................................................................................6–46

ComponentT esting.....................................................................................6–53

ServiceandRepairs.................................................................................6–138

Chapter7:Chassis..........................................................................................7–1

GeneralInformation.....................................................................................7–2

ServiceandRepairs.....................................................................................7–3

Chapter8:CuttingDecks................................................................................8–1

GeneralInformation.....................................................................................8–2

ServiceandRepairs.....................................................................................8–3

Chapter9:OperatorCab................................................................................9–1

GeneralInformation.....................................................................................9–2

ServiceandRepairs.....................................................................................9–4

AppendixA......................................................................................................A–1

ElectricalDrawingDesignations....................................................................A–2

HydraulicSchematic....................................................................................A–3

ElectricalSchematic(machineserialnumbersbelow316000200)................A–4

Groundsmaster®5900&5910Page7Preface

16227SLRevB