Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

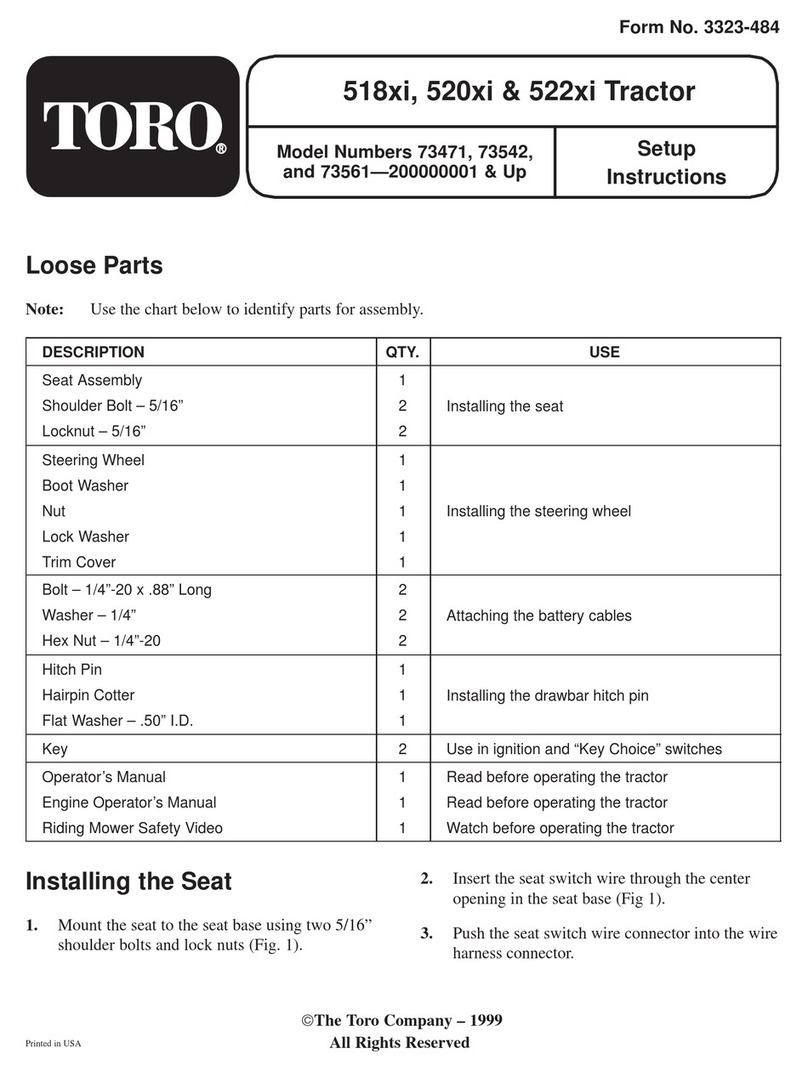

Setup........................................................................5

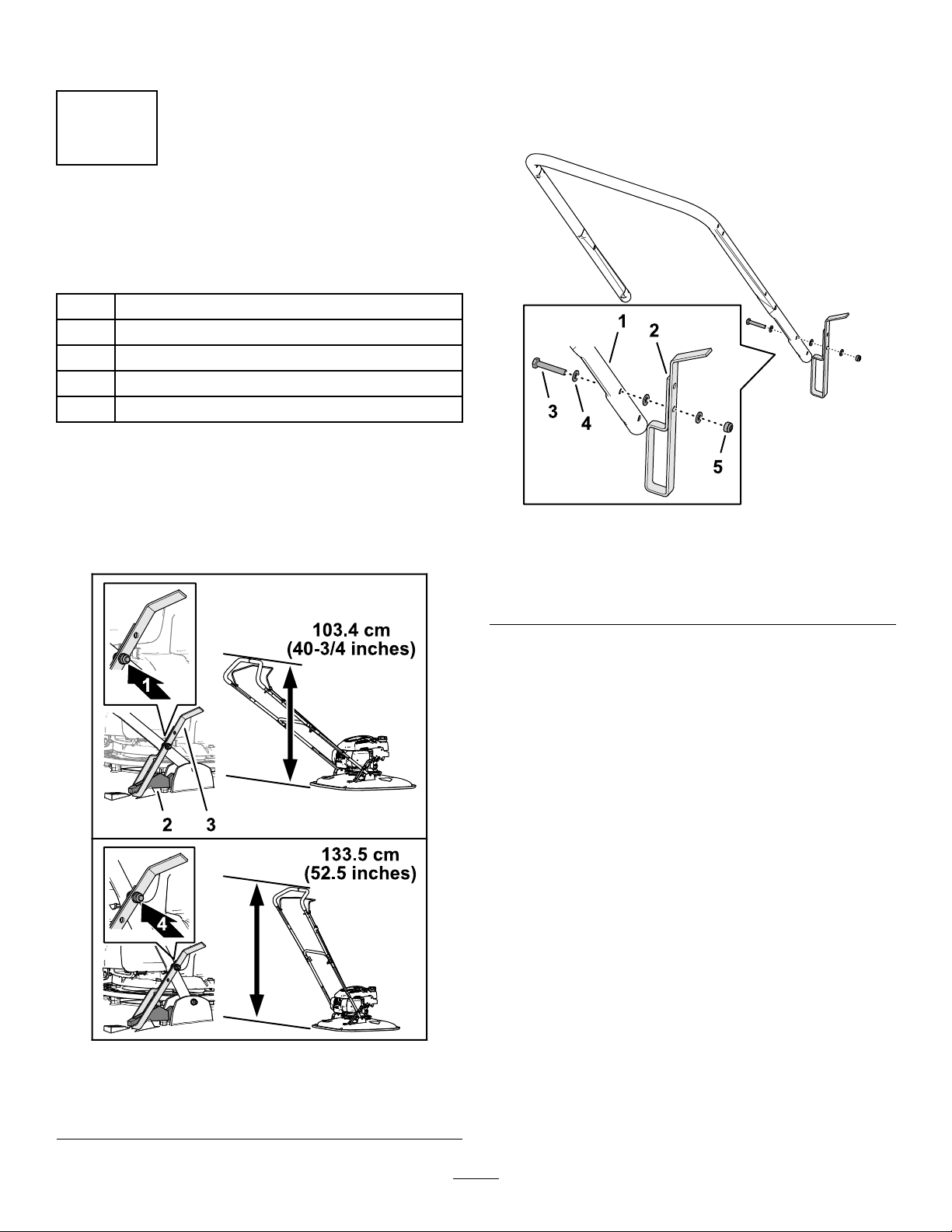

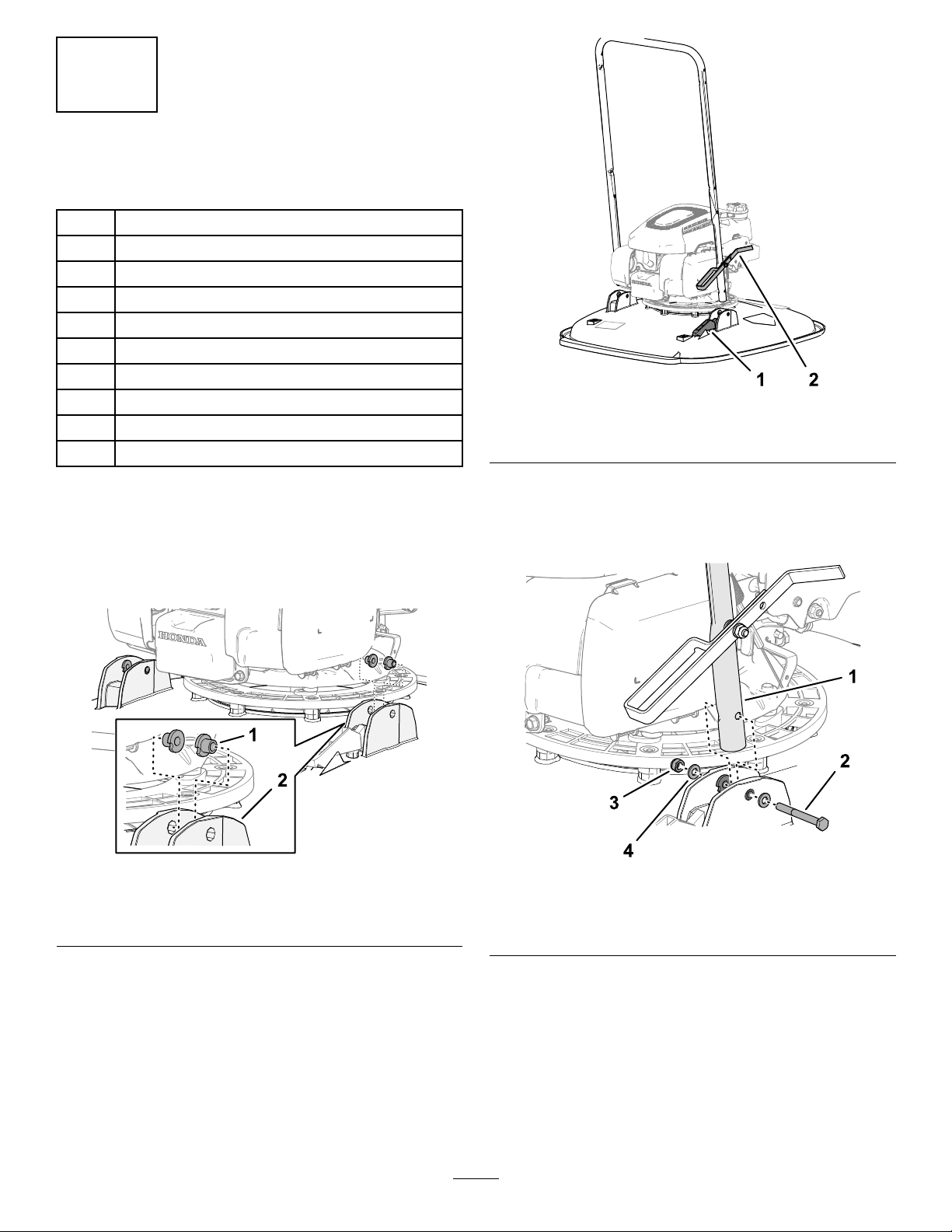

1InstallingtheHandlebarFootstop.....................5

2InstallingtheHandlebar...................................5

3AddingOiltotheEngine...................................8

ProductOverview.....................................................9

Controls...........................................................10

Specications..................................................10

Attachments/Accessories.................................10

BeforeOperation..................................................11

BeforeOperationSafety....................................11

FuelSpecication..............................................11

FillingtheFuelTank...........................................11

CheckingtheEngineOilLevel..........................12

DuringOperation.................................................12

DuringOperationSafety...................................12

FuelShutoffValve.............................................13

StartingtheEngine...........................................13

ShuttingOfftheEngine.....................................14

SupportingtheHandlebarwiththe

Footstop........................................................14

AdjustingtheCuttingHeight.............................14

OperatingTips.................................................16

AfterOperation....................................................16

AfterOperationSafety......................................16

Maintenance...........................................................18

RecommendedMaintenanceSchedule(s)...........18

MaintenanceSafety..........................................18

PreparingforMaintenance...............................18

ReplacingtheAirCleaner.................................19

EngineOilSpecication....................................20

CheckingtheEngine-OilLevel..........................20

ChangingtheEngineOil...................................20

ServicingtheSparkPlug...................................21

BladeMaintenance...........................................22

Storage...................................................................24

StorageSafety..................................................24

PreparingtheMachineforStorage...................24

Troubleshooting......................................................25

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395.

GeneralSafety

Important:Readtheseinstructionscarefully

beforeusingthemachine,andkeepthemfor

futurereference.

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.Localregulations

mayrestricttheageoftheoperator.

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3