potential,complywiththefollowingsafety

instructions.

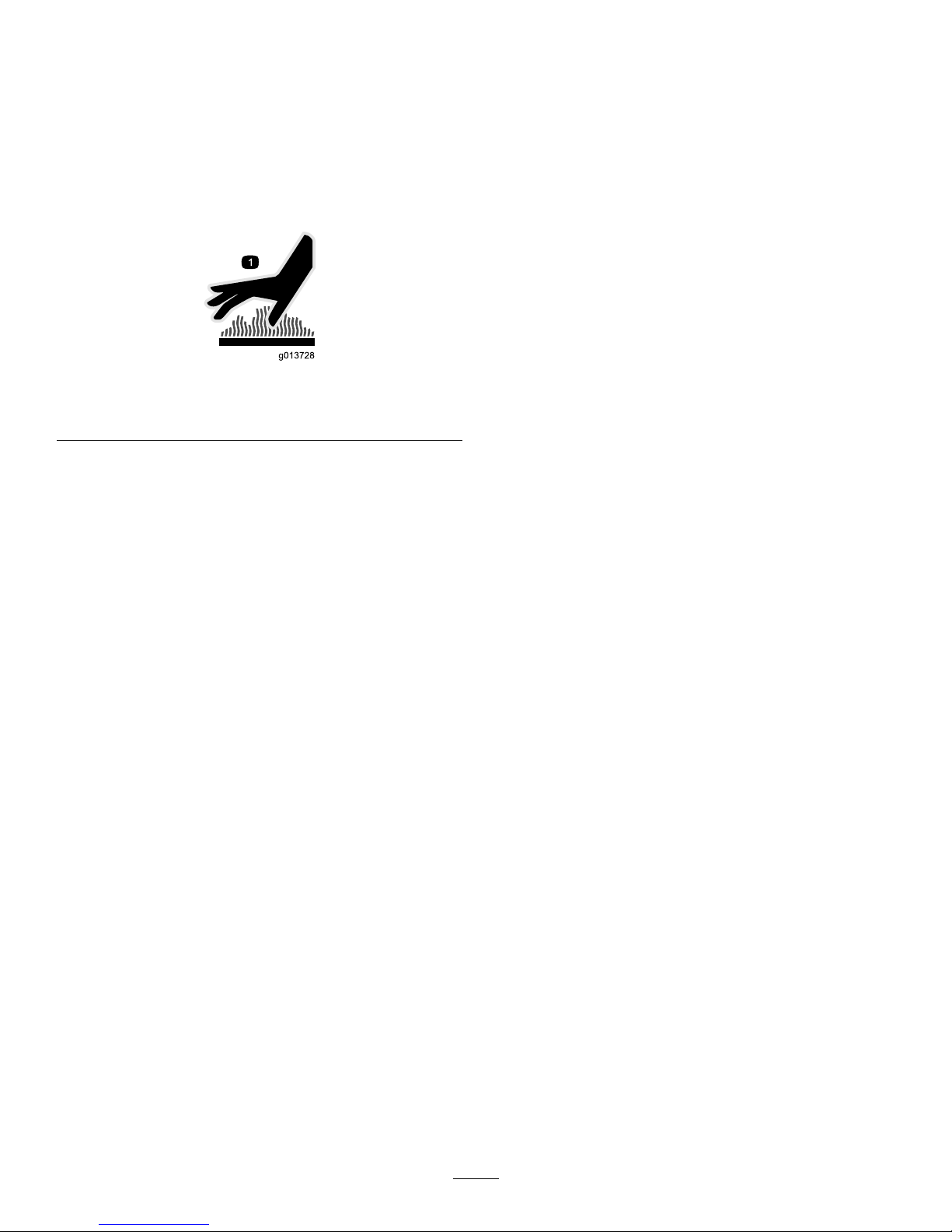

Thismachineiscapableofamputatinghandsand

feetandofthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injury.

Training

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren.

•Exercisecautiontoavoidslippingorfalling.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Avoidloosetting

clothingthatcangetcaughtinmovingparts.Wear

footwearthatwillimprovefootingonslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

llfueltankindoors.

–Neverllcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersontheground,awayfromyour

vehicle,beforelling.

–Whenpractical,removegas-poweredmachinery

fromthetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuelsuch

machineryonatrailerwithaportablecontainer,

ratherthanfromagasolinedispensernozzle.

–Keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimes,

untilrefuelingiscomplete.Donotuseanozzle

lock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilled

fuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspecied

bythemanufacturerforallmachineswithelectric

startingmotors.

•Donotattempttoclearsnowfromagravelor

crushedrocksurface.Thismachineisintendedfor

useonlyonpavedsurfaces.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwhenspecically

recommendedbymanufacturer).

•Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repairtoprotecteyesfromforeignobjectsthatmay

bethrownfromthemachine.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removetheignitionkey,thoroughlyinspectthe

machineforanydamage,andrepairthedamage

beforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtherotorbladehousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairing,orinspectingthemachine,

stoptheengineandmakecertainthattherotor

bladesandallmovingpartshavestopped.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards

andothersafetyprotectivedevicesinplaceand

working.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildren

andothersaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

2