ThissparkignitionsystemcomplieswithCanadianICES-002.

Contents

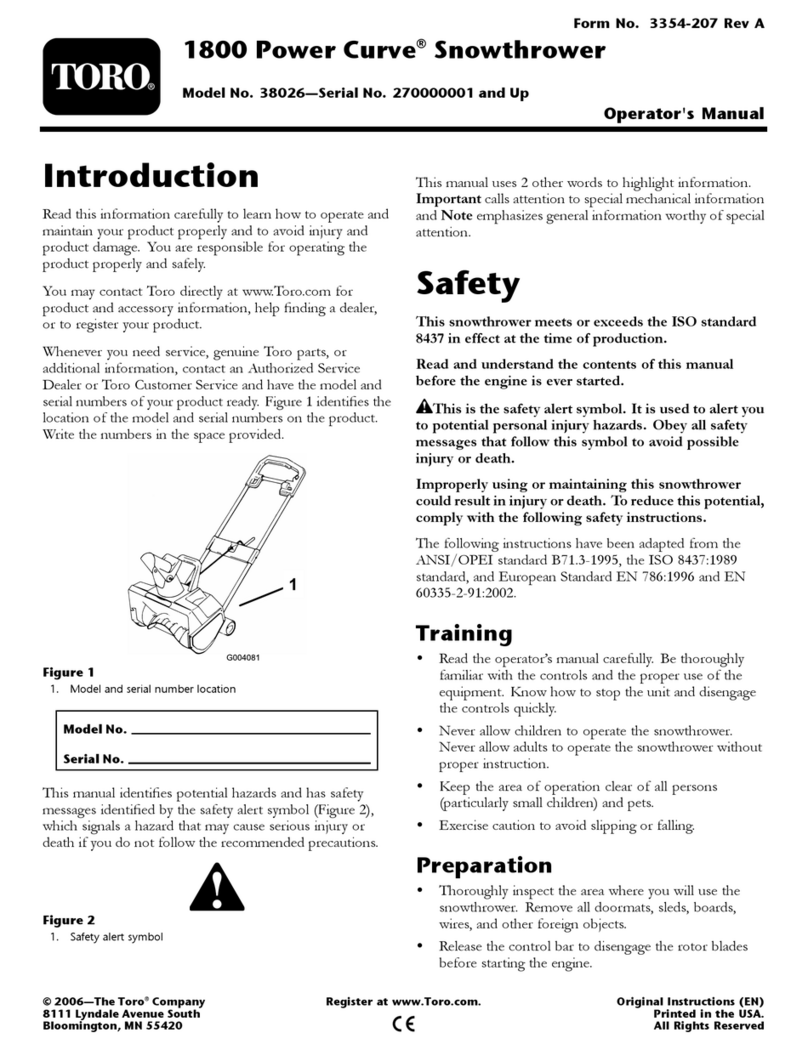

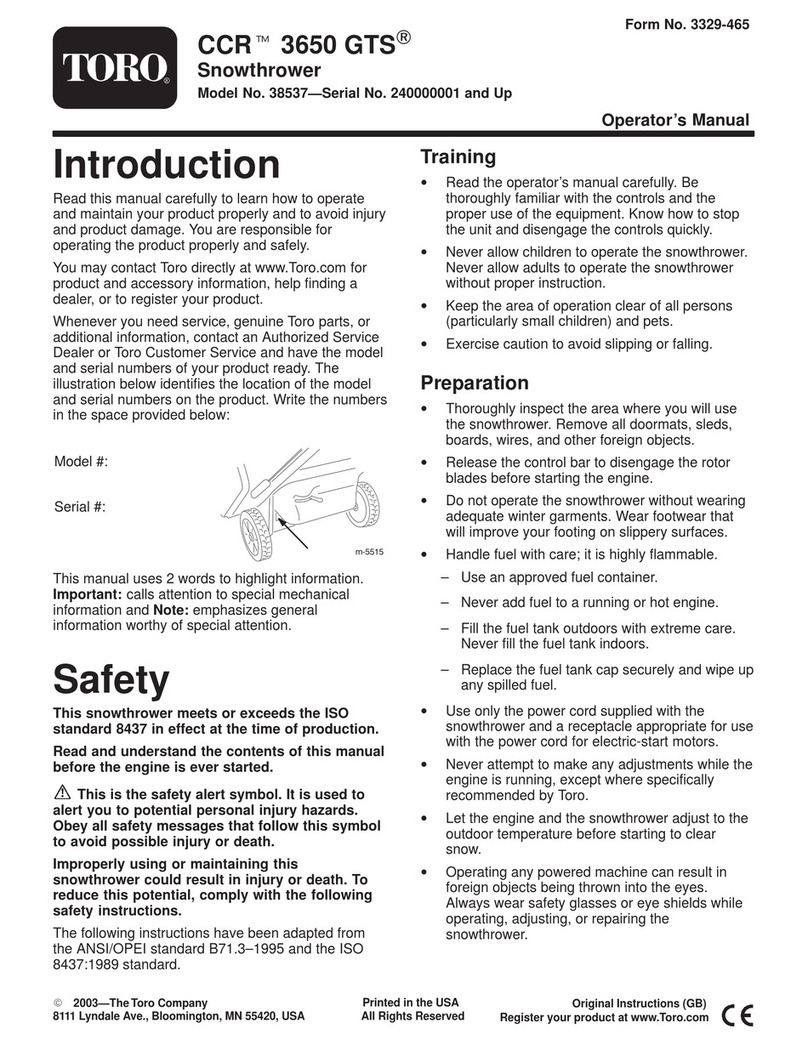

Introduction..................................................................1

Safety...........................................................................2

SoundPressure.......................................................2

SoundPower..........................................................2

Vibration................................................................2

SafetyandInstructionalDecals.................................3

Setup............................................................................5

1InstallingtheUpperHandle....................................6

2InstallingtheWheelClutchCableEnds....................6

3InstallingtheTractionControlLinkage....................7

4InstallingtheChuteControlRod.............................8

5ConnectingtheHeadlightandHandWarmer

WiretotheEngine...............................................9

6FillingtheEnginewithOil......................................9

7CheckingtheTirePressure....................................10

8CheckingtheSkidsandScraper..............................10

9CheckingtheTractionDriveOperation...................10

ProductOverview.........................................................11

Operation....................................................................12

BeforeOperation......................................................12

Safety....................................................................12

FillingtheFuelTank...............................................12

DuringOperation.....................................................12

Safety....................................................................12

StartingtheEngine.................................................13

StoppingtheEngine...............................................15

OperatingtheHandWarmers..................................16

OperatingtheTractionDrive...................................16

UsingtheWheelClutchLevers.................................16

OperatingtheSpeedSelector...................................17

OperatingtheAuger/ImpellerDrive.........................17

OperatingtheQuickStick®.....................................17

UncloggingtheDischargeChute..............................18

OperatingTips......................................................18

AfterOperation........................................................19

Safety....................................................................19

PreventingFreeze-up..............................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

MaintenanceSafety.................................................20

PreparingforMaintenance.......................................20

CheckingtheEngineOilLevel.................................21

CheckingandAdjustingtheSkids.............................21

CheckingandAdjustingtheTractionCable................21

CheckingtheAugerGearboxOilLevel......................22

ChangingtheEngineOil.........................................23

ReplacingtheSparkPlug.........................................23

AdjustingtheDischargeChuteLatch........................24

ReplacingtheDriveBelts.........................................25

ReplacingtheHeadlightBulb...................................25

Storage........................................................................26

PreparingtheMachineforStorage............................26

RemovingtheMachinefromStorage.........................26

Troubleshooting...........................................................27

Safety

ThismachinemeetsorexceedstheISO8437

specicationsoftheInternationalStandards

Organizationineffectatthetimeofproduction.

•Shutthemachineoffbeforeunclogging,servicing,or

fueling.

•Readandunderstandthecontentsofthemanualbefore

youstarttheengine.Makesureeveryoneusingthis

productknowshowtousetheproductandunderstands

thewarnings.

•Donotputhandsorfeetnearmovingcomponentson

themachine.

•Donotoperatemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingareaandunderthe

watchfulcareofaresponsibleadultotherthanthe

operator.Neverallowchildrentooperatethemachine.

SoundPressure

Thismachinehasasoundpressurelevelattheoperator’sear

of89dBAwhichincludesanUncertaintyValue(K)of1

dBA..Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO11201.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof105

dBAwhichincludesanUncertaintyValue(K)of3.75dBA..

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

CAUTION

Long-termexposuretonoisewhileoperatingthe

machinemaycausesomehearingloss.

Wearadequatehearingprotectionwheneveryou

operatethemachineforanextendedperiodoftime.

Vibration

Measuredvibrationlevelforthelefthand=4.7m/s2.

Measuredvibrationlevelfortherighthand=5.6m/s2.

UncertaintyValue(K)=2.2m/s2.

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

2