TORREY PINES SCIENTIFIC EchoTherm IN35-12VDC User manual

OPERATING MANUAL

EchoTherm™

PROGRAMMABLE DIGITAL CHILLING INCUBATOR

MODELS IN35 AND IN45-12VDC

DOCUMENT NUMBER IN35-03

Revised 15 February 2012

TORREY PINES SCIENTIFIC, INC.

2713 Loker Ave. West

Carlsbad, CA 92010

Telephone: (760)-930-9400

Fax: (760)-930-9480

Web Site: www.torreypinesscientific.com

TABLE OF CONTENTS

GENERAL PAGE

I. INTRODUCTION 3

II.WARRANTY 3

III. RETURN OF ITEMS 3

IV.CAUTIONS 3,4

V.SETUP 4,5

VI. GENERAL DESCRIPTION 5

OPERATION

VII. FRONT AND REAR PANEL 6, 7

VIII. SIMPLE OPERATION 8

IX. SIMPLE TEMP, TIMER, RAMP, AND

AUTO-OFF SETTINGS 8, 9, 10

X. PROGRAMMABLE OPERATION 10, 11

XI. CALIBRATION & POWER FAILURE PROTECTION 11, 12

XII. RS232 13

2

I. INTRODUCTION

Congratulations on your purchase of a Torrey Pines Scientific EchoTherm™ Model

IN35 or IN45 Programmable Digital Chilling Incubator. You will find it easy to use and

maintain. Please read these instructions carefully to insure that you receive the

maximum benefit from it. II. WARRANTY

Torrey Pines Scientific warrants this unit to be free from defects in material and

workmanship for a period of one year from the date of purchase. If repair or adjustment

is necessary within the one year period, and has not been the result of abuse or misuse,

please return the unit, freight prepaid, and correction will be made without charge. Out

of warranty products will be repaired on a charge basis. Be sure to fill in and return

the enclosed warranty registration card.

III. RETURN OF ITEMS

Authorization must be obtained before returning items for any reason. When

applying for authorization, please include data regarding the reason the items are to be

returned. For your protection, items must be carefully packed to prevent damage in

shipment and insured against possible damage or loss. Torrey Pines Scientific will not

be liable for damage resulting from careless or insufficient packing. A 15% restocking

charge will be made on all unauthorized returns.

NOTE: Torrey Pines Scientific reserves the right to make improvements in design,

construction and appearance without notice

IV. CAUTIONS

HEATED SURFACES

The Models IN35 and IN45 Chilling Incubators have a temperature range from 4.0ºC

(39.2ºF) to 70.0ºC (158.0ºF). At 70.0ºC the wire racks and other metal surfaces inside

the chamber are hot enough to cause burns if touched. Please use care when placing

samples into or removing samples from a heated chamber.

ELECTRICAL

The IN35 and IN45 Chilling Incubators are made in models that operate from a

universal, bench top power supply that takes AC inputs from 100VAC to 260VAC,

50/60Hz and converts that to 12 volts DC for the unit. This makes the instrument

intrinsically safe since it uses only low voltage DC to operate. Even so take the normal

care and precautions one would use with any electrical appliance.

3

ENVIRONMENTAL OPERATING CONDITIONS

The IN35 and IN45 are intended for indoor use. Ambient temperatures for the lab

should not exceed the range of 15ºC to 22ºC for proper performance of the instrument.

Temperatures from 5ºC to 40ºC will not affect the structure of the unit. Maximum

relative humidity of 80% for temperatures up to 31ºC decreasing to 50% for relative

humidity at 40ºC should not be exceeded.

This product is suitable for installation category II, pollution degree II.

CONDENSATION

Condensation can occur in the sample chamber when working at very low temperatures

for long periods in a humid environment. Precautions should be taken to assure that

your samples are not affected. Something as simple as placing a paper towel on the

bottom of the chamber can help. If condensation needs to be completely eliminated, a

good amount of desiccant may be needed. If condensation occurs, it will run toward the

front of the chamber where it can easily be cleared.

GENERAL

The IN35 and IN45 are designed for laboratory use and for use only as instructed in this

manual. If the instrument is used in a manner not specified by the manufacturer, the

protection provided in the design of the equipment may be impaired.

V. SET UP INSTRUCTIONS

The IN35 and IN45 Programmable Digital Chilling Incubators are extremely simple to

use, set and forget units. The digital, microprocessor design and PID temperature

control will assure that the correct temperature as set is attained and held.

SET UP

1. Unpack the unit carefully. Be sure to save the packing material in case the unit

needs to be returned to the factory for service.

2. The IN35 weighs 45 pounds (20.4 kg), and the IN45 is 56 pounds (25.2 kg).

Both are bulky, and have no handles. It is best to have two people remove the

unit from its box and place it on the lab bench. Always cradle the unit from the

underside.

3. Plug the power supply cable into the jack on the rear of the unit. Plug line cord

into a properly grounded three-wire outlet of proper voltage.

4

4. Position the unit on a bench where it has at least 6" (15.24 cm) clearance from

the back of the unit to the wall, bench or other obstruction. The cooling fan on

the rear of the unit needs to draw air clearly to cool the Peltier unit. Also, there

must be about 3" (7.62 cm) clearance on either side of the unit and 6” (15.24 cm)

on top of the unit to allow proper venting.

5. Place the wire racks provided into the slots selected.

6. Turn the unit on by the main On/Off switch on the rear panel. The LCD on the

front panel will illuminate and be in the temperature/timer display mode. The

fans on the rear panel and inside the instrument chamber will start to run. The

instrument is now ready to use.

VI. GENERAL DESCRIPTION

The Torrey Pines Scientific Chilling Incubators are digitally controlled and Peltier driven.

Because they are Peltier driven, they have no CFC’s or other refrigerating gases. Also,

being Peltier driven, the units have the ability to heat and cool and control exactly at

or near ambient room temperature. The units can hold temperatures accurately, and

reproduce temperatures exactly. The chamber is molded ABS plastic and the racks are

electro-polished steel.

Since the units are Peltier driven there is a fan in the chamber and one on the rear of

the units. The internal fan is used to keep the chamber at a uniform temperature

throughout. There is an inner chamber door of clear lexan to help hold the chamber

temperature while viewing the sample.

Temperature is sensed by a microchip inside the chamber. The settable temperature

range is from 4.0ºC to 70.0ºC. The unit has a membrane keypad with tactile touch and

audible feedback for setting temperature, temperature ramp, timer, auto-off, and three

programs of ten steps each.

The timer is in days, hours, minutes and seconds. The timer can be set to 99:59:59:59

days, hours, minutes, and seconds maximum. When the timer counts to zero it will

sound the audible alarm for one minute and the timer will start to count up. The unit can

be set to turn off the heater/chiller at the end of a timed event by using the AUTO-OFF

function.

The IN35 and IN45 are supplied with an RS232 port for recording temperature data at

one data point per second. More information is available on this in a later chapter.

5

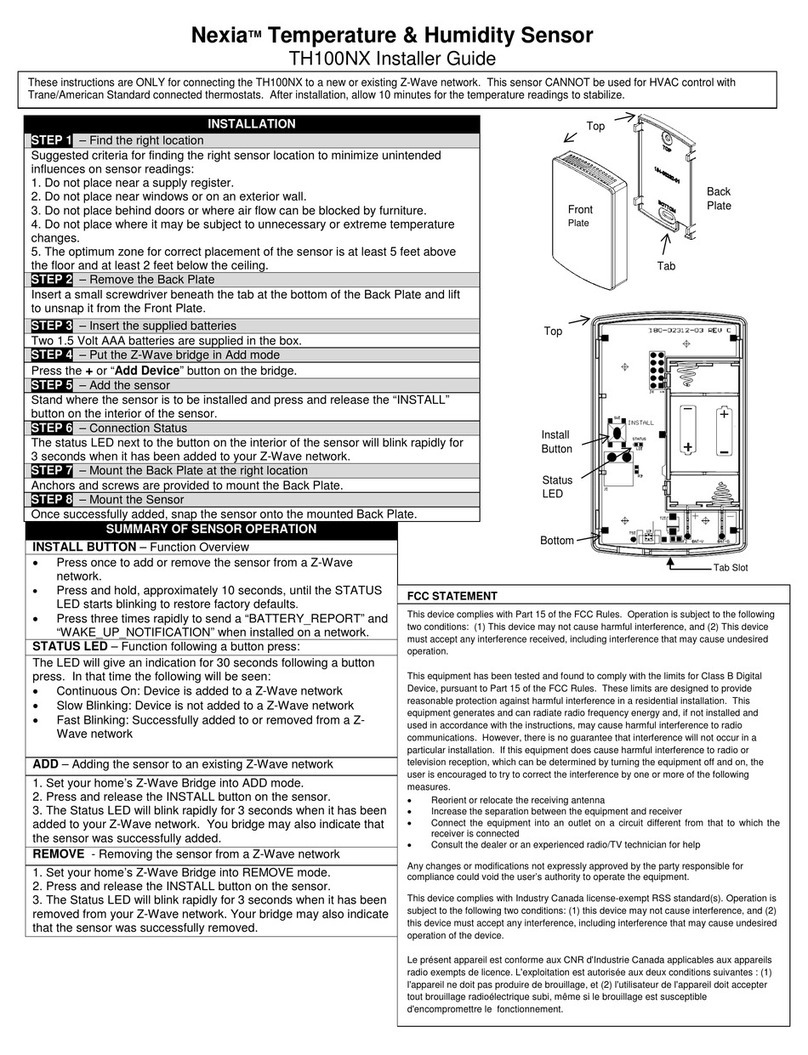

VII. FRONT AND REAR PANEL

FRONT PANEL

__________________________

37.0 36.9 25.0

00:00:00:00

__________________________

37.0 25.0

1-1 00:00:00:00

The front panel of the IN35 and IN45 Programmable Chilling Incubators has a digital

display and keyboard for monitoring and controlling all functions. When the power is

turned on, the display will show the actual chamber temperature in the center of the top

line of the display and the timer with all zeros across the bottom line.

The display is a two line, 16-digit, alphanumeric, back-lighted LCD. When a target

temperature has been set, the display will show the target temperature to the left of the

actual chamber temperature. When a temperature ramp has been set that value will

appear to the right of the actual chamber temperature.

NOTE: The front door of the unit can be completely removed if wanted. Just

open the door wide and lift it straight up. It is a handy feature for

cleaning or other uses.

6

REAR PANEL

The rear panel of the IN35 and IN45 has a connector jack for the power supply and the

main On/Off switch. In addition, the rear panel has an I/O port for the RS232 and a

reorder label. The I/O port will be discussed later in the chapter on the RS232. The

label tells the model number, serial number, operating voltage of the unit, power

consumption and the address information for Torrey Pines Scientific.

The I/O port will, when used with the proper connector, allows the user to collect

chamber temperature data using a computer.

7.

VIII. SIMPLE OPERATION

The IN35 and IN45 are fully programmable heating/chilling incubators. With them the

user has the ability to write and store in memory three programs of as many as ten

steps each for instant recall and use later. Also, each incubator can be used to set a

single temperature, temperature ramp, and timed function without going into the

memory of the unit. The memory should be used to store complex routines where the

temperature can be changed automatically to other temperatures, at given rates of

change if wanted, and held at those temperatures for specific times.

IX. SIMPLE TEMPERATURE, TEMPERATURE RAMP, TIMER, AND AUTO-OFF

SETTINGS

All of these functions are easily set from the keyboard. Please note that the keyboard

has both tactile and audible feedback.

SETTING TEMPERATURE

1. Depress and release the TEMP key. The display will show three zeros to the left

of the actual chamber temperature. The digit on the right of the three will be

flashing.

2. Use the LEFT ARROW in the center of the membrane switch to move the

settable digit to the left. Now use the UP ARROW or DOWN ARROW to scroll to

the temperature setting wanted for that digit. Use the RIGHT ARROW to move

to the next digit to the right. Use the UP ARROW or DOWN ARROW to set that

digit. Use the RIGHT ARROW to move to the right to set the final digit if wanted.

3 Depress ENTER. The target temperature is now set. The actual chamber

temperature as displayed in the center of the top row of the display will now start

to change and go toward the target.

4 To remove the temperature target hit TEMP, ERASE. The target temperature is

now gone and the unit will stop heating or chilling as previously instructed.

Note: If you wish to cancel an instruction made before entering the value,

hit CANCEL. To achieve the minimum temperature of 4ºC the ambient

temperature of your laboratory should not be over 24ºC. The unit has a

below ambient temperature range from ambient room temperature. This

range is about 18ºC to 20ºC and is load dependent. It may take longer to

reach very low temperatures when the chamber is fully loaded.

The unit has a power failure backup circuit. When power fails and then

returns, the unit will continue to run at the temperature it was running when

power failed.

8

When power returns, the temperature displayed will flash to let the user know that

a power interruption has occurred. To stop the temperature display from

flashing, touch CANCEL.

SETTING A TEMPERATURE RAMP

Temperature ramping is increasing or decreasing temperature at a given rate... a

change of temperature over a specified time. The setting is always in degrees C/Hr.

When a ramp is set, the setting will be displayed to the right of the chamber

temperature.

Note: Always set the temperature ramp before the target temperature is set. And

remember, the ramp rate can only be set to go as fast as the unit can drive the

sample if no ramp rate were used. Generally speaking, the unit will go from

temperature “A” to temperature “B” faster without a ramp rate being set.

The maximum ramp rate settable is 99.9ºC/Hr.

1 Depress RAMP. Note that the digits to the right of the actual chamber

temperature will illuminate with the far right digit flashing.

2 Use the UP or DOWN ARROW to set the flashing digit. To move to the other

digits to be set use the LEFT or RIGHT ARROW.

3 When the value is set press ENTER. The ramp rate is now set.

SETTING TIMER

The timer is a count down timer that can be set to a maximum of 99 days, 59 hours, 59

minutes, and 59 seconds. It can be set to be used with an auto-off function that will turn

the heater or chiller off at the end of the count down period. The auto-off function is

separate from the timer. The timer can be used without auto-off.

1. Depress the TIME key. The timer display, which is across the whole of the lower

line of the display, will start to flash the digit to the far right, the 1 second digit.

2. To move to the left and set days, hours, or minutes, press the LEFT ARROW to

the desired digit. Press the UP ARROW or DOWN ARROW until the value

sought is reached. Scroll left or right using the RIGHT ARROW and LEFT

ARROW to get to the other digits, and set them using the UP ARROW or DOWN

ARROW until the timer value sought is reached.

3 Press ENTER and the display will show AUTO-OFF, ENTER/CANCEL? Hitting

ENTER will start the timer with the auto-off function set to turn the heater/chiller

off at the end of the count down. Hitting CANCEL will cancel the auto-off function

making the timer count down without an instruction to turn off the heater/chiller.

9

NOTE: The timer will count down to zero. At zero, the audible alarm will sound

once a second for one minute. Also, as the timer starts to sound, the display for

the timer will start to count up letting the user know how much time has passed

since the timed even ended. The audible alarm can be turned off any time during

the first minute by pressing CANCEL.

X. PROGRAMMABLE OPERATION

The IN35 and IN45 have the ability to store three programs in memory for instant recall

and use at any time. Each program has ten steps maximum where one step is a

temperature, time and ramp function (if wanted). At the end of each program there is a

cycle step that can be selected which will repeat the program up to 99 times. These

programs are stored in CMOS and cannot be lost by a power failure or by turning off the

unit. However, if power fails during a program run, when it returns, the unit will have

lost its instructions and will be sitting with the same program step as when power failed.

Some rules for programming:

To erase all programs in memory, depress and hold the EDIT key for about 5

seconds. The display will show ERASE PROGRAMS, ENTER/CANCEL. Hitting

ENTER will erase the programs and the display will show PLEASE WAIT... The

programs will then be erased. This erases ALL programs in memory. Hitting

CANCEL will cancel the instruction. To change or erase one program the user

must go into the program and remove each instruction.

The timer can be used in two ways in a program. The timer can be used with a

ramp function or without a ramp function. When the timer is used with a ramp

function, the timer does not start to count down until the target temperature is

reached. When the timer is used without a ramp function, the timer starts to

count down as soon as the program starts. If the user wants a timed event to

start after the target temperature is reached, but does not want to wait for a

ramped approach to the target temperature to take place, set the ramp at 99.9. In

almost all cases, this ramp rate is faster than the unit can approach the target

temperature without a RAMP, and it will appear as though no ramp rate is being

used. The timer will start to count down after the target temperature is reached.

RUNNING A PROGRAM STORED IN MEMORY

1 Press RUN. The display will show PROGRAM 1.

2 If program 1 is to be run press ENTER. If program 1 is not the choice, use the

UP ARROW to scroll to program 2 or 3. When the program is chosen, press

ENTER and the program stored in that site will start to run.

10

HOW TO WRITE A PROGRAM

1 Press EDIT

2 Select the program site (1,2 or 3) using the UP or DOWN ARROW.

3 Hit ENTER. The display will show the program number, the program step and

then the timer value. 1-1 00:00:00:00 Now temperature, timer and ramp

function can be set.

4 Enter the ramp value first (if a ramp function is to be used) and touch ENTER,

then a temperature value and ENTER, and then a timer value and ENTER. The

display will show all values as set. Program step 1 is now set.

5 Press the UP ARROW to go to step 2. The display will show 1-2 00:00:00:00.

This shows that program 1 step 2 is available to be set. Repeat the steps above

to set the values for ramp, temperature and time.

6 Proceed through the steps until the program is written.

Note: If a mistake is made while entering a program step, just hit CANCEL

on that step and make the new entry. To go back to a prior program step,

hit the DOWN ARROW. Likewise, to go forward to another step in a

program, hit the UP ARROW.

7 After the last program step data has been entered, press ENTER. The display

will now show CYCLE 01. This gives the user the choice of having the program

just entered cycle one or more times up to 99 times maximum. If 01 is entered,

the program will run once. If 02 is entered, the program will repeat. 03 will cause

the program to run 3 times, etc.

8 After the CYCLE has been selected, press ENTER and the program is finished

and stored in memory.

XI. CALIBRATION

NOTE: The unit stores the calibration in memory even through power failures. The

temperature calibration is set at the factory and should be accurate enough for most

applications. However, the user may wish to calibrate the unit to his own standard.

This can be done in the field following the instructions below. The calibration may be

done at a single point or at two separate temperatures for straight line interpolation.

CALIBRATION

The unit is sent to the user with two point calibration for accuracy at every temperature.

If single point calibration is used be sure to clear the memory first. Follow the

instructions below for both single point and two point calibration

11

Clearing Calibration

Before setting calibration, always clear the existing calibration. To clear calibration:

1. Hold the TEMP key for 5 seconds until the display says CALIBRATE? on the top

line and ENTER/CANCEL on the bottom line of the display.

2. Depress ENTER

3. Then depress ERASE. The display will now say ERASE CAL? On the top line

and ENTER/CANCEL on the bottom line of the display.

4. Depress ENTER

The existing calibration is now erased.

Single Point Calibration

1- Set the unit to the target temperature to be calibrated. Measure the chamber

temperature using your laboratory standard. Be sure to allow the chamber and

your thermometer time to equilibrate at the target temperature you desire.

2- Push and hold the TEMP key for five seconds until the display says

CALIBRATE? on the top line of the display and ENTER/CANCEL on the bottom

line.

3- Depress ENTER.

4- Enter the value onto the display as read from your temperature standard and

depress ENTER.

Single point calibration is now complete and will be held in memory until changed.

Two Point Calibration

For two point calibration, one calibration temperature must be above 37.0 ºC and the

other must be below 37.0º C. For best results, use temperatures around 10.0 ºC and

60.0º C. Follow the calibration procedure as for a single point. Then repeat the

procedure at the second point. When you calibrate the second point, the calibration of

the first point is not affected. However, all other temperatures will adjust to a “straight

line” through the two calibration points.

NOTE: Measuring the chamber temperature is easy to do, but not necessarily

accurately. Generally speaking, glass thermometers found around a lab are not

accurate enough or readable enough to do a good job. Good, certified glass

thermometers are available from lab supply dealers as are fairly accurate digital

thermometers.

12

XII. RS232

The IN35 and IN45 Chilling Incubators have been designed with an RS232 interface.

The port is on the rear of the unit and is a standard D subminiature connector. This

interface is output only for recording temperature data. These units cannot be

controlled via this port. If the application requires that an external computer be used to

control an incubator, the IN30 and IN40 have the RS232 interface capable of doing this.

The instructions for connection and use follow.

RS232 INTERFACE SPECIFICATION

Parameters: 2400 baud, 8 data bits, 1 stop bit, no parity. No handshake hardware or

software is necessary. It will work well on a Windows terminal program per these

settings.

The chamber temperature is sent once a second in ASCII digits with a terminating

carriage return.

Pins in use on the RS232 jack are: Pin 1 (upper right pin when looking at the jack) is

ground. Pin 3 (third pin from the right on the upper row) is RX. Pin 4 (fourth in from the

right on the upper row) is TX.

13.

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

S+S Regeltechnik

S+S Regeltechnik AERASGARD KLQ Operating Instructions, Mounting & Installation

Ekinex

Ekinex EK-DF2-TP Applications manual

Zephyr

Zephyr PRB24C01AS-ADA Use, care and installation guide

Pranarom

Pranarom 38526UL-107 user manual

Daikin

Daikin KRCS01-7B installation manual

USA Measurements

USA Measurements US-731S operating manual