GRT100

7

The following items are displayed on the LCD.

- Setting

- Metering

- Event records

- Fault records

- The number of disturbance records

- Any failure message detected by the automatic monitoring

Password protection can be provided from the setting

menu on the LCD to provide security for relay setting

changes. After the password has been set, the password

must be entered to access the setting menu from a

local or remote PC as well as on the LCD.

Details of metering, fault records, and relay failures can

be monitored by pressing the VIEW key. The VIEW

key can be pressed without removing the relay front

cover.

Arbitrary signals can be assigned to the four user

configurable LEDs.

Two monitoring jacks are operable when the test

mode is selected in the LCD window. An oscilloscope

can be connected to the relay through these jacks.

Selection of output signals to the monitoring jacks can

be set from the LCD menu.

Local PC

The user can communicate with the GRT100 from a

local PC via the RS232C port on the relay fascia. The

following data can be viewed or analysed on the local

PC with RSM100 software.

- Setting

- Metering

- Event records

- Fault records

- Disturbance records

Relay Setting and Monitoring (RSM)

GRT100 can be connected to the RSM system via

the RS485 interface at the rear of the relay. The user

can operate the relay from a remote PC in the same

way as from a local PC.

A maximum of 32 x 8 relays can be connected to the

remote PC in multi-drop mode, via the protocol

converter G1PR2. The G1PR2 can be provided with

maximum 8 ports and each port supports maximum

32 relays addressing.

The RSM100 software is also used to communicate

with the relay and to view or analyse disturbance

records on the remote PC.

The data transmission rate between relays and the

protocol converter is 64kbps.

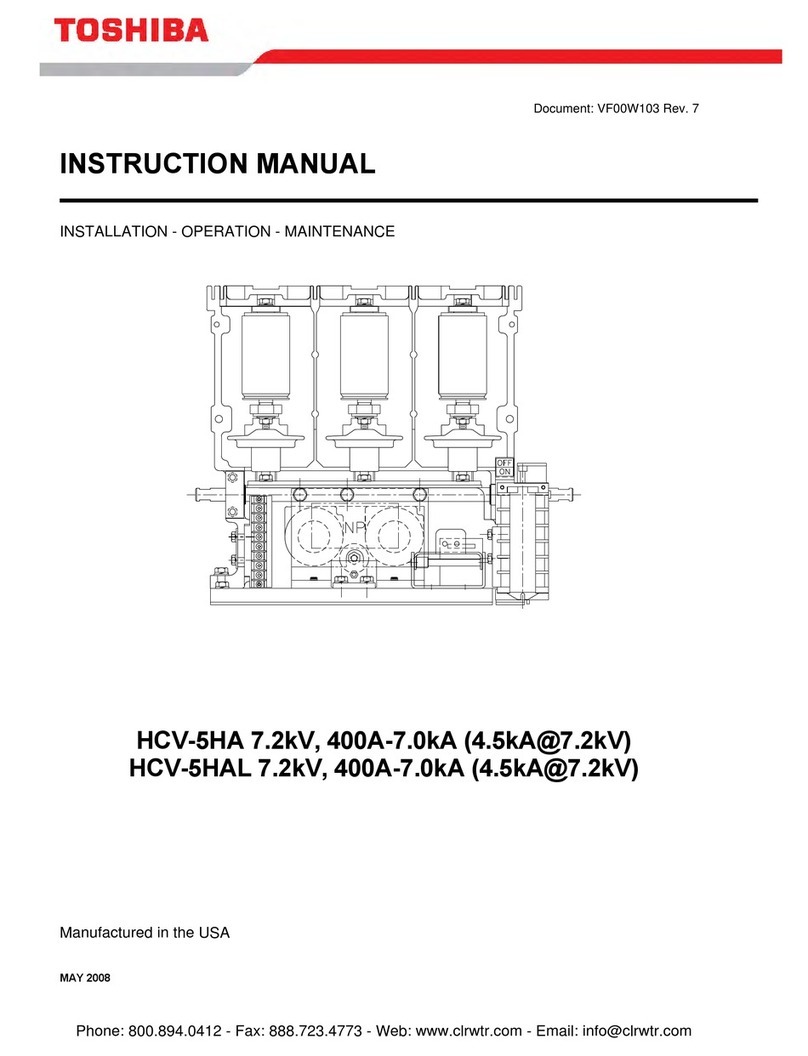

Figure 9 shows the configuration of the RSM system.

Fig. 9 Relay setting and monitoring system

IEC60870-5-103 Communications

GRT100 supports the IEC60870-5-103

communication protocol. This protocol is used for

communication with a substation control and

monitoring system and is used to transfer measurand

data, status data and general commands between

the relay and the control system.

Relay Setting

The user can input or change settings using the

operation keys on the relay fascia or via a local or

remote PC with the RSM system.Password protection

is provided to change settings.

Eight active setting groups are provided. This allows

the user to set one group for normal operating

conditions while other groups may be set to cover

alternative operating conditions.

Configurable Binary Output Contacts

GRT100 provides 13 or 23 user configurable normally

open output contacts used for indication and alarm.

The number of outputs varies according to the relay

model.

Binary Inputs

GRT100 is provided with 8 binary inputs for trip

and/or indication of external protection devices, etc.

The binary input circuits are provided with a logic

level inversion function.

PROTOCOL

CONVERTER

G1PR2

Protocol converter