t!1ay.31.2012 9:15Att1 No. 1510 P, 4

TABLE OF CONTENTS Page ii

SAFETY

RECEIVING,STORAGEANDHANDLING ,........,,4

Receiving and Unpacking .........4

Acc€pl6nca lnspection ,...4

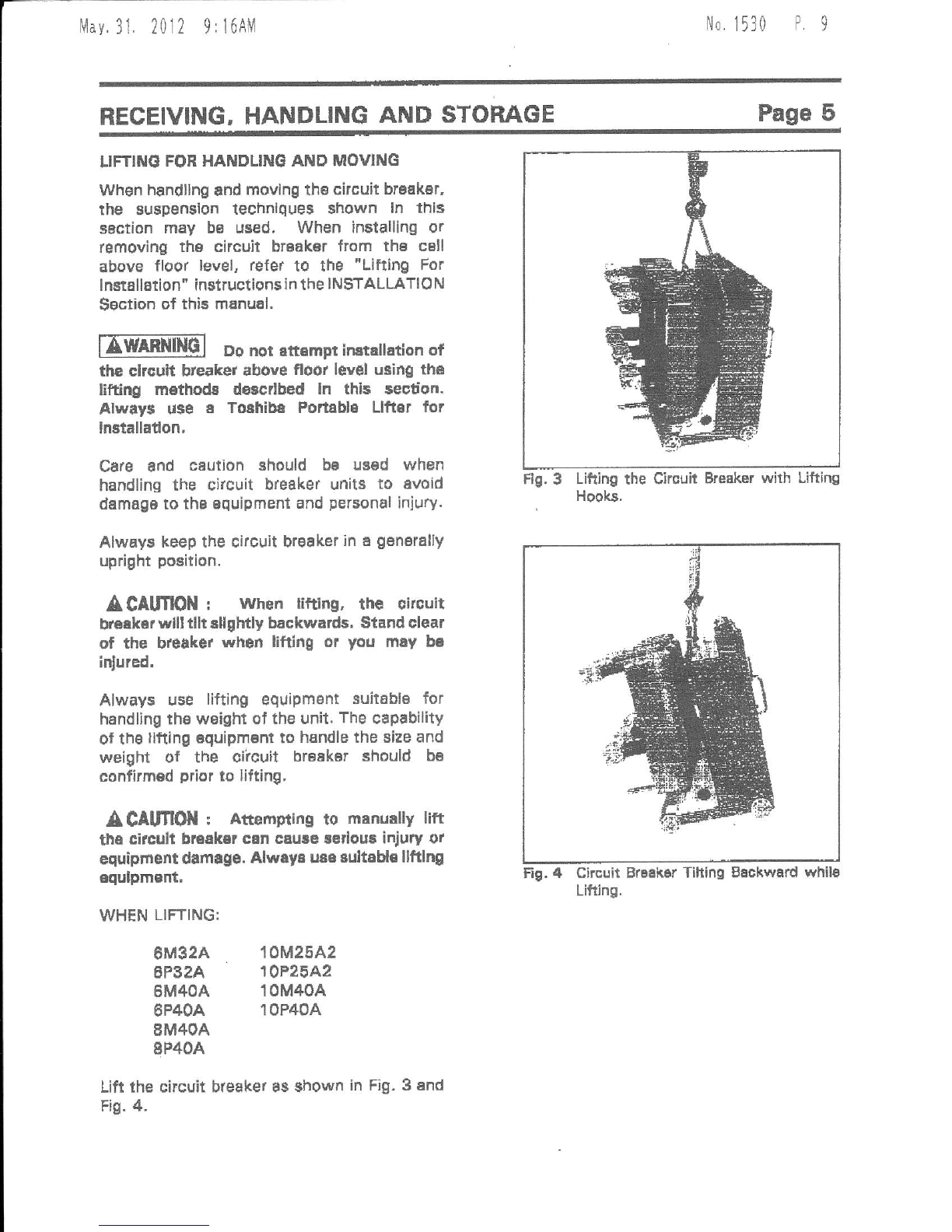

Lifting for Handling and Moving " " ' 5

Stotage, ..'.". t,

lnspection During Stolage ........- 6

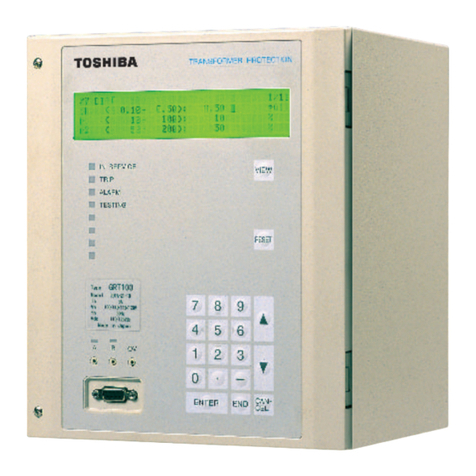

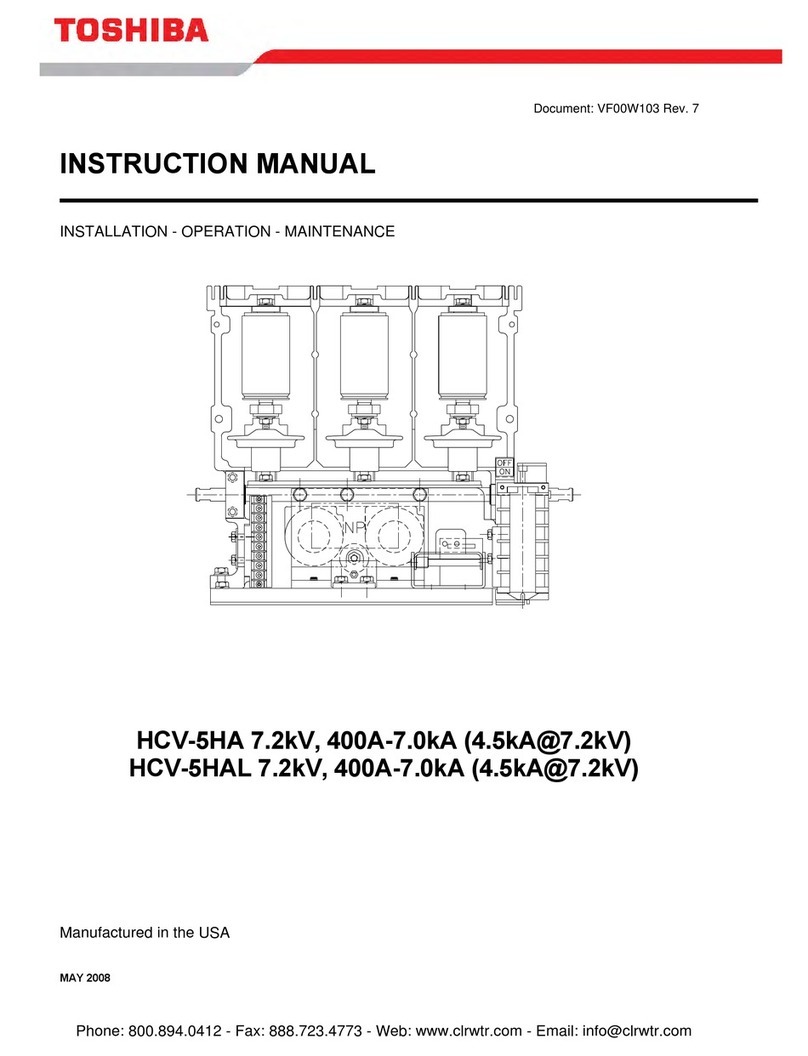

GENERALDESCRIPTION .,..,...7

gafety Deviceg ........' I

lnterlock Lever , , ........9

Sell Coupling Type Secondary (Csntrol Circuit) Disconngcts , . ' . . 10

INSTALLATION .,..., 11

Service Conditions .... ..'...... 11

Bating.. ...... 11

Lifting tor lnstellation ',.' 13

Using the Portable Lifter ...'.'.'. 13

Moving the Circuit Breaker in the Cell .-.....15

PRE-ENERGIZATION CHECK ..,, 18

General , .. ... . 18

Elactrical Checks . ...... t8

oPERATtoN ..,,".., 19

Manual Operation..... .'..'.". 19

Electrical Op€ration . ' ... 20

Controf Ckcult Oparation ..,. '., , ' ZO

Closing Sequence..... ..'.20

Charging Sequence '.......20

Tripping (Oponing) Saquanca ....."' 20

Mechanism Operation ....25

Closing . ,....... 25

Charging .......' 25

Tripping , ....... 25

Trip Frae .""...25

MAINTENANCE ...,,, 26

Maintenance Progtam .... 26

Maintgnanca R€cord , .," 26

Servioing Equipment ..... ?7

lnspaction and Maintenance Type3.. '..'.'.2e

lnspgction and Mainlenanc€ lnterv8ls '. ', ',. 30

Wipe Measutement ... ...... '.. 36

Vacuum Chack , ..-...' 37

Troubleshoothg Guidelines .,"".41

Replacement of Parts . ... 44

Auxiliary Switch, "'.'....45

Closing Coil and Trip Coil , .. .... ' ' ' 47

Control Citcuit Board . ..'..4S

Control Circuit Board Fuse '."' . . .. . 51

Feplacement Pans List ... 53

CoNVERS|ONS . ^.... 54

WARBANTYandLIMITATIONOFLIABILITY ..'..'' 57