Toshiba 32WL66Z User manual

Other Toshiba TV manuals

Toshiba

Toshiba 21CSZ7DR User manual

Toshiba

Toshiba 29CJZ6DR User manual

Toshiba

Toshiba 27A14 User manual

Toshiba

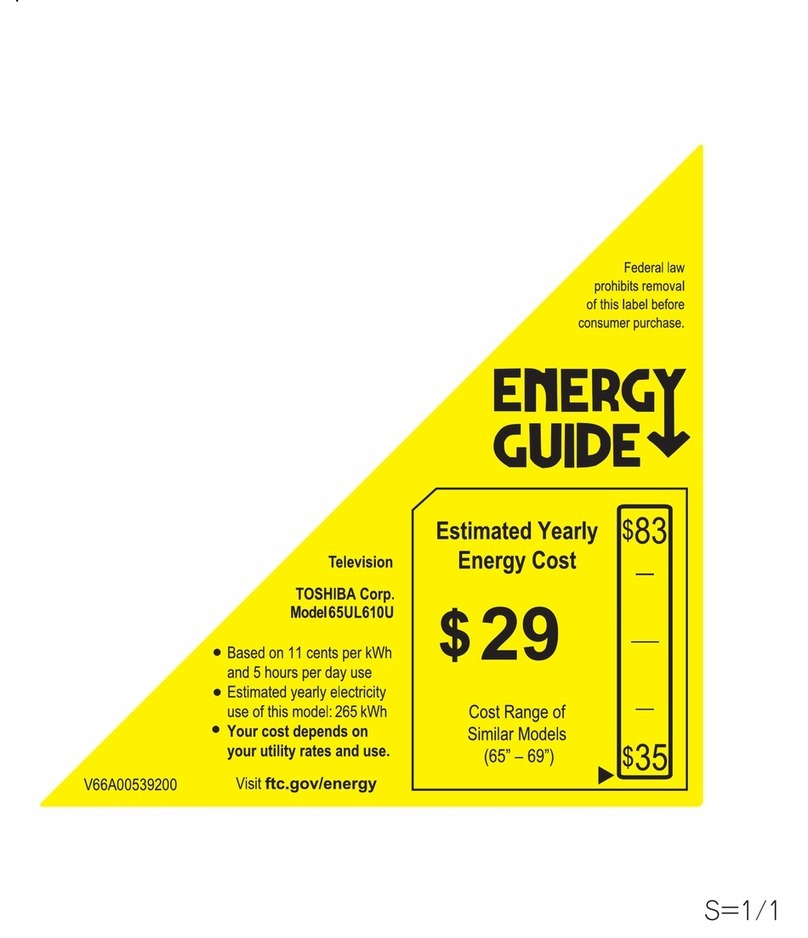

Toshiba 65UL610U Assembly instructions

Toshiba

Toshiba FSTPURE ColorStream 14AF42 User manual

Toshiba

Toshiba 65V6763DB User manual

Toshiba

Toshiba 20AF44 User manual

Toshiba

Toshiba CZ32V61 User manual

Toshiba

Toshiba 55UL5A63DG User manual

Toshiba

Toshiba 20A45C User manual

Toshiba

Toshiba CX35F60 User manual

Toshiba

Toshiba 48L1433DG User manual

Toshiba

Toshiba 29CZ8URB User manual

Toshiba

Toshiba 32AF45 User manual

Toshiba

Toshiba MD20FL3 User manual

Toshiba

Toshiba 55L3753DB User manual

Toshiba

Toshiba 24/32 WL2C Series User manual

Toshiba

Toshiba 43L3753DB User manual

Toshiba

Toshiba TheaterWide 23HL84 User manual

Toshiba

Toshiba CN32D90 User manual