–2–

EN

Thank you for purchasing this Toshiba Hot Water Module.

Please read carefully through these instructions that contain important information, and ensure that you understand

them.

After completing the installation work, hand over this Installation Manual and Owner’s Manual as well as the

Owner’s Manual provided with the outdoor unit to the user, and ask the user to keep them in a safe place for future

reference.

Generic Denomination: Hot Water Module

Definition of Qualified Installer or Qualified Service Person

The hot water module must be installed, maintained, repaired and removed by a qualified installer or qualified

service person. When any of these jobs is to be done, ask a qualified installer or qualified service person to do them

for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge described in

the table below.

Agent Qualifications and knowledge which the agent must have

Qualified installer

• The qualified installer is a person who installs, maintains, relocates and removes the air conditioners

(including the hot water modules) made by Toshiba Carrier Corporation. He or she has been trained

to install, maintain, relocate and remove the air conditioners (including the hot water modules) made

by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such operations by

an individual or individuals who have been trained and is thus thoroughly acquainted with the

knowledge related to these operations.

• The qualified installer who is allowed to do the electrical work involved in installation, relocation and

removal has the qualifications pertaining to this electrical work as stipulated by the local laws and

regulations, and he or she is a person who has been trained in matters relating to electrical work on

the air conditioners (including the hot water modules) made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in

installation, relocation and removal has the qualifications pertaining to this refrigerant handling and

piping work as stipulated by the local laws and regulations, and he or she is a person who has been

trained in matters relating to refrigerant handling and piping work on the air conditioners (including the

hot water modules) made by Toshiba Carrier Corporation or, alternatively, he or she has been

instructed in such matters by an individual or individuals who have been trained and is thus thoroughly

acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to working

at heights with the air conditioners (including the hot water modules) made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in such matters by an individual or

individuals who have been trained and is thus thoroughly acquainted with the knowledge related to

this work.

Qualified service

person

• The qualified service person is a person who installs, repairs, maintains, relocates and removes the

air conditioners (including the hot water modules) made by Toshiba Carrier Corporation. He or she

has been trained to install, repair, maintain, relocate and remove the air conditioners (including the hot

water modules) made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed

in such operations by an individual or individuals who have been trained and is thus thoroughly

acquainted with the knowledge related to these operations.

• The qualified service person who is allowed to do the electrical work involved in installation, repair,

relocation and removal has the qualifications pertaining to this electrical work as stipulated by the local

laws and regulations, and he or she is a person who has been trained in matters relating to electrical

work on the air conditioners (including the hot water modules) made by Toshiba Carrier Corporation

or, alternatively, he or she has been instructed in such matters by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to do the refrigerant handling and piping work involved in

installation, repair, relocation and removal has the qualifications pertaining to this refrigerant handling

and piping work as stipulated by the local laws and regulations, and he or she is a person who has

been trained in matters relating to refrigerant handling and piping work on the air conditioners

(including the hot water modules) made by Toshiba Carrier Corporation or, alternatively, he or she has

been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters relating to

working at heights with the air conditioners (including the hot water modules) made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in such matters by an individual or

individuals who have been trained and is thus thoroughly acquainted with the knowledge related to

this work.

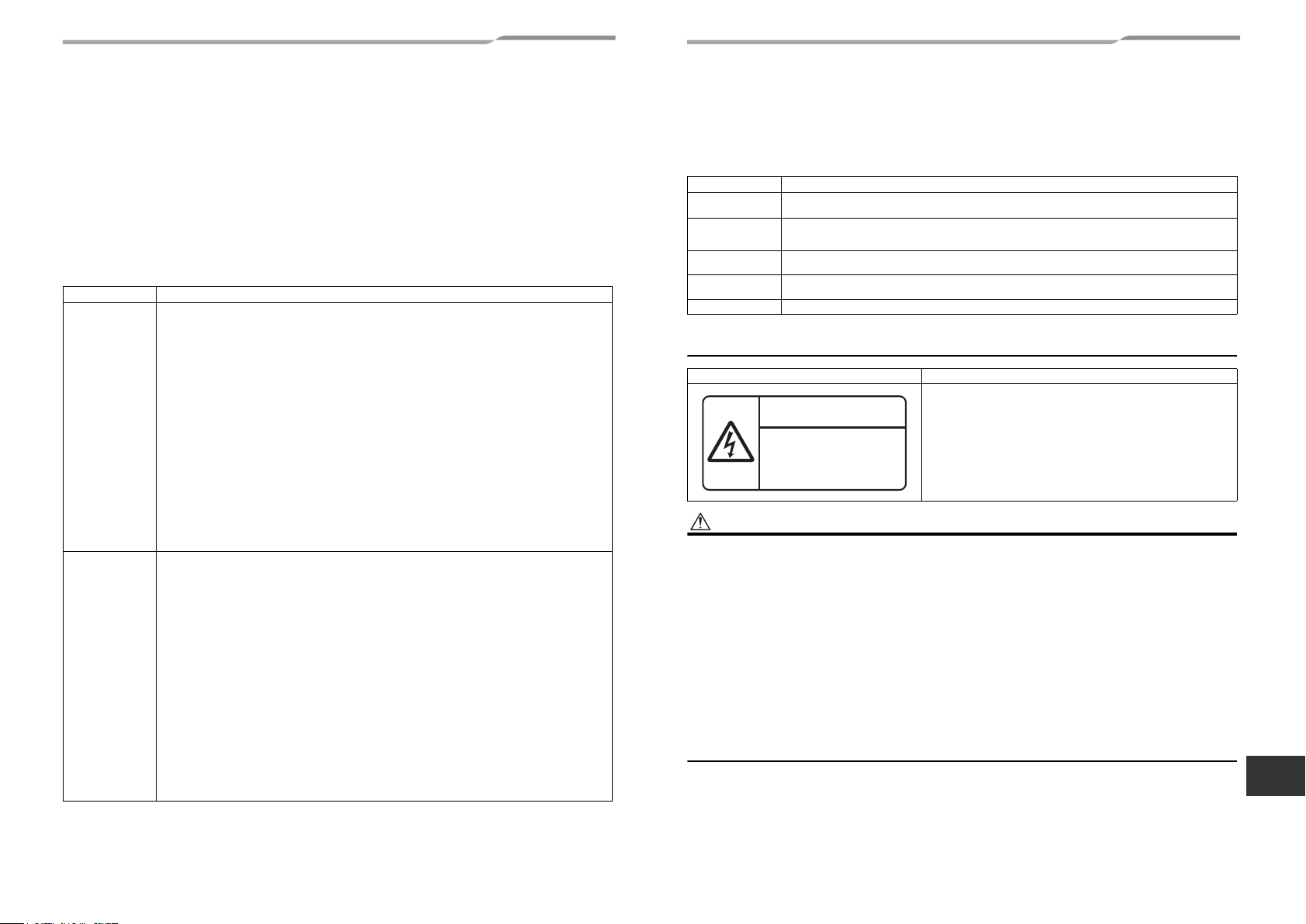

Definition of Protective Gear

When the hot water module is to be transported, installed, maintained, repaired or removed, wear protective gloves

and ‘safety’ work clothing.

In addition to such normal protective gear, wear the protective gear described below when undertaking the special

work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns,

electric shocks and other injuries.

Warning indications on the hot water module

• This is the part for transportation. Be sure to remove this part before

operating the unit.

• To avoid water leak, wrap some sealing tape around the screw part.

• Do not operate VRF system before the commissioning of this product

is fully completed. Failure to do so will result in water freezing and

bursting/failure of the plate heat exchanger.

Set the DIP switch 4 of SW09 on the P.C. board of the header outdoor

unit "ON". (Factory default is "OFF")

VRF system will be stopped to avoid water freezing when the power

supply is disconnected.

Work undertaken Protective gear worn

All types of work Protective gloves

‘Safety’ working clothing

Electrical-related

work

Gloves to provide protection for electricians and from heat

Insulating shoes

Clothing to provide protection from electric shock

Work done at heights

(50 cm or more) Helmets for use in industry

Transportation of

heavy objects Shoes with additional protective toe cap

Repair of outdoor unit Gloves to provide protection for electricians and from heat

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power

supplies before servicing.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote

electric power supplies

before servicing.

3-EN 4-EN

+00EH99897401-3_00Ta.book Page 2 Wednesday, May 11, 2016 3:36 PM