Townlabs TL518 User manual

1

2

Table of contents

Table of contents........................................................................................................................................ 2

TL518 PART LIST.................................................................................................................................... 3

Unpacking.................................................................................................................................................. 8

Installation.................................................................................................................................................. 9

General Safety and Warnings .................................................................................................................. 10

Specifications:.......................................................................................................................................... 11

Printer Port and Input Connector Wiring................................................................................................. 12

Tohoko Ricoh Type 7K00011 Servo Motor Specifications .................................................................... 14

DSP Servo Controller .............................................................................................................................. 17

Spindle Speed Control ............................................................................................................................. 18

Periodic maintenance............................................................................................................................... 18

Removing Ball Screws............................................................................................................................. 19

X and Y Lead Screws Axial Free Play Adjustment................................................................................. 20

Z-Axis Free Play Adjustment .................................................................................................................. 20

X, Y, and Z Motor Tuning................................................................................................................... 21

A-axis Motor Tuning ........................................................................................................................... 22

Port Setup............................................................................................................................................. 22

Motor Outputs configuration ............................................................................................................... 23

Output Signals configuration............................................................................................................... 23

Sources for replacement Parts.................................................................................................................. 24

Cutting tools and accessories links.......................................................................................................... 24

3

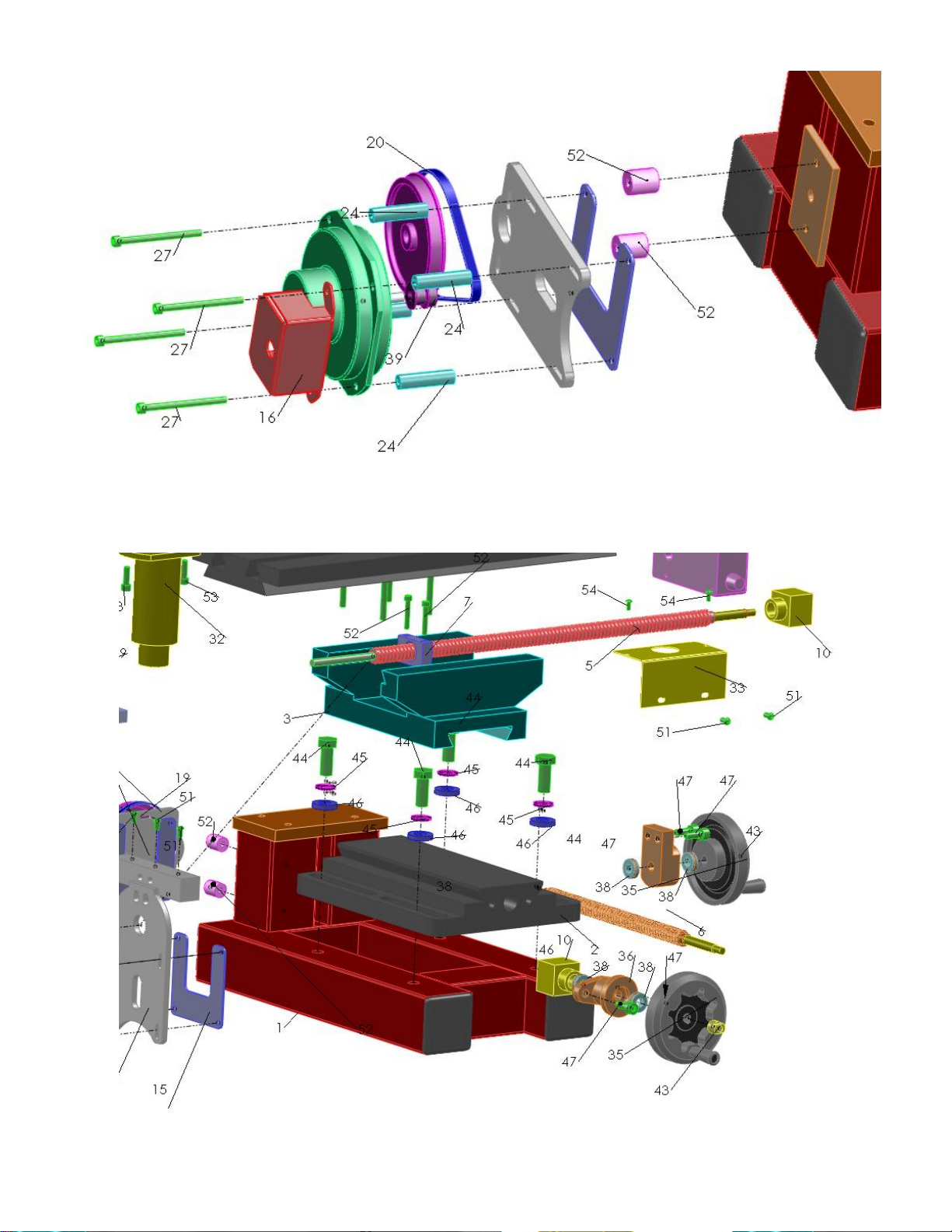

TL518 PART LIST

1 TL518 BASE

2 X/Y TABLE BASE

3 Y CARRIAGE

4 X CARRIAGE

5 X LEAD SCREW

6 Y LEAD SCREW

7 X BALL NUT HOLDER

8 Z BASE

9 Z LINEAR BEARING

10 BALL NUT

11 Z SHAFT BRACE

12 Z LINEAR SHAFT

13 Z CARRIAGE ASSEMBLY

14 Z PLATE TOP

15 PLATE MOTOR BACK

16 MOTOR COVER

17 MOTOR SERVO

18 X MOTOR COVER

19 SPROCKET LARGE

20 TIMING BELT SERVO

21 TIMING BELT SPINDLE

22 X MOTOR PLATE

23 X PLATE SPACER

24 SPACER MOTOR SERVO

25 SPACER SPINDLE

27 SCREW 8-32 X 2 1/4

28 Y MOTOR PLATE

29 SPINDLE MOTOR

BRACKET

30 JAMER PLATE

31 SPROCKET SPINDLE

32 SPINDLE ASSEMBLY*

33 SPINDLE COVER

34 SPEED CONTROLLER

35 X/Y HAND WHEEL

36 Y TABLE BEARING

37 X TABLE BEARING

38 BEARING THRUST 10MM

39 SPROCKET MOTOR

40 Z LEAD SCREW

41 SCREW 8-32 X 2 1/2

42 BEARING THRUST 5/16

43 NUT HANDWHEEL

44 SCREW ½ X 1 ¼

45 SPLIT WASHER ½

46 WASHER ½

47 SCREW M8 X 20

48 SCREW SOCKET LOW HEAD

M8 X 25

49 SCREW SOCKET M8 X 25

50 SCREW M5 X 20

51 SCREW BUTTON 10-32 X 3/8

52 SCREW 10-32 X 1.25

53 SCREW M6 X 20

54 SCREW 6-32 X 3/8

4

5

6

7

8

Unpacking

1. Release the gib and the Z-jam screw.

2. This screw is useful during manual machining operations. Do not over tighten it.

3.

4.

5. Wipe clean all the grease from the machine and oil all the moving parts.

6. Make sure that all moving parts are moving freely.

7. Make sure that the spindle timing belt is stretched enough and that the motor sprocket doesn’t

rub on the Z-plate.

9

8. Clean thoroughly ball screws. During machining protect the ball screws from the metal chip

particles. Keep them clean all the time.

9. Wipe clean all the grease from the machine and oil all the moving parts.

Installation

The machine has four threaded holes on the bottom of the base. It is recommended to install leveling legs

or 3/8”-16 screws to level the machine on sturdy surface. Alternatively it is possible to bolt the machine

base to the table surface. This method is preferable if you will be machining heavy parts and the part

weight may tilt the machine when the X-carriage is in the extreme right or left position.

The location of the threaded inserts on the bottom of the base is shown on the picture below.

10

General Safety and Warnings

• Wear appropriate safety glasses.

• Install machine on a sturdy surface and bolted to the tabletop using 3/8x16 machine screws.

• Ensure that the work piece and cutter are mounted securely before taking a cut.

• Check that work is mounted squarely.

• Mount work in a vise that is bolted or held magnetically to the table. Use proper hand tools to

make adjustments.

• Hold milling cutters with a cloth to avoid being cut when handling them.

• Move table as far as possible from cutter while setting up work to avoid injuring your hands.

• Mill the largest surface first.

• Keep hands, brushes and rags away from the revolving milling cutter.

• Use a vacuum, brush or rake to remove cuttings only after the cutters have stopped moving.

• Change cutting compounds periodically.

• Keep cutters sharpened correctly and in good condition.

• Keep working surface clear of scraps, tools and materials.

• Keep floor around the milling machine free of oil and grease.

• Use lifting equipment when appropriate to move heavy work to or from milling machines.

Before starting, make sure that:

• All guards are in place

• Work is properly secured in place

• Bolts used to hold down work clear the tooling

• Tooling and supporting pieces are properly tightened in position

• Table stops are secured properly

• Handles on all feed screws are in neutral

• Table is free of stock, tools or other loose material

• The arbor and arbor support are clear of the work

Ensure that the following factors are considered when setting cutting speed:

• Material to be machined

• Type of cutter

• Finish required

• Depth of cut

• Rigidity of machine and work piece

• Do not wear gloves, rings, watches or loose clothing. Tie back long hair.

• Do not attempt to mount, measure or adjust work until cutter is completely stopped.

• Do not use an excessively heavy cut or feed as it can cause the cutter to break. The flying pieces

could cause serious injury.

• Do not reach over or near a revolving cutter. Keep hands at least 30 cm (12 in.) from a revolving

cutter.

• Do not lean or rest hands on a moving table.

• Do not make any adjustments while the machine is running.

• Do not use paper shims to check the distance from the cutter to the stock.

11

• Do not move the operating levers without knowing what they control and what action is going to

take place.

• Do not leave machine unattended while it is running.

• Use liquid cooling when possible to prevent airborne dust especially when working with plastics

such as fiberglass or phenolics.

Specifications:

Spindle Motor 120 V, 28000 RPM

Spindle Speed 100 - 6500 RPM,

Electronic Speed Control

Spindle Rotation CW

Milling Capacity ¾ Face Mill on mild steel

Ball Screws Pitch 0.200”

Maximum X Travel 10”

Maximum Y Travel 6”

Maximum Z Travel 10”

Swing 11”

X/Y Dial Resolution 0.001”

Table Size 18 5/8” x 6”

Base Size 10 1/8” x 9 3/8”

Spindle taper MT2

Weight 170 Lb.

Shipping weights 200 Lb.

12

Printer Port and Input Connector Wiring

Printer port connector Input Connector

PIN PRINTER PORT CONNECTOR INPUT CONNECTOR PIN

1 Spindle Power

2 Step X

3 Direction X

4 Step Y

5 Direction Y

6 Step Z

7 Direction Z

8 Step A

9 Direction A

10 Input 3

11 Input 4

12 Input 7

16 Cooling Pump Power

18 Common 9

1 Is connected to +5VDC

13

Important:

LEDs can be seen through the controller cover are lit under normal operation.

If one of the axes reaches the end of motion or cannot move for any reason, all axes

will stop moving to prevent damage to the machine and motors.

The LEDs will blink indicating the need for a reset.

In order to reset the controller you have to shut it off and then turn it on again.

All previous axes position will be lost.

LED blinking CODES:

• 1 BLINK: Stuck motor. The encoder error exceeded maximum allowed

error

• 2 BLINKS: Motor Halt Command from other motor. The other motor

signaled en error causing the controller to halt all the motors.

• 3 BLINKS: Over-current.

• 4 BLINKS: Thermal overload.

If the controller stops durin

g

machinin

g

, low the feed, axis acceleration or depth

of cut.

14

Tohoko Ricoh Type 7K00011 Servo Motor Specifications

• Nominal voltage 24VDC

• No load power 55 watt

• No load speed 4600 RPM.

• Nominal torque 12 oz.in. @ 2.3 amp, 4000 RPM.

• Maximum current 10 Amp.

• Encoder resolution 400 per rev.

15

16

Fine-tuning.

Number of step per inch for each axis may change slightly according to the precise lead screw pitch for a

particular machine. It is a good practice to fine-tune each axis number of steps per inch according to a dial

indicator reading as it is shown on the picture.

Using your software move the corresponding axis by one inch and adjust if necessary the software setup

according to the actual indicator reading.

Repeat this procedure for all axes.

17

DSP Servo Controller

1. X, Y, Z, A connectors are for motors of the corresponding axis.

2. Input connector is not used for normal operation. It is intended for future add-ons, such as Home

or Limit switches.

3. Printer Port connector is connected to a computer printer port with the furnished cable.

4. Spindle receptacle on the front panel energizes by the M3 or M03 statement in the program. It

turns off with M5 or M05 statement in the program. The spindle speed controller should be

plugged into it.

5. Cooling receptacle energizes by the M8 or M08 statement in the program. It turns off with M9 or

M09 statement in the program. This receptacle is used to control a cooling pump. Don’t plug a

vacuum cleaner into this receptacle because of the current limitation.

6. 120 V Power input has a built in fuse holder. The fuse is 10amp, 5mm size.

7. The manual On-Off switch may be used during tool change. When a program calls for a tool

change it is possible to shut of the controller, change the tool and manually bring the Z-axis to the

previous position. Then turn the controller on again to continue the program.

8. When operating the mill manually, unplug motors from the controller.

9. For a safety reason turn the controller power on only after the computer program is on the

computer screen. During computer boot-up the printer port outputs are in unpredictable state and

the controller can randomly turn the spindle or cooling pump on without warning.

18

Spindle Speed Control

Periodic maintenance.

• Do not over tight gib screws on dovetail axes. Gibs are metal strips that sit on one side of a

dovetail slide, such as the cross-slide and compound, and which are adjustable to take up any slack

or slop so that the dovetail slide is very smooth. The table should move smooth by hand cranks.

All dovetails are hand lapped. However as any mechanical equipment the mill requires some

running time to make the matching parts fit. After 10-20 hours of operation it may be necessary to

adjust gib screws on all axes.

The fuse is located in the bottom portion of the power

entry on the back of the controller. Use a small

screwdriver to pull open the fuse compartment.

The fuse is 5mm size and rated 10 amps.

Spindle speed control adjustment is located on the right

side of the spindle carrier. The front switch central

p

osition turns spindle off. In VA

R

-position spindle

RPM is adjustable. In FULL-position spindle turns at

full speed regardless of the know position. The spindle

RPM scale is not calibrated. It is ratiometric to the

maximum speed.

19

After gib screws adjustment secure all jam nuts.

• Use good quality machine oil to lubricate all moving surfaces. Avoid using WD40 and such

products with additives. They may create residue build-ups.

• Use lubricating grease on all lead screws.

• Never use a drill chuck in milling operation. Use only supplied MT2 collets.

Removing Ball Screws

Do not remove ball screw from the ball nut without inserting an arbor into a ball nut to prevent loosing

balls.

Follow the procedure:

1. Attached an cardboard arbor tight to the end

of the ball screw

2. Engage and rotate both the arbor and the ball

screw.

3. Make sure that the arbor is inserted into

entire screw

4. Secure the arbor with a plastic tie.

20

When re-assemble follow the reverse procedure.

The cardboard arbor is included with the mill

X and Y Lead Screws Axial Free Play Adjustment

An excessive axial free play in the thrust bearings may be compensated as follow:

1. Hold the wheel nut with the 10mm

ranch (Pos. 2) and release the hex jam

screw with the hex driver (Pos. 3).

2. Holding wheel (Pos. 1) with your hand

tight the wheel nut with the ranch (2).

Don’t over tighten it.

3. Holding the ranch (2) tight the hex jam

screw with the driver (3).

Z-Axis Free Play Adjustment

Adjusting the nut as shown on the picture

below may compensate an excessive axial

free play in the thrust bearings on Z-axis.

You may hold the Z-Ball Screw when

doing this. Don’t over-tighten the nut!

Table of contents

Popular Power Tools manuals by other brands

AEG

AEG A18ERW38B Original instructions

NRD

NRD Sentinel 6210 Installation operation & maintenance

NetterVibration

NetterVibration NED 605 operating instructions

Ironton

Ironton 45981 owner's manual

Haussmann Xpert

Haussmann Xpert PNT108-B Operator's manual

Scheppach

Scheppach DP13 Translation from the original instruction manual