Toyo DBH Series User manual

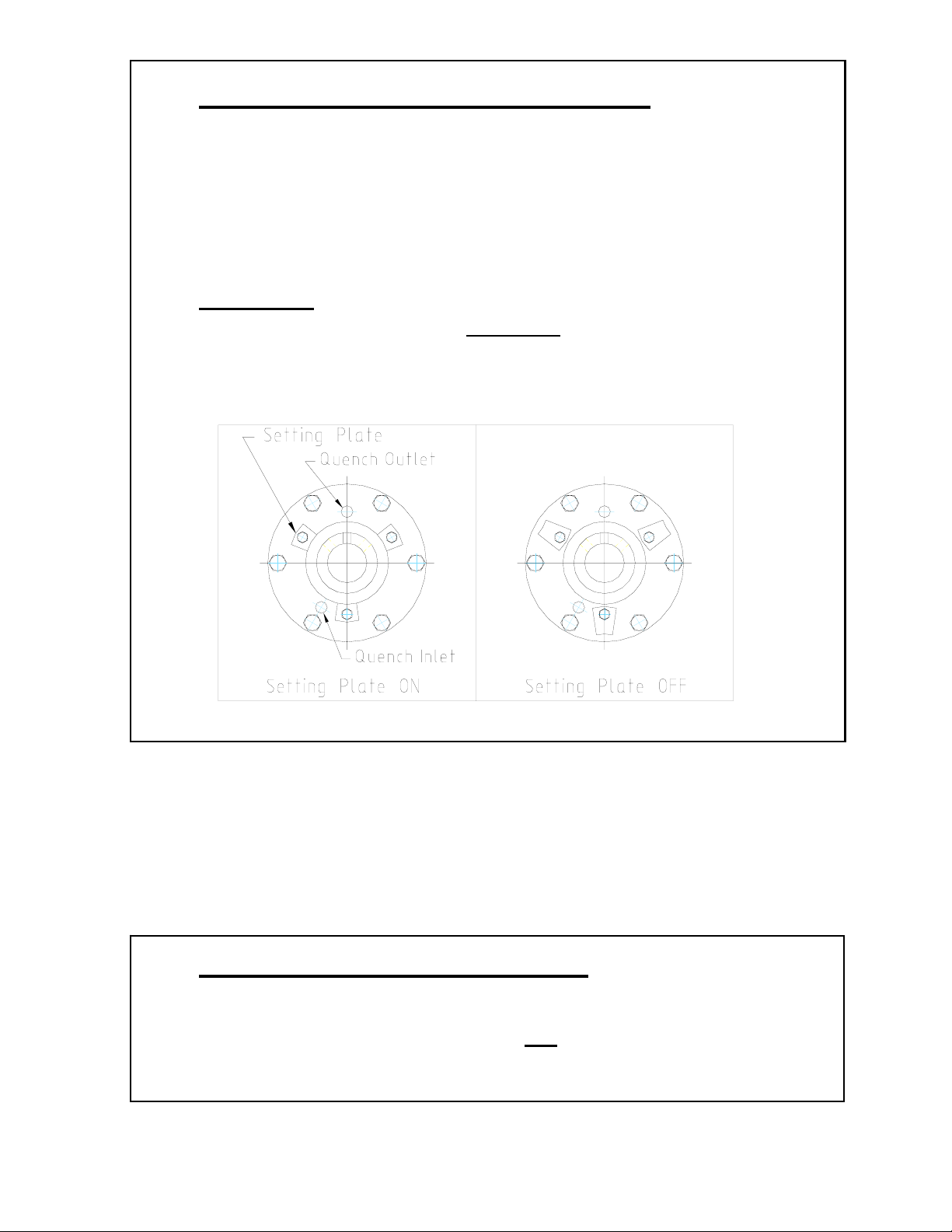

2. For Stuffing Box Pumps

- See section 5.6.2 and 6.2.2 in manual.

- Flush water must be turned ON before pump is started.

1. For Mechanical Seal Pumps

- See section 5.6.2 and 6.2.1 in manual.

- Toyo recommends a continuous clean water quench of ¼ - ½

gpm at maximum 5 psi (inlet is at bottom), if there is no quench

water never operate the pump dry.

Warning

Prior to pump start up REMOVE mechanical seal Setting

Plates (Qty. 3) installed for shipping.

Failure to do so can cause seal damage and leakage.

CUSTOMER: Industrial Pump Systems

PURCHASE ORDER: 9762

PUMP MODEL: DBH-100/75MD-ROH

PUMP SERIAL NUMBER: D-30051-52

TYPE DBH

HORIZONTAL SLURRY PUMPS

INSTALLATION,

OPERATION &

MAINTENANCE

INSTRUCTIONS

TOYO PUMPS NORTH AMERICA CORPORATION

2853 Douglas Road Telephone: (604) 298-1213

Burnaby, British Columbia Fax: (604) 298-7773

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH MAINTENANCE OPERATION AND

INSTALLATION MANUAL

DOCUMENT NO: TED-039 REV. NO: 10 PAGE 1 OF 80

PREPARED BY: KSH DATE: MAY 1 1997

APPROVED BY: SN DATE: SUPERSEDES:

EFFECTIVE: MAY 5 2005 PUMP SERIAL NUMBER:

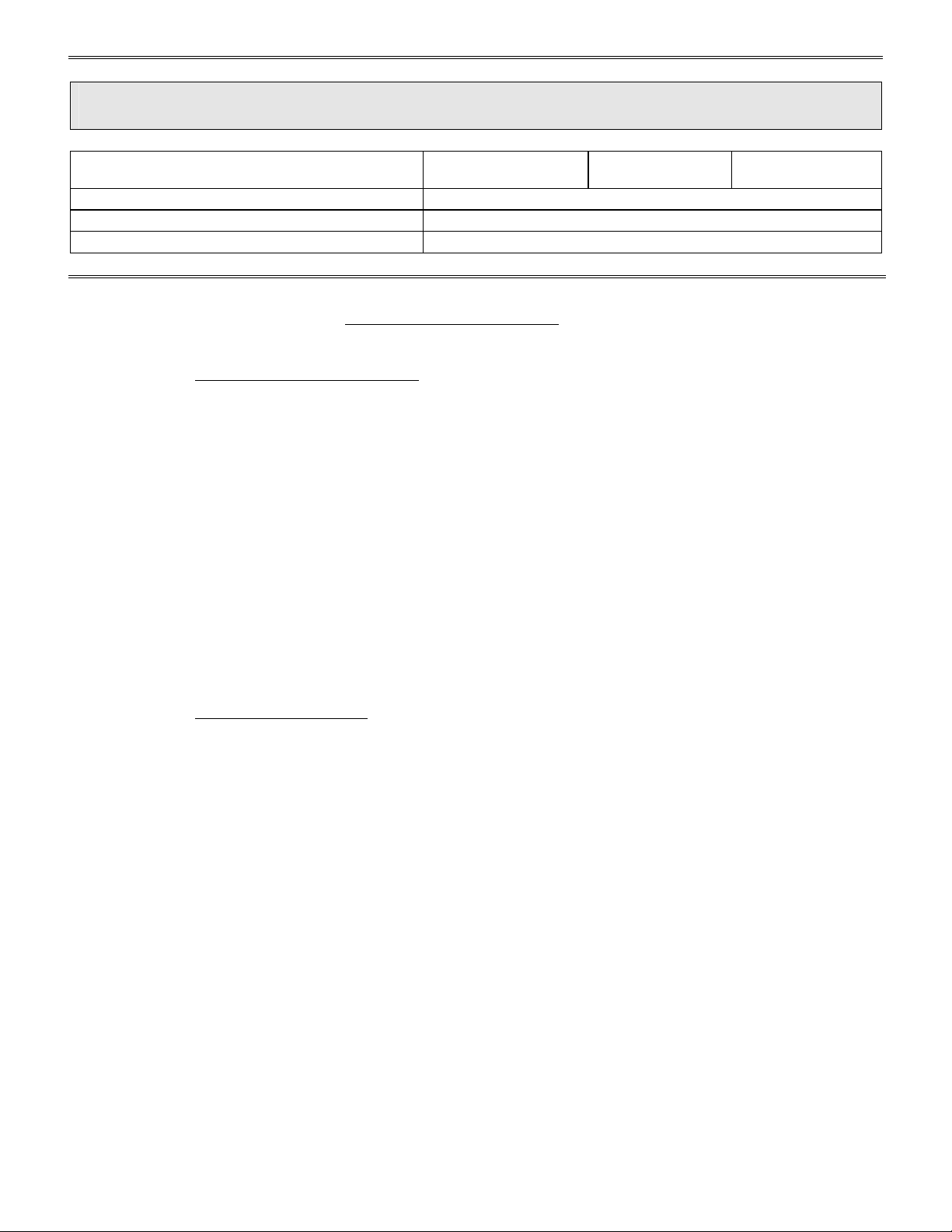

1.0 TECHNICAL DATA SHEET

CUSTOMER : Industrial Pump Systems

LOCATION :

APPLICATION : Mine Dewatering

PUMP MODEL : DBH-100/75MD-HC-ROH

EQUIPMENT NUMBER :

TAG NUMBER :

PUMP SERIAL NUMBER : D-30051

METALLURGY : HCr

OPERATING CONDITIONS

FLOW (USGPM)

NORMAL : 600

MAX :

MIN :

TDH (FEET) : 420

SLURRY S.G. : 1.05

SOLIDS % BY VOLUME :

MAX. PARTICLE SIZE (IN.) : 0.63

TEMPERATURE °F : 60

pH :Neutral

PUMP DATA

PUMP SPEED (RPM) : 1780

IMPELLER DIA. (IN.) : 19.7

SEAL TYPE : SiC Mechanical Seal

BEARING FRAME : F500

ASSEMBLY WEIGHT : 2164 KG [4761 lb.]

FOR COMPLETE PUMP DATA SHEET SEE SECTION 10.0

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH MAINTENANCE OPERATION AND

INSTALLATION MANUAL

DOCUMENT NO: TED-039 REV. NO: 10 PAGE 1 OF 80

PREPARED BY: KSH DATE: MAY 1 1997

APPROVED BY: SN DATE: SUPERSEDES:

EFFECTIVE: MAY 5 2005 PUMP SERIAL NUMBER:

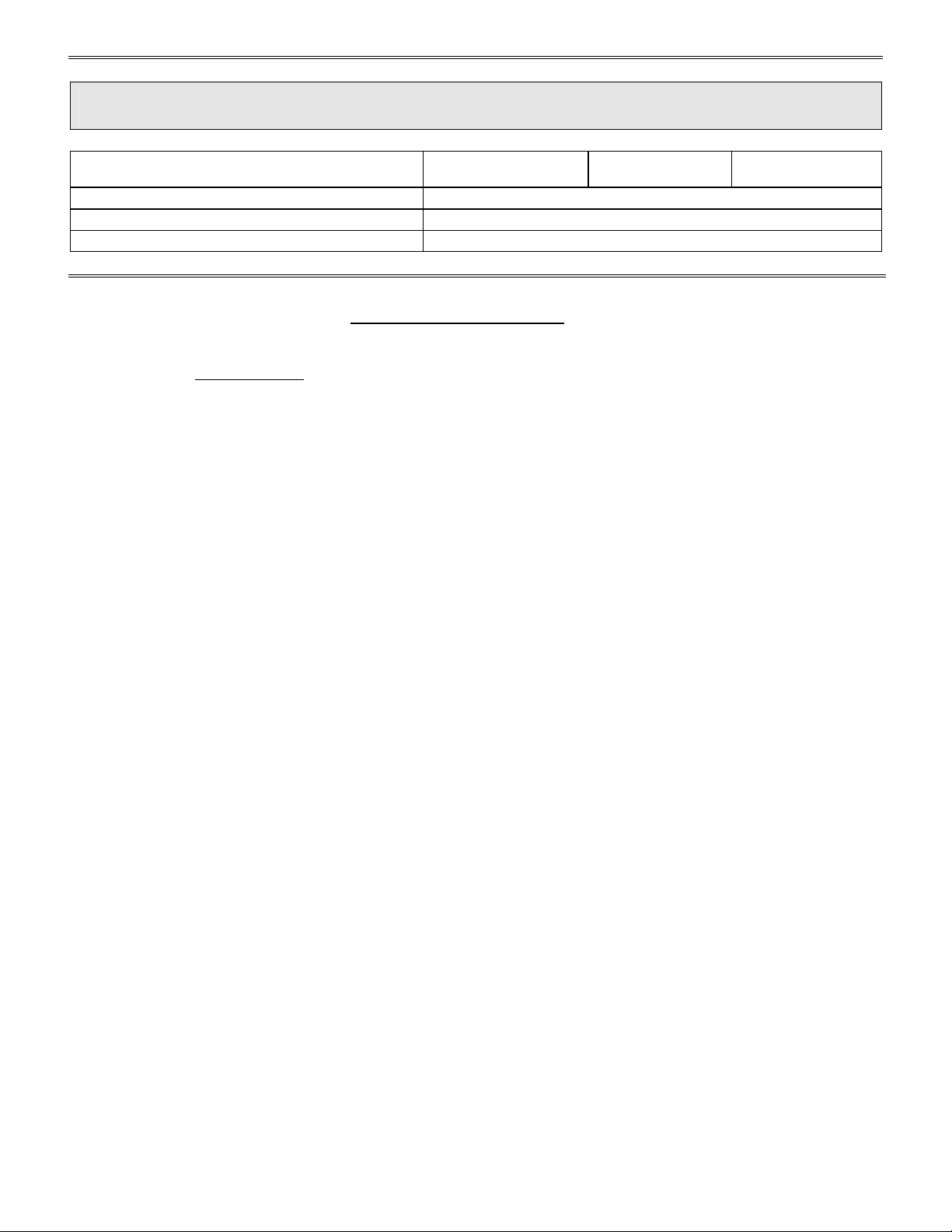

1.0 TECHNICAL DATA SHEET

CUSTOMER : Industrial Pump Systems

LOCATION :

APPLICATION : Mine Dewatering

PUMP MODEL : DBH-100/75MD-HC-ROH

EQUIPMENT NUMBER :

TAG NUMBER :

PUMP SERIAL NUMBER : D-30052

METALLURGY : HCr

OPERATING CONDITIONS

FLOW (USGPM)

NORMAL : 600

MAX :

MIN :

TDH (FEET) : 420

SLURRY S.G. : 1.05

SOLIDS % BY VOLUME :

MAX. PARTICLE SIZE (IN.) : 0.63

TEMPERATURE °F : 60

pH :Neutral

PUMP DATA

PUMP SPEED (RPM) : 1780

IMPELLER DIA. (IN.) : 19.7

SEAL TYPE : SiC Mechanical Seal

BEARING FRAME : F500

ASSEMBLY WEIGHT : 2164 KG [4761 lb.]

FOR COMPLETE PUMP DATA SHEET SEE SECTION 10.0

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 2 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

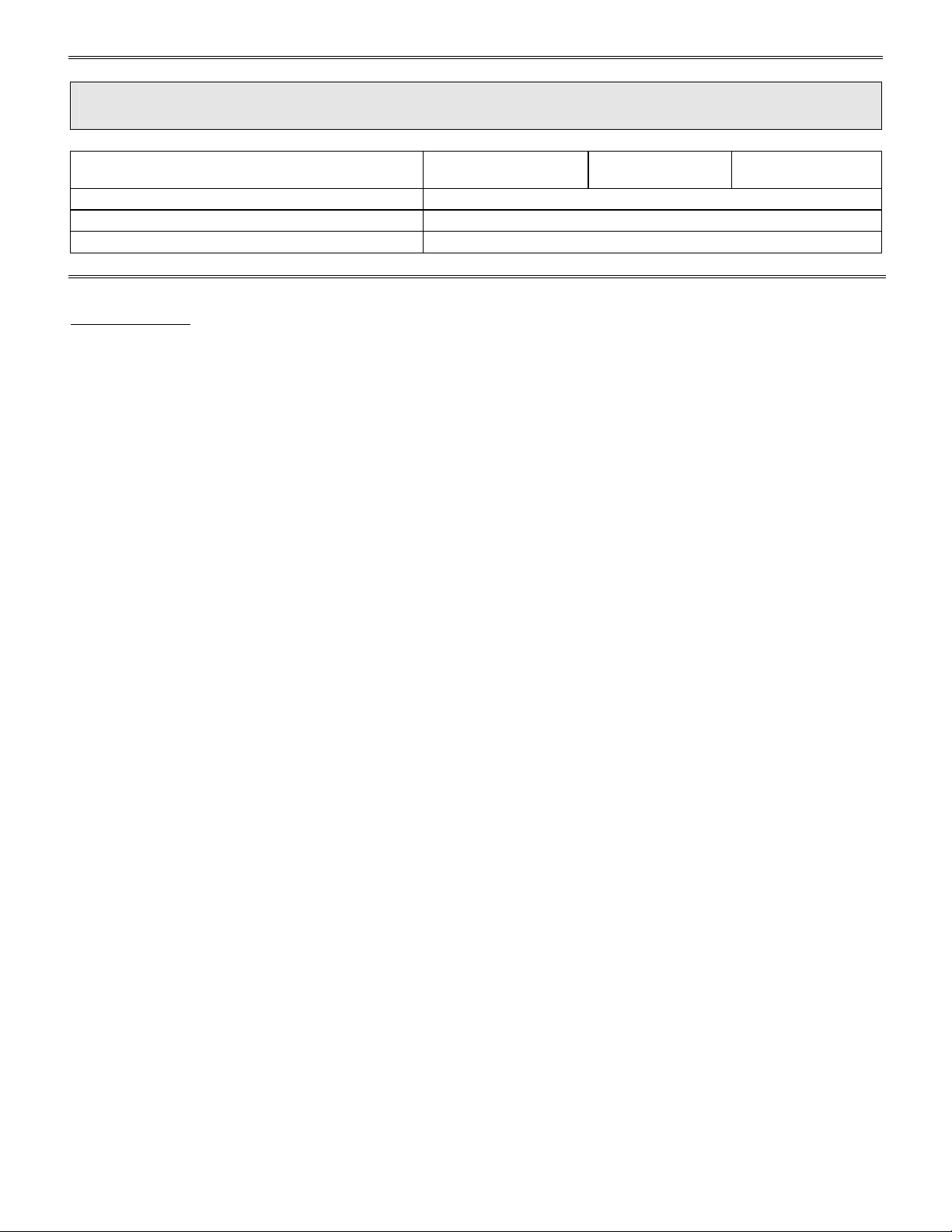

1.1 CUSTOMER FILL IN DATA SHEET

START-UP OPERATING CONDITIONS

FLOW (USGPM) NORMAL : MAX. : MIN. :

DISCHARGE PRESSURE (PSI) :

SUCTION PRESSURE (PSI) : (IN.Hg):

SLURRY S.G. :

SOLIDS % BY VOLUME :

MAX. PARTICLE SIZE (IN.) :

TEMPERATURE :

pH :

START-UP PUMP DATA

PUMP SPEED (RPM) :

POWER DRAW (AMPS) :

OIL TEMPERATURE (°F) :

NOTES :

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 3 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

TABLE OF CONTENTS

SECTION 1.0 TECHNICAL DATA SHEET

1.1 CUSTOMER FILL IN DATA SHEET

SECTION 2.0 INTRODUCTION

SECTION 3.0 WARRANTIES

SECTION 4.0 SAFETY

SECTION 5.0 INSTALLATION

5.1 CHECK UPON ARRIVAL

5.2 STORAGE

5.2.1 NEW PUMP AND EQUIPMENT STORAGE

5.2.2 USED PUMP STORAGE

5.2.3 SPARE PARTS STORAGE

5.3 HANDLING

5.4 ALIGNMENT

5.5 MOUNTING

5.5.1 CONCRETE MOUNTING

5.5.2 STEEL FRAME MOUNTING

5.6 PIPING

5.6.1 SUCTION AND DISCHARGE

5.6.2 SEAL PIPING

5.7 POWER SUPPLY

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 4 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

TABLE OF CONTENTS (ctd)

SECTION 6.0 OPERATION

6.1 ROTATION

6.2 SHAFT SEAL

6.2.1 MECHANICAL SEAL

6.2.2 STUFFING BOX

6.2.3 CENTRIFUGAL SEAL

6.3 START UP

SECTION 7.0 MAINTENANCE

7.1 INSPECTION AND ADJUSTMENT FOR WEAR

7.1.1 GENERAL

7.1.2 IMPELLER CLEARANCE ADJUSTMENT

7.1.2.1 VISUAL INSPECTION

7.1.3 FRONT PULL OUT

7.1.4 BACK PULL OUT

7.1.5 IMPELLER REMOVAL

7.1.6 MECHANICAL SEAL INSPECTION

7.1.7 STUFFING BOX INSPECTION

7.1.7.1 LOW FLOW STUFFING BOX

7.1.7.2 FULL FLOW STUFFING BOX

7.1.8 BEARING CLEARANCE ADJUSTMENT

7.2 LUBRICATION

7.2.1 BEARING LUBRICATION

7.2.2 BEARING HOUSING SEAL LUBRICATION

7.3 TROUBLE SHOOTING

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 5 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

TABLE OF CONTENTS (ctd)

SECTION 8.0 BEARING FRAME ASSEMBLY

8.1 SHAFT PRE-ASSEMBLY

8.2 BEARING END COVER PRE-ASSEMBLY

8.3 BEARING HOUSING ASSEMBLY

8.4 BEARING CLEARANCE SETTING

8.5 SHAFT SLEEVE, FLINGER AND HARDWARE ASSEMBLY

8.6 FRAME ADAPTER, FEET AND BASE PLATE ASSEMBLY

8.7 BEARING SIDE LINER, MECHANICAL SEALS AND STUFFING BOX

8.7.1 BEARING SIDE LINER ASSEMBLY

8.7.2 MECHANICAL SEAL INSTALLATION

8.7.3 LOW FLOW STUFFING BOX

8.7.4 FULL FLOW STUFFING BOX

8.7.5 LOW FLOW WATER INLET

8.7.6 FULL FLOW WATER INLET

8.7.7 STUFFING BOX INSTALLATION

SECTION 9.0 WET END ASSEMBLY

9.1 IMPELLER INSTALLATION

9.2 CASING ASSEMBLY

9.2.1 WEAR RING INSTALLATION

9.2.2 SUCTION THROAT LINER INSTALLATION

9.2.3 CASING INSTALLATION

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 6 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

TABLE OF CONTENTS (ctd)

SECTION 10.0 APPENDIX

10.1 LUBRICATION GUIDE

10.2 BOLT TORQUE TABLE (A3670)

10.3 TOOL LIST (A3703)

10.4 TYPICAL PUMP SPEED vs. TORQUE CURVE (A3080)

10.5 WEIGHTS AND DIMENSION TABLE (B3497-B3501)

10.6 CENTRIFUGAL PUMP DATA SHEET

10.7 PUMP PERFORMANCE DATA

10.7.1 CERTIFIED PUMP TEST REPORT (IF APPLICABLE)

10.7.2 PUMP PERFORMANCE CURVE (IF APPLICABLE)

10.7.3 HYDROSTATIC PRESSURE TEST CERTIFICATE (IF APPLICABLE)

10.8 BEARING FRAME ASSEMBLY DRAWING

10.9 PUMP ASSEMBLY DRAWING

10.10 STUFFING BOX ASSEMBLY DRAWING (IF APPLICABLE)

10.11 PUMP GENERAL ARRANGEMENT DRAWING

10.12 MECHANICAL SEAL INSTRUCTIONS (IF APPLICABLE)

10.12.1 MECHANICAL SEAL ASSEMBLY DRAWING (IF APPLICABLE)

10.13 PARTS LIST

10.14 AUXILIARY EQUIPMENT

10.14.1 ELECTRIC MOTOR INFORMATION (IF APPLICABLE)

10.14.2 COUPLING INFORMATION (IF APPLICABLE)

10.14.3 GEAR REDUCER INFORMATION (IF APPLICABLE)

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 7 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

TABLE OF DRAWINGS

Drawing B3337 : Impeller Clearance Adjustment....................................................................... 18

Drawing B3339 : Front Pull Out................................................................................................. 21

Drawing B3338 : Back Pull Out ................................................................................................. 24

Drawing B3340 : Impeller Removal ........................................................................................... 27

Drawing B3346 : Bearing Clearance Adjustment ........................................................................ 30

Drawing B3298 : Shaft Pre-Assembly ......................................................................................... 37

Drawing B3299/1 : End Cover Pre-Assembly (Lip Seal)............................................................... 40

Drawing B3299/2 : End Cover Pre-Assembly (Bearing Isolator)................................................... 41

Drawing B3300/1 : Shaft Installation (Lip Seal) ........................................................................... 44

Drawing B3300/2 : Shaft Installation (Bearing Isolator) ............................................................... 45

Drawing B3301/1 : Bearing End Play (Lip Seal)........................................................................... 48

Drawing B3301/2 : Bearing End Play (Bearing Isolator)............................................................... 49

Drawing B3302/1 : Shaft Sleeve / Hardware (Lip Seal)................................................................ 52

Drawing B3302/2 : Shaft Sleeve / Hardware (Bearing Isolator).................................................... 53

Drawing B3303 : Frame Adapter Feet / Base Plate ...................................................................... 56

Drawing B3304 : Back Liner / Seal, Stuffing Box......................................................................... 57

Drawing B3341 : Mechanical Seal Installation ........................................................................... 60

Drawing B3342 : Stuffing Box, Low Flow Pre-Assembly ............................................................. 63

Drawing B3343 : Stuffing Box, Full Flow Pre-Assembly.............................................................. 66

Drawing B3344 : Water Inlet / Low Flow, Full Flow................................................................... 69

Drawing B3345 : Stuffing Box Pre-Assembly .............................................................................. 70

Drawing B3305 : Impeller Installation........................................................................................ 73

Drawing B3347 : Casing Assembly............................................................................................. 76

Drawing B3348 : Casing Installation........................................................................................... 79

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 8 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

2.0 INTRODUCTION

Your new Toyo “DBH” pump has been designed and manufactured to perform for many years with a

minimum of maintenance. However, parts will wear and need replacing sooner or later. The time

period between maintenance will greatly depend on the service and your maintenance program.

This manual has been compiled to help you minimize your maintenance and speed repairs when

required. Read and understand this manual.

Please provide the Serial Number of your equipment if additional manuals are needed.

In the front of the manual you will find a “Technical Data Sheet”. Most of this sheet will be filled in

at Toyo. However, there may be sections that are left blank. It is advisable to fill in these sections for

future reference.

NOT ALL PUMPS ARE OF STANDARD CONFIGURATION

WHEN ORDERING PARTS ALWAYS REFER TO PUMP SERIAL NUMBER. THIS NUMBER IS

FOUND ON THE NAME PLATE ON THE PUMP AND ON THE “TECHNICAL DATA SHEET” OF

THIS MANUAL.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 9 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

3.0 WARRANTIES

Seller warrants that the products covered by this contract conform to applicable drawings and

specifications accepted in writing by Seller, will be free from defects in material and workmanship,

will be merchantable and will perform in accordance with the detailed specifications accepted in

writing by Seller. These warranties extend for a period of twelve (12) months from the date of

installation or eighteen (18) months from the date of shipment, whichever occurs first. Buyer’s

exclusive remedy and Seller’s sole duty under these warranties is to repair or replace the product.

Normal wear and tear on Seller’s product shall not constitute a warranty defect. THERE ARE NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, WHICH EXTEND BEYOND THOSE SET FORTH

ABOVE. THE WARRANTY OF MERCHANTABILITY IS LIMITED TO THE TIME PERIOD SPECIFIED

ABOVE. These warranties are contingent upon the product being stored, installed, maintained, and

operated in accordance with good engineering practices and the instructions contained in the

Operating and Maintenance Manual.

Seller’s total responsibility for damages whether arising in contract or tort arising out of or relating to

its performance of this contract or the products covered hereunder shall be limited to the contract

price for the product. In no event shall Seller be liable for any incidental or consequential damages

such as lost profits, loss of use of productive facilities or equipment, expenses or damages incurred in

reliance on Seller’s performance hereunder or lost production whether suffered by buyer or any third

party

Seller will be responsible for compliance with federal, provincial and municipal laws, codes, and

regulations relating to the manufacture of the products. Seller warrants that the products comply with

OSHA standards on drive guard design and construction in effect at the time of manufacture and

makes no other warranty with respect to any other standards. Seller shall not be responsible for failure

of parts to fit properly due to deterioration of or modification to Buyer’s existing equipment for which

such parts are furnished. Seller makes no warranty or guarantee that the equipment or parts supplied

hereunder will comply with any existing performance of Buyer’s equipment.

Seller reserves the right to furnish substitutes for material not available or whose use is restricted,

provided such substitute material is of equal quality and performance.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 10 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

4.0 SAFETY

Do not install the equipment other than in accordance with the instructions contained in this manual.

When required information can not be found in this manual, contact the nearest TOYO branch office.

This instruction book should be read completely before starting installation, maintenance or

operation. The equipment is capable of trouble free operation when properly installed, operated and

maintained. These instructions present the basic information and methods required for proper

installation and maintenance.

This pump has been designed to provide safe and reliable service, however it is both a pressure

vessel and a piece of rotating machinery. The operator(s) must exercise good judgment and proper

safety practices to avoid damage to the equipment and surroundings and to avoid personal injury.

The instructions in this manual are intended for personnel with a general training in operation and

maintenance of centrifugal pumps.

It is assumed that your safety department has established a safety program based upon a thorough

analysis of industrial hazards. Before installing, operating or performing maintenance on the pump

and associated components described in this manual, it is suggested that the safety program is

reviewed to ensure that it covers the hazards arising from high speed rotating machinery. In general,

all personnel should be guided by all the basic rules of safety associated with the equipment and the

process.

It should be understood that the information contained in this manual does not relieve operating and

maintenance personnel of the responsibility of exercising normal good judgment in operation and

care of the pump and its components.

TOYO Pumps reserves the right to change the design, construction or material of any part without

incurring the obligation of installing such changes on pumps already delivered.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 11 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

5.0 INSTALLATION

5.1 CHECK UPON ARRIVAL

The unit must be inspected immediately upon arrival and any irregularities and damages due

to shipment must be reported to the carrier and TOYO pumps. A copy of this manual as well

as instruction sheets for other equipment (such as drive components etc.) are included in the

shipment. Put these papers in a safe, accessible place for ready reference when required. It is

important that the entire contents of this manual are studied before installation.

Pump parts and accessories may be packed inside shipping container, or attached to skids in

individual packages. Inspect all containers, crates and skids before discarding.

5.2 STORAGE

5.2.1 NEW PUMP AND EQUIPMENT STORAGE

If your new pump is to be stored for a long period of time before use, the following

procedures must be adhered to in order for TOYO to extend the normal warranties.

Notify TOYO that the equipment is to be stored and that the storage procedures will be

followed. Depending on size and type of equipment a visual inspection may be

required. Notify TOYO when equipment is to be removed from storage and put into

service. Failure to notify TOYO will result in your warranty being void. Your new

pump will arrive lubricated, ready for use. A small amount of grease or suitable

protectant must be applied to all exposed, unpainted metal surfaces such as shaft drive

end, shaft sleeve etc. Plug all flush water inlet ports on the stuffing box or mechanical

seal. Suitable covers out of plywood or plastic must be installed on the suction and

discharge flanges and any other openings on auxiliary equipment to provide adequate

protection against dirt, dust and nesting animals.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 12 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

5.2.1 (ctd)

Equipment should be stored in a dry location and situated on an even surface with no

strains applied. If stored outdoors, the equipment must be covered with a waterproof

tarp secured to the equipment or skid. During storage, rotating equipment shafts must

be rotated by hand to relubricate the bearing surfaces and to prevent the bearings from

being damaged.

ROTATE ONCE A MONTH

Grease the bearing housing seals with new grease (1 to 2 shots).

5.2.2 USED PUMP STORAGE

A used pump should be completely disassembled and all parts cleaned and inspected.

All unpainted metal surfaces should be coated with grease or suitable protectant. All

previously painted parts should be touched up or repainted. Reassemble the pump as

per Sections 8.0 and 9.0 and store as per Section 5.2.1.

5.2.3 SPARE PARTS STORAGE

Spare parts may not arrive at your site with adequate protection for long term storage

unless it was specified in your parts order. It is the customer’s responsibility to ensure

that all spare parts are prepared and packaged for long term storage. Components such

as bearings, mechanical seal assemblies and parts should be left in their original sealed

containers. The long term storage of elastomer (rubber) parts must be given

consideration since elastomers may have a short shelf live under certain circumstances.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 13 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

5.3 HANDLING

Use care when moving pumps. Rough handling can cause breakage or permanent

misalignment. Sling pumps so that any protruding components will not be damaged. Do not

use choke type sling or chain arrangements for skids or containers.

Make sure that the lifting equipment is rated to safely handle the weight of the pump and

auxiliary equipment.

See Section 1.0, TECHNICAL DATA SHEET for weight information.

5.4 ALIGNMENT

The pump was checked during assembly and testing for proper alignment of the drive

equipment. Handling during shipment, storage or preparation for installation could have

caused distortions. For direct or gear reducer driven units the alignment must be verified upon

installation prior to start-up. Follow the drive manufacturers instructions and tolerances for

angular and parallel alignment.

5.5 MOUNTING

5.5.1 CONCRETE MOUNTING

Anchor bolts should be sized to approximately 1.5 mm (1/16”) smaller than mounting

holes provided on pump base. These bolts will not be subject to shear and therefore

should be the type that will resist pull out. Ideally the bolts should be set in the

concrete.

5.5.2 STEEL FRAME MOUNTING

If a pump is to be mounted on steel frame, the frame must be of sufficient member

depth and strength to support pump weight and dynamic load between a given span.

Mounting bolts should be sized 1.5 mm (1/16”) smaller than the mounting holes in

base. Bolts should be Grade 6.4 (ANSI Grade 5) or better.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 14 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

5.6 PIPING

5.6.1 SUCTION & DISCHARGE

Suction and discharge piping should be of proper wall thickness and diameter to

handle flow and pressures required for your pump. Pump flanges will be drilled for

proper ANSI bolt pattern for pipe size and pressure. All piping should be

independently supported. Pump casing should never bear the weight of the piping.

(Pump casing may break and later removal of casing would be difficult.) Flexible pipe

or expansion type joints are recommended for suction and discharge side of pump

provided that they are of non- collapse type.

5.6.2 SEAL PIPING

Seal water must be supplied to pump if a Mechanical Seal or a Full or Low Flow

Stuffing Box is used. This water must be of sufficient pressure and volume. See

Operation Section for type of seal installed.

5.7 POWER SUPPLY

Power supply should be as per local and national codes. All wiring and installation of

disconnects, etc., should be performed by qualified personnel.

6.0 OPERATION

6.1 ROTATION

After your pump is installed properly, you must check for proper rotation.

DISCONNECT ALL DRIVE EQUIPMENT

If you check rotation with drive equipment connected and the rotation is incorrect, the

impeller may INSTANTLY UNSCREW causing serious damage to pump. When viewed from

suction end, rotation is counter clockwise. At this point rotate shaft by hand to check impeller

clearance. If you have proper motor rotation and impeller clearance, the pump is now ready

to be started. Install and tighten belts or couplings. Install all guards.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 15 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

6.2 SHAFT SEAL

6.2.1 MECHANICAL SEAL

If your pump is equipped with a mechanical seal, make sure that all centering tabs and

cartridge retainers have been removed before operating pump. There should be no

visible leakage from the seal area during operation or shut down unless the mechanical

seal is equipped with a quench arrangement. Toyo recommends a continuous clean

water quench of ¼ - ½ gpm at maximum 5psi (inlet is at bottom), if there is no quench

water never operate the pump dry.

6.2.2 STUFFING BOX

If your pump is equipped with a Full or Low Flow Stuffing Box, snug the gland

follower, being careful not to over tighten.

FLUSH WATER MUST BE TURNED ON BEFORE PUMP IS STARTED

The following chart gives flow rates for Full and Low Flow.

FRAME F200 F300 F400 F500 F600 F650 F800

CONFIG LF FF LF FF LF FF LF FF LF FF LF FF LF FF

LIT/MIN 2.5 11 4 15 7 27 7 27

10 38 10 38

15 60

GPM 0.7 3 1 4 1.9

7 1.9

7 2.6 10 2.6 10

4 15.9

Gland flush water should be 5 to 10 PSI above discharge pressure of pump. If water

is being pumped, then gland flush water may come from the discharge side of the

pump, but this water must be clean so that no sand, etc., is pumped into Gland area. A

valve should be installed in line to adjust flow. Provide a drain for discharge water

Open suction valve, start pump and let it come up to RPM and pressure.

For a Full or Low Flow Stuffing box seal, tighten the gland follower until a small trickle

of water is coming from around the gland follower. Let pump run for 10 to 15 minutes

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 16 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

6.2.2 (ctd)

to be sure packing does not overheat. New packing will wear and seat in, and will

require adjustment from time to time. These seals will leak clear water while running

and may leak slurry when stopped if there is a large suction head present. Gland Flush

water may be left on while pump is not running.

6.2.3 CENTRIFUGAL SEAL

If your pump is equipped with a Centrifugal Seal, grease the seal with 10 or 15 shots of

grease before installing the automatic greaser and starting. The gland follower should

be snugged before starting the pump. Do not over tighten the gland follower or you

will burn the packing and cause damage to the shaft sleeve.

Open suction valve, start pump and let it come up to RPM and pressure.

For a Centrifugal Seal, tighten packing until no leaks occur. Do not over tighten. Let

pump run for 10 to 15 minutes and re-check. A Centrifugal Seal should not leak while

pump is running, but may leak when pump is stopped if there is a large suction head

present.

6.3 START UP

During the first few days of operation while all parts are still new, observe the suction and

discharge gage readings as well as the motor amperage. If a flow meter is available monitor

the pump output as well.

Record these readings in the TECHNICAL DATA SHEET provided in Section 1.0 for future

reference.

These readings should be taken and recorded periodically and will help you to establish an

inspection and maintenance schedule. Keeping track of your pumps performance will make it

easier to identify problems before they become serious and cause undue damage.

TOYO PUMPS NORTH AMERICA CORPORATION

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TITLE: DBH INSTALLATION OPERATION AND

MAINTENANCE MANUAL DOCUMENT NO:

TED-039 REV. NO: 10 SHEET 17 OF 80

PREPARED BY: KSH RELEASE DATE: MAY 1 1997

APPROVED BY: SN REVISION DATE: MAR 15 2007

SUPERSEDES: REVISED BY:

7.0 MAINTENANCE

7.1 INSPECTION & ADJUSTMENT FOR WEAR

7.1.1 GENERAL

After your pump has been in service for awhile, the impeller, casing and suction wear

liner will become worn causing the pump to lose efficiency. The speed with which

these parts will wear will depend on the material and concentration being pumped.

As noted in the “Operation Section”, the suction and discharge pressure, as well as the

flow and AMP draw should have been recorded in the “Notes” of the Technical Data

Sheet located in Section 1.0 of this manual.

By comparing the original data with your current readings, the wear and efficiency of

your pump can easily be determined.

The output flow and pressure dropping off with an increase in amperage draw on the

motor signals wear of the wet end components requiring adjustment.

After the pump has been adjusted several times, the wet end parts should be visually

inspected.

This manual suits for next models

1

Table of contents

Other Toyo Water Pump manuals

Popular Water Pump manuals by other brands

DROPSA

DROPSA 0400605 User and maintenance manual

Clarke

Clarke ISP11A Operating and maintenance instructions

Grouw!

Grouw! 18043 instruction manual

Calpeda

Calpeda NC Original operating instructions

Groeneveld

Groeneveld BEKA-ONE Original operating and assembly manual

Kremlin-Rexson

Kremlin-Rexson AIRMIX 20-50 FT Original manual