Toyo DP 6 30-40HP Series User manual

TOYOPUMPS EUROPE Edition 27.07.2007

USERSMANUAL

Heavydutyslurrypumps

TOYOPUMPS EUROPE Edition 03.11.2009

SAFETYINSTRUCTIONS

TOYOPUMPS EUROPE Edition 03.11.2009

Usersmanual

forToyo pumps

type«DP..-630~40HP»

Thisusersmanualwillhelpyou to

maintainyourToyopumpinoptimum

working condition foralongtime.

Pleaseread carefullybeforeusing the

pumpand keep forfuturereference.

Takenoteof the serialnumberwhich

you can findon theidentification plate

of yourpump.

The manufacturerreservestherighttomodify

specificationsandconcept of theseproducts

without previousnotice.

Edition 27.04.2007

TOYO PUMPS EUROPE

ParcIndustrielSud –Zone II

Rue de l’Industrie, 41–1400Nivelles–Belgique

Tel.: (32)67.64.55.37

Fax. : (32)67.64.55.31

E-mail : info@toyopumpseurope.com

Website: www.toyopumpseurope.com

TOYOPUMPS EUROPE Edition 03.11.2009

CONTENTS

Introduction 1

Precautionsbeforeoperating 1

Noteson driving 2

Maintenanceandtroubleshooting 3

Pointstobe attentive4

Troubleshootinglist5

Disassembling procedures7

Assemblingprocedures9

Technicalspecifications11

Pumpperformancecurve 12

Dimensions 13

Sparepartslist 14

Exploded viewdrawings19

TOYOPUMPS EUROPE Edition 03.11.2009-1-

INTRODUCTION

Awrong utilisationandaninadequatemanipulationofthe pumpwill causeunsatisfactory

performancesand earlytroubles.Therefore,pleaseread thisinstructionmanualcarefully

beforeoperating.

PRECAUTIONSBEFOREOPERATING

1.Powersupply

Check the powersupplyvoltage andfrequency byreferring tothe identification plateon

the pump.

Operationofthepumpon adifferentpowervoltage fromthe specifiedvoltagewillcause

impossibilityof pumping up andmotorburning.

2. Grounding

Makesuretoconnectthepumpcorrectlytothe earth.The earth-cableisthe greenand

yellowcolouredone.

3. Rotationdirection

Astothe rotatingdirection,counterclockwiserotation viewing fromthe suctionintakeside

(lowerside ofthe pump)isthe correctwayofrotating.The rotation direction ismentioned

on the identification plateofthe pump.

Afterconnecting the pump,letitturnoutoftheliquidtobepumped foraninstant, inorder

tocheck the direction ofthe motorbyobserving the agitator.Attention,theagitatorcould

detachitself when turning inoppositedirection.

You onlyneedtoinverttwoofthe threealimentation wireswhenevertheelectricmotor

turnsinthewrong direction.

Rotation withoutbeingsubmerged foralongerperiodoftimecausesdamagestothe

seals.

The rotating direction of theagitatorcan be verifiedinstantaneously.

Neverdrivethe pumpinoppositedirection, asthiscausesearlydamagestothe pump.

4. Protectionofelectricmotor

Inanycase,itisnecessarytoprotectthepumpwithacorrectlycalibrated thermal

protectiontoavoidanyoverload and toinstallastart-stop switch.

Pumpsgoing up from15 HPand morewillhavetobe setup withareactorstarterbox.

The supplierofthe pumpcan adviseyouthe adequatematerial.

TOYOPUMPS EUROPE Edition 03.11.2009-2-

5. Cabtyrecable

a)The useofacabtyrecablewhichhasan inferiorsection orasuperiorlengththen

recommended can makethe starting up ofthepumpimpossibleand provokedamages

tothe motor.

Concerning thecharacteristics ofthe cabletouse,pleaserefertothe technical

characteristics of thepump.

b)Toavoidtearingoutthecable,makesurethatthe lengthofthe alimentationcable

correspondstothe depthat whichthe pumpwillhavetowork.

Whenlengtheningthecable,whichisfixed tothe pumpwithasecond cable,you

shouldmakesurenot tosubmerge theirconnection.

6. Dischargehose

The diameterofthe discharge hosefixed tothe pumphastobe adapted tothe

diameterofthe hosenippleofthepump.Thedischargehosewillpreferablybe fixed

withhalf-circularcollars.

NOTES ONDRIVING

a)Foryoursafety,nevertouchthe agitatorwhenthe pumpisconnected,andneverpass

underneaththepumpwhileitissuspended.

b)When the pumpisinduty, it hastobe immersed untilthe levelindicated on the schema

representing the dimensionsofthe pump.

c)If possible,avoidusing the pumpinconditionsthatprovokean overload.

See inparticulartoimmersethe pumpprogressivelyuntilthe materialtopumpis

reached.

d)Inspectthe good working condition ofthe pumpbysecuring thatthe intensityofthe

currentdoesnot exceed the value indicated onthe identification plateof the pump.

e)Avoidsuspendingthepump(verticalmodels)insuchwaythat itmightget buriedatthe

bottom.

f)Oncethelevelofthepumped liquidbecomesinsufficient, noisy functioning and

abnormalweararegenerated. Inthiscase, add liquidorstop the pumpand wait forthe

liquidtorise.

g)Despitetheeffectofthe agitator,oversized materials,suchaspiecesofwood,etc.

havethe propensitytopresentthemselvesatthe entranceofthe pump.Thereforethe

pumphastobe equippedwithironbarspermitting objectsofthe samedimensionas

the holesof the strainer. Consult yoursupplier.

TOYOPUMPS EUROPE Edition 03.11.2009-3-

h)The densityofthe pumped liquidcan beverified byraising ordescending thepump.A

toheavy densitycan provokethe blockage ofthe discharge hoseand ofthe pumpand

makepumping impossible. Heavy densitieshavetobe avoided.

i)Useasufficientresistantchain,whichwillbeattached tothe lifting eyesprovided on

the pumpfortransporting orhandling thepump.The anglebetween the twopartsof

the chainmaynot overshoot 60degrees.

j)Neversuspend the pumpbyitsalimentationcable.

k)Rinsethe pumpand the dischargehosewithcleanwaterbeforeturning it off.

MAINTENANCEAND TROUBLESHOOTING

a)Measureperiodicallythe voltageofthe alimentationcurrenttoverifythatthe pump

works at the correct voltage.

b)The insulation resistanceofthe motorhastobe verified atleastonceamonth.If the

resistanceof the motorisinferiorto100MOhm, the winding of the electricmotorhasto

be dried and thetightness of the cableschecked, etc.

c)The oilcapacityinthe undercoverhastobeverified every500 hours. Therefore,place

the pumphorizontally(verticalpumps).If needed,addoilasspecifiedinthe tableof

technicalcharacteristics ofthe pump(normalorbiodegrading)through theopening

provided tothisend.

d)If the presenceofwaterinthe oilisestablished(whitishemulsion),orifthe oilcontains

solidparticles(mud,etc.),itmeansthatthe sealsaredefective.Theirreplacementis

then required.

e)The quantityofoilinthe undercoverofthe pumpisspecified inthe technical

specificationsofthe pump.

f)If the flowofthe pumpisdiminishing,the spacebetween the impellerdisc and the

impellerhastobe checked.The recommended spaceisindicatedinthe technical

specificationsofthe pump.

TOYOPUMPS EUROPE Edition 03.11.2009-4-

POINTSTO BE ATTENTIVE

a)The maximumliquidtemperatureforthestandardversionsis60 °C.

b)Avoidthatpumped materials(ex.mud,…)arestickedon the motorpartofthe pump.

Thiscan provokean abnormalheatingof themotor. Clean thepumpif thisoccurs.

c)If airoccursinthedischarge hose,ithappensthattheliquidcannotbepumped any

more.Inthatcase,verifyifthedischarge hoseisplacedashorizontalaspossible(ex.

avoidtolarge spacebetween the floaters).

TOYOPUMPS EUROPE Edition 03.11.2009-5-

TROUBLESHOOTING LIST

Thepumpisindutybutdoesn’tturnevenas theswitchisin“ON”position.

•Thepumpemitsnosound:

-Electricalimentationproblem:

àVerifyif the networkisundertension and/orthegeneratorworks properly.

-Defectiveconnection orbreakdownof one of the alimentation wires:

àVerifyall connectionsand check thestateof the wires.

-Alimentation throwone singlephase:

àVerifythe connectionsand fuses.

•Thepumpemitsasound :

-Aforeign bodyblocs theagitatororisjammedbetween impellerand impellerdisc :

àRemovetheforeign body.

-The impellerdisc isblocked against theimpeller:

àAdjustthe spacebetween thetwopartsasindicated inthe technical

characteristics.

-Abearing isbroken :

àReplacethe bearing.

-Wirebreakdowninone of the wiresinsidethe windingof thestator:

àConsult yoursupplier.

-The statorisburned:

àConsult yoursupplier.

Thepumpturnswhentheswitchisin“ON”positionbut…

•Thepumpemitsanabnormal sound:

-Aforeign bodyblocs theagitatororisjammedbetween impellerand impellerdisc :

àRemovetheforeign body.

-The impellerdisc isincontact withthe impeller:

àAdjustthe spacebetween thetwopartsasindicated inthe technical

characteristics.

-Defectivebearing :

àReplacethe bearing.

TOYOPUMPS EUROPE Edition 03.11.2009-6-

•Theflowofthepumpistoweak:

-The pumpturnsinthe oppositedirection :

àInversetwoof thethree alimentation phases.

-The levelof the pumped liquidisinsufficient :

àAdd tothe level.

-Obstruction at theentranceofthe pumporat the discharge hose:

àVerifyand clean up.

-Airinthe discharge hose:

àPlacethe hoseashorizontalaspossible.

-Wearof theimpellerand the impellerdisc :

àAdjustthe spacebetween thetwopartsasindicated inthe technical

characteristics.

-The pumpprovided toworkin60 Hzisfurnished in50 Hz:

àConsult yoursupplier.

-Insufficient discharge pressure:

àConsult yoursupplier.

•Thethermal protection disconnects:

-The densityof thepumped liquidistoimportant :

àLowerthedensitybylifting the pumpand/orbydiluing the pumped materials.

-Important voltage drop :

àReplacethe alimentation cablebyacablewithcorrectsection and lengthas

indicated inthe technicalspecification of the pump.

-The impellerdisc isincontact withthe impeller:

àAdjustthe spacebetween thetwopartsasindicated inthe technical

characteristics.

-One of thephasesismissing :

àCompleteinspection outofthe liquidofthe electriccircuitgoing fromthe

sourceuntill the electricmotor.

-The pumpprovided toworkin50 Hzisfurnished in60 Hz:

àConsult yoursupplier.

-The electricmotorisburned:

àConsult yoursupplier.

TOYOPUMPS EUROPE Edition 03.11.2009-7-

DISASSEMBLING PROCEDURES

Chooseadryandcleanplacetodismantleand reassembleyourpumpand installabase

on whichyou can putthe pump.It isalsowisetoprepareafewsmall boxesinwhichyou

can put thesmall partsdismantledfromthe pump. Preparealsosomerags, oiland tools.

The numbersmentioned between parenthesisesinthe descriptioncorrespond totheparts

numbersinthe sparepartslist.

1.Disassemblingoftheelectriccable

a)Unscrewthe cap nuts(1C)en removethe leadcover(8).

b)Disconnectthe electriccable(7A)oftheterminalboard(99A)andremovethe packing

(2).

c)Incaseyou wanttodismantlethe motorcase(28),you need,atthisstage,alsoto

disconnect fromthe terminalboard(99A)the wirescoming out fromthe electricmotor.

d)If you wishtoreplacethe electriccable(7A), unscrewthe cap nuts(106C)and release

the packinggland (3)withthe cableprotectiontube (6), the packing set ring (5)andthe

packings(4).

2. Disassemblingofthepumpsection

a)Placethe pumphorizontallyandfixitinsuchwaythatitcannotmoveduringthe

disassembling procedure.

b)The cutterfan(81)isscrewed (normalrightthread)on theshaft(29).Todismantlethe

cutterfan,hititwithamalletorhammer,byinterposingabronzeoraluminiumjig,on

one ofthe cornersofthe cutterfan.Unscrewit incounterclockwisedirection,thepump

seen frombeneath(aspiration side).

c)Unscrewthe set bolts(79A)andremovethe strainer(80).

d)Unscrewthe cap nuts(69C)andremovethe suction cover(74)togetherwiththe

impellerdisc (73)withthe adjustbolts(69D).Removethe packing(77)andclean

carefullyitslocation inthevortexcasing.

e)Separatethe suction cover(74)fromthe impellerdisc (73)byunscrewing thecapnuts

(76C)usingthe adjust bolts(85).

f)Unscrewthe impellernuts(83). Removethe impellercollar(82), theimpeller(72).

g)Unscrewthe cap nuts(69C)and removethe vortexcasing(56).Takecarenotto

damage the threatof the shaft (29). Removethe packing (68)and the key(55).

h)Unscrewthe cap nuts(67C)and removethe deliverycover(71).Takecarenotto

damage the threatof the stud bolts(67A).

TOYOPUMPS EUROPE Edition 03.11.2009-8-

3. Disassemblingoftheshaft sealedsection

a)Unscrewthe setbolts(21)and removethe oil inletcovers(66)fromthe opening inthe

undercover(37). Collect the lubricationoilinarecipient.Removethe packings(65).

b)Unscrewthe bolts(35A)and removethe oilsealhousing B(61)usingthe adjustbolts

(35C). Removethe packing(62).

c)Removethe distancesleeve(54)and the O Ring (53).Removethe shaft sleeveB(51)

and the bearinglock plateB(48).

d)Unscrewthe setbolts(64A)and pullouttheoilchambercover(60)withtheadjust

bolts(64C). Removethe packing (63).

e)Fortaking outthe bearing (47),unscrewthe setbolts(59A),removethe bearingset

plate(46), andthenextract the bearingbypressure.

f)Removethe bearingsleeve(45)andunscrewthe setbolts(35A)toextracttheoil seal

housing A(58). Removethe packing (57).

g)Removethe O Ring (40)and theshaft sleeveA(44).

h)Removethe oilseals(41)(49),the Rareflon seals(43)(52)and the spacerings(42)(50)

fromthe housings(58)(61).

4. Disassemblingofthemotorsection

a)Set up the pumpup side down, posed on the uppercover.

b)Unscrewthe bottomcap nuts(32C)of the motorcase(28).

c)Liftup the undercover(37)rotor(30)and shaft (29)assemblyusing alifting device.

Separatethemfromthe motorcase(28)withhelpof theadjust bolts(32D).

d)Unscrewthe set bolts(35A)ofthe bearing cover(34).

e)Separateshaft (29)and rotor(30)fromthe undercover(37)usingalifting device.

f)Laydownthe shaft (29)withrotor(30)horizontallyandpulloutthe bearings(38)(39)

and the internalbushofthe bearing(23)withhelpof anappropriated extractor.

g)The wirescoming out ofthe statorhastobepreliminarydisconnected of the terminal

boardof the pump(see 1c)andthen unscrewthe uppercap nuts(32C)ofthe motor

case(28). Separatethemotorcase(28)withstator(31)fromthe uppercover(16)of

the pump. Removethe packing (19).

h)If necessary, pullout the bearingcoverA(26)and the externalbushof the bearing(23)

fromthe uppercover(16).

TOYOPUMPS EUROPE Edition 03.11.2009-9-

The disassembling of the pumpisnowfinished. Takecaretoclean allpartsbefore

reassemblingthem.

ASSEMBLING PROCEDURES

Toreassemblethepump,itissufficienttofollowthe disassemblingproceduresinopposite

direction. Pleasefind herebelowthe specificassembling instructions.

1. Bearings

a)The bearingsmaybe mounted bypression exerted on the internalring ofthebearing

bythe instrumentalityofajig.Donotforgettogreasethe shaft and the internalring of

the bearing beforemounting.

b)Nevertheless,itisrecommended toheatthebearingsbeforemounting.Inthiscase,

heatupthebearingsbyinductionorinoilatmaximum120°Cand slidethemon the

shaft. Afterwards,letthe bearingscooldownbyair.

c)Useonlygreaseforbearing lubrication orlithiumgrease.

2.Sealsinundercover

a)Verifythe condition oftheshaftsleevesAand B(44)(51)and theoilsealhousingA

and B(58)(61)beforebeginning theassemblyofthe pump.Replacethe shaft sleeves

if the surfaceisused, grooved, oreven showing the basemetal. Theirsurfaceneedsto

be rigorouslysmoothtoassurethe tightness.All sealsintothe undercoverhavetobe

replaced.

b)Attention,the sealshavetobe mounted sothatthe opening ofthe sealisshowing the

bottomof the oilsealhousing(impellerside).

The oilsealswillbe completelyfilled up withwater-resistantgreasebeforemounting

intothe oilsealhousing.

Putthe oil andRareflonsealsintothe oil sealhousing(58)-(61),andthisinthe same

orderasshownon the exploded view.Forthis,useahammerand ajig(schema1).

Neveruseahydraulicsystem.Proceed withcarebyexercising themostuniform

pressureaspossible.Adeformed sealloosesitsefficiency.Notraceof paintat allmay

be foundon theoilseal.

TOYOPUMPS EUROPE Edition 03.11.2009-10-

3.Otherseals

Renewallsealsafterdisassembling.

4. Clearance betweenimpellerandimpellerdisc

Unscrewthe cap nuts(76C).Pushthe impellerdisc (73)againstthe impeller(72)withthe

adjustbolts(85).Unscrewthe adjustbolts(85)withhalfaturn.Fasten thecap nuts(76C)

and the adjustbolts(85).Measuretheclearancebetween the impellerdisc and the

impeller.Thisclearancehastobe between 1.0and 1.5mm.Verifythe clearancewitha

gauge.Turntheshaftofthe pumpbyhand.Nofrictionisadmitted atall.Ifnecessary,

repeat the operation.

5. Electricconnection

Connect thepumpasshownon the drawingherebelow.

N.B. : Donotforgettofillup the undercoverwithoil.Therefore,usethe opening intothe

undercover. Type and oilquantityismentioned inthe technicalspecificationssheet

of the pump.

Table of contents

Other Toyo Water Pump manuals

Popular Water Pump manuals by other brands

Wilo

Wilo WCC17-20.50 Installation and operating instructions

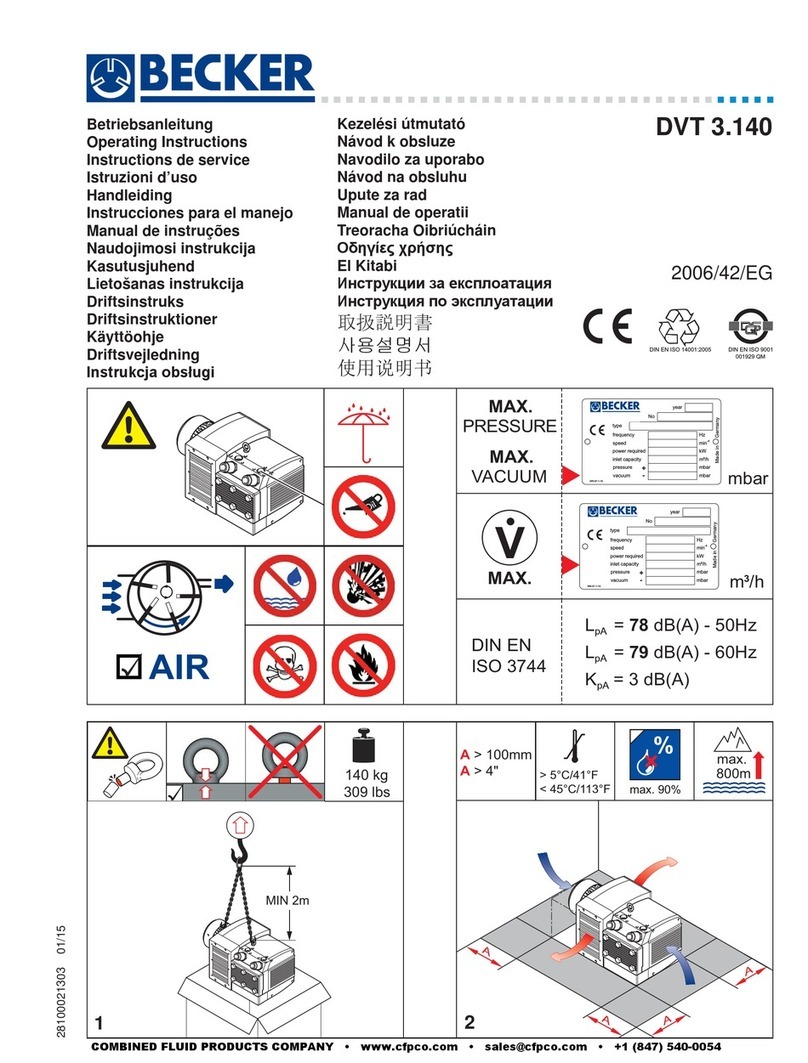

Becker

Becker VT 4.2 operating instructions

Liberty Pumps

Liberty Pumps Builder S30 Series installation manual

Becker

Becker dvt 3.140 operating instructions

Pentair

Pentair AURORA 654A Instruction and repair manual

BUSCH

BUSCH MINK MV 0500 B manual