Tra TRBC60 User manual

09/23

Heavy Duty Brush Cutter

TRBC60, TRBC72

Operator’s Manual

Revision Notes

Date

2

TRBC Heavy Duty Brush Cutter

Page left blank intentionally

3

TRBC Heavy Duty Brush Cutter

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Tar River dealer. Read manual

instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the

Owner’s/Operator’s Manual are completed before releasing equipment to the owner.

TO THE OWNER:

Read this manual before operating your Tar River equipment. The information presented will prepare you to

do a better and safer job. Keep this manual handy for ready reference. Require all operators to read this manual

carefully and become acquainted with all the adjustment and operating procedures before attempting to

operate. Replacement manuals can be obtained from your selling dealer. The equipment you have purchased

has been carefully engineered and manufactured to provide dependable and satisfactory use. Like all

mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified. Observe all safety

information in this manual and safety decals on the equipment. For service, your authorized Tar River dealer

has trained mechanics, genuine Tar River service parts, and the necessary tools and equipment to handle all

your needs. Use only genuine Tar River service parts. Substitute parts will void the warranty and may not meet

standards required for safe and satisfactory operation.

Record your implement model and serial number in the space provide below. Your dealer will need this

information to give you prompt, efficient service.

Model Number: ______________________________________

Serial Number: _______________________________________

Date Purchased: ______________________________________

4

TRBC Heavy Duty Brush Cutter

Introduction …………………………………………………………………………………………….. 5

Technical Specifications ……………………………………………………………………………….. 5

Safety …………………………………………………………………………………………………… 6

Safety Signal Words ……………………………………………………………………………………. 6

General Safety Guidelines ……………………………………………………………………………… 7

Safety Decal Care ………………………………………………………………………………………. 7

Before Operation ……………………………………………………………………………………….. 8

During Operation ……………………………………………………………………………………….. 9-12

Highway And Transport Operations …………………………………………………………………… 13-14

Operating Instructions…………………………………………………………………………………... 15-17

Maintenance…………………………………………………………………………………………….. 18

Knife Replacement..…………………………………………………………………………………….. 19

Technical Data and Operational Characterisics………………………………………………………… 20-21

Torque Specifications ………………………………………………………………………………….. 22

Parts Breakdown ……………………………………………………………………………………….. 23-37

Warranty ………………………………………………………………………………………………... 38

Table of Contents

5

TRBC Heavy Duty Brush Cutter

Thank you for purchasing your TRBC Heavy Duty Brush Cutter. The TRBC Heavy Duty Brush Cutter is built

for those demanding jobs and built heavy to withstand years of hard work.

Technical Specifications

• Low-flow cutter (16/25)

• Open faced, heavy duty deck

• 6” Cutting capacity

• Hydraulic direct drives & internal relief valve

• Bi-directional cutting

• Extreme blade pan that is extra large to maintain force & momentum

• 3 cutting blades

• Units come standard with flat faced couplers & hoses

• Standard universal Skid Steer Mount

TRBC60 TRBC72

Weight 1,074 lbs. 1530 lbs.

Mount Universal Skid Steer Universal Skid Steer

Cutting width 60” 72”

Number of blades 33

Flow 14-20 gpm 14-20 gpm

Cutting capacity 4” 5”

Introduction

6

TRBC Heavy Duty Brush Cutter

Safety

It is important that you read the entire manual and to become familiar with this product before you begin using

it. This product is designed for certain applications only. The manufacturer cannot be responsible for issues

arising from modification. We strongly recommend this product not be modified and /or used for any

application other than that for which it is designed. If you have any questions relative to a particular

application, DO NOT use the product until you have first contacted us to determine if it can or should be

performed on the product.

Read and understand this manual and all safety signs before operating and maintaining . Review the safety

instructions and precautions annually.

Safety Signal Words

TAKE NOTE! This safety alert symbol found though out this manual is used to call you attention to

instructions involving you personal safety and the safety of others. Failure to follow these instructions

can result in injury or death.

This symbol means:

Attention!

Become alert!

Your safety is involved!

Note the use of the signal words, DANGER, WARNING and CAUTION with the safety

messages. The appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Important Safety Information

7

TRBC Heavy Duty Brush Cutter

General Safety Guidelines

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many accidents

occur which could have been avoided by a few seconds of thought and a more careful approach to handling

equipment. You, the operator, can avoid many accidents by observing the following precautions in this section.

To avoid personal injury, study the following precautions and insist those working with you, or for you, follow

them.

Replace any DANGER, WARNING, CAUTION or instruction safety decal that is not readable or is missing.

Location of such decals are indicated in this manual. Do not attempt to operate this equipment under the

influence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow

persons to operate or assemble this unit until they have read this manual and have developed a

thorough understanding of the safety precautions and of how it works.

To prevent injury of death, use a tractor equipped with a Roll Over Protection System (ROPS). Do not paint

over, remove or deface any signs or warning decals on your equipment. Observe all safety signs and practice

the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question,

Don’t try it!

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

• Replaced parts that displayed a safety sign should also display the current safety sign

• Safety signs are available from your Distributor or Dealer Parts Department or the factory.

Safety Decal Care

Important Safety Information

8

TRBC Heavy Duty Brush Cutter

How to install Safety Signs:

• Be sure that the installation area is clean and dry.

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the decal over the specified area and carefully press the small portion with the exposed sticky

backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of decal backing paper.

• Carefully study and understand this manual.

• Do not wear loose-fitting clothing, which may catch in moving parts.

• Always wear protective clothing and substantial shoes.

• Assure that all tires are inflated evenly.

• Give the unit a visual inspection for any loose bolts, worn parts or cracked welds, and make necessary

repairs. Follow the maintenance safety instructions included with this manual.

• Be sure that there are no tools lying on or in the equipment.

• Do not use the unit until you are sure that the area is clear, especially of children and animals.

• Don’t hurry the learning process or take the unit for granted. Ease into it and become familiar with your

new equipment.

• Practice operation of your equipment and its attachments. Completely familiarize yourself and other

operators with its operation before using.

• Use a tractor equipped with a Roll Over Protection System (ROPS) and fasten your seat belt prior to

starting engine.

• The manufacturer does not recommend usage of tractor with ROPS removed.

• Move tractor wheels to the widest recommended settings to increase stability.

• Securely attach to towing unit. Use a high strength, appropriately sized hitch pin with a mechanical retainer

and attach safety chain.

• Do not allow anyone to stand between the tongue or hitch and the towing vehicle when backing up to the

equipment.

• Do not use the unit until you are sure that the area is clear, especially of children and animals.

Before Operation

Important Safety Information

9

TRBC Heavy Duty Brush Cutter

• Children should not be allowed on the machine.

• Clear the area of small children and bystanders before moving the machine.

• If using a towing unit, securely attach implement by using a hardened 3/4” pin, a metal retainer, and safety

chains if required. Shift towing unit to a lower gear before going down steep downgrades, thus using the

engine as a retarding force. Keep towing vehicle in gear at all times. Slow down for corners and rough

terrain.

• Make sure you are in compliance with all local and state regulations regarding transporting equipment on

public roads and highways. Lights and slow moving signs must be clean and visible by overtaking or

oncoming traffic when machine is transported.

• Beware of bystanders, particularly children! Always look around to make sure that it is safe to start the

engine of the towing vehicle or move the unit. This is particularly important with higher noise levels and

quiet cabs, as you may not hear people shouting.

• NO PASSENGERS ALLOWED! Do not carry passengers anywhere on, or in, the tractor or equipment,

except as required for operation.

• Keep hands and clothing clear of moving parts.

• Do not clean, lubricate or adjust your equipment while it is moving.

• When halting operation, even periodically, set the tractor or towing vehicle brakes, disengage the PTO,

shut off the engine and remove the ignition key.

• Be especially observant of the operating area and terrain. Watch for holes, rocks or hidden hazards. Always

inspect the area prior to operation.

• DO NOT operate near the edge of drop-offs or banks.

• DO NOT operate on steep slopes as overturns may result.

• Operate up and down (not across) intermediate slopes. Avoid sudden starts and stops.

• The brush cutter must be equipped with all protective guards (as provided by the manufacturer) against

access to moving parts. Guards must be complete and fully functional. Never operate the implement with

guards removed.

• When stepping on the brush cutter, be aware that the surface may be slippery. Place your feet only where

there are protrusions provided for this purpose, which are shown in the figure below.

During Operation

Important Safety Information

10

TRBC Heavy Duty Brush Cutter

• Your brush cutter discharges debris out the front of the machine. When cutting with the Brush Cutter,

NEVER discharge material toward bystanders. All bystanders must be AT LEAST 75 feet away when

operating the cutter. NEVER allow bystanders near the machine while in operation. When cutting near

bystanders is unavoidable, DO NOT operate the cutter without the front guard flap in place (if equipped

with guard flap).

• ALWAYS clear the cutting area of objects (bottles, rocks, fencing wire, etc.) that may be picked up and

thrown.

• ALWAYS use a shatterproof cab door or the 3/8” thick safety chain that came with your Brush Cutter

(optional) when cutting. The door is used not only to protect the operator from flying debris, but also from

overhanging or protruding objects (tree limbs, rebar, vines etc.) from entering the cab and operator injury.

Important Safety Information

Debris Discharge Warnings

11

TRBC Heavy Duty Brush Cutter

• ALWAYS disengage power to the Brush Cutter and shut the skid steer loader engine off prior to leaving

the operator's cab or performing any inspection or maintenance to either the brush cutter or the skid steer

loader.

• NEVER place hands or feet under the Brush Cutter deck or near the blade system while the unit is in

operation.

• NEVER articulate (roll) the deck downward to a degree that exposes the operator to the blade system.

• ALWAYS release the pressure on the hydraulic system of the cutter prior to removing the attachment from

the skid steer loader or working on any part of the hydraulic system. Hydraulic hoses and components

operate under extreme pressure and heat. A small stream of fluid from a pinhole leak in a hydraulic hose

can penetrate the skin and/or cause burns. Whenever hydraulic fluid is injected into the body, seek medical

attention at once to reduce chances of a dangerous infection. ALWAYS wash skin with soap and water

after contact with hydraulic fluid, as it is an irritant to skin and eyes.

• Your Brush Cutter has been designed to reduce the likelihood of hydraulic system leakage. Each and every

hydraulic system is checked prior to shipment. However, over time, any hydraulic system may develop

fluid leaks. Small leaks may produce high-pressure discharge flows capable of causing injury should skin

come in contact with such discharge.

• Leaking fluid can make the deck and ground surfaces very slippery, causing difficulty in using tools and

also increasing the possibility of slips and falls. ALWAYS wipe away all fluid that may have leaked during

maintenance.

• NEVER operate a Brush Cutter on a "high-flow" skid steer loader unless the cutter is equipped with a

"high-flow" motor. Motor failure can occur if such use is performed. Damage incurred to the hydraulic

motor due to "high - flow" usage is not covered. Please refer to the front cover of the manual for the

maximum allowable flow for your Brush Cutter.

•

Important Safety Information

Rotating Parts Warnings

Hydraulic System Warnings

12

TRBC Heavy Duty Brush Cutter

• Use the oil recommended by the manufacturer, it is forbidden to use the brushcutter when there is a

different type of hydraulic oil in the vehicle than in the machine.

•

•

•

Maintenance

•

•

•

•

•

•

•

•

•

•

-

•

Important Safety Information

13

TRBC Heavy Duty Brush Cutter

• Adopt safe driving practices.

• Keep the brake pedals latched together at all times. Never use independent braking with machine in tow

as loss of control and/or upset of unit can result.

• Always drive at a safe speed relative to local conditions and ensure that your speed is low enough for an

emergency stop to be safe and secure. Keep speed at a minimum.

• Reduce speed prior to turns to avoid the risk of overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in gear to provide engine braking when going downhill. Do not

coast.

• Do not drink and drive!

• Comply with state and local laws governing highway safety and movement of farm machinery on public

roads.

• Use approved accessory lighting, flags and necessary warning devices to protect operators of other vehicles

on the highway during daylight and nighttime transport. Various safety lights and devices are available

from your dealer.

• The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their

use. Local laws should be checked for all highway and marking requirements.

• When driving the tractor and equipment on the road or highway under 40 kph (20 mph) at night or during

the day, use the amber warning lights and a slow moving vehicle (SMV) identification emblem.

• Plan your route to avoid heavy traffic.

• Be a safe and courteous driver. Always yield to oncoming traffic in all situations, including narrow

bridges, intersections, etc.

• Be observant of bridge loading ratings. Do not cross bridges rated at lower than the gross weight at which

you are operating.

• Watch for obstructions overhead and to the side while transporting.

• Always operate in a position to provide maximum visibility at all times. Make allowances for increased

length and weight of the equipment when making turns, stopping the unit, etc.

• Pick the most level route when transporting across fields. Avoid the edges of ditches or gullies and steep

hillsides.

• Be extra careful when working in inclines.

Highway and Transport Operations

Important Safety Information

14

TRBC Heavy Duty Brush Cutter

• Maneuver the tractor or towing vehicle at safe speeds.

• Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury or death.

• Avoid loose fill, rocks and holes, they can be dangerous for equipment operation or movement.

• Allow for unit length when making turns,

• Operate the towing vehicle from the operator’s seat only.

• Never stand alongside of unit with engine running or attempt to start engine and/or operate machine while

standing alongside of unit.

• Never leave running equipment attachments unattended.

• As a precaution, always recheck the hardware on equipment following every 100 hours of operation.

Correct all problems. Follow the maintenance safety procedures.

Highway and Transport Operations

Important Safety Information

15

TRBC Heavy Duty Brush Cutter

Attaching the Brush Cutter

The installation of your Brush Cutter is the same for any other powered attachment for your skid steer loader:

1. Using the attached instructions, connect the Safety chain to skid steer prior to using Brush Cutter.

2. Pull up to the brush cutter and connect it to your skid steer loader.

3. Secure the lock down lever or levers.

4. Connect the hydraulic hoses from the brush cutter to your machine. The hoses provided are equipped with

quick- disconnect fittings (both male and female) for ease of use.

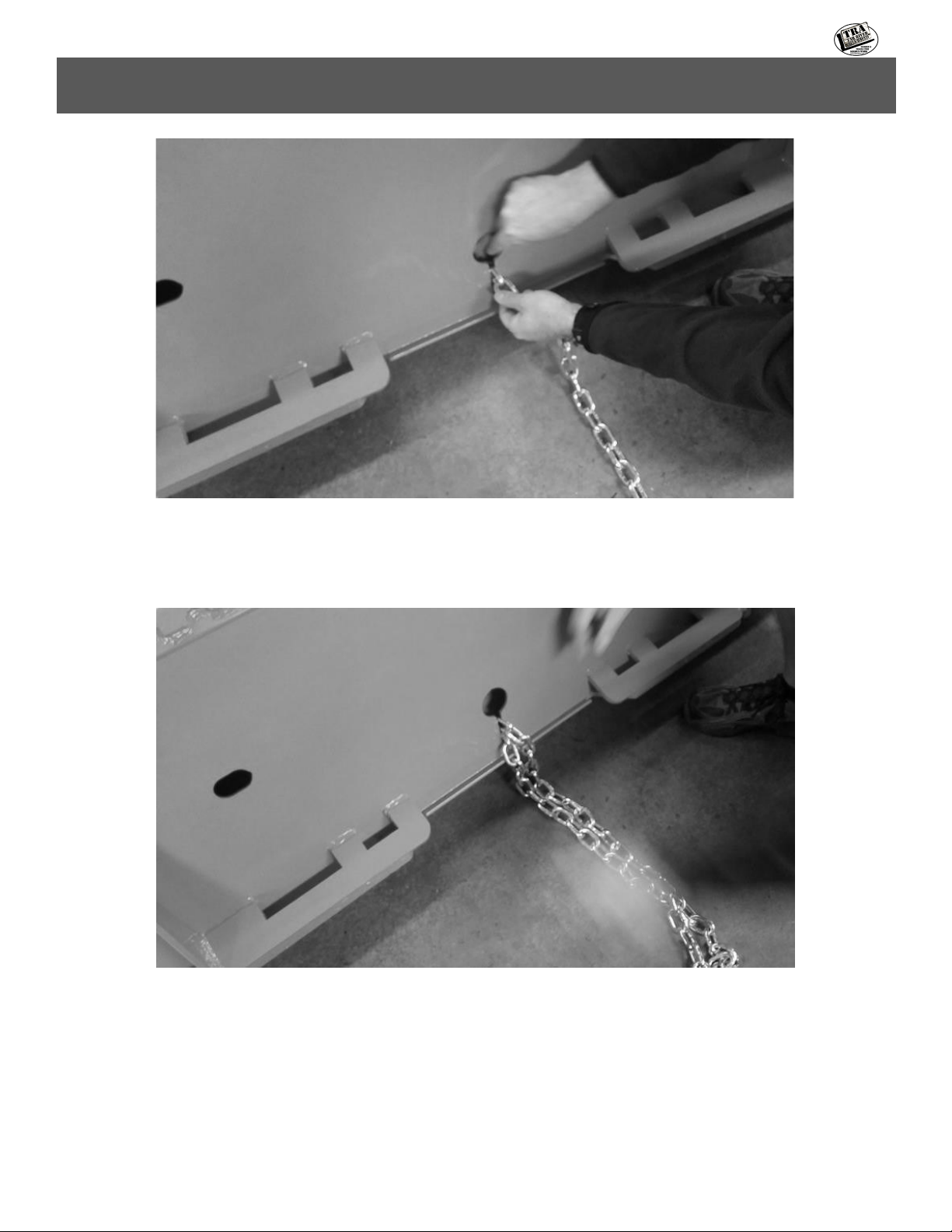

Step 1: Locate link hole at back of unit

Operating Instructions

16

TRBC Heavy Duty Brush Cutter

Step 2: Using one end of safety chain, drop number of desired links into link hole.

Once chain is in place check to ensure it is secure and cannot be pulled back through link hole.

Step 3: Take the loose end of the chain and secure it to the Brush Cutter.

Step 4: Pull chain back to Brush Cutter placing this end of the chain into the link hole. Make sure this end of

the chain is secure and cannot be pulled back through the link hole. After following these steps to ensure the

safety chain is properly connected. You may now proceed to connect skid steer to the Brush Cutter.

Operating Instructions

17

TRBC Heavy Duty Brush Cutter

Cutting Operation

The brush cutter is capable of, and in fact intended to be utilized for, mulching trees and other vegetation of

varying heights and diameters of up to 5” - 6”. As a safety feature, when cutting large diameter vegetation, the

Brush Cutter is equipped with a hydraulic motor cushion valve for shut down of the blade system. This feature

lessens the chance of damaging the cutter's hydraulic system or blade system when cutting larger diameter

vegetation. Directions for use are as follows:

Cutting Ground Level Vegetation

Raise the rear of the brush cutter approximately 4” - 5” above ground level. The deck of the brush cutter

should be sloping downward and away from the operator. This is the optimum position for cutting materials

that are close to the ground. Please note: If the operator can see the blade system in operation, the back of the

brush cutter is raised TOO HIGH!

Cutting Ground Level Vegetation

Raise the front deck of the brush cutter up approximately l’ - 2’ above ground level. Do not lift the rear portion

of the deck. Keep it approximately 4" -5" above ground level. Slowly drive into the vegetation and use the

hydraulic tilt (roll) to bend or push the vegetation over. As you bend the vegetation over and drive into it, the

blades will cut it into. The vegetation can now be mulched by rotating the front of the brush cutter and driving

forward several feet. Then roll the back of the cutter down and back-drag atop the vegetation.

Operating Instructions

18

TRBC Heavy Duty Brush Cutter

• Before each use and after 6 hours of operation of the brush cutter, check its technical condition, including

the condition of screw connections.

• It is forbidden for people to stay under the raised brush cutter, there is a risk of serious injury by being

crushed by structural elements.

• Do not use unfastened, hanging parts of work clothes during work, assembly, disassembly, adjustment.

Keep them away from structural elements that may catch them.

• Due to natural wear and tear, the condition of: bearings, screw connections, hydraulic system elements

should be checked

• Relieve residual oil pressure before working on the hydraulic system.

• Any modifications to the brush cutter release the manufacturer from any liability for any resulting damage

or injury.

• It is forbidden to carry out any work (maintenance, repair) under the lifted and unsecured machine.

• Comply with the general rules of industrial safety.

• Repair, maintenance and cleaning work should only be carried out with the ignition key removed from the

vehicle's ignition, the parking brake applied and secured against access by third parties.

• When replacing parts, use only original parts from the manufacturer, who is not responsible for the use of

non-original parts.

• For work requiring the brush cutter to be lifted, an approved mechanical or hydraulic lift should be used for

this purpose. When lifting the machine, additionally use stable and durable supports. It is forbidden to

work only under the suspension system of the carrying vehicle and to use supports made of fragile

elements (hollow bricks, bricks, concrete blocks, etc.).

Maintenance

19

TRBC Heavy Duty Brush Cutter

The condition of the knives should be checked before each use of the machine, and after 6 hours of labour.

Steps to follow when replacing knives:

1. Before replacing the blades, park the brush cutter on a level surface, turn off the engine in the vehicle,

secure the vehicle and the machine against sliding, make sure that the power supply to the brush cutter is

turned off, take care of your own safety when changing the blades. Use personal protective equipment such

as gloves, protective glasses.

2. Unscrew the M20 nut (No. 1 in the figure below)

3. Remove the M20 screw, washer and bushing holding the knife (No. 2,3,4)

4. Evaluate the condition of the knife bushing shown in number 3. If it is worn, it must be replaced.

5. Remove the worn knife (No.5)

6. Put on new: knife, bolt, nut. Reassemble everything in the reverse order using thread locker on the screw

connection.

7. Tighten the M20 nut with the appropriate torque in accordance with the “Torque Specification Chart” on

page 20 and minimum bolt class 8.8.

Knife Replacement

Failure to comply with the above rules may pose a risk to the operator and bystanders, and may lead

to damage to the brush cutter. The user is responsible for damages resulting from non-compliance

with these rules.

20

TRBC Heavy Duty Brush Cutter

TRBC-60

Main dimensions

Technical data and operational characteristics

Lp. Name Unit Parametre

1Type - Rotary

2Cung width [mm] 1500

3Power demand [kW] 20

4Number of work units [pcs.] 1

5Number of knives [pcs.] 3

6Cung height high [mm] 85

7Cung unit rpm [RPM] 500±50

8Max. work speed [km/h] 2-5

9Transport speed [km/h] 15

10 Max. system pressure [bar/MPa] 210/21

11 Oil ow [l/min] 75

12 Hydraulic sockets - Compable with ISO 7421-1

13 Oil type - SUPER UDT, API GL-4+

14 Mass [kg] 487

15 Length [A] [mm] 1795

16 Height [B] [mm] 635

17 Width [C] [mm] 1512

This manual suits for next models

1

Table of contents