3

Stop coasting

blade by contact

with cut material.

OPERATOR SAFETY

SDressproperly.Alwayswearsafetyglasses

or similar eye protectionwhen operating,or

performingmaintenance onyour unit (safe-

ty glasses are available). Eye protection

should be marked Z87.

SAlways wear face or dust mask if operation

is dusty.

SAlways wear heavy, long pants, long

sleeves, boots, and gloves. Wearingsafety

leg guards is recommended.

SAlways wear foot protection. Do not go

barefoot or wear sandals.

SSecure hair above shoulder length. Secure

or remove loose clothing and jewelry or

clothing with loosely hanging ties, straps,

tassels, etc. They can be caught in moving

parts.

SBeing fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning blade.

SStayalert.Donotoperateunitwhenyouare

tired,ill, upset or under influence ofalcohol,

drugs, or medication. Watch what you are

doing; use common sense.

SWear hearing protection.

SNeverstartorruntheengineinsideaclosed

room or building. Breathing exhaust fumes

can kill.

SKeep handles free of oil and fuel.

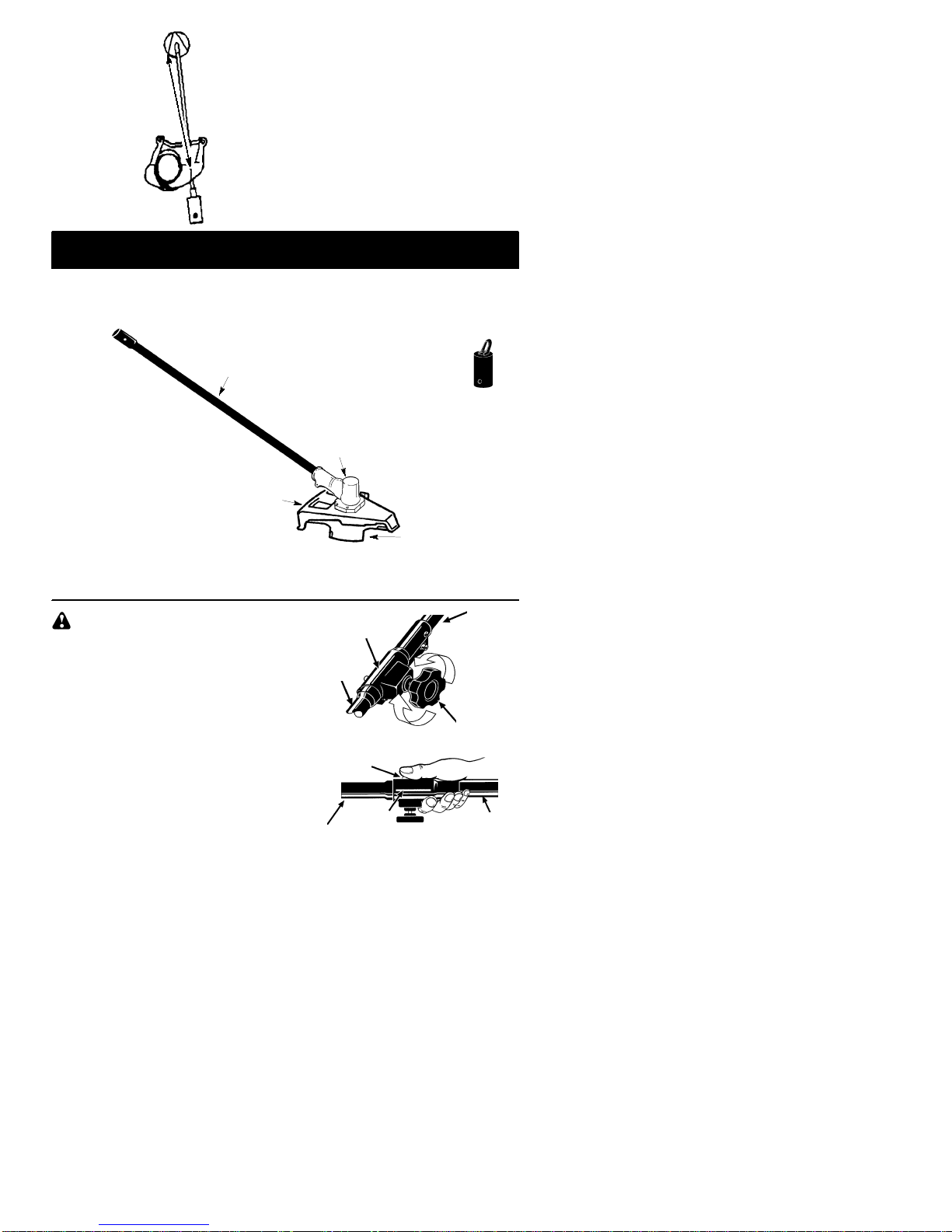

SAlways use the handlebar and a properly

adjusted shoulder strap when using brush-

cutter attachment (see ASSEMBLY).

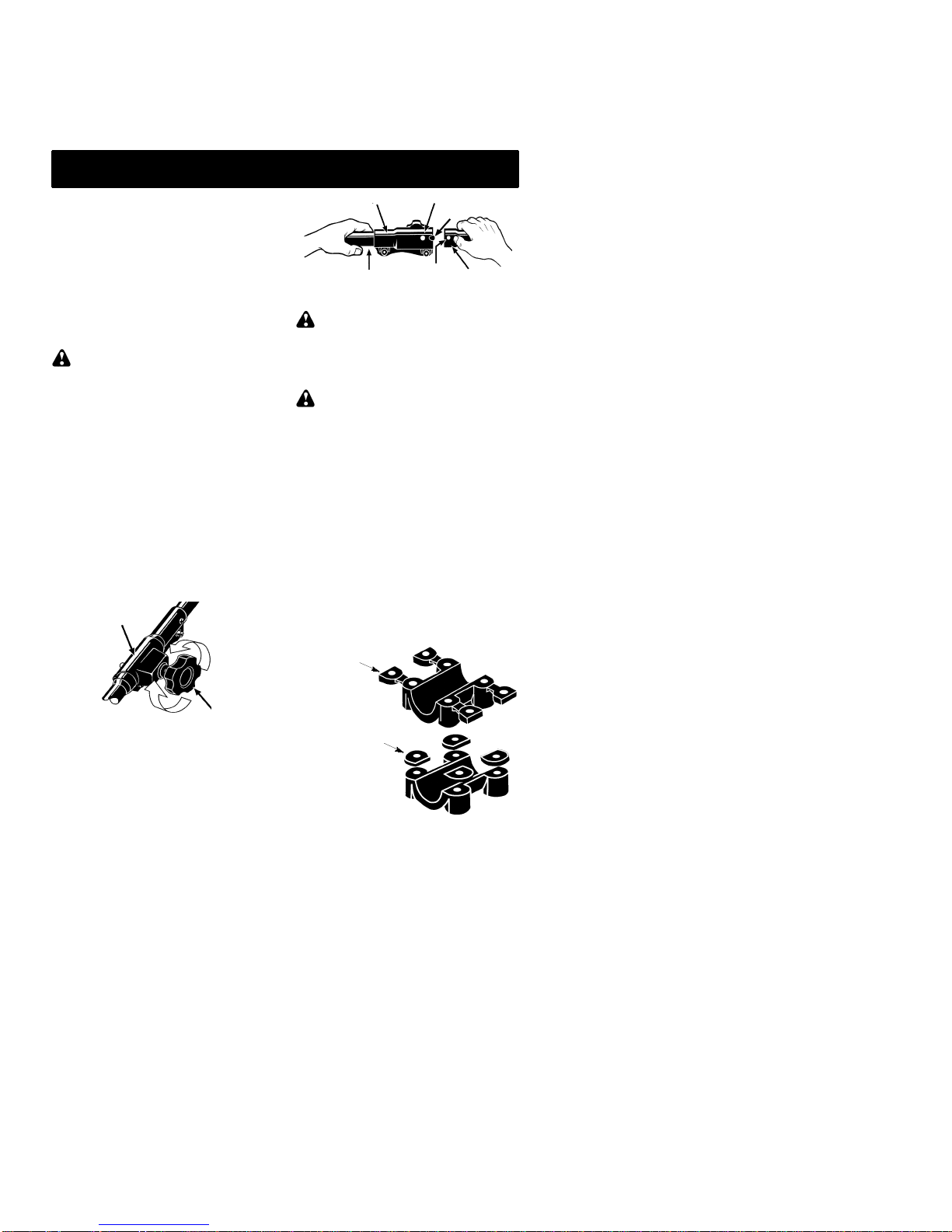

UNIT/MAINTENANCESAFETY

WARNING: Disconnect powerhead

spark plug (or disconnect powerhead from pow-

er source) before performing maintenance.

SLook for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep unit in good

working condition.

SThrow away blades that are bent, warped,

cracked, broken, or damaged in any other

way. Replace trimmer head parts that are

cracked, chipped, broken, or damaged in

any other way before using the unit.

SMaintain the unit according to recom-

mendedprocedures.Keepthebladesharp.

Never use flailing devices, wire, rope,

string, etc.

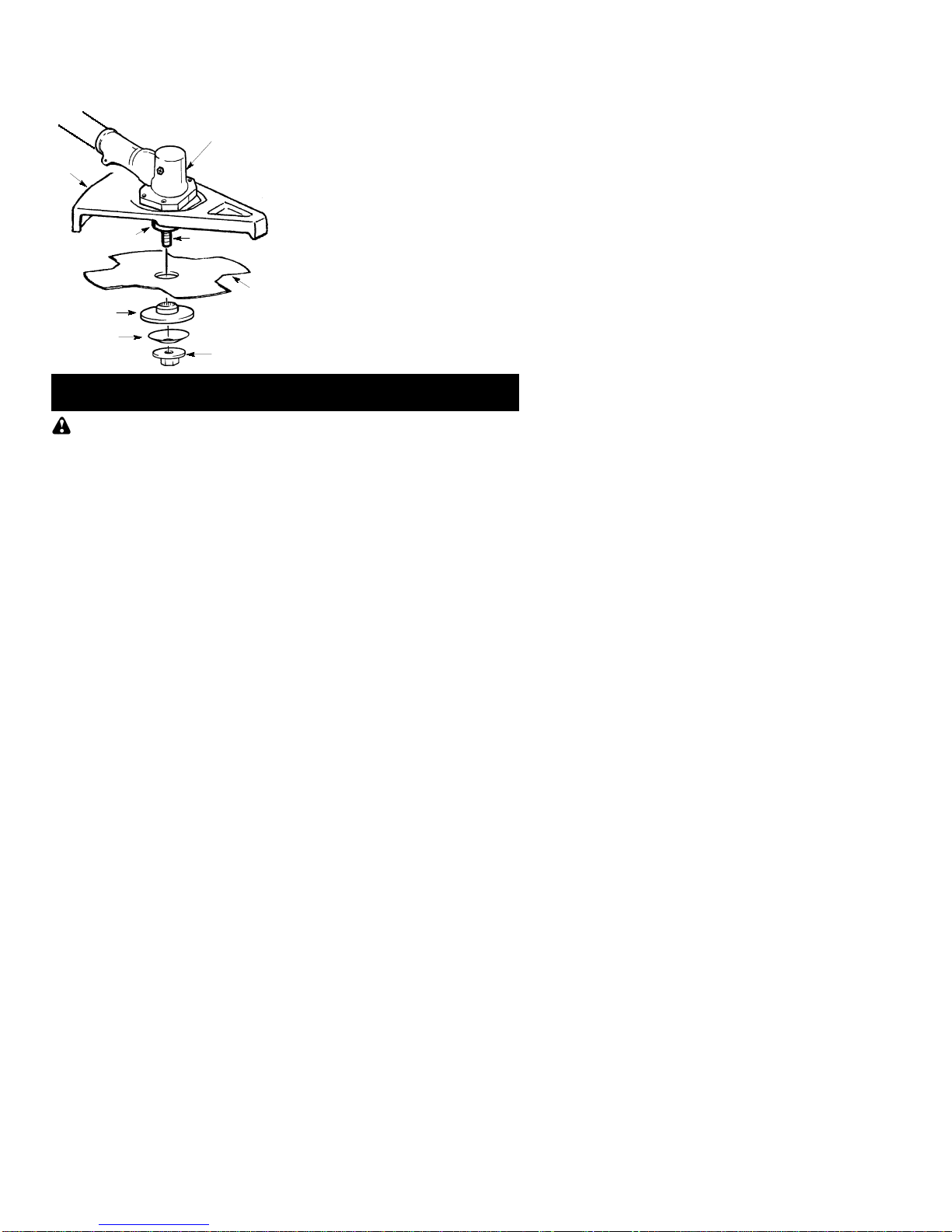

SUse only specified blade; make sure it is

properly installed and securely fastened.

SNever start engine with clutch shroud re-

moved. Theclutch can fly off and cause se-

rious injury.

SBe sure blade stops turning when engine

idles.

SMakecarburetoradjustmentswiththelower

end supported to prevent the blade from

contactinganyobject.Holdtheunitbyhand;

do not use the shoulder strap for support.

SKeep others away when making carburetor

adjustments.

SUse only recommended Poulan/Weed

Eater!accessories and replacement parts.

SHave all maintenance and service not ex-

plained in this manual performedby an au-

thorized service dealer.

FUEL SAFETY

SMix and pour fuel outdoors.

SKeep away from sparks or flames.

SUse a container approved for fuel.

SDo not smoke or allow smoking near fuel or

the unit or while using the unit.

SAvoid spilling fuel or oil. Wipe up all fuel

spills before starting engine.

SMove at least 10 feet (3 meters) away from fu-

eling site before starting engine.

SStop engine and allow it to cool before re-

moving fuel cap.

SRemove fuel cap slowly.

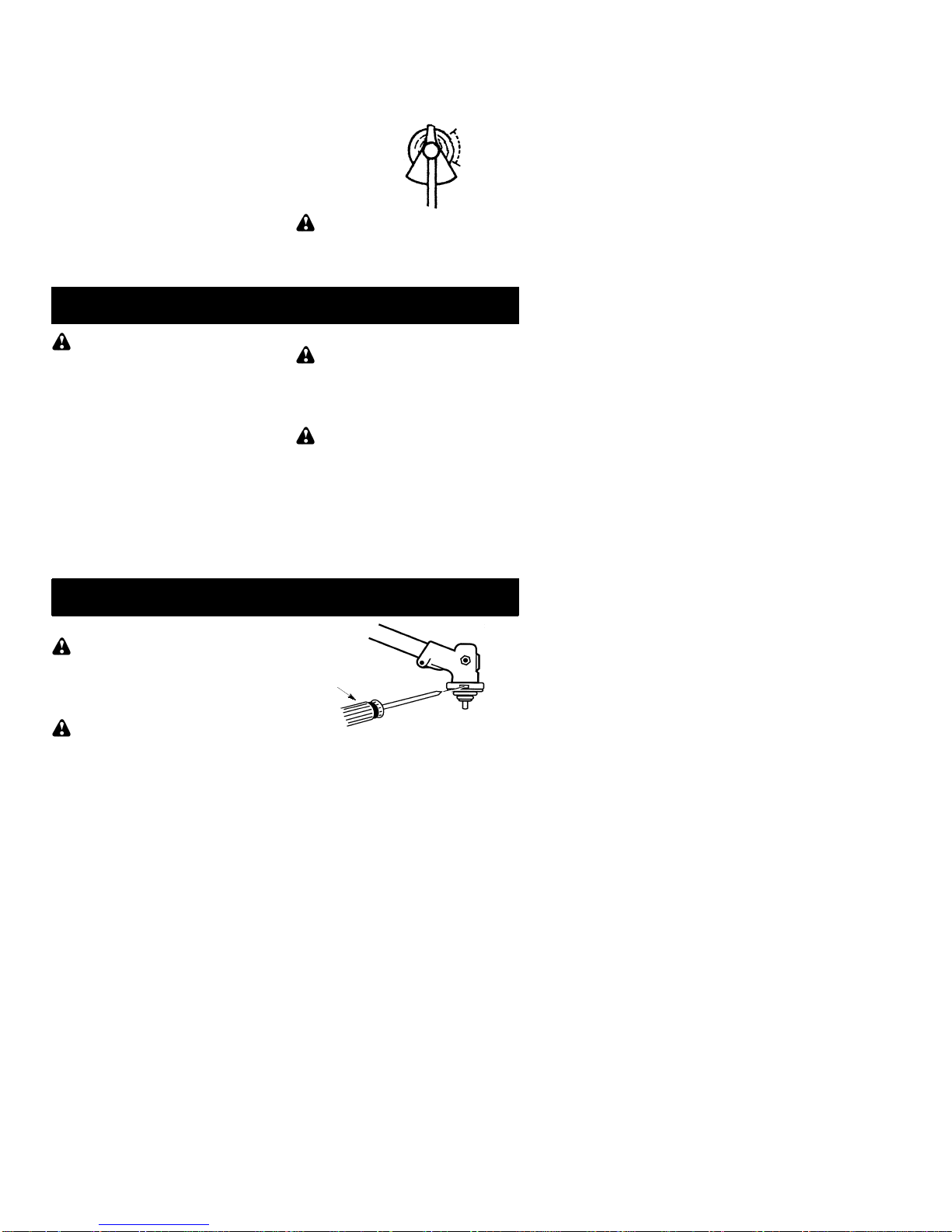

CUTTING SAFETY

WARNING:Inspect the areato be cut

beforeeachuse.Removeobjects(rocks,bro-

ken glass, nails, wire, string, etc.) which can

be thrown or become entangled in the blade.

SKeepothersincludingchildren,animals,by-

standers, and helpers at least 50 feet (15

meters) away. Stopthe engine immediately

if you are approached.

SAlways keep engine on theright--handside

of your body.

SHold the unit firmly with both hands.

SKeepfirm footingand balance. Donot over-

reach.

SKeep blade below waist level.

SDo not raise powerhead engine above your

waist.

SKeepall partsof your bodyaway fromblade

and muffler.

SCut from your left to your right. Cutting on

the right side of the shield will throw debris

away from the operator.

SUse only in daylight or good artificial light.

SUse only for jobs explained in this manual.

TRANSPORTINGAND STORAGE

SStopthe powerheadengine beforecarrying

unit.

SKeep muffler away from your body.

SAllow engine to cool andsecure unit before

storing or transporting it in a vehicle.

SEmpty the fuel tank before storing or trans-

portingtheunit.Use upfuel left in thecarbu-

retor by starting the engine andletting it run

until it stops.

SStoreunitand fuel in an areawhere fuelva-

pors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

SStore unit so the blade cannot accidentally

cause injury.

SStore unit indoors, out of reach of children.

If situations occur which are not covered in this

manual, use care and good judgment. If you

need assistance, call 1--800--554--6723.