Tracker PRO Series User manual

Information specifically for:

IL-TRACKER575S/1

V1.3

This manual contains important information.

Please read before operating fixture.

2

© 2005 Techni-Lux Inc.

3

IMPORTANT INFORMATION

Save original packing and documentation for warranty, service and return issues.

Limited Warranty: This warranty covers defects or malfunctions in this equipment. This warranty lasts

for a period of one year from date of purchase. It is the owner’s responsibility to provide invoices for

proof of purchase, purchase date and dealer or distributor. If purchase date can not be provided,

warranty period will start at manufacture date. It is the sole discretion of Techni-Lux to repair or replace

parts or equipment. All shipping will be paid by purchaser. This warranty does not cover lamps, fuses,

belts, power semiconductors, relays, cleaning, standard maintenance adjustments or normal wear items

or any problem resulting from the following: improper wiring, incorrect voltage (including low or over

voltage conditions and lightning), abuse, misuse, improper maintenance or an act of God or damage

resulting from shipping. Warranty will be null and void if the product is altered, modified, misused,

damaged, or subjected to unauthorized repairs. Lamps are covered by relevant manufacturer warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state. Any liability for consequential and incidental damages is expressly disclaimed. No other warranty,

expressed or implied is made. Techni-Lux liability in all events is limited to, and shall not exceed, the

purchase price paid.

Returning equipment and Repairs: All returns must be accompanied by a Return Merchandise

Authorization (RMA) number and sent pre-paid. Contact the dealer or Techni-Lux directly to obtain an

RMA. The RMA number must be clearly listed on the shipping label. Due care must be exercised in

packing all merchandise to be returned. All repairs must be accompanied by a written explanation of the

claimed problem or error encountered. Techni-Lux is solely responsible for determining a product’s

eligibility for coverage under warranty. If returning for consideration of credit, all accessories and

documentation, original protective material and cartons must be included and the equipment, packing

and carton must be in new resalable condition. Credit for returned merchandise will be issued at the

lowest current price and is subject to a restocking fee of 20%. No returns accepted on discontinued

items. Techni-Lux is not responsible for merchandise damaged in transit and reserves the right to refuse

any return that is damaged by the carrier, not accompanied by a Return Authorization Number (RMA#) or

sent by freight collect.

Claims: All claims must be made within seven (7) days of receipt of merchandise. Any physical

damage must be reported to carrier upon receipt of merchandise.

Please record the following information for future reference:

Model Number: IL-TRACKER575S/1

Serial Number: ________________________________________

Dealer: ______________________________________________

Date of Purchase: ______________________________________

www.Techni-Lux.com

10779 Satellite Boulevard

Orlando, FL 32837

U.S.A.

4

Table of Contents

Specifications .............................................................................................................................5

Fixture Overview.......................................................................................................................5

Physical.....................................................................................................................................5

Lamp Source.............................................................................................................................5

Environmental...........................................................................................................................6

Electrical ...................................................................................................................................6

Control ......................................................................................................................................6

Optics........................................................................................................................................6

Gobo / Color Size......................................................................................................................6

Rigging......................................................................................................................................6

Unit Parts.....................................................................................................................................7

Unpacking ...................................................................................................................................8

Power...........................................................................................................................................9

Voltage Selection......................................................................................................................9

Lamp..........................................................................................................................................10

Lamp Installation.....................................................................................................................10

Lamp Alignment......................................................................................................................11

Mounting ...................................................................................................................................11

Data Link DMX-512 ...................................................................................................................12

Data Terminator......................................................................................................................12

Adapter 5-to-3 pin ...................................................................................................................12

Control Panel Menu..................................................................................................................13

Start Address............................................................................................................................13

Example..................................................................................................................................13

DMX-512 Channels ...................................................................................................................14

CH 1-4 : Pan / Tilt Movement..................................................................................................14

CH 5 : Movement Speed Pan/Tilt..........................................................................................15

CH 6 : Control Reset/Lamp...................................................................................................15

CH 7 : Focus.........................................................................................................................15

CH 8 : Color Wheel 1............................................................................................................16

CH 9 : Color Wheel 2............................................................................................................17

CH 10 : Prism..........................................................................................................................17

CH 11 : Fixed Gobo Wheel.....................................................................................................18

CH 12 : Rotating Gobo Wheel.................................................................................................18

CH 12 : Rotating Gobo Wheel.................................................................................................19

CH 13 : Gobo Rotation & Index...............................................................................................19

CH 14 : Iris..............................................................................................................................20

CH 15 : Zoom..........................................................................................................................20

CH 16 : Shutter .......................................................................................................................20

CH 17 : Dimmer ......................................................................................................................20

Photometric Charts ..................................................................................................................21

Installing Gobos........................................................................................................................22

DMX-512 Background...............................................................................................................23

Maintenance..............................................................................................................................24

Troubleshooting .......................................................................................................................25

Wiring Diagram.........................................................................................................................26

Accessory Items.......................................................................................................................27

5

Specifications

Fixture Overview

•Pan range of movement: 530 degrees

•Tilt range of movement: 280 degrees

•High resolution 16 Bit Pan/Tilt movement for accurate positioning

•Pan/Tilt motor speed

•Consistent & auto correcting Pan/Tilt positioning

•Color wheel with 9 dichroic colors plus open

•Color wheel with continuous rotation for rainbow effect

•Additional color wheel with 9 dichroic colors plus open

•Remote lamp on and off

•Remote reset

•UV black light effect

•3-facet rotating prism, variable speed in both directions

•Static effect/gobo wheel with 9 gobos plus open

•Gobo wheel with 6 rotating, indexable and interchangeable gobos plus open

•Gobo wheel with continuous rotation

•Remote selection of stepped zoom degrees: 15°, 18°, 22°

•Motorized focus

•Motorized iris

•Variable shutter for strobing effects and quick blackouts

•Motorized dimmer from 0 to 100%

•Control via DMX512 using 3 pin In/Out XLRs

•Uses 17 Channels of DMX

•Digital display for DMX addressing and fixture settings

•Ventilation via forced air

•Anti-reflective coated glass optics

•High efficiency parabolic glass reflector

•Lamp: CSR575/2SE or MSR575/2

•Luminous output: 49,000 Lux

Physical

Color Black

Width 18 in (45.7cm)

Depth 18 in (45.7cm)

Height 27 in (68.6 cm)

Weight 91 lbs (41.3 kg)

Gross Weight 103 lbs (46.7 kg)

Lamp Source

Lamp Type 575w Metal Halide Discharge

Base GX9.5

Lamps GE - CSR575/2SE or Phillips - MSR575/2

Lamp Specs 575w, 1000 Hour, 7200°K Color Temp, 49000 Lumens

Ballast Type Magnetic

6

Environmental

Maximum ambient temperature 105°F (40°C)

Maximum exterior surface temperature 176°F (80°C)

Minimum distance to flammable surface 3.3ft (1m)

Minimum distance to illuminated surface 4ft (1.2m)

Electrical

Factory Setting 120v 60Hz

Selectable Voltages 100v / 115v / 208v / 220v @ 50 or 60Hz

Rated Power 850W, 7A @ 120v

Fuses 15A Time Delay (Slow) Size: ¼” x 1¼”

Control

Protocol USITT DMX512 (1990)

Channels 17

Pan / Tilt Resolution16 bit

Data I/O 3 Pin XLR (Cannon)

Modes Master / Slave / DMX

Optics

Reflector High efficiency Dichroic coated Parabolic

Lenses Anti-reflective coated

Zoom 15°, 18°, 22° Stepped, Selectable Focus Correction

Gobo / Color Size

Gobo Outside Diameter 1.06” (26.9mm)

Image Diameter 0.91” (23mm)

Thickness Max 0.138” (3.5mm)

Rigging

Position Floor or Truss mount

Orientation Any

Mounting Points 2

Clamp Orientation 0°, 90°, 180°, 270°

Safety Point Eye Bolt

7

Unit Parts

Front panel:

10 - Mode-button

11 - Enter-button

12 - Up-button

13- Down-button

14

- Display

Rear panel:

5 -Power switch

6 -DMX output

7- DMX input

8- Power cord

9- Fuse holder

1- Moving head

2- Yoke

3- Carry handles

4 - B a s e

8

Unpacking

Immediately upon receipt, carefully unpack and inspect the fixture to verify that all parts are

present and have been received in good condition. If any parts appear damaged from shipping

or the shipping carton shows signs of mishandling, retain all packing material for inspection and

notify the shipper immediately. Save all original packing and carton. In the event that the

merchandise is to be returned, the original carton and packing must be used. The customer will

be billed for a new carton and packing if merchandise is received without the original carton and

packing. The plastic bag shipped with the fixture can be used to keep the fixture clean if stored

or installed in a temporarily dusty environment. Do not operate fixture with plastic bag in place.

Save Shipping Materials

The packing and carton are designed to provide the fixture with protection during

shipping. Save original packing and documentation for warranty, service and return

issues. Additional charges will be applied to return items not received in original or

incomplete packing.

Claims

Physical damage must be reported to the Freight Carrier or Shipping Company upon

receipt of merchandise. Damage incurred in shipping is the responsibility of the Freight

Carrier or Shipping Company. It is the customer's obligation in the event that

merchandise is received damaged caused by shipping to notify the Freight Carrier or

Shipping Company immediately. All other claims not related to damage incurred during

shipping must be made to the Dealer or Distributor within 7 (seven) days of receiving

merchandise.

Returns

Returned merchandise must be sent prepaid, in the original packing with a Return

Merchandise Authorization number (RMA) clearly listed on the shipping label. Items

sent by Freight Collect or without a RMA number will be refused. Call your sales person

and request a RMA prior to shipping. Be prepared to provide the model number, serial

number and a brief description of the nature of the return. Shipping damage resulting

from inadequate packaging is the customer’s responsibility. Customer will be charged

additional shipping charges to return products received in non original packing and or

cartons.

9

Power

Do not apply power to the fixture until input voltage setting and power source are verified.

For protection against electric shock, fixture must be connected to suitable earth ground.

Make sure fixture is cool and disconnected from power mains before any service.

The listed current rating is its average current draw under normal conditions. All fixtures must be

powered directly from a switched circuit. This fixture cannot be run on a rheostat or dimmer

circuit even if used solely for a 0% to 100% switching. Before applying power to a fixture, check

that the fixture’s input voltage matches the power source voltage. Consult a qualified electrician

if there are any concerns about proper connection to power.

Pin

Cable (EU) International

Brown

Light blue

ellow/Green

Y

Black

White

Green

Live

Neutral

Earth

L

N

Cable (US)

Voltage Selection

Make sure fixture is cool and disconnected from power mains before any service.

This fixture ships from the factory set for 115v 60Hz operation unless otherwise specified

or marked. Before accessing the Transformer Connection, make sure fixture is cool and

physically disconnected from power mains. Remove the metal cover that extends

across the base from the Power Input to the Display. It is held by 9 Phillips screws. Two

connections must be moved to adjust input voltage and one must be moved to adjust

Line Frequency.

Transformer Ballast

10

Lamp

Make sure fixture is cool and disconnected from power mains before any service.

Do not touch the lamp glass with bare fingers. Wear eye protection when handling lamp.

When operating, always allow the lamp to cool at least 5 minutes before attempting to re-strike

the lamp. Not doing so can cause damage to the fixture and lamp. This fixture uses a 575w

Metal Halide Discharge lamp. Either a CSR575/2SE from GE or a MSR575/2 from Phillips can

be fitted. Both lamps have an average rated life of 1000 hours. The lamp manufacturer

determines the rated lamp life under specific test conditions. Factors such as the number of

strikes, lamp orientation, line voltage and lamp temperature all affect the actual number of hours a

lamp will operate. Lamp temperature is the most controllable and with routine cleaning and

maintenance, can be kept in the optimal range to allow the maximum possible life. As Discharge

lamps age, the glass envelope becomes weaker increasing the chance of failure due to the high

internal pressures. Rupture could result in damage to the fixture and/or injure people nearby.

Lamp manufacturers state operating a lamp beyond its rated number of hours constitutes a

considerable risk for lamp rupture. Lamp manufacturers recommend lamps be replaced once the

rated life of a lamp has been reached.

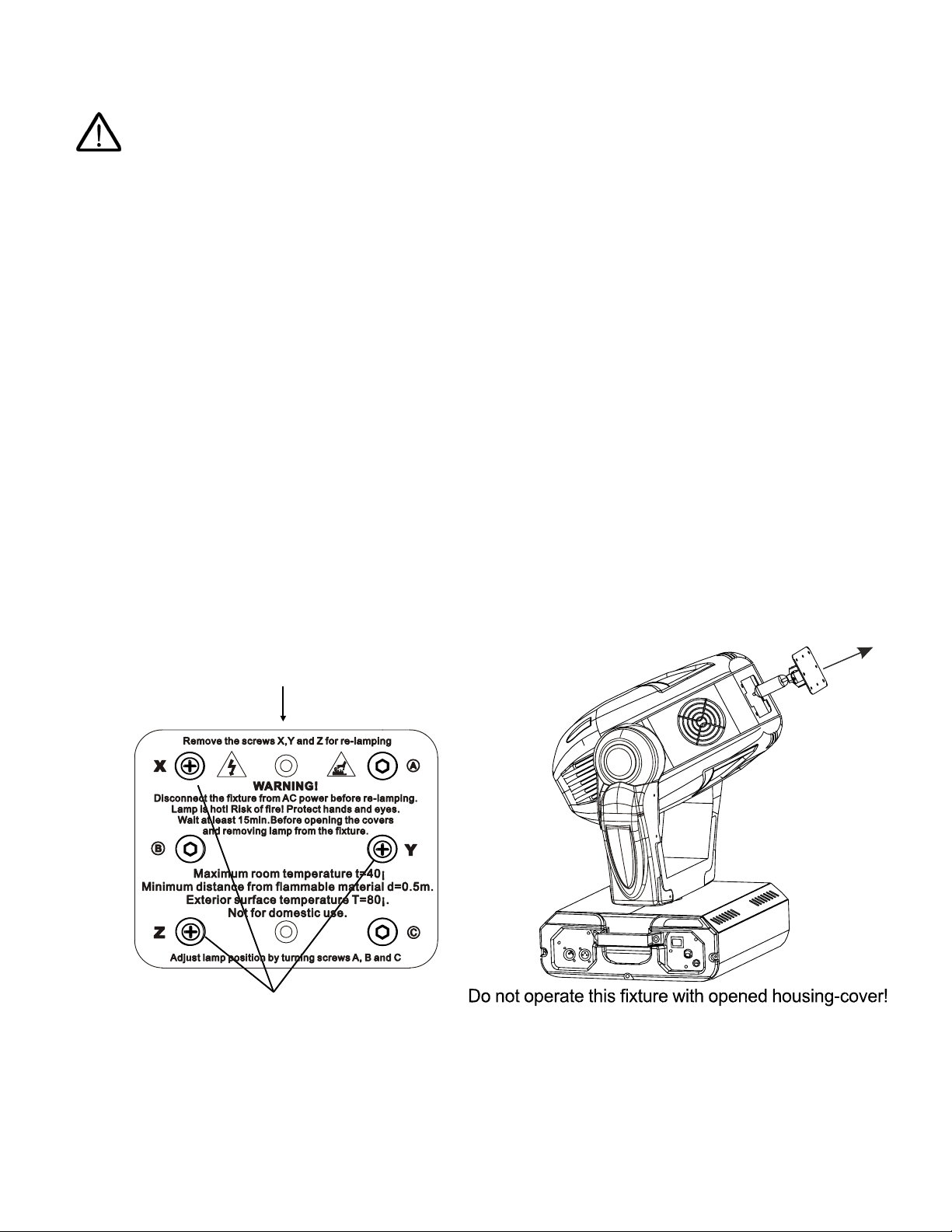

Lamp Installation

1. Physically disconnect fixture from power mains.

2. Locate the Lamp Cover. Do not proceed until the Lamp Cover is cool to touch.

3. Remove the 3 fastening screws labeled X, Y and Z.

4. Carefully draw out Lamp Cover and lamp. Remove old lamp (if installed). Never

handle lamps with bare hands. Dispose of lamp properly.

3

p

hilli

p

s screws "X,Y,Z"

L

amp cover

5. Insert new lamp into socket. Ensure lamp is properly seated.

6. Carefully replace Lamp Cover and lamp. Ensure that lamp wires are not pinched or in

contact with the lamp when the Lamp Cover is fully installed.

7. Replace the 3 fastening screws labeled X, Y and Z.

11

Lamp Alignment

Due to slight variations between lamps it may be necessary to perform fine adjustments

to remove excessively dark or bright spots in the output field. The lamp holder is aligned

at the factory, large adjustments to the alignment will not be necessary. Excessively

bright spots can damage optical components.

1. Apply power to the fixture.

2. Using a controller, strike the lamp with

shutter and dimmer to 100% and project an

open white beam on a flat neutral colored

surface.

3. Center the bright spot of the beam using

the Adjustment Screws A, B and C.

4. After centering the bright spot of the beam,

turn each Adjustment screw ¼ turn either

all clock wise or all counter clock wise until

the projected beam is as evenly bright as

possible.

Mounting

Always consult a qualified professional when rigging. This fixture may be placed on any flat

surface or truss that is capable of safely supporting the weight. When selecting a mounting

position, take into consideration access for routine maintenance. This fixture may be mounted in

any position provided there is adequate room for movement and ventilation. Mount the fixture

securely using two mounting clamps and a safety cable. An Eye Bolt is provided for safety

attachment. Safety cables must always be attached to the fixture. Do not use handles as

secondary mounting points. Do not mount in a place where the fixture will be exposed to rain,

high humidity, extreme temperature changes or restricted ventilation. Do not obstruct the vents

or fans. Keep fixture a minimum of 3.3ft (1m) from flammable materials.

3 ad

j

ustment screws "A,B,C"

12

Data Link DMX-512

For data, this fixture uses 3 pin XLR (Cannon) type connectors and shielded twisted pair cable

approved for EIA-422/EIA485 use. Fixtures are connected in Daisy Chain topography with only

one data source and no branching is allowed. Systems using 5 pin DMX interfaces can be

accommodated by purchasing 3-to-5 pin adapters or building adapter cables.

Data Terminator

A Data Terminator can be connected to the DATA OUT connection

of the last fixture to reduce the effects of noise in the signal; it is not

required for all installations. To make a Data Terminator, connect a

120-ohm ¼ watt resistor across pin 2, Data Negative (S-) and pin 3,

Data positive (S+). A qualified technician can determine if a Data

Terminator is needed.

Adapter5-to-3 pin

Numbers designating each pin can be found on connectors. Converting between the two

XLR types is done in a pin-to-pin fashion. Connect the shields to pin 1, then connect pin

2 to pin 2 and pin 3 to pin 3. This is true for converting either 5 to 3 pin or 3 to 5 pin

regardless of either connector’s gender. Pins 4 and 5 are not used on the 5 pin XLR

connectors.

5PinXLR(Plug)

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

3 XLR (S )

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin ocket

5 Pin XLR (Socket)

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

3 XLR (Plug)

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin

DMX

-

IN

1

2

3

- Ground

- Signal (-)

- Signal (+)

XLR Connector - Plug:

DMX-

O

U

T

1

2

3

- Ground

- Signal (-)

- Signal (+)

X

LR Connector - Socket:

DMX512

120

Ω

13

Control Panel Menu

Use the fixture’s Control Panel to access the Control Menu. The MODE Key moves between

options, UP/DOWN selects

the Action of the option and

ENTER confirms the

selection. Settings are stored

and recalled on subsequent

power cycles.

Start Address

The Start Address of a fixture is set using the “Addr” mode in the Control Panel Menu. Consult

the manual of the system’s DMX512 controller to select a desirable addressing scheme before

addressing fixtures. Each fixture connected to the DMX-512 data link requires a Start Address

to indicate the first DMX channel containing data designated for that fixture, see DMX-512

Background. Valid Start Addresses range from 1 to 512. Fixtures requiring more than one

channel for control will read subsequent channels up to the total number of channels required.

A fixture requiring five (5) channels of DMX, set to a Start Address of eleven (11), would read

data from channels: 11 and 12, 13, 14, 15. The next logical Start Address would be channel

16. Because all fixtures see the same data, fixtures may be set to any address without concern

to order in the DMX-512 chain or physical location. Choose a Start Address so the channels

used do not overlap with other fixtures. In some cases, it may be desirable to set two or more

same type fixtures to the same Start Address. In this case, the fixtures will be slaved together

and respond to the same data.

Example Select Start Addresses for 4 fixtures each requiring 17 channels of DMX.

Since these are the first fixtures added to the system, the first unit will be set to Start

Address=1. This fixture occupies DMX channels 1 thru 17. The next DMX channel

available for a Start Address is found by adding the previous fixture’s Start Address to its

channel requirement: 1+17=18. DMX channel 18 is the next available Start Address. In

this example, to maximize channel usage no empty channels are left between fixtures so

the second Start Address is set to DMX channel 18. The second fixture occupies DMX

channels 18 thru 34. Repeat the process for the remaining two fixtures: 18+17=35 and

35+17=52. Therefore, the four 17 channel fixtures have Start Addresses of 1, 18, 35 and

52. Repeat the technique once more for the first free channel in the system, 52+17=69.

Channels 69 thru 512 are available for expansion of the system.

Mode Function Action

No = Not Inverted

Yes = Inverted

DMX Start Address

Fixture Reset

Color Wheel 2 Movement Mode

No = Not Inverted

Yes = Inverted

Selectable 1 to 512

No = Default

Yes = Initiate Reset

No = Stepped Change

Yes = Linear Change

Color Wheel 1 Movement Mode

No = Stepped Change

Yes = Linear Change

Gobo Wheel Movement Mode No = Stepped Change

Yes = Linear Change

Lamp ON/OFF On = Lamp on

Off = Lamp off

Working mode = DMX-512 mode

= Automatic Demo

14

DMX-512 Channels

The Tracker 575 Spot requires 17 channels of DMX.

Channel Function

1 Pan Coarse Movement

2 Pan Fine Movement

3 Tilt Coarse Movement

4 Tilt Fine Movement

5 Movement Speed Pan/Tilt

6 Control Reset/Lamp

7 Focus

8 Color Wheel 1

9 Color Wheel 2

10 Prism

11 Fixed Gobo Wheel

12 Rotating Gobo Wheel

13 Gobo Rotation & Index

14 Iris

15 Zoom

16 Shutter

17 Dimmer

CH 1-4 : Pan / Tilt Movement

The Pan and Tilt motors use a position feedback system. If the position of either is

disturbed, the fixture will correct automatically. The Pan and Tilt Menu Modes can be

used to alter the default direction of movement. Movement speed is either automatically

determined by the fixture or manually set using Channel 5 Pan/Tilt Movement Speed.

Pan range is 530° of movement. Tilt range is 280° of movement.

CH 1 – Pan Coarse Movement (530°)

CH 2 – Pan Fine Movement

CH 3 – Tilt Coarse Movement (280°)

CH 4 – Tilt Fine Movement

DMX Value Function

0 – 255 Movement - Minimum to Maximum

15

CH 5 : Movement Speed Pan/Tilt

When set to zero (0) the fixture automatically determines the Pan/Tilt speed. Other

values are used to set the movement speed manually.

CH 5 – Movement Speed Pan/Tilt

DMX Value Function

0 Auto Speed

1-255 Fixed Speed - Fast to Slow

CH 6 : Control Reset/Lamp

Fixture reset and Lamp On/Off control is accessed from a single channel. The “No

Function” values provide buffer zones between functions and are not values to which the

channel should be set. In the case of noisy faders or unintentional movement, the buffers

will prevent slight variations in value to toggle Lamp states or start a fixture Reset.

CH 6 – Control Reset/Lamp

DMX Value Function

0-127 No Function

128-139 RESET then Lamp ON (3 second delay)

140-229 No Function

230-239 Lamp OFF (3 second delay)

240-255 No Function

CH 7 : Focus

Adjusts the focus of the projected image. When using both Gobo wheels, varying the

Focus can create many interesting effects.

CH 7 – Focus

DMX Value Function

0-255 Focus – Near to Far

16

CH 8 : Color Wheel 1

Color Wheel 1 holds 9 solid colors. Bi-Color and Color Scroll effects can also be set and

used in conjunction with Color Wheel 2 to create many color combinations.

CH 8 – Color Wheel 1

DMX Value Function

0-9 Open

10-19 Open/Red

20-29 Red

30-39 Red/Yellow

40-49 Yellow

50-59 Yellow/Magenta

60-69 Magenta

70-79 Magenta/Green

80-89 Green

90-99 Green/Orange

100-109 Orange

110-119 Orange/Blue

120-129 Blue

130-139 Blue/Pink

140-149 Pink

150-159 Pink/UV-Blacklight

160-169 UV-Blacklight

170-179 UV-Blacklight/Deep Orange

180-189 Deep Orange

190-199 Deep Orange/Open

200-255 Rainbow Color Scroll – Slow to Fast

17

CH 9 : Color Wheel 2

Color Wheel 2 holds 7 solid colors plus CTO and CTB color shifts. Bi-Color effects can

be set and used in conjunction with Color Wheel 1 to create many color combinations.

CH 9 – Color Wheel 2

DMX Value Function

0-12 Open

13-25 Open / Lt. Red

26-38 Lt. Red

39-51 Lt. Red / Lt. Yellow

52-64 Lt. Yellow

65-77 Lt. Yellow / Lt. Purple

78-90 Lt. Purple

91-103 Lt. Purple / Lt. Green

104-116 Lt. Green

117-129 Lt. Green / Lt. Orange

130-142 Lt. Orange

143-155 Lt. Orange / Blue

156-168 Blue

169-181 Blue / Lt. Blue

182-194 Lt. Blue

195-207 Lt. Blue / CTO (3200°K)

208-220 CTO (3200°K)

221-233 CTO (3200°K) / CTB (6000°K)

234-246 CTB (6000°K)

247-255 CTB (6000°K) / Open

CH 10 : Prism

The Prism effect uses a 3 facet prism to create multiple beams. The effect can be

rotated in either direction at variable speeds.

CH 10 – Prism

DMX Value Function

0-4 Open

5-127 Prism w/ Rotation – CW, Slow to Fast

128-132 Prism w/o Rotation

133-255 Prism w/ Rotation – CCW, Slow to Fast

18

CH 11 : Fixed Gobo Wheel

The Fixed Gobo Wheel contains 9 fixed gobos. In addition to the variable Vibrate and

Gobo Scroll modes, using both Gobo wheels and varying the Focus can create many

interesting effects.

CH 11 – Fixed Gobo Wheel

DMX Value Function

0-9 Open

10-19 Fixed Gobo 1

20-29 Fixed Gobo 2

30-39 Fixed Gobo 3

40-49 Fixed Gobo 4

50-59 Fixed Gobo 5

60-69 Fixed Gobo 6

70-79 Fixed Gobo 7

80-89 Fixed Gobo 8

90-99 Fixed Gobo 9

100-111 Fixed Gobo 1 Vibrate - Slow to Fast

112-123 Fixed Gobo 2 Vibrate - Slow to Fast

124-135 Fixed Gobo 3 Vibrate - Slow to Fast

136-147 Fixed Gobo 4 Vibrate - Slow to Fast

148-159 Fixed Gobo 5 Vibrate - Slow to Fast

160-171 Fixed Gobo 6 Vibrate - Slow to Fast

172-183 Fixed Gobo 7 Vibrate - Slow to Fast

184-195 Fixed Gobo 8 Vibrate - Slow to Fast

196-207 Fixed Gobo 9 Vibrate - Slow to Fast

208-255 Fixed Gobo Scroll - Slow to Fast

0

1

2

3

4

5

6

7

8

9

19

CH 12 : Rotating Gobo Wheel

The Rotating Gobo Wheel contains 6 replaceable gobos, 3 metal and 3 glass. The Gobo

Rotation & Index channel controls the position and rotation of the gobos. Using both

Gobo wheels and varying the Focus can create many interesting effects.

CH 12 – Rotating Gobo Wheel

DMX Value Function

0-36 Open

37-73 Rotating Gobo 1 (Metal)

74-110 Rotating Gobo 2 (Metal)

111-147 Rotating Gobo 3 (Metal)

148-184 Rotating Gobo 4 (Glass – Blue Field Random Dots)

185-221 Rotating Gobo 5 (Glass – Fire Texture Dichroic)

222-255 Rotating Gobo 6 (Glass – Clear Texture)

CH 13 : Gobo Rotation & Index

Rotating gobos can be rotated in either direction or indexed to a fixed orientation.

CH 13 – Gobo Rotation & Index

DMX Value Function

0-40 Indexed – 0 to 540°

41-158 Rotation – Slow to Fast

159-255 Rotation Reverse – Slow to Fast

0

6

5

4

3

2

1

20

CH 14 : Iris

The Iris allows the diameter of the beam to be reduced.

CH 14 – Iris

DMX Value Function

0-255 Beam aperture – Large to Narrow

CH 15 : Zoom

The three step zoom feature of this fixture has two modes. The Focus Correction mode

will make adjustments to help keep the image in focus when changing beam angles. The

No Focus Correction mode will not adjust the focus when changing beam angles.

CH 15 – Zoom

DMX Value Function

0-32 15° Beam Angle – No Focus Correction

33-65 18° Beam Angle – No Focus Correction

66-98 22° Beam Angle – No Focus Correction

99-127 No Effect

128-170 15° Beam Angle – Focus Correction

171-213 18° Beam Angle – Focus Correction

214-255 22° Beam Angle – Focus Correction

CH 16 : Shutter

The Shutter functions in three modes. Standard Strobe Effect where the shutter

Opens/Closes at a fixed rate. Pulse Strobe Effect where the Open and Close speeds are

different. Random Strobe Effect runs the shutter at irregular intervals.

CH 16 – Shutter

DMX Value Function

0-31 Closed (Black Out)

32-63 Open

64-95 Strobe Effect - Slow to Fast

96-131 Pause in current position

132-159 Pulse Strobe Effect - Slow to Fast

160-191 Pause in current position

192-223 Random Strobe Effect

224-255 Open

CH 17 : Dimmer

The dimmer is used to vary the intensity of the beam from full open to dark.

CH 17 – Dimmer

DMX Value Function

0-255 Intensity - Dark to Full Open

This manual suits for next models

2

Table of contents