S A F E T Y

TO START ENGINE

ALWAYS start the engine in the open air

DO NOT smoke when refuelling

DO NOT mix OIL with the fuel

ALWAYS stop the engine before making any adjustments,

refuelling, moving or cleaning, or when the unit is unattended

USE ONLY unleaded petrol or diesel from fuel containers designed

for this purpose - refuel outdoors only and replace the tank

cap securely

IN CASE of petrol spillage move the machines away from the area

of spillage and allow the petrol vapours to dissipate before

starting the engine

DO NOT remove any safety guards that are fitted

DO NOT touch any moving parts or attempt any maintenance

whilst the machine is running - KEEP HANDS AND FEET

AWAY

BEFORE starting work clear the work area of any objects that

could damage the machine

DO NOT allow children or anyone uninstructed to operate the

machine - KEEP ANIMALS AWAY

o

DO NOT use on slopes or banks of more than 20 - unless you are

using the Kohler engine machine

ALWAYS wear suitable clothing to give personal protection

including footwear that offers a good grip

NEVER put hands or feet under mower decks

AVOID wearing loose garments that may catch in moving parts

KNOW how to stop the machine in an emergency

NEVER select reverse gear with your back to a wall or other

immovable object

NEVER interfere with any control settings on the engine

IF A FAULT develops DO NOT attempt any repair - immediately

contact the supplier from whom the machine was obtained

VISUALLY INSPECT the machine before use - ensure all tines, nuts

and bolts are tight and not worn or damaged and replace tines

if necessary

KEEP IN MIND the operator is responsible for accidents or hazards

occurring to people or property

WEAR eye and ear protection and protective footwear

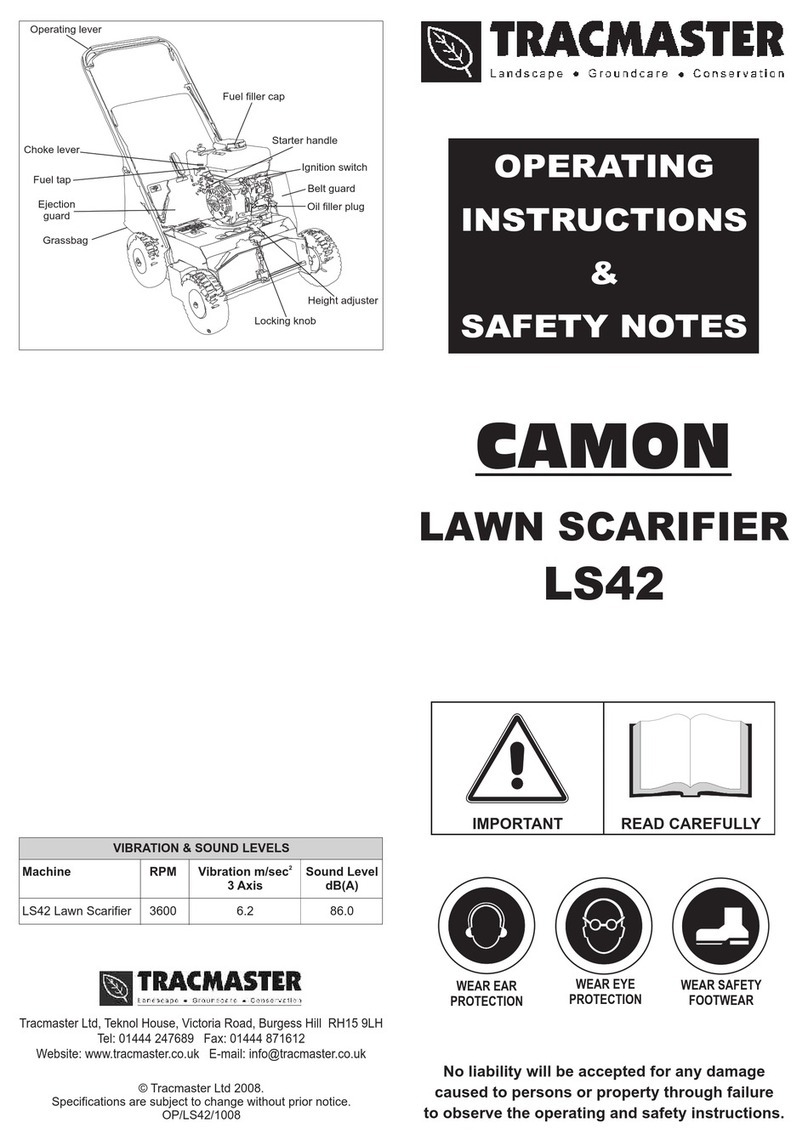

Check the fuel level - use either unleaded petrol or diesel, depending on

your engine type.

Always remove the fuel cap slowly to release tank pressure and keep

your face and eyes away from the tank.

Check the engine oil level.

Ensure the butterfly is in the central position (L).

Pull in the clutch lever and secure with locking clip (B & F).

Ensure PTO lever is disengaged (E).

Turn the fuel tap to ‘ON’ position - if the engine is cold turn on the choke -

petrol engine only.

Apply half throttle.

Gently pull the recoil starter handle until resistance is felt and then give a

good strong pull to start the engine.

Push the choke back in and return the throttle to idle speed (petrol

engine only) and allow the engine to idle for 2-3 minutes. This will allow

the oil to warm up to ensure correct operation.

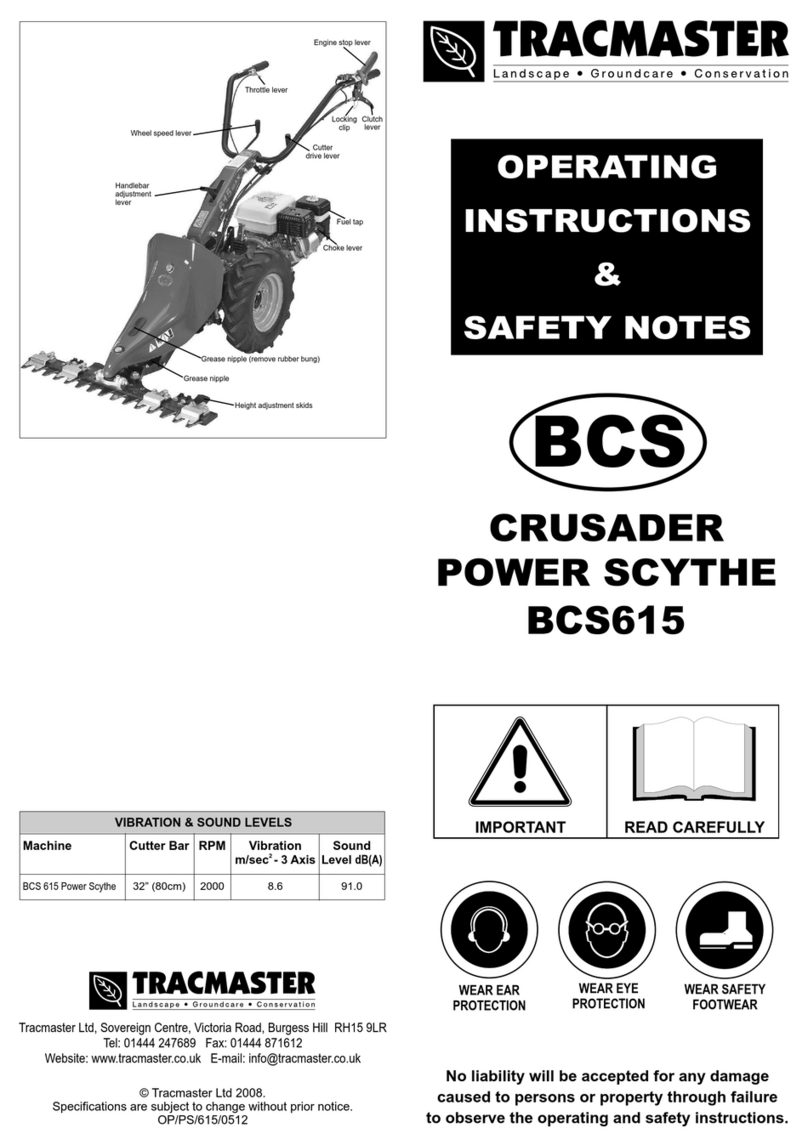

Pull in the clutch lever (B).

Close the throttle (C).

Ensure the butterfly is in the central position (L).

Disengage the PTO drive to the implement (E).

Release the clutch lever slowly (B).

Release the red stop levers (A).

WARNING: If any abnormal vibrations or sounds occur, STOP the

engine and check the machine and the implement.

WARNING: THE EXHAUST COVER MAY BE HOT - DO NOT TOUCH

TO STOP ENGINE

OPERATION

MAINTENANCE GUIDE

Pull the clutch lever up to the handlebar to release the locking clip (B & F).

Select the working speed required for mowing, sweeping, or snow

clearing by using the right-hand gear lever (D).

Engage drive to the implement by using the PTO left-hand gear lever (E).

Increase engine speed (not if the scythe cutter bar attachment is in use)

and release the clutch lever slowly and fully (C & B).

Keep at least one red engine stop lever depressed as the engine will

stop if both are released (petrol engines).

Push the butterfly clockwise to move the machine forwards. When fully

depressed clockwise, the butterfly will lock in place. To release simply

push anti-clockwise (L).

Steer the machine by pulling in the steering clutch levers fully and

releasing the lever fully as required (H & I).

NOTES: PTO lever (E) must only be operated with the clutch lever (B)

pulled up and the engine on tick over.

Never change wheel speed when driving the machine. It must be

stopped first.

Do not operate both steering levers together to stop the machine.

NOTE: With the engine running and the butterfly (L) in the central

position if the clutch lever (B) is released the machine will not move but it

st nd rd

is possible to select 1 , 2 , or 3 gear (D).

Push the butterfly anti-clockwise to reverse the machine. When fully

depressed anti-clockwise the butterfly will lock in place, to release

simply push clockwise (L).

WARNING: Never engage reverse gear with your back to a wall, fence

or other immovable object.

ENGINE - See separate engine manufacturer’s manual.

GEARBOX - Check oil level using the oil plug (A) ensuring level is

between (B) and (C). If necessary top up with AGIP Rotra JD/F 80W or

Shell Donax TD or equivalent.

CLUTCH - Check there is

sufficient free play in the cable.

As the clutch wears, the cable will

tighten up. Release the adjuster

on the clutch lever and screw in to

increase the free play. On no

account must the cable be tight.

The cable end float should be

approximately 3mm.

S T E E R I N G C L U T C H E S -

Steering clutch cables act on the

long black levers on the side of

the wheel hubs. Ensure the end float of these cables is 2-3mm. If

necessary screw in the adjuster on the steering lever to increase free

play.

GENERAL - Keep all cables lubricated and grease the detent ball on

the wheel speed selector gate. Check the tightness of all nuts and bolts

at regular intervals.

Always store the machine with the clutch lever pulled in and secured

with the locking clip.

This machine is fitted with an automatic parking brake which is engaged

when the engine is off and when the engine is running with the butterfly

in the central position.

On the gearbox cover there is a red lever which if turned clockwise

disengages the parking brake to allow the machine to be pushed.

To re-engage mechanical traction to the wheels turn the red lever anti-

clockwise to its original position.

(A)

To stop the machine release the butterfly and allow it to return to the

central position (L).

To stop the machine release the butterfly and allow it to return to the

central position (L).

REVERSING

The gearbox oil must be changed every 50 hours to ensure

correct operation of the machine.