S A F E T Y

TO START ENGINE

ALWAYS start the engine in the open air

DO NOT smoke when refuelling

DO NOT mix OIL with the fuel

ALWAYS stop the engine before making any adjustments,

refuelling, moving or cleaning, or when the unit is

unattended

USE ONLY unleaded petrol from fuel containers designed for

this purpose - refuel outdoors only and replace the tank cap

securely

IN CASE of petrol spillage move the machines away from the

area of spillage and allow the petrol vapours to dissipate

before starting the engine

DO NOT remove any safety guards that are fitted

DO NOT touch any moving parts or attempt any maintenance

whilst the machine is running - KEEP HANDS AND FEET

AWAY

BEFORE starting work clear the work area of any objects that

could damage the machine

DO NOT allow children or anyone uninstructed to operate the

machine - KEEP ANIMALS AWAY

o

DO NOT use on slopes or banks of more than 20

ALWAYS wear suitable clothing to give personal protection

including footwear that offers a good grip

AVOID wearing loose garments that may catch in moving parts

KNOW how to stop the machine in an emergency

NEVER interfere with any control settings on the engine

NEVER select reverse gear with your back to a wall or other

immovable object

IF A FAULT develops DO NOT attempt any repair - immediately

contact the supplier from whom the machine was obtained

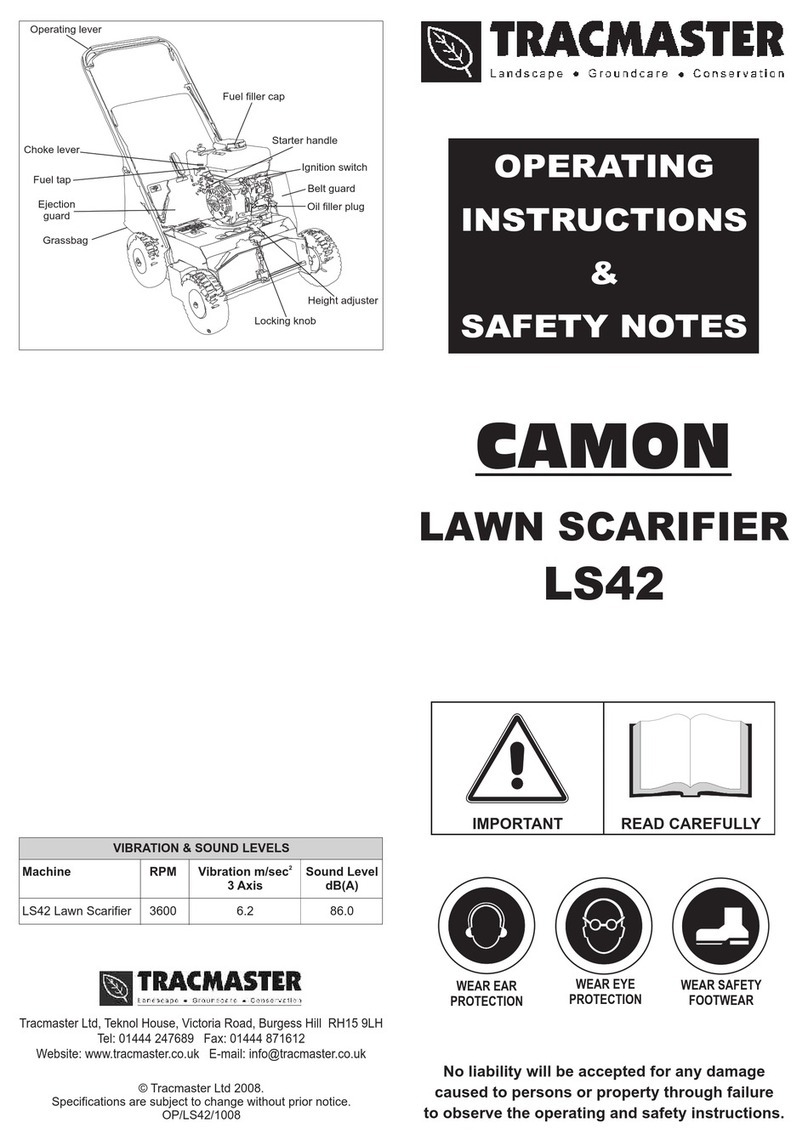

VISUALLY INSPECT the machine before use - ensure all teeth,

nuts and bolts are tight and not worn or damaged and

replace teeth if necessary

KEEP IN MIND the operator is responsible for accidents or

hazards occurring to people or property

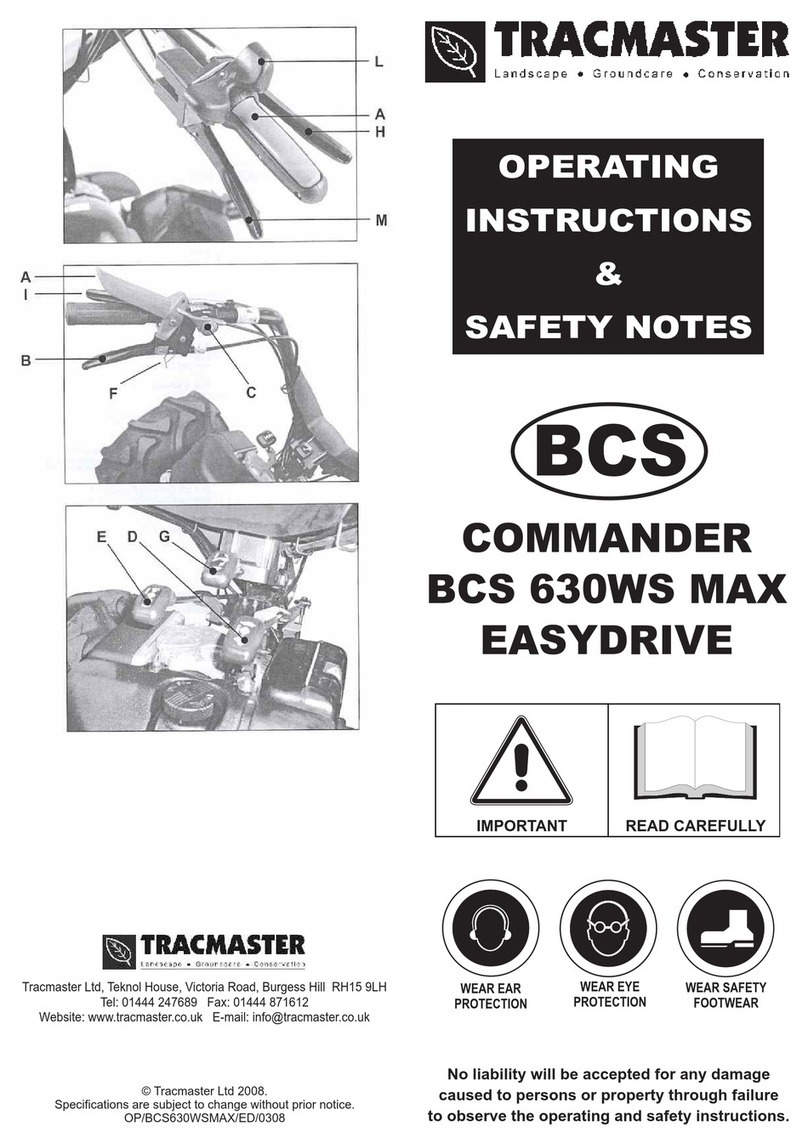

Check the engine oil level. Top up with 10w/40 oil if necessary.

Check fuel level. Only use unleaded petrol from a clean container.

Never re-fuel when the engine is hot or running. Leave 1” air space in

the fuel tank.

Depress the engine stop lever (the red lever on the left handlebar)

then pull up the clutch lever and secure with locking clip.

Ensure the wheel speed lever is in neutral ‘O’ position.

Apply half throttle (the lever on the right handlebar).

Turn the fuel tap to ‘ON’ position, if the engine is cold set the choke

lever to ‘ON’ position.

Pull the recoil start handle gently until it engages then give it a good

strong pull to start the engine.

When the engine has started, release the choke lever after a few

seconds and return the throttle lever to idle position.

OPERATION

TO STOP ENGINE

OPERATING HINTS

MAINTENANCE GUIDE

Use handlebar adjuster to set handlebar height.

Pull up clutch lever (located on left handlebar). This will automatically

release stop lever locking clip.

Select forward gear by using the wheel speed lever.

Engage the cutter bar by using the cutter bar drive lever.

Raise the throttle slightly, release the clutch lever gently and fully,

keeping the red engine stop lever depressed as engine will stop if

released.

Commence work.

Close the throttle.

Pull up the clutch lever.

Locate the wheel speed lever in neutral position.

Disengage drive to the cutter bar.

Release clutch lever.

Release engine stop lever completely.

WARNING: THE EXHAUST COVER MAY BE HOT - DO NOT

TOUCH

After every hour of operation stop the engine and remove the spark

plug cap. Check engine oil level (recommended oil SAE 10w/40).

Wash down and re-oil the sliding parts after each day of use.

Lubricate grease nipples every day (where fitted).

Use an old paintbrush to smear grease over the cutter blades.

Replace the spark plug cap.

Do not turn the machine on its side for cleaning.

When the machine is not in use always leave the clutch lever pulled in

and secured with locking clip.

Best results are obtained with the engine at a low throttle setting,

which enables the bar to cut cleanly and gives less wear and tear on

the reciprocating parts, which in turn reduces maintenance.

NB: If you are working on a slope, always work across the slope -

never up or down.

On rough terrain, the bar should be raised by the height adjuster skids

to prevent the blades from digging into the ground.

Always wear gloves.

WARNING: If any abnormal vibrations or sounds occur, STOP the

engine immediately and check the machine and the cutter bar. If you

have any concerns contact your supplier.

For engine maintenance please refer to engine manufacturers

manual.

NEVER USE MORE THAN

¼ THROTTLE WHEN THE

BAR IS OPERATING

!