Tradeflame Oxypower User manual

IMPORTANT

Read instructions before operation.

Save these instructions.

Congratulations on the purchase of your OXYPOWER Blow Torch Kit.

This equipment is designed for metal cutting, soldering, brazing, welding, hardening

and heating of all ferrous and non-ferrous metals. This gas equipment is able to weld

metal without the use of oxy-acetylene equipment. With a total weight of less than

5kg including cylinders, this kit allows you to carry out jobs similar to those performed

by much heavier equipment in areas when larger equipment is not practical.

Please follow the instructions in order to obtain the best working performance of this equipment.

Great care should be taken in using this equipment as it reaches very high working temperatures.

OXYPOWER Blow Torch Kit

PART NO: 212001

PRODUCT MANUAL

PRODUCT IDENTIFICATION

1. Metal carry stand/cartridge holder

2. Oxygen pressure regulator (blue knob)

3. Oxygen pressure gauge

4. Fuel pressure regulator (orange knob)

5. Fuel pressure gauge

6. Flash back arrestors

7. Oxygen cartridge (not included)

8. Fuel cartridge (not included)

9. Hose

10. Torch handle

11. Torch oxygen control knob (blue)

12. Torch fuel control knob (orange)

13. Lance

14. Replaceable tip

15. Welding goggles

(Do not use with electric welding)

16. Ignition striker 15

2

3

1

7

8

6

6

6

4

5

GENERAL INSTRUCTIONS

A gas such as TF/ULTRA GAS - Performance Gas – MAPP®Replacement*or Propane

(referred to as fuel in this document) is liqueed in the cartridge and therefore the

contents of the cartridge can be estimated by the weight of the cartridge.

Oxygen is compressed gas within the cartridge and the difference between the

weight of a full cartridge and of an empty one is not easily recognised.

The oxygen regulator is tted with a high- pressure gauge that allows you to check the

contents of the oxygen cartridge. As the oxygen is stored in a gas state it is impossible to

ascertain the contents of the oxygen cartridge by the weight of it. When the oxygen cartridge

is full, the gauge should read 110 bar of pressure. This indicates that the oxygen cartridge

is full. When the oxygen cartridge is empty the gauge should read 0 bar of pressure.

The fuel regulator is tted with a low-pressure gauge that allows you to check

and control the delivery of the fuel released from the fuel cartridge.

The quoted approximate use times have been calculated considering a correct mixture

of oxygen and gas. Incorrect mixtures could alter these times considerably.

When storing this kit, we recommend removing the regulators from the cartridges completely.

16

13

14

12

11

10

2

9

*MAPP®is a registered trademark of the Linde Group

6

6

x2

TO ASSEMBLE

1. Ensure the fuel regulator valve is off

(turn knob 4 fully clockwise to -).

2. Make sure the seal inside the fuel

regulator is seated properly and

is in good working condition.

3. Screw the fuel regulator 4onto the fuel

cartridge 8in a clockwise direction,

hand tighten only. DO NOT OVER TIGHTEN.

4. Ensure the oxygen regulator valve is off

(turn knob 3fully clockwise to -).

5. Make sure the seal inside the oxygen

regulator is seated properly and

is in good working condition.

6. Screw the oxygen regulator 2 onto the

oxygen cartridge 7in a clockwise direction,

hand tighten only. DO NOT OVER TIGHTEN.

NOTE: It may be easier to screw the cartridges

onto the regulators in a clockwise direction.

Hand tighten only. DO NOT OVER TIGHTEN.

IMPORTANT: Before lighting the ame

make sure that all connections have been

properly made. Check that there are no

leaks with the appropriate gas leak spray

or a solution of soapy water. Repeat this

operation every time a cartridge is replaced.

STAND ASSEMBLY INSTRUCTIONS

This equipment is supplied with a

metal stand / cartridge holder.

1. Once you have connected the cartridges

to the regulators, slide each cartridge into

one side of the stand, making sure that the

buttery nut on the back of the stand is

screwed onto the bolt just enough to hold

the front metal cartridge strap in place.

2. Once you have both cartridges inserted

into the stand, tighten the buttery nut

until it stops. Do not over tighten as you will

damage the buttery nut or the centre bolt.

3. When inserting the cartridges make sure that

the hoses are not tangled, and the cartridges

are put on the correct sides of the stand

in order for the hoses not to be crossed.

3

INSTRUCTIONS FOR USE

The kit uses a non-rellable oxygen cartridge

(white) and a non-rellable gas cartridge

(yellow or blue). These must be purchased

separately. See specications on page 7.

Before beginning the work, ensure

the valves of the torch are closed.

Make sure that:

• The 11 torch oxygen valve is

completely closed by turning the blue

knob in a clockwise direction.

• The 12 torch fuel valve is completely

closed by turning the orange

knob in clockwise direction.

• The 2 oxygen cartridge regulator

valve is completely closed by turning the

blue knob in a clockwise direction.

• The 4 fuel cartridge regulator valve

is completely closed by turning the

orange knob in a clockwise direction.

• Both pressure regulators are completely

tightened on the cylinder (clockwise direction).

TO IGNITE

It is recommended that in normal use

the pressure regulator knobs are opened

completely, with ame adjustment controlled

by the torch knobs. For storage, transport

and cartridge replacement, the pressure

regulator knobs should be completely closed.

1. Turn the blue knob of the oxygen cartridge

pressure regulator 2in an anti-clockwise

direction until fully open. Turn the orange knob

of the fuel cartridge pressure regulator 4in

an anti-clockwise direction until fully open.

2. Turn the orange fuel knob of the torch 12

anti-clockwise to open and immediately

ignite the torch using an ignition source

(striker 16 included with the kit).

Note that if the fuel knob allows too

much fuel, the ame will not ignite.

3. Regulate the pressure of the fuel using the

fuel knob on the torch until the yellow ame

remains attached to the tip of the torch.

Torch valve knobs

-/OFF

+/ON

12

11

-/OFF

Cartridge Regulator Knobs

+/ON

2

4

4

4. Slowly turn the blue oxygen knob of

the torch 11 anti-clockwise to open

until you obtain a light blue ame.

5. An excess of oxygen can cause the ame to

separate from the torch tip or to extinguish.

In this case close the oxygen and fuel valves

and repeat the operation from point 1.

The equipment is now ready to perform your work.

By regulating the amount of fuel and

oxygen it is possible to obtain several

different ames for carrying out different

types of work from heating to cutting.

We recommend only turning the fuel and

oxygen on once the material for work is

ready: this avoids wasting oxygen and fuel,

and reduces the risk of accidental ignition.

TO EXTINGUISH

1. Slowly close the blue oxygen knob of the

torch 11 by turning it clockwise. The

ame colour should change to a yellow

colour indicating that the oxygen has

now been removed from the ame.

2. Slowly close the orange fuel knob of the

torch 12 by turning it anti-clockwise. This

should then extinguish the ame all together.

3. Turn both the orange 4and blue 2

knobs at the regulators in a clockwise

direction. This will close off the gas

and oxygen at the regulators.

4. To purge the fuel and oxygen from the

hose and torch, turn both torch knobs

in an anti-clockwise direction for a

short period, then close again.

Storage

1. Always disconnect the regulators from

the cartridges when not in use.

2. Store the torch and cartridges

is a safe, dry place.

3. Keep out of reach of children.

4. Never expose cartridges to heat, sparks, or

ame. Never leave in direct sunlight. Never

store at temperatures above 49°C (120°F).

5. Never store in living spaces.

6. Never rell these cartridges. Relling

may cause explosion. It is illegal

to rell these cartridges.

7. Never put in luggage or take

on trains or aircraft.

8. To discard, contact local recycle centre.

Never put in re or incinerator.

Do not puncture.

Flame types

5

Yellow ame

- fuel only

Orange ame

- insufcient oxygen

Blue ame

- ideal

Transparent ame

- excess oxygen

IN THE EVENT OF A FIRE

If safe to do so, immediately close oxygen

cartridge valve; this should be enough to

extinguish the ame. Close fuel cartridge

valve as well and extinguish re with

appropriate reghting equipment.

If the danger is too great to ght the

re, leave the equipment, evacuate the

area and call the re authorities.

TIP REPLACEMENT

Ensure all gas supply to the torch is turned off.

Use the appropriate tool to tighten

and loosen the tips.

DO NOT over tighten.

Store tips in a clean, dry environment. Any

dirt represents a blocking hazard for the tip.

CARTRIDGE REPLACEMENT

It may be easier to remove cartridges

from the storage frame before

attempting to replace one or both.

1. Close the pressure regulator completely by

turning the knob in a clockwise direction

(Blue 2 Oxygen, Orange 4Fuel).

2. Unscrew the exhausted cartridge.

3. Screw the new cartridge and repeat the

Assembly Instructions on page 3.

CARTRIDGE SPECIFICATION

For replacement fuel:

TF/ULTRA GAS Part No: 326439

Propane Part No: 326438

For replacement oxygen:

Oxygen Part No: 211423

SAFETY

Welding equipment regulators ensure

supply at low and constant pressure. In

addition, the equipment has six ash back

arrestors that ensure equipment safety.

Always inspect this equipment before use. This

includes connections, hose and torch assembly.

If you detect a leak in the equipment (gas smell),

bring it immediately outside in a well-ventilated

area with no ammable sources, where you

can nd and stop the leak. If any problems

exist DO NOT attempt to use this equipment.

• Always extinguish the ame before

placing torch on a surface.

• Ensure hose is not bent.

• Never point the ame towards cartridges

(they should never get hot), hoses (they can

burn), parts of the body or other persons.

• Do not operate the equipment in

space-constrained sites.

• Place the equipment main body

on a horizontal surface.

• Use the equipment outside or

in a well ventilated place.

• Work in a safe and clean area and

remove all oily and combustible

materials, and re hazards.

• Wear necessary equipment for eye protection.

• Avoid oily or greasy clothing.

• Wear protective gloves that avoid burns

when handling hot materials and equipment,

allow the welded material and the

components to cool down before touching

or moving them to a different location.

• Wear protective clothing to avoid contact of

parts of the body with sparks and hot material.

• Do not try to move the equipment

by pulling the hoses.

6

OXYGEN AND FUEL CONSUMPTION

The rate of oxygen and fuel consumption

is strongly inuenced by the tip selection,

ame size and nature of work.

As an estimate:

7

TEMP OXYGEN FUEL TIP SIZE OXYGEN TIME FUEL TIME

3000°C 110 L

Part No:

211423

TF/ULTRA

GAS 400 g

Part No:

326439

40 L/hr Part No: 211445 2 hr 30 min 14 hr 30 min

50 L/hr Part No: 211456 2 hr 11 hr 30 min

70 L/hr Part No: 211467 1 hr 40 min 9 hr

100 L/hr Part No: 211478 1 hr 10 min 6 hr 30 min

WORK PREPARATION

When using this equipment proper preparation

is ALWAYS required. This includes:

1. Cleaning the area to be worked on

with sandpaper or a wire brush.

2. Removing any paint or other materials

that may inhibit bonding.

3. Using ux when required.

4. Understanding what materials are being

worked with and using the appropriate

welding, brazing, or soldering rods or solder.

MAINTENANCE

• Use only genuine replacement parts.

• Never use equipment if any

components appear damaged.

• Important: Do not carry out any type of

operations on single parts; it may result in

serious risks for the user. If the equipment

does not function properly, contact

Customer Service on 1300 555 197.

• Carefully follow instructions provided.

• For maintenance and storage of

protective glasses, see the instructions

for use provided with them.

• Regular inspection of equipment is

required to ensure correct function.

• Many of the components used in this

equipment cannot be repaired and are

designed this way to ensure safety.

WARNING

• To avoid any injury or damage, only ignite

the torch when it is clear of hands, clothing,

or any other combustible materials.

• The torch becomes extremely hot

during and after operation. Care must

be taken to avoid accidental burns.

• Ensure the ame is completely

extinguished after use.

• Protect from direct sunlight. Do not expose

to temperature above 49°C/120°F.

• The kit is designed to use with ammable

gas under pressure. Do not disassemble

puncture or incinerate cartridges after use.

• For maximum protection always wear welding

goggles (supplied with this kit), gloves and

other appropriate safety equipment.

• Keep out of reach of children.

• The installation and adjustment made in

the factory of this equipment should not be

changed. Altering, removing components and

/or using parts which are not recommended

by the manufacturer can be very dangerous.

• It is strongly recommended that you only use

original parts made for this equipment, oxygen

cartridge Part No: 211423, fuel cartridge

Part No: 326439 or 326438. Using different

types of cartridges can be dangerous. Read

the safety section and these instructions

carefully before using this equipment.

Distributed by

TradePem Idustrial Pty Ltd

www.tradeame.com

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

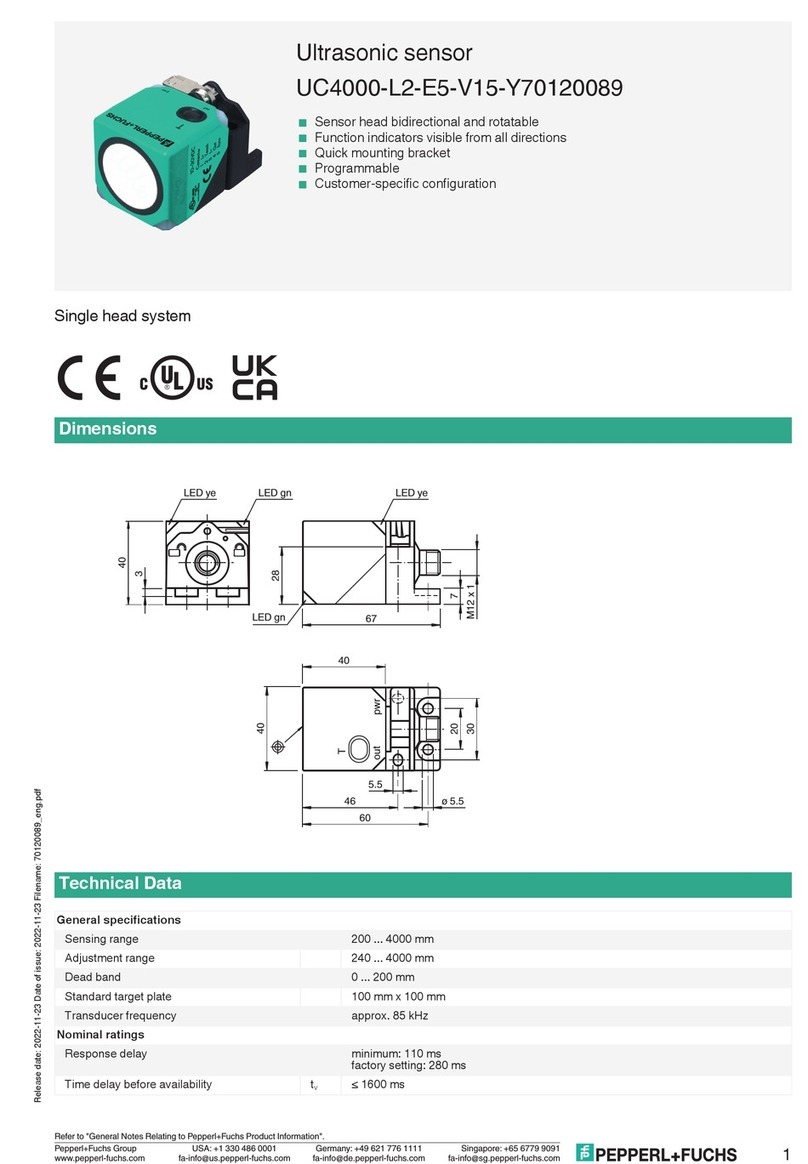

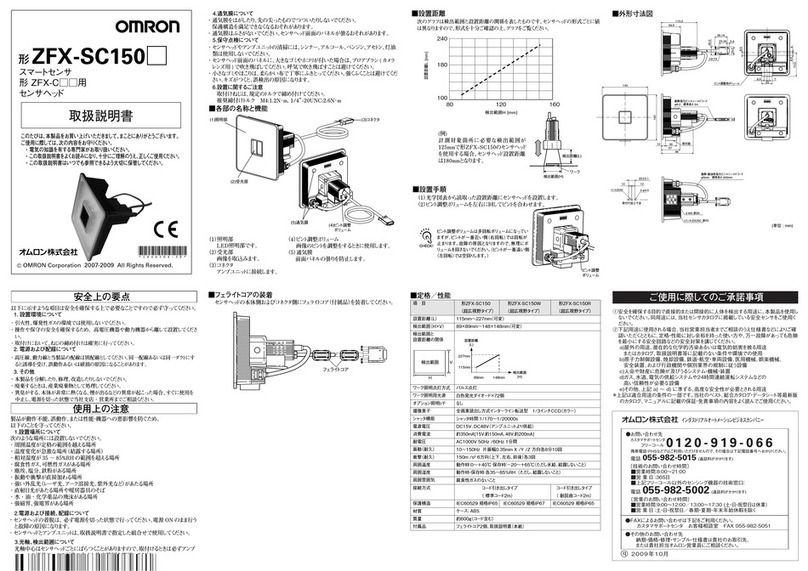

Omron

Omron ZFX-SC150 instruction sheet

M-Audio

M-Audio Audiophile USB manual

Endress+Hauser

Endress+Hauser Liquiphant operating instructions

IFM Electronic

IFM Electronic VSA003 installation instructions

Digital Control Systems

Digital Control Systems AirSense 310en Operator's manual

Grixx

Grixx GROEXTBP15B01 user guide