7. Close the cap correctly to prevent liquid leaking out when working.

8. Grip the canister handle to replace the canister in its compartment inside the solution tank.

9. Connect the male insert to the female insert in the cap of the detergent canister.

10. Rotate the recovery tank into the work position. Make sure that the recovery tank retainer system is correctly engaged.

For BMg machines with a 10 litre tank, after lling the solution tank with clean water, proceed as follows:

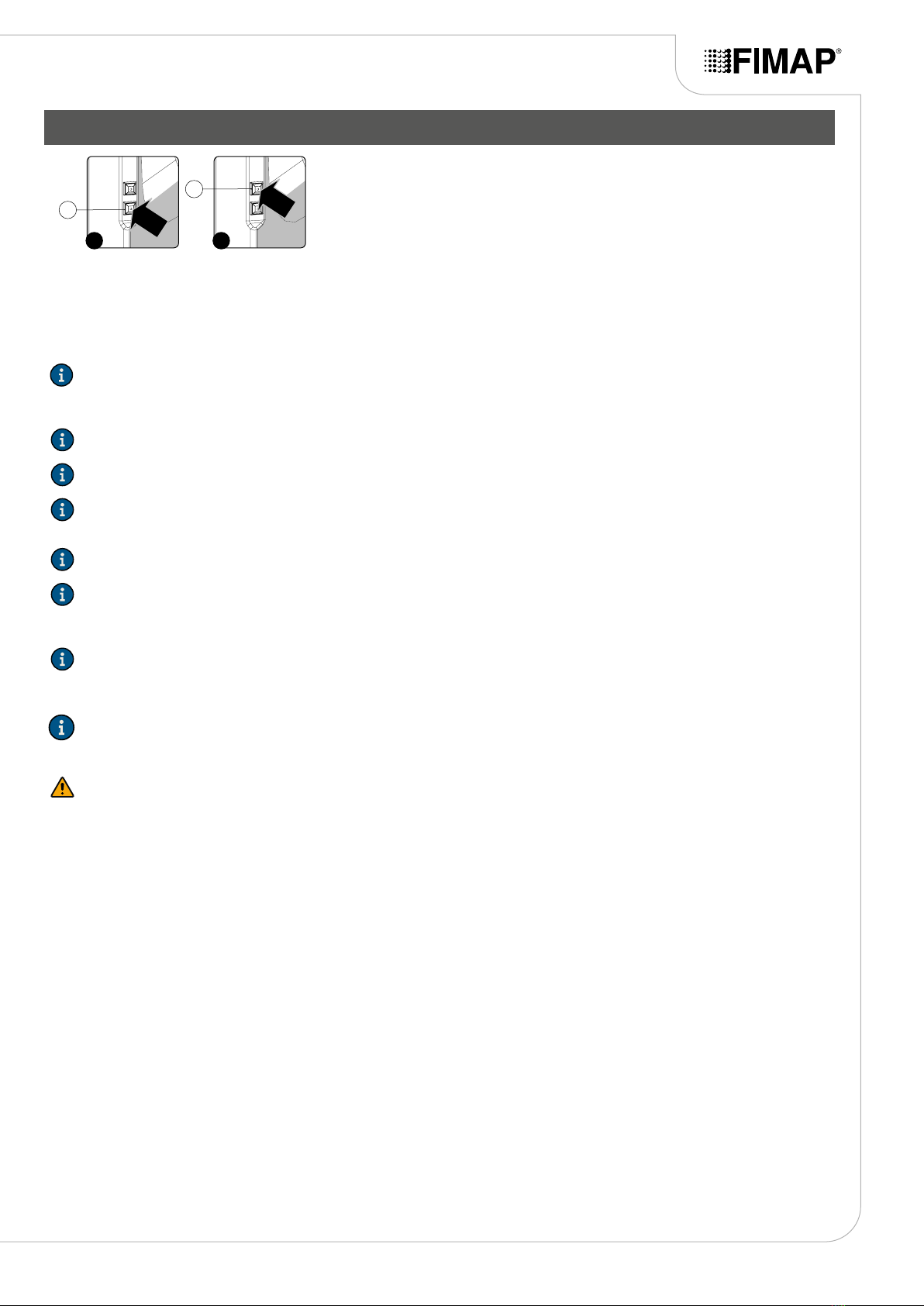

1. Disconnect the male insert (6) from the female insert (7) on the cap of the detergent canister (Fig.5).

N.B.: before pulling on the male insert, push the lever in the female insert.

2. Grip the handle on the detergent canister (8) to remove it from the compartment in the front of the machine (Fig.6).

3. Unscrew the cap (9) of the detergent canister (Fig.7).

4. Fill the tank with the sanitizing chemical product in the concentration and manner indicated on the label by the manufacturer of the sanitizing

product.

CAUTION: It is recommended to wear the appropriate PPE (Personal Protective Equipment), suitable for the work to be carried out.

5. Close the cap correctly to prevent liquid leaking out when working.

6. Grip the canister handle to replace the canister in its compartment in the front of the machine.

7. Connect the male insert to the female insert in the cap of the detergent canister.

For BMg machines with a 20 litre tank, after lling the solution tank with clean water, proceed as follows:

1. Unscrew the cap (10) of the detergent canister (Fig.8).

2. Fill the tank with the sanitizing chemical product in the concentration and manner indicated on the label by the manufacturer of the sanitizing

product.

CAUTION: It is recommended to wear the appropriate PPE (Personal Protective Equipment), suitable for the work to be carried out.

3. Close the cap correctly to prevent liquid leaking out when working.

For MMg and Magna machines, ll the solution tank with clean water and then proceed as follows:

1. Unscrew the cap (11) that can be found by the steering column (Fig.9).

2. Fill the tank with the sanitizing chemical product in the concentration and manner indicated on the label by the manufacturer of the sanitizing

product.

CAUTION: It is recommended to wear the appropriate PPE (Personal Protective Equipment), suitable for the work to be carried out.

3. Close the cap correctly to prevent liquid leaking out when working.

Before beginning to sanitize, it is necessary to:

1. Check that the quantity of sanitizing solution in the solution tank is correct for the type of work to be carried out; if not, rell the solution tank.

See paragraph FILLING THE SOLUTION TANK WITH WATER, in the machine's use and maintenance manual, as well as the paragraph

“SANITIZING SOLUTION” on page 5.

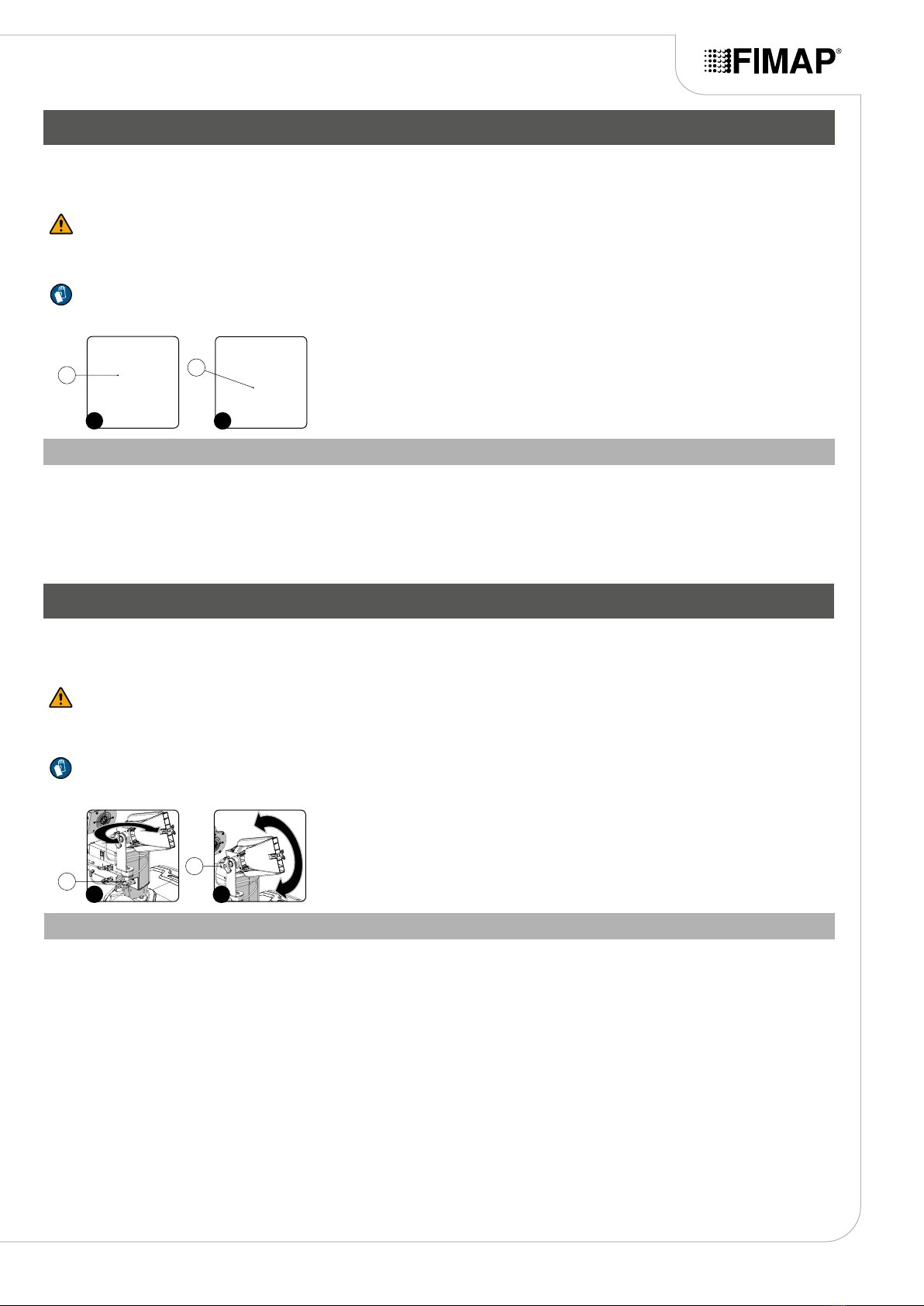

2. Check that the main machine switch is in position "0", turn the key a quarter turn counter-clockwise. With the machine o, remove the key

from the instrument panel.

3. Connect the battery connector to the main system connector on the machine; the two connectors are located inside the machine, in the

battery compartment.

WARNING: It is recommended that all installation and maintenance operations be carried out by expert personnel, trained at the

specialised assistance centre.

4. Move to the right rear part of the machine and check that the electro-brake, present in the traction gear motor, is engaged; turn the lever

clockwise.

5. Move to the front of the machine and check that the water system lter cap is closed, otherwise tighten it.

PREPARING TO WORK

6