TraffiCalm M75-SPTOP-000S Operating manual

Important Information

Your guide to install and

connect a TraffiCalm Top of Pole

Solar Power Kit

Applies to:

M75-SPTOP-000S

M75-SPTOP-000C

M75-SPTOP-000N

PN: 029-05280-0000 rev A

5676 E. Seltice Way

Post Falls, Idaho 83854

1.855.738.2722 | www.trafficalm.com

PG 2

<Intro>

Fast Facts - If you read one thing, let this be it.

• This system is supplied as a complete kit to

provide 12V power to a TraffiCalm device

• This design is specifically designed for mounting

to the top of a 4.5” (OD) round post. If you’ve

spec’d some other post, this kit was mis-ordered

• TraffiCalm has made every effort to supply the

hardware necessary to install this kit to most

standard road-side installations. However, it may

be necessary to source other components (not

included) for the variety of installations this kit

could apply to.

PG 3

<Intro>

What’s included?

Solar Panel and Mount

• A 60W, 100W, or 150W solar panel (depending on

what was ordered)

• qty 1 NPT/SAE threaded 1-1/2” post extension

• qty 2 single threaded 1-1/2” support pipes

• qty 1 x-pipe fitting

• qty 2 Pelco end caps

• qty 1 x-pipe threaded cap (aluminum)

• qty 2 standard drilled channel brackets

• qty 3 NPT threaded lock rings

• qty 2 serrated pipe clamp assemblies

• qty 1 Post Top Hub with lock ring

• Assorted assembly hardware

• Wiring harness, panel to controller

• qty 2 weather tight wiring seals

• Solar Controller (applies to 100 and 150 Watt

models only)

Battery and Control Cabinet

• Qty 1, 2, or 4 35Ah AGM Batteries

• Powder coated enclosure

• Enclosure to post mounting bracket

• Sunsaver 10L or 20L Charge Controller

• Wiring harness

PG 4

<Panel Bracket>

Before Assembly...

Ensure all set screws and lock rings are loosened or

removed. Irreparable thread damage can occur if set

screws are left exposed in the thread.

They will all be used later, so don’t dispose of them!

Assemble the Post Top Bracket

1. On all three pipe extensions install lock rings to

the straight cut threads (SAE), as seen below

2. Fully thread the two single threaded pipes to the

x-pipe fitting, directly across from one another, as

sen below.

3. Fully thread the straight threaded (SAE) side of

the double threaded pipe to the x-pipe fitting at a

90°angle to the pipes assembled in step 1, result

seen below

4. Across the bracket from this pipe, install the

x-pipe threaded cap, fully seat it in the x-pipe

5. It is now okay to tighten the lock rings and set

screws on this assembly, no further adjustment

will be required

This assembly provides the structural support to the

solar panel. It is important that all parts be threaded

and tightened sufficiently.

PG 5

<Prep Panel>

Before Assembly...

Following this sequence is critical. There are com-

ponents that cannot be accessed past other install

steps if done out of order.

Assemble the Panel Wiring Harness

The panel harness features a single cable consisting

of two wires- red and black. The wiring harness

features fast connections at the panel end to

expedite installation.

1. Unless already done, remove one full tapout

from the bottom of the junction box with a flat

screwdriver and hammer to accommodate cable

ingress

2. Open the panel’s junction box to access the

wiring location terminals

3. Install one side of the length of conduit to box

4. Each panel is different, and suppliers change the

connection methods regularly. But in general

connect the black wire as far left as possible, and

the red wire as far right as possible. Supplemental

guides will be provided where needed

5. Allow the harness to hang loosely and proceed

PG 6

<Prep Panel>

Assemble the mounting structure to the panel

The mounting structure features basic hardware

components assembled to the panel’s frame, and

integrates the frame for support.

1. Assemble qty 4toothed clamps to universally

drilled cross supports with four 3” long x 1/4” bolts

and four 1/4” nuts.

2. Assemble the qty 2 universally drilled supports

across the height of the panel as shown below

3. The cross support bolts can be fully secured to

the solar panel frame. The nuts are sprung to

assist with assembly, so ensure the spring is fully

compressed and the bolt is tightened sufficiently

to prevent loosening.

4. Do not assemble the panel to the support

structure yet.

PG 7

<Assemble To Post>

A Note Before Proceeding...

We recommend that as much assembly be

accomplished on the ground before hoisting the

assembly up on the pole. We have determined that

at this point the solar panel is ready to be mated to

the SlimLine Controller or Collaborator Hub already

installed on the pole. If circumstances would benefit

from more assembly before mating to the pole,

proceed at your own discretion.

Mating the mounting structure to the pole top hub

(Controller or Collaborator)

The mounting structure is supported by the double-

threaded pipe assembled on page 4. This will

thread into the pole top Hub. As mentioned before,

loosen the set screw on the Hub before affixing the

structure.

Thread the assembly to the Hub as much as possible.

The result will appear as seen below. Do not tighten

the set screw just yet.

PG 8

<Assemble To Post>

Mating the solar panel to the mounting structure

1. With the serrated clamps fully assembled, but

loose, slide one side onto one side of mounting

structure as shown below

2. Slide the panel the opposite direction to capture

both serrated clamps on the mounting structure’s

horizontal pipes

3. Tighten all bolts just tight enough to allow for

adjustment, but not slack.

4. To maximize solar panel aiming consider the

following best practices

• The angle of the panel should equal the geographical

latitude of the installation

• The panel should face geographical (not magnetic)

south

• If heavy snow cover is expected a steeper angle may be

more effective beyond matching the latitude

• If shadowing is expected throughout the day, rotating

the panel toward the best exposure to sunlight is

advisable.

Making sure it performs for years to come...

1. With the panel aimed as best as possible,

all the clamps and set screws previously left

loose can be tightened to prevent movement,

especially consider loosening from wind.

12

PG 9

6

3Installation Requirements

This section describes the components, tools, and

information you must have available before

installing TraffiCalm 140Ah Solar Kit.

3.1

Equipment Requirements

In addition to the Driver Feedback Sign to be

installed, you will need the following suggested

items if you intend to follow these directions:

oPole and Footing material

oStainless steel banding and banding clips and

application tool or adjustable steel banding

for installing Battery Box & Sign

oAssorted hand tools.

oSocket set and drive handle.

oU-Bolts for installing solar panel

3.2

Installation of Solar Panel

NOTE

It is the installer’s responsibility to

ensure that this installation

complies with local and national

codes.

Use a pole of proper size with an appropriate footing

for the soil and load conditions. Consult with a

professional Civil engineer for proper pole selection

and footing design for the local area. Assemble

the solar panel mounting bracket using directions

supplied with the mounting bracket components.

Install the mounting bracket onto the pole with user

supplied (U-Bolts).

In northern latitudes aim the bracket at true South,

not magnetic south. True South is the direction

facing the sun parallel to the shortest shadow of the

day cast by the sign pole, which occurs at “Solar

Noon”. To estimate what time solar noon will occur

in your area go to the NOAA web site with your

longitude and latitude.

http://www.srrb.noaa.gov/highlights/sunrise/sunrise.h

tml

Set the bracket angle using your current latitude +15

degrees as measured from horizontal (flat) to the final

position. Example: If the latitude is 45-degrees, set

the panel angle 60-degrees away from flat. You may

be able to get a small amount of additional power by

calculating the set angle using: Latitude *0.9 +29.

This results in a steeper angle than the other method,

optimizing collection around the noon hours during

the winter months, which is when the most solar

energy is available.

Install the solar panel onto the mounting bracket.

3.3

Battery Box Installation

Note: you may wish to cover the solar panel during

daylight installation to prevent accidental short

circuit of energized panel during installation.

Attach the “I” bracket to the battery box using

the included hardware.

a. Attach the “I” bracket to the center holes of

the battery box using two 3/8-16 x 1-1/4 inch

bolts, two 3/8-inch flat washers, and two

lock washers. (These bolts are hidden when

the battery box is mounted on the pole.)

b. Install 3/8-16 x 1-inch bolts in the remaining

four holes of the bracket with a flat washer

and a lock washer on each bolt.

Attach the battery box to the pole with user-

supplied 3/4-inch banding and a buckle in two

places (as close to each cross arm of the bracket

as possible).

Connect battery power to the Electronic Control

System (ECS) see Figure 3-1 (15” DFB ECS

35Ah, 70Ah, and 140Ah Solar Kits.

12V Radar Speed Sign

Radar

Speed Sign

Battery box may

include up to 4

batteries

<System Assembly>

PG 10

8

b. Connect the solar panel red wire to the

positive (+) terminal of the solar charger “SOLAR +”

terminal (4).

c. Connect the solar panel black wire to the

solar charger “SOLAR –“ terminal (3).

Check the panel operation and battery charging using

a volt meter. During daylight hours, if the battery

voltage rises above night levels, then the solar panel

and charger are working.

Monitor the charge process through a full charge. If

the charge voltage is excessive, then the charger may

have failed and will damage the batteries unless

action is taken to disconnect the solar panel until

repairs are made.

The charger is temperature compensated. It is

normal for the charge voltage to be higher when the

weather is cold, and lower when the weather is hot.

The normal full charge voltage varies -28mV per

degree C of deviation from 25°C.

Note: The solar panel only provides power

when illuminated by the sun. If the panel was

covered during installation, remove the cover

before performing this test.

For best results, start with a new fully charged

battery. Never mix old and new batteries. Be sure

to ground the solar panel rack and battery box

properly according to code.

8

c. Connect the battery box red wire (+) to the

panel + on the solar panel terminal block.

Connect the battery box black wire to panel

negative in the panel terminal block.

8. Connect the solar panel wires to the solar

charger in the battery box. See Figure 3-3.

a. Make sure the opaque cloth is still covering

the panel.

b. Connect the solar panel red wire to the

<System Assembly>

PG 11

8

7

Shown with optional beacon cable set, see your

display installation manual for other display size

connections).

Figure 3-1. 15” Display ECS Access Panel

a. Route the supplied 5 foot conduit with DC

power wire and ground cable from the

battery box to the bottom of the ECS. It can

be installed at either the top or bottom of the

battery box, but if installed at the bottom,

extra wire (#14 Red and Black, not supplied)

will have to be spliced in to make up the

extra length used.

b. At the bottom of the ECS, remove the access

panel and route the power cord and green

ground wire through the conduit receptor

located on the access panel. Plug in the

power connector to the power connector

receptacle located inside the ECM. Connect

the ground wire to the green wire located

inside the ECS.

c. Secure the conduit to the conduit receptor.

d. Install the access panel cover.

Route solar panel wires to the battery box. See

Figure 3-2.

a. Remove the battery box cover.

b. In the battery box, remove the two right side

screws and loosen the two left side screws on

the solar charger.

c. Pull the charger away from the mounts and

allow it to hang out of the way.

d. Remove the insulation panel that was under

the charger and store it in a safe place. (This

gives access to the conduit fittings from

inside of the enclosure.)

e. Install the wires and cable from the sign and

solar panel (solar panel left, sign right)

through the provided conduit fittings, and

then tighten the conduit connectors onto the

pre-installed fittings.

f. Replace the insulation panel removed earlier,

and re-install the solar charger.

Figure 3-2. Remove Solar Charger from

Battery Box

Connect ECS wires to solar charger in battery

box. See Figure 3-3.

a. Connect the ground wire from the display to

the solar charger mounting screw.

b. Connect the ECS power cable lead with the

white stripe to the solar charger terminal

marked “LOAD +”, which is terminal 6.

c. Connect the other ECS power cable lead to

the terminal marked “LOAD –“, which is

terminal 5.

Figure 3-3. Wiring Solar Charger

in Battery Box

Install the batteries in the battery box. Install the

battery Ring Lug stubs onto the batteries first.

Then connect the batteries to their respective

connectors (one set provided per shelf) in the

harness matching orange to orange and black to

black. The operating voltage is 12VDC. At this

point the display has power.

Connect the wires to the solar panel.

a. At the solar panel, make sure the opaque

cloth is still covering the panel.

<System Assembly>

PG 12

<Warranty Statement>

TraCalm Systems provides the following warranty for its trac calming solutions

whether sold directly by TraCalm or by an authorized TraCalm distribution partner.

• TraCalm Systems warrants this product, excluding batteries, will be free of defect in

materials and workmanship for a period of ve (5) years beginning on the day the end

user receives the product. Warranty is only valid if the product is ineective for its

intended purpose due to defects in materials or workmanship.

• Warranty is only valid if the product is installed, operated and maintained in

accordance with the manufacturer’s instructions and recommendations (available

upon request).

• TraCalm’s sole responsibility, and the purchaser’s and users’ exclusive remedy, shall

be that TraCalm will either repair or furnish replacements for defective parts.

• Replacement parts will carry the unexpired warranty of the parts they replace. Any

repairs conducted on out-of-warranty items will carry a 90 day warranty.

• Claims made under this warranty will be honored only if TraCalm is notied of a

failure within the warranty period, reasonable information requested by TraCalm is

provided, and TraCalm is permitted to verify the cause of the failure.

• TraCalm assumes no liability for any incidental or consequential damages, in any

way related to the product regardless of the legal theory on which the claim is based.

• TraCalm Flashing Sign Systems are designed, tested, and warranted to operate as

a matched component system. The warranty is voided if all system components for

controllers, collaborators, and LED rings are not TraCalm equipment and third party

devices are substituted without prior written approval from TraCalm.

This warranty does not cover damage resulting from:

• Accidents, vandalism, impact with a foreign object, or acts of God.

• Product modications made by someone not authorized by TraCalm

• Failure of Customer to follow TraCalm’s published operating instructions,

• Failure to follow TraCalm’s published site selection and installation instructions,

• Removal or relocation of the unit,

• Electrical work external to the unit, virus/hacker activity, and external computer

errors.

THIS WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES AND

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY.

This manual suits for next models

2

Popular Antenna manuals by other brands

Continu.us

Continu.us CA-1000 WIFI Simple setup guide

ST Engineering Electronics

ST Engineering Electronics MDM2510 installation guide

Ten-Haaft

Ten-Haaft Oyster V Series Operating Manual and Installation Instructions

Vivanco

Vivanco TVA 501 operating instructions

Beyerdynamic

Beyerdynamic AT 91 operating instructions

CG Antenna

CG Antenna GW-1000 user manual

M2 Antenna Systems

M2 Antenna Systems 2068-26-2 Assembly instructions

qpcom

qpcom QP-A02424G user manual

Alpha Antenna

Alpha Antenna ProMaster user guide

stellar labs

stellar labs 30-2370 installation guide

TerraWave Solutions

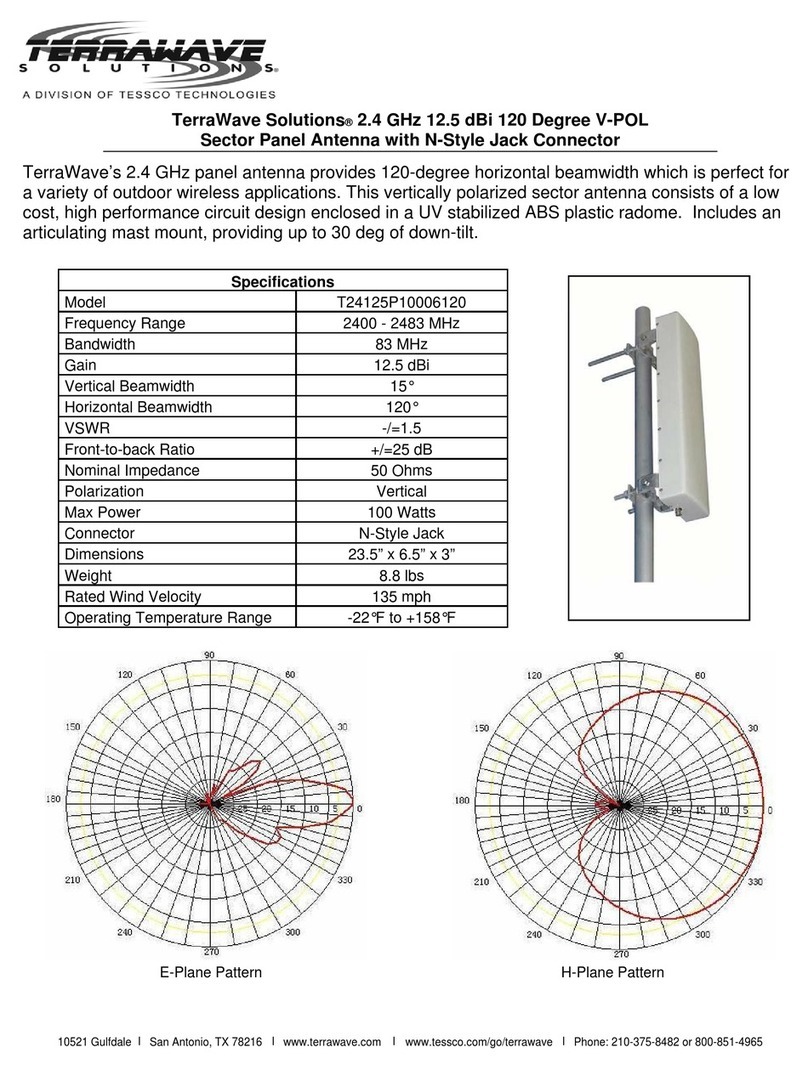

TerraWave Solutions T24125P10006120 instructions

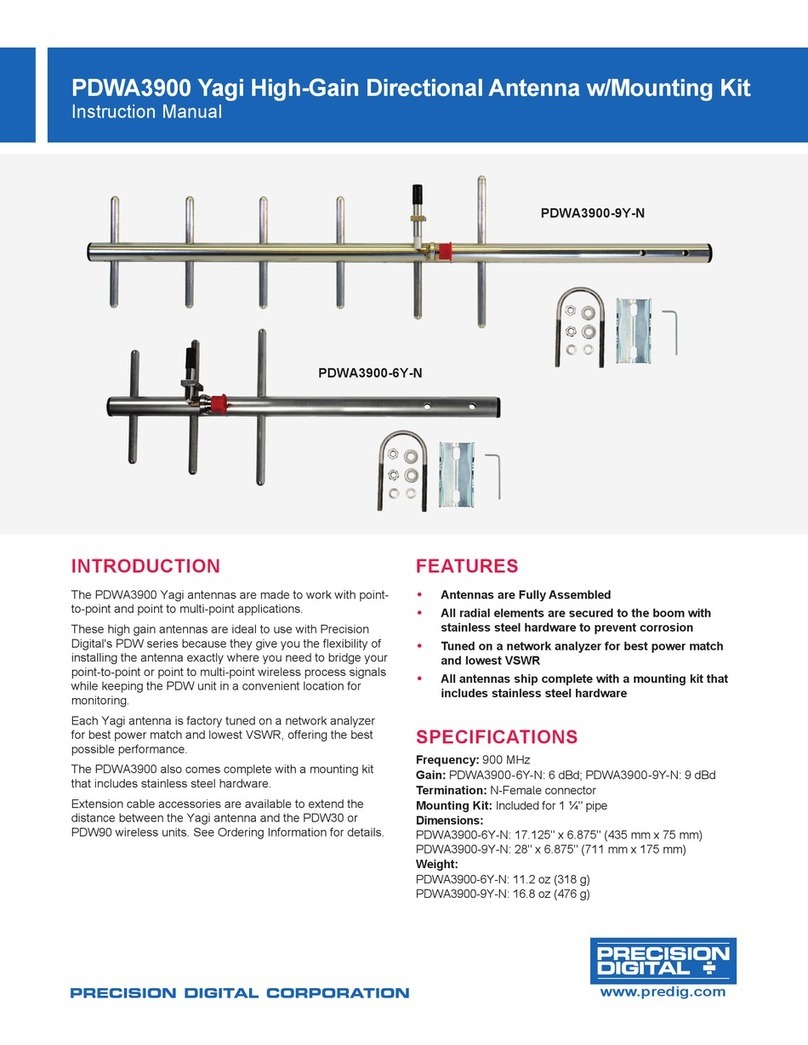

Precision Digital Corporation

Precision Digital Corporation Yagi PDWA3900 instruction manual