Transcom 5302 Series User manual

1

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Optical Time Domain Reflectometer

1. Unpacking Inspection

Before you receive this instrument, please carefully check the product appearance and quality according to

the packing list to find the possible damage caused in the transport process. If the package is found

damage, please keep the original packing materials, give an immediate notice to the freight company and

contact the supplier to solve this problem.

The product package should be provided with the power cord, adapter, analysis software installation CD,

user manual, etc together with the instrument, for detail, see the packing list. If the materials in the packing

box are discovered incomplete, please contact your supplier agent to solve them in a timely manner.

Table 1-1 Basic components of 5302 series Optical Time Domain Reflectometer

ITEM

NAME

QUANTITY

Host machine

5302 Optical Time Domain Reflectometer

1

Standard

accessories

Power cord

1

Power adapter

1

User manual

1

CD (containing 5302 simulation analysis

software)

1

Engineering plastics packing box

1

2. Overview of Instrument

5302 series handheld optical time domain reflectometer (OTDR) is a new generation of intelligent optical

measuring instrument designed for the optical fiber communication system testing by zhe Electronics

Technology Co., Ltd.. This product is mainly used to measure the parameters of optical fibers and cables,

such as length, loss, and connection quality, etc.; it can realize the accurate positioning of event points and

fault points, and can be widely used in the construction, maintenance testing and emergency repair of the

optical fiber communication systems as well as the research, production and production measurement of

optical fibers and cables and so on. This product can provide you with the highest performance of solutions

for installation and construction of fiber optic network construction and the subsequent fast and efficient

maintenance and troubleshooting testing.

2

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

5302 has novel appearance, durable; it has the simplest interface and intuitive operation in the OTDR

industry; among the same type of handheld products, its unique dual operation mode of key plus touch

screen can greatly simplify the user’s application; with one-key analysis, it can quickly obtain the test results.

The events are displayed in the main interface in a way of list, and such information includes event number,

type, event location (distance), loss, reflection, event point attenuation, total loss, etc..; the whole machine

adopts the intelligent power management mode; the high capacity of lithium battery can make the whole

machine working for more than 10 hours, so it is very suitable for outdoor environments for a long time.

3. Notices

External power supply

Power adapter input meets the following requirements: 100V ~ 240V, 50/60Hz; @ 1.8A.

Power adapter output meets the following requirements: 19V ± 1V, 3.42A Polarity: center positive.

Please use the external power supply in strict accordance with the specification; otherwise it

may cause damage to the device.

Internal battery

Inside the instrument is the 5302 Series OTDR dedicated lithium battery. To give full play to the

performance of the battery, please charge the instrument with the internal battery and use up the electric

quantity before using this instrument, and then charge the battery. The first time of charging should be

no less than 10 hours. The charging temperature range of the battery inside the machine is 0℃~50℃.

When the ambient temperature is too high, charging will be automatically terminated for your safe use.

When the instrument is not in service for more than 2 months, timely charge it to maintain the electric

quantity of the battery; do not take out the battery without permission; do not keep the battery close to

the fire source and intense heat; do not open or damage the battery; the battery must be taken out when

the instrument is stored for a long time. The temperature range for long term storage of battery is

-20℃~45℃.

Laser safety

When using this instrument, avoid eyes to look at the laser output port directly, nor look at the end of the

optical fiber when testing; when the instrument is not in operation, please cover the dust cover of the

optical output port.

When the visible red light of the instrument is on, please do not look at the output port of the red light

directly, nor look at the end of the optical fiber at the output end of red light directly.

Instrument maintenance

1. The warranty period of the whole machine is 18 months and that of the battery is 6 months. The

items accompanied with the product are not within the warranty scope.

2. The light output connector of the instrument is quick-wear part, which is not within the warranty

scope.

3

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

3. If the instrument is damaged or in performance reduction caused by irresistible external factors,

they will not be within the warranty scope.

4. If the instrument is damaged or in performance reduction caused by improper operation, they

will not be within the warranty scope.

5. Users are forbidden to dismantle this instrument without the permission of the company

or designated authorized entity; otherwise, it will lose the qualification of warranty

permanently!

Return of Instrument

If the product needs to be returned due to product calibration or other reasons, please contact your

supplier in advance and briefly explain the reasons for product return, so as to provide effective and

timely services for you.

When returning your product, please notice that:

Pack the instrument with polyethylene and other soft thin cushion to protect the completeness of

the instrument shell;

Please use the original hard packing box. If other package is used, ensure that there is at least 3

mm thick of soft object around the instrument;

Fill out the warranty card correctly, including the company name, address, contact person, contact

phone, problem description, etc.;

Deliver the products to the supplier’s agent in a reliable way.

Chapter 2 Basic Operation of 5302 OTDR

1. Introduction

OTDR is a precise optical measuring instrument made according to the backscatter principle of Rayleigh

scattering and Fresnel reflection when the transmission of laser in the optical fiber. It can be widely used in

the installation and construction, maintenance and repair and monitoring application of optical fiber and

fiber cables. It can be used to measure the length, attenuation, connection quality and fault location of

optical fibers and cables, etc..

When transmission of light in the optical fiber, the optical pulses in the optical fiber transmission will

generate Rayleigh scattering due to the defects of optical fiber and non-uniformity of the mixed components.

Of which, a part of light signal will be scattered back along the direction opposite to the incident pulse,

therefore, it is called backward Rayleigh scattering. Through observing the intensity changes of backward

Rayleigh scattering light signal, the loss distribution, connection quality and other features of optical fibers

and cables can be accurately measured. Besides, according to the theory of optical transmission, when the

light encounters the boundary of the two transmission media of different refractive indices in the

transmission process (for example, connectors, mechanical connection, fracture or optical fiber termination

points), Fresnel reflection phenomenon may occur. Through receiving the Fresnel reflection signal on

regular basis, the position of the discontinuity points along the length of the optical fiber can be accurately

determined. The size of reflection depends on the refractive index difference and boundary surface flatness.

4

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

2. Description of the OTDR test event type

OTDR test event refers to the abnormal points that may cause loss or a sudden change in the reflected

power, including various types of connection and bending, cracks or fracture in the fiber link, which may

cause the transmission signal loss.

The OTDR test events are mainly divided into two types: reflection events and non-reflective events.

2.1 Reflective event

When the laser pulse emitted from OTDR is transmitted along the measured optical fiber, which encounters

a mechanical connection point or the end of the optical fiber, reflection phenomenon will occur due to the

change of the refractive index, and some of the light energy will return along the optical fiber to the

instrument. Through receiving this reflected signal, the instrument will detect this reflection event, which will

be presented as upward spike signal of a certain width in the curve. The width of the spike is mainly

determined by the width of the tested pulse, as shown in Fig. 2-1.

Fig. 2-1 Reflective event chart

2.2 Non-reflective events

When the laser pulse emitted from OTDR is transmitted along the measured optical fiber, which encounters

a welding point, bending that may causes loss of some energy, there is no great change to the refractive

index, therefore, the reflection phenomena do not occur or can be negligible. OTDR detection can detect

the non-reflective event parameters of this point through the energy change difference of backscattering to

the OTDR receiving end. The non-reflective events can produce a light energy drop signal in the curve and

its drop amplitude represents the power attenuation condition, as shown in Fig. 2-2.

Fig. 2-2 Chart of non-reflective event

5

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

3. Description of 5302 series OTDR interface

3.1 Optical connection ports of 5302 OTDR

The optical connection ports of 5302 OTDR can be divided into OTDR output interface and visible red light

output port which both adopt FC/PC optical connector (can be changed to SC/PC and ST/P).

Fig. 2-3 Schematic diagram of 5302 optical interface

When using OTDR or visible red light, do not directly look at the corresponding light output

interface.

3.2 5302 OTDR Power Supply Interface

5302 Series OTDR power port is on the right side of the instrument.

Input requirement: 19V±1V,≥2 A, Polarity: positive in the center.

Fig. 2-4 Schematic diagram of 5302 power port

Please use the adapter provided by the manufacturer to charging this instrument, otherwise, it

may cause damage to the instrument.

3.3 Data Interface

This instrument is equipped with USB interface, which is located on the left side of instrument. Trough this

interface, the test trace stored in the instrument can be uploaded to the computer through this interface, and

carry out follow-up analysis and processing with the PC machine data analysis software, print and produce

report forms, etc..

6

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Fig. 2-5 Schematic diagram of 5302 data interface

4. Operation interface and button of 5302 Series OTDR

The operation interface of 5302 Series OTDR is very simple, which is mainly divided into operation window

area and menu display area. When the instrument is started to enter the application interface, the interface

appearing on the display screen is the main operating window, as shown in Fig. 2-6. The main operating

window includes all six main operating menu bars of OTDR and each menu bar contains different

sub-windows. Through these operation buttons, start the different sub-windows to realize the corresponding

functions. (Details see the operation method).

Figure 2-6 the OTDR main operating window diagram

The description of notes is as follows:

(1) the OTDR function menu area, where the yellow background indicates the current menu selection

location.

(2) sub-operations area of the test parameters and test results. This area can be changed according to

different selections of menu.

(3) the main instrument display interface area.

4.1 Menu structure and functional description

5302 Series OTDR has the simplest and quick operation way in the industry. The whole main user interface

contains only 6 menu options. Through the optimized operating mode, it can conform to the user’s daily

habits; besides, the unique key plus touch screen function operating mode of the similar products in the

industry can facilitate the operation and eliminate the tedious process of frequent movement of cursor.

7

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Fig. 2-7 Schematic diagram of main window menu bar

Fig. 2-7 shows the schematic diagram of the six main menu of 5302 Series OTDR,which respectively

“waveform operation”, “parameter setting”, “curve save”, “file operation”, “system information”, “help” from

left to the right.

4.2 Description of the OTDR button functions

The functions of various buttons on the keys are as follows:

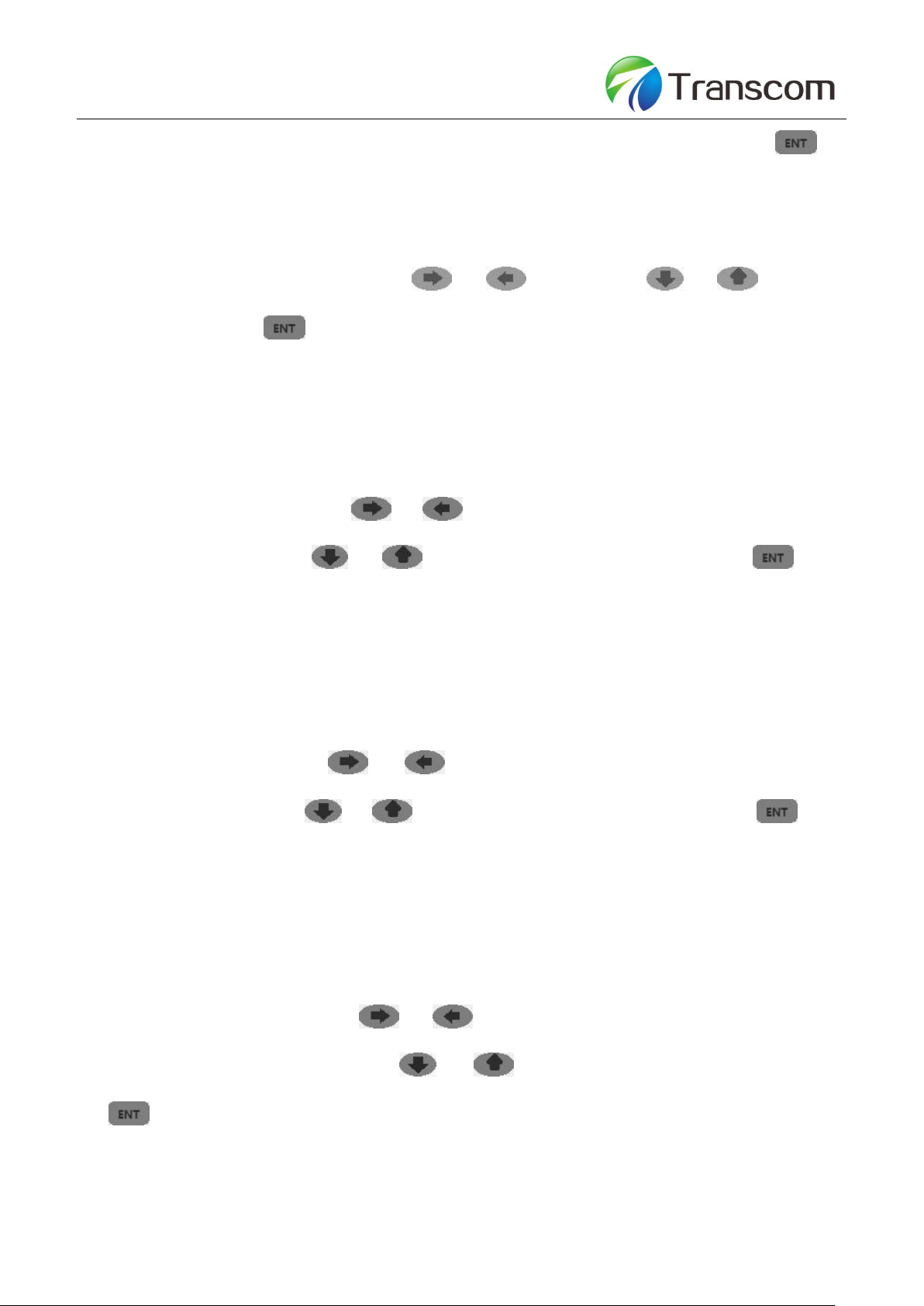

The four keys in the “menu operating key” marked in the above figure 2-8 are mainly for the menu operation,

to realize the menu selection, entry and exit, etc. of which:

:Left movement in the OTDR operation menu.

:Right movement in the OTDR operation menu.

8

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

:The menu of the currently selected cursor. If this menu contains subordinate menu interface, then

when pressing this key, the corresponding sub-interface will pop up.

:The menu of exit the current cursor, or the corresponding sub-interface.

The five keys “navigation keys” marked in Fig. 2-8 are mainly to realize the movement, switching of cursor

and the parameter selection and modification in sub-interface, of which:

Key:

Move the current cursor to the left under the main operating window;

Move the parameter options upwards under the parameter setting sub-interface;

Move the keyboard characters to the left under the curve save sub-interface;

Modify the operation type under the file operation sub-interface;

Move to the left to select the system time and language under the system information

sub-interface.

Key:

Move the current cursor to the right under the main operating window;

Move the parameter options downwards under the parameter setting sub-interface;

Move the keyboard characters to the right under the curve save sub-interface;

Modify the file operation path under the file operation sub-interface;

Move to the right to select the system time and language under the system information

sub-interface.

Key:

Move the waveform upwards under the waveform movement menu;

Expand the waveform horizontally under the waveform horizontal expansion / compression

menu;

Expand the waveform vertically under the waveform vertical expansion / compression menu;

Modify the value of the parameters under the parameter setting sub-interface;

Modify the path under the curve save sub-interface;

Select the file to be operated under the file operation sub-interface;

Modify the value of the item where the cursor is under the system information sub-interface;

Use to page up under the help information interface.

9

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Key:

Move the waveform downwards under the waveform movement menu;

Compress the waveform horizontally under the waveform horizontal expansion /

compression menu;

Compress the waveform vertically under the waveform vertical expansion / compression

menu;

Modify the value of the parameters under the parameter setting sub-interface;

Modify the path under the curve save sub-interface;

Select the file to be operated under the file operation sub-interface;

Modify the value of the item where the cursor is under the system information

sub-interface;

Use to page down under the help information interface.

Key:

Switch the cursors A and B under the waveform operating menu;

Confirm and exit the parameter setting sub-interface and this function is equivalent to the

key.

Key: OTDR testing and stop key.

When the OTDR operating interface displays as the main operating window, press down this button to start

the OTDR module to test the optical fiber and display the test curve in the main operating window. The test

is divided into automatic test, real-time test and average test. The test way can be set in the OTDR

parameter setting window.

Key: curve analysis key.

Press down this key under the OTDR operation interface to analyze the displayed curve. Give the analysis

results under the curve. If no curve or the curve has no the event to meet the condition, it is a null operation.

Key: Visible red light operation key

When the OTDR is in the non-test status, press and hold this key for about 2 seconds, and this light is on,

indicating that the visual fault positioning function is started under the DC mode; at this time, press the key

once again, the key light flickers, and the visual fault positioning function working way changes to the

flickering way; and press the key once again, the visual fault positioning function is closed and the light of

the key is off.

10

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Key: On / off key.

When the instrument is under the off state, press this key about 1s, the instrument is started to enter the

OTDR operating interface and display the main operation window. When the instrument is switched on,

press and hold this button for about 1 second to switch off the instrument.

4.3 Description of 5302 Series OTDR test parameters and setting method

Correct setting the measurement parameters of the instrument is necessary for the accurate measurement

of the optical fibers. Therefore, prior to the use of the instrument, it is necessary to set parameters as

required. The test parameters of OTDR are mainly testing wavelength, measurement range, pulse width,

channels, refractive index, fiber optic correction coefficient and event threshold value, etc..

In the main operating interface, move the cursor to the parameter setting menu through the menu

operating key or , then press the key , the parameter setting interface will pop up.

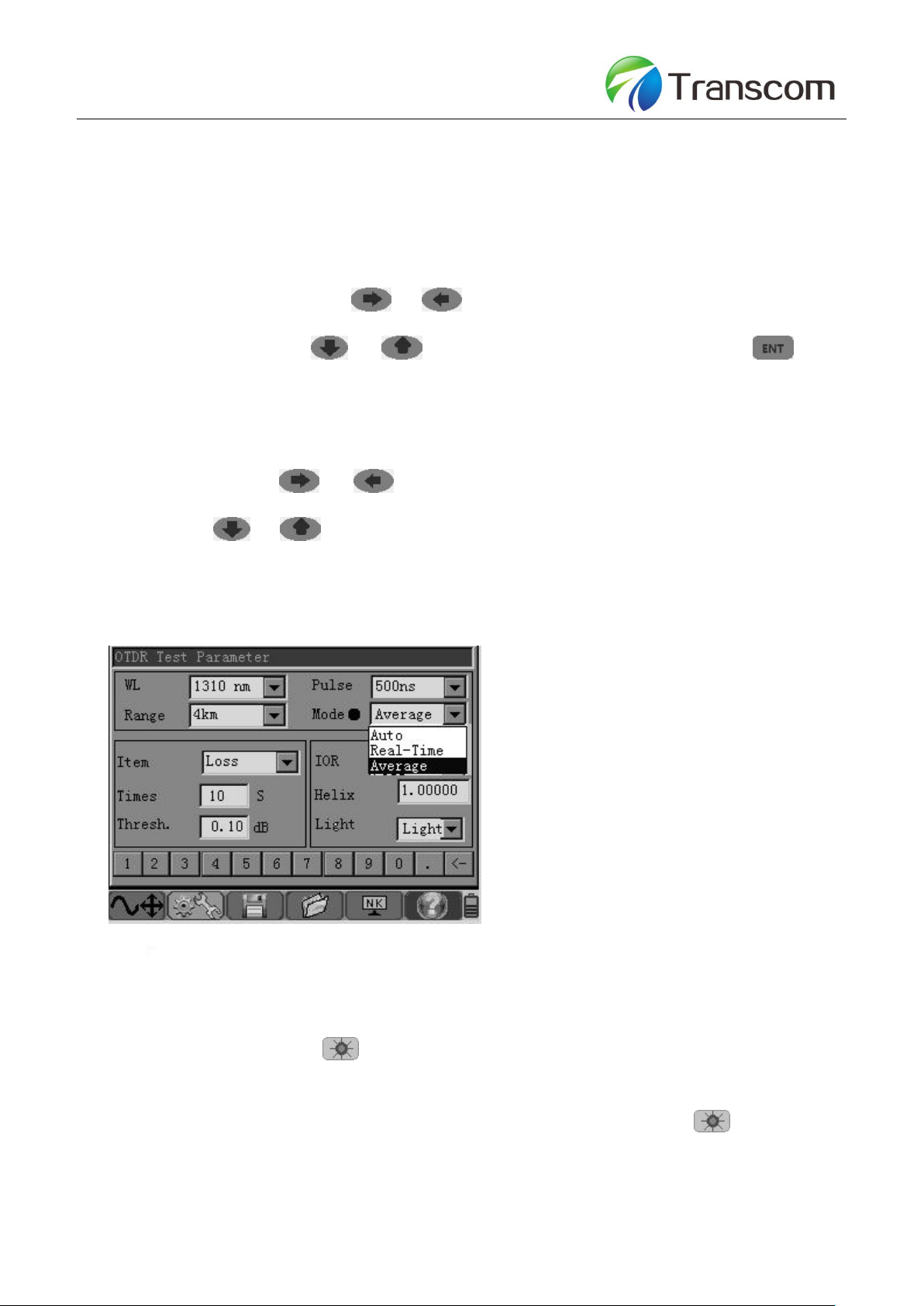

Figure 2-9 5302 parameter setting interface

4.3.1 Description of parameters and setting method

WL(nm): to set the OTDR test wavelength.

Setting method: Under the parameter setting interface, move the cursor to the wavelength option via

the navigation key or , and press the key or to select the wavelength value,

or directly click on the touch screen wavelength window to select it, and press the key to save

the setting and exit the window.

■Range (km): set the scope of the scan path. The range should be set according to the actual length of

the optical fiber. The predefined range should be greater than the length of the measured optical fibers;

usually it is more than twice of the length of the optical fibers to be measured. Under the automatic test

mode, it is not required to set by the users.

Setting method: Under the parameter setting interface, move the cursor to the option Range via the

11

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

navigation key or , and press the key or to select the value of the range, or

directly click on the touch screen range window to select it, and press the key to save the setting and

exit the window.

Pulse (ns): Set the laser pulse width emitted from instrument. The selection of pulse width will affect

the dynamic range and resolution of the test curve. The large pulse width may obtain a high dynamic

range and test a long optical fiber, but the resolution is poor; the small pulse width may have high

resolution, but it can test a short distance. Users need to make appropriate choice between the

dynamic scope and blind spot. Under the automatic test mode, users need not set them.

Setting method: Under the parameter setting interface, move the cursor to the option Pulse

Width via the navigation key or , and press the key or to select

the value of the range, or directly click on the touch screen range window to select it, and press

the key to save the setting and exit the window.

■Mode: Used to select the way of OTDR scan event. Select the “real-time test”, “average test” and

“automatic test”.

Of which, the “real-time test” is to perform real time scan on the test link and display the test results, to

perform dynamic monitoring on the links before and after connection conveniently.

“Average test” is to accumulate the scan results for many times and perform average processing,

which can further enhance the testing curve quality and the testing precision.

“Automatic test” is an intelligent test way. Under this mode, the instrument can automatically carryout

the matching of the test conditions according to the test links; users are not required to set the test

conditions manually.

Setting method: Under the parameter setting interface, move the cursor to the option Test Method

via the navigation key or , and press the key or to select the test method, or

directly click on the touch screen test method window to select it, and press the key to save the

setting and exit the window.

■Item: Used to select the type of the OTDR test events; select the “average loss”,

“connection loss” and “reflection loss”.

Of which, the “average loss” is used to test the parameters such as total loss, spacing and

average loss between two points in the test link; through moving the location of the cursor point, it can

realize the measurement of any two points in the whole link.

“Connection loss” is used to test the connection point, welding points or the macrobend loss

characteristics of the test link.

“Reflection loss” is used to conduct test on the losses of the reflection events in the link.

Setting method: Under the parameter setting interface, move the cursor to the option Test Item via

the navigation key or , and press the key or to select

12

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

the test item, or directly click on the touch screen test item window to select it, and press the key

to save the setting and exit the window.

Times: under the modes of “average test” and “automatic test”, it is used to set the time of them.

Setting method: Under the parameter setting interface, move the cursor to the option Average

Number of Times via the navigation key or , press the key or to select the

value, and press the key to save the setting and exit the window.

■Thresh:

The event threshold for curve analysis. When the event point is discovered through curve anlayis, the

events that the loss between events is greater than the threshold value will be listed in the list of events,

and those that the loss between events is less than the threshold value will be ignored.

Setting method: Under the parameter setting interface, move the cursor to the option Event

Threshold via the navigation key or , or directly click on the touch screen Event Threshold

window and press the key or to select the threshold value; and press the key to

save the setting and exit the window.

■IOR: Refractive index.

The refractive index of the optical fiber may affect the optical fiber transmission speed, so the setting of

refractive index will directly affect the accuracy of the measuring distance. The refractive index of

optical fibers is provided by the manufacturer.

Setting method: Under the parameter setting interface, move the cursor to the option Refractive

Index via the navigation key or , or directly click on the touch screen Refractive Index

window and press the key or to select the set refractive index; and press the key to

save the setting and exit the window.

■Helix:

The setting of the cable correction factor is to consider the change of the optical fiber length and optical

cable length after the optical fiber is changed to optical cable. This parameter can be obtained from the

optical cable manufacturer.

Setting method: Under the parameter setting interface, move the cursor to the option Optical Cable

Correction via the navigation key or , or directly click on the touch screen Optical Cable

Correction window and press the key or to select the correction value; and press the

key to save the setting and exit the window.

13

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

■Thresh:

The event threshold for curve analysis. When the event point is discovered through curve anlayis, the

events that the loss between events is greater than the threshold value will be listed in the list of events,

and those that the loss between events is less than the threshold value will be ignored.

Setting method: Under the parameter setting interface, move the cursor to the option Event

Threshold via the navigation key or , or directly click on the touch screen Event Threshold

window and press the key or to select the threshold value; and press the key to

save the setting and exit the window.

■Light: To set the light of LCD

Setting method: Under the parameter setting interface, move the cursor to the option Event Llight

via the navigation key or , or directly click on the touch screen Event Light window and

press the key or to set the light of LCD.

4.4 Description of testing ways of 5302 series OTDR

There are 3 kinds of test modes of 5302 OTDR: automatic test, real time test, average test.

Fig.2-10 Setting of test modes of 5302 OTDR

4.4.1 Automatic Test

When the OTDR test mode is set to automatic test, users only need to set the test wavelength and

time; after pressing the key , OTDR will automatically adjust the test parameters to test the fiber

link and users are not required to set the related parameters. When the testing is over, display the test

curve in the main operating window; during the test process, press the key once again to

immediately stop the test and obtain the test results.

14

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

4.4.2 Real –time test

When the OTDR test mode is set as real time test, users need to set the measurement range, pulse

width , and other parameters according to the length of the optical fibers to be tested; press the key

, OTDR can perform real time scanning test of the tested optical fiber link. The test curves in the

main operating window will be refreshed continuously until pressing the key again, and then

OTDR will stop testing.

4.4.3 Average test

When the OTDR test mode is set to the average test, users need to set the range, pulse width, and

other parameter according to the length of the tested optical fibers; press down the key, OTDR

can perform average test on the the tested optical fibre link according to the set test parameters and

the test curves in the main operating window will be subject to average processing until the average

number of times displayed ih the interface is equal to the set one, OTDR stops the testing. In the

average test process, press down the key again, OTDR will immediately stop testing.

4.5 Description of test items of 5302 series OTDR

The test items of 5302 OTDR include average loss, connection loss and reflection loss.

Fig. 2-11 Setting of test methods of 5302 OTDR

4.5.1 Average loss test

At this time, OTDR can perform test on the distance between cursor A and cursor B, the loss between

them and the average loss of the optical fiber segment where cursors A and B are located. Through the

navigation key, the cursors A and B can be switched and the positions of them can be modified, so that

customers can observe the detailed characteristics of each fiber link distance.

15

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Fig. 2-12 Average loss test of 5302 OTDR

4.5.3 Connection loss test

At this time, four cursors are displayed on the main interface of OTDR. Besides, the test results show the

connection loss of the connection points where the cursor A is located and the average loss of the optical

fiber segments before and after the connection points.

As shown in Figure 2-13, move the cursors A and B before and after the connection events to be tested and

close to the two sides of the event respectively. Move the small cursor at the front of cursor A to the far end

of the previous segment of linear area of the event to be tested (linear area A) and move the small cursor at

the back of the cursor B to the far end of the following segment of linear area of the event to be tested

(linear area B), at this time, read the connection loss value of the connection event through SP location.

Fig. 2-13 Connection loss test of 5302 OTDR

4.5.3 Reflection Loss Test

At this time, two cursors A and B occur in the main interface of OTDR. When testing the reflection event loss,

move the cursor A to the front of the reflection event and close to the jumping edge, and then move the

cursor B to the top of the reflection event. Read the reflection loss value of the reflection event through the

Ref position.

16

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Fig. 2-14 Reflection loss test of 5302 OTDR

5. Description of application method of 5302 series OTDR

5.1 Automatic analysis of the waveform and check the list of events

After the OTDR stops the testing and the test curve is obtained, press down the key , conduct

analysis on the obtained curve, and perform screening and positioning of the event points according to

the set event threshold value to obtain the length, loss, average loss and other information of the optical

fiber links. Besides, display the event point information at the event list column in the main operating

window.

Press the key or the key can check the information of all event points in the list of events.

Fig. 2-15 Analysis results of 5302 OTDR

In the sub-operating window of event list:

:indicate that this event is a non-reflective event point, generally the event caused by splices,

splitters, fiber bending or extrusion, etc..

:indicate that this event is a reflective event point, generally the event caused by movable connector

of the optic fiber link.

:indicate that this event point is the end of optical fiber.

17

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

5.2 Move, switch the cursor and set the mark point

Set the position of the mark points through moving the position of the cursor. Move the current activated

cursor to the left and right via the navigation key or . When continuously hold the key

or and moving 10 data points, the active cursor will move rapidly and move 10 data points

each time. Release the key or , then the active cursor will stop moving; or directly click on

the touch screen and move the currently activated cursor to the appropriate touch point. Press the key

of the navigation keys to switch the cursor points.

5.3 Zooming and shift of waveform curve

To facilitate users to carry out manual analysis on the tested curve, when the test of 5302 Series OTDR

is over, the menu key is placed on horizontal zoom-in and zoom-out of the curve operating menu

in default, and at this time, just directly press the navigation keys and to realize the

horizontal zoom-in and zoom-out of the test curve in the center of currently activated cursor. At this time,

the key or in the navigation keys can be shifted left or right to move the cursor.

When continuously pressing the key in the menu operating keys, or clicking on the curve

operating menu in the touch screen, at this time, this menu can realize the alternative switching among

, and .

6. Visual red light fault positioning

With the built-in high-power visual red light fault positioning function, 5302 OTDR can discover the

breakpoint of the short-distance optical fiber link or the position of a large loss point very conveniently and

intuitively. Combing with OTDR function, it can realize the seamless monitoring of the link test so that the

maintenance personnel can discover the problems of the links timely and take measures to save the test

time.

There are two output modes for the visible red light of 5302sOTDR:

DC mode;

AC mode.

In the OTDR test main interface, when the OTDR is under the non-test status, press and hold the key

for about 2s, the light is on, indicating that the visual fault positioning function is started and the

working mode is DC mode; press this key once again, the light of the key flickers and the working mode

of the visual fault positioning function is changed to AC mode; press this key again, the visual fault

positioning function is closed and the light of the key is off. If pressing the key to start the OTDR

18

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

function before starting the visual red light fault positioning function, then the visual red light fault

positioning function will be automatically closed and switched to the OTDR test function.

7. File management operation

The 5302 Series OTDR file management operations are described as follows, mainly including file save,

reading, copy, deletion, etc..

7.1 Save the waveform files

When the automatic measurement or manual measurement is over, save the measurement curve. The

contents of the saved curve are the curve and related information of curve.

In the main interface of test, select the menu via the menu operation key or , press

the and the curve save window will pop up.

Fig. 2-16 5302 OTDR file save

Navigation keys: or : move the key to select the button on the small keyboard.

: enter the character in the small button selected to the square cursor location of the file name input

window. If the button selected is , then delete the character before the square cursor.

or : used to modify the path save path.

Of which, the storage path can be set to internal memory and U disk.

Press the key to confirm the operation and exit the window;

Press the key to delete this operation and exit the window;

Note: the above operation can be completed by directly clicking on the touch screen.

7.2 Read, copy, delete waveform files

In the main interface of test, select the menu and press the key via the menu operation key

19

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

or , and the file operation window will pop up.

Fig. 2-17 Reading, copy and deletion of 5302 files

Select the operation type via the navigation key . There are 3 types: read, copy and delete;

Of which, when selecting the copy way and the read path is internal memory, copy the memory files to the U

disk;

When the read path is U disk, copy the U disk files to the internal memory.

key: select the operation path, which can be divided into two types: internal memory and U disk.

or key : used to select the operation files.

key : used to select all of the operation files.

Press the key to confirm the operation and exit the window;

Press the key to delete this operation and exit the window;

Note: the above operation can be completed by directly clicking on the touch screen.

8. Set the system time and language, screen brightness and view the system information

In the main test interface, select the menu via the menu operating key or , press the

key and the system information setting window will pop up.

20

SHENZHEN TRANSCOM TECHNOLOGY LIMITED / 303, Building 4, Fantasia MIC Plaza,Nanshan District,Shenzhen,China.

Tel: +86 755 88278677 / Fax: +86 755 26029402 / Web: www.sz-transcom.com

Fig. 2-18 5302 system information setting interface

The navigation key or :move the cursor ■ to select the operation item;

or key: used to modify the parameters of the operation item.

Press the key to confirm the operation and exit the window;

Press the key to delete the operation and exit the window;

9. View help information

In the main test interface, select the menu via the menu operating key or , press the

key and the help information window will pop up.

Figure 2-19 5302 Help Information

Navigation key or : used to page down, page up.

Table of contents

Other Transcom Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics Y3501A1220KG/010LN Installation and operating manual

Leica

Leica RX1200 user manual

Toshiba

Toshiba G3 Workbook

Honeywell

Honeywell Satellite XT 9602-0200 4-20 mA Operation guide

YOKOGAWA

YOKOGAWA 700987 user manual

Agilent Technologies

Agilent Technologies 35670A Service and operator's guide